After following X's success in these threads:

http://www.diyaudio.com/forums/full-range/292130-ff85wk-rs225-8-passive-fast.html

http://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-ref-monitor-65.html

I decided I would like to try this combo as a starting point for what I hope will be come a nice pair of 'reference' speakers. I've been building more amps, pre-amps etc. lately and find myself wanting a consistent 'known state' platform to test them on.

Also, a good excuse to buy more drivers and make more sawdust.

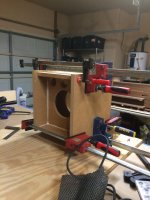

To that end, I got an hour or so after work today to get most of the pieces cut for a first prototype box for the RS225.

Internal dimensions are: 10" wide X 12" tall X 14" deep. This creates a 0.972cu/ft (27.52 liters) enclosure. Not counting driver frame, and the 2 'window pane' braces.

General outline:

~25liter sealed enclosure for the RS-225

~1.2liter sealed 'dagger tl' (Thank you X for that awesome name!) for the, well, other driver.

The other driver being an FF85WK, TC9FD, or 10F/8424. Depending on measurements, and what sounds best to my ears.

I am hoping to reduce box resonance and thus hd(as I understand it, at least) with the thick material, window pane braces, etc. Details below about construction plans.

Ultimately, this would use a passive crossover to make testing amps that much easier. I have a miniDSP 4x10, and at least one 2x4 available for testing/development until the final design is done.

I'm also open to adding a tweeter, should the measurements or my ears demand it. I have a spare pair of B&G Neo3's on hand, and I do quite like them, but I would be open to just about anything that's not too expensive.

General construction paramters:

1"(25mm) Baltic Birch for all enclosures

~3/4"(18mm) Baltic Birch for the window pane braces

~1 1/2" - ~ 2" MDF/BB for the Baffle on the RS225's enclosure.

Flush mount all drivers

'Faceted' baffle for the RS225, inspiration from, among others, Troels Gravesen's 'Ellam Flex' baffle:

I'll attach a few pics of the prototype bits I made tonight. The chamfers/round-overs aren't done yet on the braces, baffle, etc. I'm using ~3/4" MDF for the enclosure and braces, and ~1.5" MDF(2 3/4" pieces laminated) for the baffle.

My plan for next steps are as follows:

1- glue up test enclosure.

2 - glue 1/2" natural wool felt to some of the interior panels

3 - Add some polyfill stuffing, after weighing it.

4 - Measure

5 - Adjust stuffing, etc.

rinse and repeat

Hope to have some measurements soon. I'm fairly green to measurement protocols, but I think I have a good idea what needs to be done. I have a UMIK-1 and assorted bits to do the measuring.

Any and all insights, criticisms, analysis and feed back are very welcomed!

Thanks!

Gable

http://www.diyaudio.com/forums/full-range/292130-ff85wk-rs225-8-passive-fast.html

http://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-ref-monitor-65.html

I decided I would like to try this combo as a starting point for what I hope will be come a nice pair of 'reference' speakers. I've been building more amps, pre-amps etc. lately and find myself wanting a consistent 'known state' platform to test them on.

Also, a good excuse to buy more drivers and make more sawdust.

To that end, I got an hour or so after work today to get most of the pieces cut for a first prototype box for the RS225.

Internal dimensions are: 10" wide X 12" tall X 14" deep. This creates a 0.972cu/ft (27.52 liters) enclosure. Not counting driver frame, and the 2 'window pane' braces.

General outline:

~25liter sealed enclosure for the RS-225

~1.2liter sealed 'dagger tl' (Thank you X for that awesome name!) for the, well, other driver.

The other driver being an FF85WK, TC9FD, or 10F/8424. Depending on measurements, and what sounds best to my ears.

I am hoping to reduce box resonance and thus hd(as I understand it, at least) with the thick material, window pane braces, etc. Details below about construction plans.

Ultimately, this would use a passive crossover to make testing amps that much easier. I have a miniDSP 4x10, and at least one 2x4 available for testing/development until the final design is done.

I'm also open to adding a tweeter, should the measurements or my ears demand it. I have a spare pair of B&G Neo3's on hand, and I do quite like them, but I would be open to just about anything that's not too expensive.

General construction paramters:

1"(25mm) Baltic Birch for all enclosures

~3/4"(18mm) Baltic Birch for the window pane braces

~1 1/2" - ~ 2" MDF/BB for the Baffle on the RS225's enclosure.

Flush mount all drivers

'Faceted' baffle for the RS225, inspiration from, among others, Troels Gravesen's 'Ellam Flex' baffle:

I'll attach a few pics of the prototype bits I made tonight. The chamfers/round-overs aren't done yet on the braces, baffle, etc. I'm using ~3/4" MDF for the enclosure and braces, and ~1.5" MDF(2 3/4" pieces laminated) for the baffle.

My plan for next steps are as follows:

1- glue up test enclosure.

2 - glue 1/2" natural wool felt to some of the interior panels

3 - Add some polyfill stuffing, after weighing it.

4 - Measure

5 - Adjust stuffing, etc.

rinse and repeat

Hope to have some measurements soon. I'm fairly green to measurement protocols, but I think I have a good idea what needs to be done. I have a UMIK-1 and assorted bits to do the measuring.

Any and all insights, criticisms, analysis and feed back are very welcomed!

Thanks!

Gable

Last edited:

Not sure Troels would like you 'stealing' his bandwidth by hotlinking from his site.

Good point, removed the link.

I'd consider opening up the MDF on the back side of the RS225 baffle. You can tighten up the RS225 cut out with peal and stick black craft felt. I used my wife's rotary cutter to cut thin strips of the craft felt. It worked great.

My wife was not happy about the sticky residue on the rotary cutter, but now I have my own

My wife was not happy about the sticky residue on the rotary cutter, but now I have my own

Chamfered the back of the baffle, and glued the sides on tonight. Cut the rear panel down, will glue it on tomorrow when I glue the baffle on.

Hopefully will start laminating the baltic birch this weekend as well. So I can start on the enclosure for the ff85wks/tc9fd/10f testing.

Hopefully will start laminating the baltic birch this weekend as well. So I can start on the enclosure for the ff85wks/tc9fd/10f testing.

Attachments

Last edited:

I like to chamfer or round holes in braces too but it's, from a performance standpoint, irrelevant- the frequencies of concern are a non-issue inside enclosures (unless you were designing a very small scale tweeter back chamber or something)- not a critique, just noting that it's not necessary (and again- I do it too, for no good reason).

I like to chamfer or round holes in braces too but it's, from a performance standpoint, irrelevant- the frequencies of concern are a non-issue inside enclosures (unless you were designing a very small scale tweeter back chamber or something)- not a critique, just noting that it's not necessary (and again- I do it too, for no good reason).

I've wondered about that. I did a small round-over on the braces, both sides, before gluing them in. I did put a large chamfer on the back of the baffle, felt it was especially needed as the baffle is ~1.5" (~38mm) thick.

I glued the rear panel on this morning, mounted some binding posts, and wired them with disconnects for the driver's terminals, used Belden 9497, I really like this wire for speaker internals, and speaker cables. Belden makes a quality product IMO.

Had just enough time tonight to prep the prototype enclosure for the RS225 for measurements tomorrow or Sunday.

I lined the rear panel with 1/4" natural wool, as well as the 'face' of the first brace and all four walls of the front section of the enclosure.

I added 16oz of Acousta-stuff, then mounted the driver.

Hooked it up to a chip amp and my iphone and played a few test tones and I have to say I am seriously impressed by the lf output. Meaningless subjective anecdote aside.... needless to say I'm quite excited to get some real measurements.

I threw together some half-assed test baffles for the ff85wk's as well.

I lined the rear panel with 1/4" natural wool, as well as the 'face' of the first brace and all four walls of the front section of the enclosure.

I added 16oz of Acousta-stuff, then mounted the driver.

Hooked it up to a chip amp and my iphone and played a few test tones and I have to say I am seriously impressed by the lf output. Meaningless subjective anecdote aside.... needless to say I'm quite excited to get some real measurements.

I threw together some half-assed test baffles for the ff85wk's as well.

Might consider a flush mount FF85 test baffle, although the ring by the surround makes me question whether there would be any benefit.

I considered it, and will likely test with it flush mounted at some point as well.

Great work pcgab!

Nice wooodworking - very clean.

Thanks X!

I just took a few sweeps of the RS-225-8 in the prototype box. I'll post the graphs shortly.

Attachments

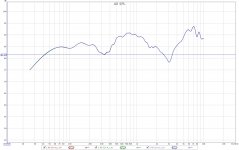

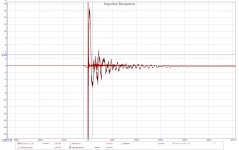

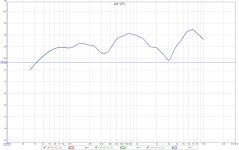

3 sweeps, ran @~0.5m distance. all 1/12 smoothed. The ~300hz drop is a little concerning, though I'm not sure where it's coming from.

I didn't have time to baseline, then adjust stuffing, so that session will have to happen in the next few days. I have 1lb of acousta-stuff fluffed and in the box. The box is ~25L.

I don't know if I have too much or too little, googling didn't provide any formulas, so I'll do the test/measuring and see how it affects response.

Any insight is greatly appreciated here. Certain behavoirs, etc. I should look out for.

Thanks!

Gable

I didn't have time to baseline, then adjust stuffing, so that session will have to happen in the next few days. I have 1lb of acousta-stuff fluffed and in the box. The box is ~25L.

I don't know if I have too much or too little, googling didn't provide any formulas, so I'll do the test/measuring and see how it affects response.

Any insight is greatly appreciated here. Certain behavoirs, etc. I should look out for.

Thanks!

Gable

Attachments

Last edited:

That looks about right. The dip at 320Hz is probably the floor bounce. Put mic 50cm away and elevate speaker at least 36in off the fooor (centerline ) and use frequency dependent window (FDW) 6 cycles in REW to remove effects of reflections. The falloff from below 1kHz is usual 5-6 Dan baffle step loss.

I'll have to measure the stand to see how high it was.

I applied the FDW and it did improve a bit. Glad to know it looks normal. I'll leave the stuffing alone for the time being.

Thank you for the insight X!

Hoping to start late this week on building the 'dagger' tl, 3-sided prism for the TC9FD/10F testing.

I applied the FDW and it did improve a bit. Glad to know it looks normal. I'll leave the stuffing alone for the time being.

Thank you for the insight X!

Hoping to start late this week on building the 'dagger' tl, 3-sided prism for the TC9FD/10F testing.

Attachments

I want to build a nice (two way) bookshelf for sometime. But the threads mention in post 1# kept me from building a two way because I find the use of an full range driver (and the Dayton Woofer) very interesting. So I am following this thread and maybe I learn something from it.

I already have one question... you put the Dayton in a 25 litres sealed box. Is this the optimum size for it? (I don't have simulation software).

Good luck with your build!

R.

I already have one question... you put the Dayton in a 25 litres sealed box. Is this the optimum size for it? (I don't have simulation software).

Good luck with your build!

R.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- 2/3 Way - 'Reference' build