Member

Joined 2009

Paid Member

You need to keep the across grain dimensions small, don't glue across the grain, and allow the cabinets to move across the grain.

Bollocks - I didn't follow any of these rules. It's all 3/4" pine glued together and all the wrong way by the sound of it. Should I trash the lot and start over ? - will covering it all over in varnish help ?

Attachments

Last edited:

Ah thanks, I feel better about their eco cred nowThe phrasing is bad, but I think what they mean is that the trees aren't primarily grown for timber. They only produce latex for ~25 years, so the growers have to clear them and plant new ones. The timber sales are just a bonus.

I'm making some speakers using the Bunnings Karri boards.

I made a lamination for the sides (200 x 460) of 16mm MDF, 16mm thick lump of Karri, then 16mm MDF using PVA. Then I ran it through my bandsaw to separate it into 2 sides of 16mm MDF and ~7mm Karri. After a few goes with the planer each side is now 16mm MDF and 4mm Karri, for a total thickness of 20mm.

I plan on doing the (125mm wide) baffle in 16mm Karri with no MDF, to allow for a generous radius on the sides. Back will be 9mm MDF, and top and bottom will be MDF with a thin layer of Karri bonded on after assembly. I did a similar setup (Tassi Oak on MDF) with my "noiseUnit" computer speakers (125 wide by 250 deep by 200 tall) and this has worked very well. As long as the real wood is significantly thinner than the MDF and it's really well bonded to the MDF there are no issues with splitting etc.

It's incredibly amusing that I live in WA, with huge Karri forests, and yet we have to import our Karri for furniture from Vietnam.

I made a lamination for the sides (200 x 460) of 16mm MDF, 16mm thick lump of Karri, then 16mm MDF using PVA. Then I ran it through my bandsaw to separate it into 2 sides of 16mm MDF and ~7mm Karri. After a few goes with the planer each side is now 16mm MDF and 4mm Karri, for a total thickness of 20mm.

I plan on doing the (125mm wide) baffle in 16mm Karri with no MDF, to allow for a generous radius on the sides. Back will be 9mm MDF, and top and bottom will be MDF with a thin layer of Karri bonded on after assembly. I did a similar setup (Tassi Oak on MDF) with my "noiseUnit" computer speakers (125 wide by 250 deep by 200 tall) and this has worked very well. As long as the real wood is significantly thinner than the MDF and it's really well bonded to the MDF there are no issues with splitting etc.

It's incredibly amusing that I live in WA, with huge Karri forests, and yet we have to import our Karri for furniture from Vietnam.

Between Bernie and Scott i have had/seen many a solid wood speaker. You need to know what you are doing.

I have torture tested a few — solid wood likes to see stable temperature & humidity, and if it is going to change it should happen slowly. From my tests, softwood seems to hold up best — Douglas Fir (a pine) and Western Red Cedar. Yew & Garry Oak were easiest to blow up.

dave

I have torture tested a few — solid wood likes to see stable temperature & humidity, and if it is going to change it should happen slowly. From my tests, softwood seems to hold up best — Douglas Fir (a pine) and Western Red Cedar. Yew & Garry Oak were easiest to blow up.

dave

Thanks to hollowboy for sharing his experience with Bunnings rubber wood. Looks really good, I could imagine the speakers built out of it , but apparently not stable enough for the purpose I have in mind. I did phone Bunnings this morning and they comfjrmed that it was kiln dried, but still thought expansion etc could be a problem.

If I lived in Tasmania I'd try and use Huon pine, lovely stable timber that takes centuries to grow, but for the same reason hard to source.

If I lived in Tasmania I'd try and use Huon pine, lovely stable timber that takes centuries to grow, but for the same reason hard to source.

16mm thick lump of Karri, then [...] After a few goes with the planer each side is now 16mm MDF and 4mm Karri, for a total thickness of 20mm.

I've just started using 5mm bamboo, laminated to ply, for a similar result.

Strand Woven Bamboo | Plyco

Damaged / 2nd hand blinds can also be 'mined' for timber that's thin, but substantially thicker than veneer. Could be a good option for someone without your tools.

It's incredibly amusing that I live in WA, with huge Karri forests, and yet we have to import our Karri for furniture from Vietnam.

We have the inverse oddness in Victoria. One excuse the logging lobby use to to chop down old growth forest on slopes is that the flat land plantations (also in Victoria) are too far away.

I've used exotic wood and French Polish - easy to work with. Always one piece of wood 30-35cm wide which of course deform after gluing. Closed box and soft suspension bass - below is 6" nanocarbon unit and Harwood AM35/Aurum Cantus 30130. Very nice sound, my best little speakers. Now I bought opposite - very light Samba wood 40mm thick.

Attachments

Where is live isn't very friendly climate wise. I've seen humidity over ninety percent at 2am, and the whole summer has been hot with it. On the other hand, the speaker is very small, front baffle barely larger than a A4 sheet of paper. Might still go wood, but maybe not rubber wood.

I haven't tried real wood, but my quest for DIY speakers that were a little bit different resulted in using slate stone - supposedly an ultimate speaker cabinet material because it's very dense / heavy, yet its layered structure prevents resonance.

( Cabinet materials | Loudspeakerbuilding )

The reason why slate isn't used more in commercial speakers is the weight - it's pretty expensive shipping 100kg speakers around the world.

(An example of premium speakers using slate would be Vroemen : Vroemen but you'd have to pay through the nose to get them anywhere but in Germany)

For DIY weight is not a problem though, as you probably won't be shipping your speakers anywhere

Here's my results:

http://www.diyaudio.com/forums/full-range/65061-range-speaker-photo-gallery-369.html#post4933327

( Cabinet materials | Loudspeakerbuilding )

The reason why slate isn't used more in commercial speakers is the weight - it's pretty expensive shipping 100kg speakers around the world.

(An example of premium speakers using slate would be Vroemen : Vroemen but you'd have to pay through the nose to get them anywhere but in Germany)

For DIY weight is not a problem though, as you probably won't be shipping your speakers anywhere

Here's my results:

http://www.diyaudio.com/forums/full-range/65061-range-speaker-photo-gallery-369.html#post4933327

Last edited:

...it's very dense / heavy...

Neither of these is an asset unless they bring very high stiffness with them.

dave

Look lovely, your happy with the sound?

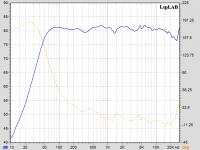

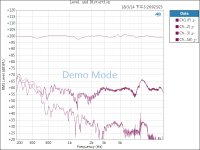

Yes, by spending weeks of time for adjust the sound. I finally make it smooth and lively. Especially for the bass, you can't believe the sound is produced by a 5.5" mid-bass unit. distortion as low as 1% @ 1m, 100dBSPL, fantastic.

Attachments

Last edited:

I bought some large cutting boards of end-grain laminated blocks of rubber wood to construct a turntable plinth. Thankfully I left them up on a shelf in my workshop for 6 months and when I took them down to work on them I found that blocks had unglued in many places and was unusable. From my experience, rubber wood is not dimensionally stable and will split apart as it dries out.Rubber wood is a composite hardwood made from felled rubber trees and, I think, kiln dried. If anyone has built a speaker from real hardwood how did it work out, and would you do it again?

I bought some large cutting boards of end-grain laminated blocks of rubber wood to construct a turntable plinth. Thankfully I left them up on a shelf in my workshop for 6 months and when I took them down to work on them I found that blocks had unglued in many places and was unusable. From my experience, rubber wood is not dimensionally stable and will split apart as it dries out.

That may well be true, but have you considered the specific product you purchased and it's suitability for the purpose?

Cutting boards are expected to be treated with food grade oils / waxes / sealants. Had they been so treated, perhaps they would not have delaminated, as they would not have been exposed to environmental conditions that dried /shrunk or absorbed moisture / grown the individual pieces. You may have purchased non-commercial grade butcher blocks and only bought what might be called commercial grade appearing butcher blocks (ie cosmetically appearing butcher block). Perhaps the construction of the butcher blocks you purchased was made from green wood innapropriate for lamination and without attention to whether the pieces were properly oriented or whether they were heartwood versus sapwood. And maybe a few more possible caveats others might be able to bring up.

My only point is I don't think your experience properly sums up the possible considerations for suitability. It may well be you are right but for the wrong reasons, or maybe your conclusions were hasty and incorrect. I think it would take more than your experiment to have me dismiss a species for consideration.

If you are using blockboard avoid the beech stuff from Romania.It seems to have something nasty in it.My brother and I both both felt really unwell after working with it despite having pretty good dust extractors on my woodworking machinery and sanders.Probably U.F. glue but who knows what else ?

Real Wood DIY Speaker Building Experience

I’ve been building speaker cabinets as a hobbyist for about 45 years (probably 40 sets) and most of them were made from 100% real wood. Yes, you do have to be aware of the moisture issues etc. but I’ve only had a couple ever “crack” and were easily repaired. I’ve built big and small and lots of configurations with no comment on which designs real wood was best for. I would like to pass on some anecdotal info. about all real wood cabinets. I had an unlimited supply of highest quality cherry, walnut, oak, poplar, maple etc. at no cost to me. I could experiment and use trial and error (real world learning) and not cost me anything but time. I can say for certain each type of wood has its own “sound”. I fell in love with the sound of wild cherry cabinets followed closely by black walnut. I did not have equipment to vet out why they sounded different but at the time I did not care - my ears was all that mattered to me. Oak and maple seem to have a more boomy, more reflective sound - not a warm sound - good for pure rock and roll music! BTW - I also own a few sets of high end manufactured speakers so know how great MDF can sound too! Anyway if you have real wood available, can afford it, and have the equipment available give it a try. The beauty can be stunning if you take time to finish them properly. I also agree with what many people have said, when working with real wood there’s a different feeling and satisfaction. The process becomes as meaningful as the end result - silly I know but for me (and others it seems) there can be a deeper satisfaction when building with real wood - in sound and in the building process. I’d love to hear from others with experience building 100% real wood cabinets. I just started building a pair of wild cherry 9 sided cabinets for a 3way design with 12” downward firing sub. I’ll post pics when I’m done. I cut the trees down in 1980 and had it milled in 1981 and stored indoors - so it should be acclimated to it’s environment. Lol.

Thanks for letting an old timer share my experiences.

I’ve been building speaker cabinets as a hobbyist for about 45 years (probably 40 sets) and most of them were made from 100% real wood. Yes, you do have to be aware of the moisture issues etc. but I’ve only had a couple ever “crack” and were easily repaired. I’ve built big and small and lots of configurations with no comment on which designs real wood was best for. I would like to pass on some anecdotal info. about all real wood cabinets. I had an unlimited supply of highest quality cherry, walnut, oak, poplar, maple etc. at no cost to me. I could experiment and use trial and error (real world learning) and not cost me anything but time. I can say for certain each type of wood has its own “sound”. I fell in love with the sound of wild cherry cabinets followed closely by black walnut. I did not have equipment to vet out why they sounded different but at the time I did not care - my ears was all that mattered to me. Oak and maple seem to have a more boomy, more reflective sound - not a warm sound - good for pure rock and roll music! BTW - I also own a few sets of high end manufactured speakers so know how great MDF can sound too! Anyway if you have real wood available, can afford it, and have the equipment available give it a try. The beauty can be stunning if you take time to finish them properly. I also agree with what many people have said, when working with real wood there’s a different feeling and satisfaction. The process becomes as meaningful as the end result - silly I know but for me (and others it seems) there can be a deeper satisfaction when building with real wood - in sound and in the building process. I’d love to hear from others with experience building 100% real wood cabinets. I just started building a pair of wild cherry 9 sided cabinets for a 3way design with 12” downward firing sub. I’ll post pics when I’m done. I cut the trees down in 1980 and had it milled in 1981 and stored indoors - so it should be acclimated to it’s environment. Lol.

Thanks for letting an old timer share my experiences.

I don’t have your experience in listening to the sound of speakers built with various wood species, but as a fellow woodworker I can absolutely attest to the joy and satisfaction of working with real wood.

Regardless of what you are building - speakers, tables, cabinets, anything at all - the constant touching and handling of real wood is a big part of the gratification.

There is something sensual about running your fingers over the surface of a well processed piece of wood. Particularly after it has been sanded down several times. Not to mention the visual satisfaction of enjoying the natural grain patterns.

None of that happens with MDF, which I believe is an awful material to use. I do not allow it my shop for any purpose. Besides the dangerous fine dust that gets everywhere it quickly dulls your cutting tools. No thanks. There are much better alternatives.

But to be able to use real wood one has to have a jointer and a planer in order to straighten out any warps and unify the thickness of pieces. I’m guessing that most people here don’t have all of that equipment. A few of us do, but probably not most.

So that leaves plywood as the alternative and it is a very good one if true European sourced Baltic Birch is used. Junk plywood from home centers is a poor choice for speakers due to the many voids and other flaws. Plus the surface veneer layers are usually thin and lacking in much grain interest.

For those of us who appreciate working with fine woods there is no alternative. Seeing and feeling it provides its own special satisfaction that can’t be matched with any other material. Thanks for bringing up the subject.

Regardless of what you are building - speakers, tables, cabinets, anything at all - the constant touching and handling of real wood is a big part of the gratification.

There is something sensual about running your fingers over the surface of a well processed piece of wood. Particularly after it has been sanded down several times. Not to mention the visual satisfaction of enjoying the natural grain patterns.

None of that happens with MDF, which I believe is an awful material to use. I do not allow it my shop for any purpose. Besides the dangerous fine dust that gets everywhere it quickly dulls your cutting tools. No thanks. There are much better alternatives.

But to be able to use real wood one has to have a jointer and a planer in order to straighten out any warps and unify the thickness of pieces. I’m guessing that most people here don’t have all of that equipment. A few of us do, but probably not most.

So that leaves plywood as the alternative and it is a very good one if true European sourced Baltic Birch is used. Junk plywood from home centers is a poor choice for speakers due to the many voids and other flaws. Plus the surface veneer layers are usually thin and lacking in much grain interest.

For those of us who appreciate working with fine woods there is no alternative. Seeing and feeling it provides its own special satisfaction that can’t be matched with any other material. Thanks for bringing up the subject.

Last edited:

Very nice, Dave.

And the great thing, which I think is underappreciated, is that while you're listening to the music your visual world is also being enhanced and gratified by simply having speakers like these in your field of view.

The two worlds, visual and audio, get together to create the total enjoyment experience. Sure, painted MDF speaker cabinets can be made to be attractive. And real wood veneers over MDF can be even more attractive.

But nothing is visually gratifying like real wood. Veneers never quite reach the same level as real wood. You can almost always tell the difference. Nothing can compare to the interest and warmth of grain in real wood.

And the great thing, which I think is underappreciated, is that while you're listening to the music your visual world is also being enhanced and gratified by simply having speakers like these in your field of view.

The two worlds, visual and audio, get together to create the total enjoyment experience. Sure, painted MDF speaker cabinets can be made to be attractive. And real wood veneers over MDF can be even more attractive.

But nothing is visually gratifying like real wood. Veneers never quite reach the same level as real wood. You can almost always tell the difference. Nothing can compare to the interest and warmth of grain in real wood.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Anyone built speakers using real wood?