The work done by the driver on the cabinet is the product of force and velocity. This is linear and doesn't change with frequency. So whatever is needed to move the cone at high frequencies goes into the cabinet just the same as at low frequencies.

Scott, in post #32 posted a Linkwitz reference:

Because the vibration energy from the driver decreases rapidly with increasing frequency it is advantageous to push the panel vibration modes up in frequency where the excitation energy is small.

The force putting work into a high Q resonance experiences a lower damping resistance than a low Q resonance. It may take longer for the maximum amplitude of a high Q resonance to be reached because it may be a lot larger but a high Q resonance will get to a given displacement quicker than a low Q resonance because there is less damping force opposing it.

A high Q resonance requires that the energy to get going is over a very narrow bandwidth, music typically does not keep hitting that bandwidth over & over again in a manor consistent enuff to supply the required energy.

dave

Good enough is the right way to look at it. Cabinet radiation is a form of distortion and so if it can be reduced to 40dB or so below the signal it will likely be inaudible. Likely because a steady state view isn't the whole story with resonances since a high Q resonance can continue after the signal has stopped. So get some decent damping in there to make medium Q resonances with peaks 40 dB or more down.I admittedly am still a bit confused over just what to do and whether the current design of my cabinet is good enough.

Looking at what the professionals do rather than just taking conflicting advice from enthusiastic amateurs can also help build confidence when you are not on top of a subject.

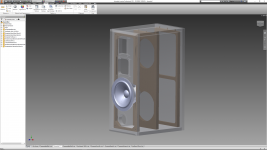

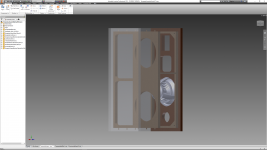

This looks like a reasonable starting place if you compare it with what tends to be done by competent speaker companies. Where you unquestionably need stiffness is the front baffle because the (rate of) work put into the cabinet is the product of the force from the driver and the velocity of the baffle where the driver is clamped. If the front baffle didn't move no work from the driver would be transferred to vibrate the cabinet (the cabinet would still be driven by the varying air pressure inside the cabinet but this is not normally the main source of cabinet vibration). The stiffer the front baffle the less energy enters the cabinet as vibration (my earlier posts are about how to handle the vibration that is in the cabinet). The front baffle also faces the listener and so it's motion is mostly easily heard in the important midrange unlike say the rear panel. If you do feel inclined to add bracing then try to arrange it so it supports and stiffens the front baffle where you can have some confidence it will do some good.At this stage I think I'll settle on 18mm sides and 25mm thick front. Most likely from ply.

Does that conclusion follow if the lower energy required at higher frequencies by the driver to make sound is also required by the cabinet to make sound?Because the vibration energy from the driver decreases rapidly with increasing frequency it is advantageous to push the panel vibration modes up in frequency where the excitation energy is small.

There is some truth in this but why in practice do the high Q resonances in metal cones get driven enough to be unpleasant even when well below the signal? Is it wise to rely on no note being played that is well aligned with the high Q resonance when the option exists to avoid it?A high Q resonance requires that the energy to get going is over a very narrow bandwidth, music typically does not keep hitting that bandwidth over & over again in a manor consistent enuff to supply the required energy.

Yes, because you also need to consider the relative massesDoes that conclusion follow if the lower energy required at higher frequencies by the driver to make sound is also required by the cabinet to make sound?

Relative masses of what?Yes, because you also need to consider the relative masses

Thanks for all the help so far people, even though admittedly for a beginner like me a lot some of it is pretty confusing.

I'm hoping to start sometime next week, though I'm not really in a particular hurry.

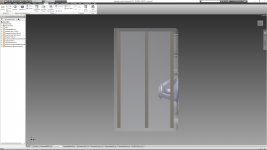

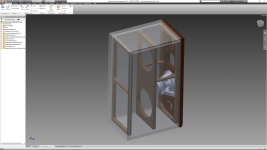

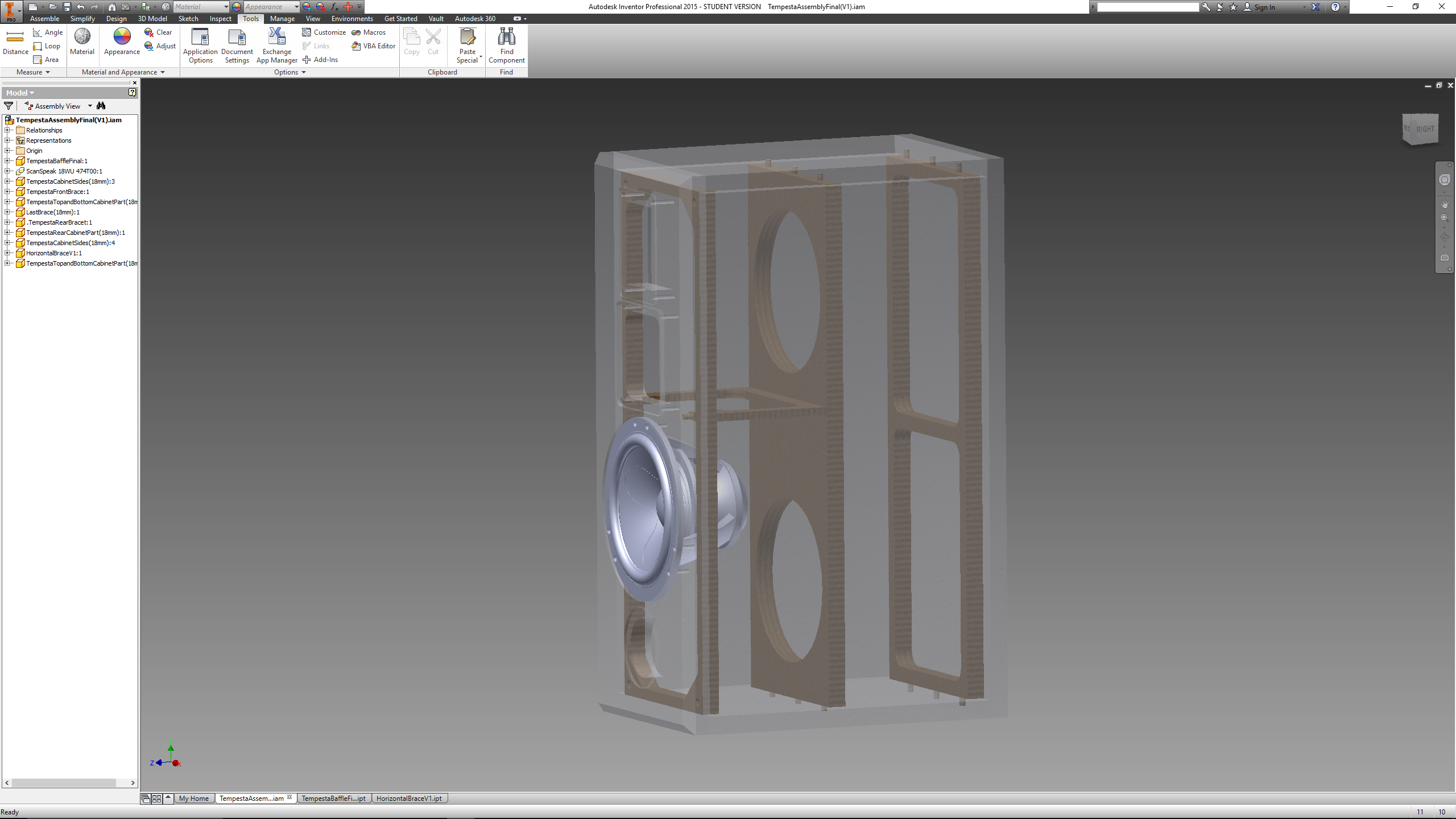

I changed the bracing slightly by adding an additionally one to the back against the rear cabinet panel.

Have 3 Vertical braces, though the middle and the last one should add some horizontal strength?.

I'm thinking about adding a horizontal brace running across the interior length of the cabinet.

I want to keep the cabinet simply, especially since my woodworking and construction skills aren't great.

Have read Troels Gravesen's page on cabinet damping, I think i'll stick with the Jaycar Acrylic speaker stuffing I have, but can anyone in Australia point me towards where I could get the 10mm felt damping stuff, that is attached to the interior walls, or can this be sourced at most fabric stores?. I live in Tas, where resources/shops can be a bit limited.

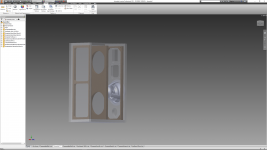

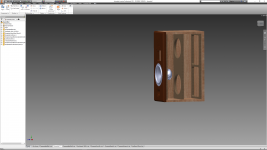

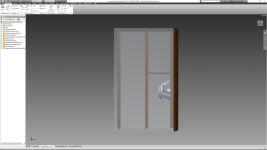

Here is what the cabinet design I have so far now looks like.

TempestaCabinet - Google Drive

Sorry about the google drive picture links, i haven't quite figured out how to directly embed into a post.

On the Speaker Picture shown it has a width of 228.6mm (9in) x 558.8mm (22in) High x 348mm Deep.

Internal dimensions are:

W=192.6mm, H=522.8mm and D=305mm

Internal volume comes out to 30.7L, slightly more than the 28.32L (1ft^3) required, although this doesn't take into account the volume the braces occupy.

Not sure whether I should widen the cabinet, which was recommended in an earlier post.

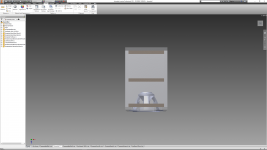

Kit has 2 crossover boards per speaker.

I can also upload my AutoDesk Inventor files if anyone wants to take a look.

I'm hoping to start sometime next week, though I'm not really in a particular hurry.

I changed the bracing slightly by adding an additionally one to the back against the rear cabinet panel.

Have 3 Vertical braces, though the middle and the last one should add some horizontal strength?.

I'm thinking about adding a horizontal brace running across the interior length of the cabinet.

I want to keep the cabinet simply, especially since my woodworking and construction skills aren't great.

Have read Troels Gravesen's page on cabinet damping, I think i'll stick with the Jaycar Acrylic speaker stuffing I have, but can anyone in Australia point me towards where I could get the 10mm felt damping stuff, that is attached to the interior walls, or can this be sourced at most fabric stores?. I live in Tas, where resources/shops can be a bit limited.

Here is what the cabinet design I have so far now looks like.

TempestaCabinet - Google Drive

Sorry about the google drive picture links, i haven't quite figured out how to directly embed into a post.

On the Speaker Picture shown it has a width of 228.6mm (9in) x 558.8mm (22in) High x 348mm Deep.

Internal dimensions are:

W=192.6mm, H=522.8mm and D=305mm

Internal volume comes out to 30.7L, slightly more than the 28.32L (1ft^3) required, although this doesn't take into account the volume the braces occupy.

Not sure whether I should widen the cabinet, which was recommended in an earlier post.

Kit has 2 crossover boards per speaker.

I can also upload my AutoDesk Inventor files if anyone wants to take a look.

Last edited:

I wouldn't bother with the light cheap ply that is around these days, on the other hand marine ply is expensive. MDF is a distant second best but it depends on your means.MDF, Marine and Birch Ply

Damping is a useful and some would say important part of a cabinet, ie laminating two sheets using a suitable adhesive such as polyurethane or even PVA. In this case mixing wood types isn't necessarily productive, usually you would use two the same.

Outer size has an effect. A roundover can be added later. Larger can have benefits IMO.The baffle dimensions given by Selah Audio are 228.6mm (9in) x 558.8m (22in).

Volume most be 1ft^3 (28.32L).

Fibreglass batts are better than dacron, and rockwool batts better still although each could have their place in the right speaker. Consider that you are doing a ported box which can put some constraints on this, depending on your priorities. Bunnings do the batts.Can anyone located in Australia, point me towards some good damping materials to use.

I already have some speaker stuffing from jaycar.

Last edited:

yes it willHave 3 Vertical braces, though the middle and the last one should add some horizontal strength?.

Front to back? Good ideaI'm thinking about adding a horizontal brace running across the interior length of the cabinet.

It would be better if the braces didn't equally divide the panels

If you are not on top of the subject technically then who to believe? Tricky but it can be fun to watch.Thanks for all the help so far people, even though admittedly for a beginner like me a lot some of it is pretty confusing.

What are you trying to achieve with the bracing? It is hard to give constructive advice without knowing. I doubt the rear bracing panel will do much towards it. The front brace might do a bit but to stiffen the front baffle more effectively the bracing panels need to support the middle and not the outside which is already supported by the side, top and bottom walls. Inserting bracing panels in one or both the other directions would be more effective if you can get round the drivers.I changed the bracing slightly by adding an additionally one to the back against the rear cabinet panel.

This one? This thread has been useful in identifying where some of the poor advice that you have been given is coming from.Have read Troels Gravesen's page on cabinet damping,

Damping for the sound waves inside the cabinet works by squeezing air through tiny gaps in the material in order to create strong velocity gradients which transfers some of the kinetic energy into heat by the action of viscosity. To work well this needs high velocity. At a wall the pressure varies strongly but the velocity is zero. The maximum velocity lies quarter of a wavelength away.I think i'll stick with the Jaycar Acrylic speaker stuffing I have, but can anyone in Australia point me towards where I could get the 10mm felt damping stuff, that is attached to the interior walls, or can this be sourced at most fabric stores?.

Sticking felt on the walls is therefore the least effective place you can put it. If you have a ported cabinet and a small volume with the woofer high pass frequency below the frequency of the lowest internal cabinet mode then ineffective damping is probably not much of a problem. However, in your case you have a tiny midrange and a relatively tall cabinet. What is the crossover frequency to the midrange and what is frequency of the lowest internal resonance of your cabinet? If you need to damp this resonance then the best place to put damping material is in the middle of the volume where the velocity of this mode is at a maximum. Keep away from the mouth of the port. You may be able to attach the damping material to convenient bracing panels.

Not sure whether I should widen the cabinet, which was recommended in an earlier post.

If the crossover has been competently designed then changing the baffle dimensions will require it to be modified. You already have the crossover?

I have pretty much everything needed for the build, including the crossover's.

I'll stick with the baffle dimensions provided by Rick over at Selah Audio then.

Not sure on the crossover points, they aren't mentioned anywhere.

Pre-Built Selah Audio Tempesta's are based on this cabinet

http://www.daytonaudio.com/media/resources/302-751-dayton-audio-mtmc-10bk-specifications-45911.pdf

Was planning on getting one but, getting one down to Australia, is around $600aud for a pair, a bit more than I'm willing to spend, plus I would also like to veneer them with a native Tasmanian wood.

I'll stick with the baffle dimensions provided by Rick over at Selah Audio then.

Not sure on the crossover points, they aren't mentioned anywhere.

Pre-Built Selah Audio Tempesta's are based on this cabinet

http://www.daytonaudio.com/media/resources/302-751-dayton-audio-mtmc-10bk-specifications-45911.pdf

Was planning on getting one but, getting one down to Australia, is around $600aud for a pair, a bit more than I'm willing to spend, plus I would also like to veneer them with a native Tasmanian wood.

You bought the kit from Selah Audio? And the crossover frequencies and slopes are not mentioned in the description? That would seem a bit odd.Not sure on the crossover points, they aren't mentioned anywhere.

The internal height of the cabinet you linked to is about 0.5m. With a few mm of extensional wall damping that will lead to the frequency of the lowest internal cabinet mode being around 350-375 Hz or so. If we assume the 2" upper midrange is crossed around 800 Hz or so then there will be significant energy inside the cabinet driving all the internal cabinet modes with frequencies below 1.5 kHz or so. You will need some reasonably effective damping for these modes. Not just a thin layer stuck to the walls but away from the walls where it will be more effective. You may also get significant midrange leakage out the port and so it may be useful to experiment with placing damping material between the woofer and the port but try to avoid restricting the air flow into the port and you don't want bits getting into the voice coil gap.

I added a horizontal brace running from the front baffle to the middle one.

Would the brace attached to the rear cabinet wall be needed or is it a bit unnecessary?.

In Troels Gravesen Cabinet damping guide, he mentioned using bitumen pads, is this something I should also use?.

Would it also be worth changing the Jaycar Acrylic Speaker Damping material for something better/different, like pink Fiberglass batting sheets.

How does this design compare to the Dayton Audio MTMC-1.0, used in the pre-built version of my speakers.

Would the brace attached to the rear cabinet wall be needed or is it a bit unnecessary?.

In Troels Gravesen Cabinet damping guide, he mentioned using bitumen pads, is this something I should also use?.

Would it also be worth changing the Jaycar Acrylic Speaker Damping material for something better/different, like pink Fiberglass batting sheets.

How does this design compare to the Dayton Audio MTMC-1.0, used in the pre-built version of my speakers.

Attachments

A shelf brace or even just a dowel between a midpoint on the baffle extending back would be better than your last addition. The idea is divide the unbraced panel areas into smaller ones to raise their resonant frequency, it's also a good idea to vary the size of these areas to spread the resonances

There is some truth in this but why in practice do the high Q resonances in metal cones get driven enough to be unpleasant even when well below the signal? Is it wise to rely on no note being played that is well aligned with the high Q resonance when the option exists to avoid it?

Hard to equate a driving element with a thin metal cone, to a much thicker, and much better damped, enclosure wall.

I wil stand by my statements. Hundreds of builds using these philosophies have turned out very inert enclosures.

dave

As Andy says, a vibrating baffle is a worst case cabinet wall vibration possible.

The baffle is also the weakest panel in the box with all th eholes cut in it. The added horizontal brace does little since you are bracing the edges. Aa additional full-height brace that also couples the midbasses to the top, bottom, and back goes a long ways to making sure a vibrating baffle does not degrade your speaker’s performance.

dave

The baffle is also the weakest panel in the box with all th eholes cut in it. The added horizontal brace does little since you are bracing the edges. Aa additional full-height brace that also couples the midbasses to the top, bottom, and back goes a long ways to making sure a vibrating baffle does not degrade your speaker’s performance.

dave

There is relatively, little space on the rear of the front baffle to attach a horizontal brace.

Would it be better if I change the horizontal brace, so that it runs across the length of the front baffle instead of just the edges.

Also how would you recommend joining the panels together.

I was thinking about using dado joints.

Would it be better if I change the horizontal brace, so that it runs across the length of the front baffle instead of just the edges.

Also how would you recommend joining the panels together.

I was thinking about using dado joints.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- First Time Speaker Build, Cabinet Advice