The wax is applied very lightly, I wouldn't worry about added mass.

Laquer however will add mass, and maybe even change other parameters?

So any spray-on coat would be thicker than wax?

I would varnish. Would use a very fluid laqueur. The parameters: less, other resonances of the driver;-)

Do not forget the backside;-!

Better, for best playing, is, to clamp the drivers. Much more effectively than using of unlaqueured and corroded drivers;-)

1. The backside is inside the cabinet so is not exposed so why lacquer or wax the rear?

2. What do you mean "clamp the drivers"?

Last edited:

1. The backside is inside the cabinet so is not exposed so why lacquer or wax the rear?

Because humid air can get there.

Just looking at the pics hurts.

Also weak on the Seas company part.

Yeah it does!

Those drivers cost about $2000 + import duties and taxes (in India that doubles the cost).

Which is why I am trying to ensure I am sure I can protect the drivers if I get a second set.

Because humid air can get there.

Thanks.

If Seas did this to me I wouldn`t buy their products anymore.

Those are not the only drivers in the world.

But well... when it is THE speaker for you...

Of course there are several other equally good driver manufacturers. Thing is i built these cabinets using a veneer that matches with the rest of the apartment (we bought several sheets of book matched veneer) and I am trying to retain the cabinets which means I would have to get drivers that fit in the cabinets.

Since drivers most manufacturers have slightly different mounting dimensions this limits me to those drivers that would perfectly fit.

I hate it to see the tragedy happening again and in even bigger scale.

To add some kind of varnish to the surface add weight and so does wax. Probably less but it still adds weight. So, how much added weight is acceptable?

The W22EX got a Mms of 28,012g according to my simulation software, that is including air mass. Seas says on the datasheet 26,2g plus 1,89g air mass, which comes to 28,09g which is extremely close and probably only differs because of different rounding methods. The effective piston area is stated with 219cm², that includes no dustcap (-> Phase Plug) but the half of the surround. To protect the membrane, the backside of the cone has to be surface treated aswell ofcourse, otherwise it's only cosmetical and the destruction will continue there unnoticed. So, let's assume it's roughly 200x2=400cm² because to be sure to seal the surface, you'd probably go over a bit of the area twice while overlapping doing so, that seems realistic to me.

I've simulated it with +5g added the fs drops to 23 Hz, which is well within the tolerance, with +10g it drops to 21,4 Hz. I took these two weights because that's the lowest I could imagine you'd be able to cover the surface front and back with wax respective clear varnish. I'm not completely sure if that's accurate, I guess that's probably pretty close. Wax might probably be adding less weight, I'm not sure about that but it seems close to that number I think.

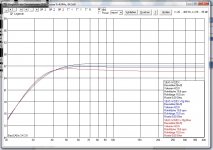

But let's just look what happens with +5 and +10g added mass:

So, in the bass it pretty much doesn't change anything worth mentioning. That seems plausible since the Fs is usually assumed to be normal if it's within +/-10..15%. The main thing here is, you are losing between 2 (+5g) and 4dB (+10g) from 80Hz upwards! That's a lot. And that means, the crossover has to be changed anyway.

Would I do that? Er, maybe the wax was an option since it is also relatively easy done but varnish is out of question. Regarding the success - I would not dare to lay out a complex prognostics regarding wax. I doubt it will save the drivers. Prolonging the remaining 'life' - yes, probably. Worth the effort? Well, since the drivers are already in a pretty bad shape, probably not.

To add some kind of varnish to the surface add weight and so does wax. Probably less but it still adds weight. So, how much added weight is acceptable?

The W22EX got a Mms of 28,012g according to my simulation software, that is including air mass. Seas says on the datasheet 26,2g plus 1,89g air mass, which comes to 28,09g which is extremely close and probably only differs because of different rounding methods. The effective piston area is stated with 219cm², that includes no dustcap (-> Phase Plug) but the half of the surround. To protect the membrane, the backside of the cone has to be surface treated aswell ofcourse, otherwise it's only cosmetical and the destruction will continue there unnoticed. So, let's assume it's roughly 200x2=400cm² because to be sure to seal the surface, you'd probably go over a bit of the area twice while overlapping doing so, that seems realistic to me.

I've simulated it with +5g added the fs drops to 23 Hz, which is well within the tolerance, with +10g it drops to 21,4 Hz. I took these two weights because that's the lowest I could imagine you'd be able to cover the surface front and back with wax respective clear varnish. I'm not completely sure if that's accurate, I guess that's probably pretty close. Wax might probably be adding less weight, I'm not sure about that but it seems close to that number I think.

But let's just look what happens with +5 and +10g added mass:

So, in the bass it pretty much doesn't change anything worth mentioning. That seems plausible since the Fs is usually assumed to be normal if it's within +/-10..15%. The main thing here is, you are losing between 2 (+5g) and 4dB (+10g) from 80Hz upwards! That's a lot. And that means, the crossover has to be changed anyway.

Would I do that? Er, maybe the wax was an option since it is also relatively easy done but varnish is out of question. Regarding the success - I would not dare to lay out a complex prognostics regarding wax. I doubt it will save the drivers. Prolonging the remaining 'life' - yes, probably. Worth the effort? Well, since the drivers are already in a pretty bad shape, probably not.

Attachments

Wax or varnish should be used on new drivers - not these that are already ruined.

If you have high precision scale take A4 paper format, measure its weight. Then apply the wax or varnish (and wait to dry) to see how much weight is added.

I highly doubt that it would be more than 1gr (probably less).

EDIT: It goes without mentioning that you're not supposed to make 7 coats of heavy lacquer to the cone. Probably two coats of very diluted stuff.

If you have high precision scale take A4 paper format, measure its weight. Then apply the wax or varnish (and wait to dry) to see how much weight is added.

I highly doubt that it would be more than 1gr (probably less).

EDIT: It goes without mentioning that you're not supposed to make 7 coats of heavy lacquer to the cone. Probably two coats of very diluted stuff.

Last edited:

I hate it to see the tragedy happening again and in even bigger scale.

The W22EX got a Mms of 28,012g according to my simulation software, that is including air mass. ...So, let's assume it's roughly 200x2=400cm² because to be sure to seal the surface, you'd probably go over a bit of the area twice while overlapping doing so, that seems realistic to me.

I've simulated it with +5g added the fs drops to 23 Hz, which is well within the tolerance, with +10g it drops to 21,4 Hz.

The main thing here is, you are losing between 2 (+5g) and 4dB (+10g) from 80Hz upwards! That's a lot. And that means, the crossover has to be changed anyway.

Would I do that? Er, maybe the wax was an option since it is also relatively easy done but varnish is out of question.

Worth the effort? Well, since the drivers are already in a pretty bad shape, probably not.

Thank you so much for this detailed report. It is simply fantastic that you would take so much time and effort to help someone. Thank you again.

I can see that if the wax or varnish exceeds 2gms or so the whole process makes no sense.

The W22 woofer works to about 300Hz (I assume the W15 woofer takes over from there) and hence for 2 octaves I would loose 2-4db if I use too much wax. I can consider a slight crossover redesign if it comes to that.

Wax or varnish should be used on new drivers - not these that are already ruined.

If you have high precision scale take A4 paper format, measure its weight. Then apply the wax or varnish (and wait to dry) to see how much weight is added.

I highly doubt that it would be more than 1gr (probably less).

Yes I do have a precision scale and I did intend to test the weight of the wax and varnish on a A4 sheet once the New year parties are done (in Mumbai, India the parties start on Dec 23rd and continue to Jan 2nd).

Meanwhile I have written to SEAS again and the reply I got is that they too are closed till Jan 2nd. I assume when they re-open they will have several emails to answer so it would be a while before they get to mine.

Happy Holidays guys. And Thanks again everyone. I will report back here once I get

a. a reply from SEAS

b. some experiments with wax and varnish (A4 is about 620cm2 so if I can keep the added weight to under 3gm on the A4 sheet I would be doing great).

Wax or varnish should be used on new drivers - not these that are already ruined.

To be honest, I would never use such a treatment to a new driver. The result (protection aswell performance) isn't guaranteed and that's a lot of money which is on the line there. I would simply chose different, non-corrosive cone drivers instead.

If you have high precision scale take A4 paper format, measure its weight. Then apply the wax or varnish (and wait to dry) to see how much weight is added.

I highly doubt that it would be more than 1gr (probably less).

EDIT: It goes without mentioning that you're not supposed to make 7 coats of heavy lacquer to the cone. Probably two coats of very diluted stuff.

Ofcourse it has to be as thin as possible. I strongly doubt you can apply varnish that precise without any fail in such tight space, how are you applying a perfect single layer on the backside of the cone? I can not imagine 1g is even possible. If 10g is a too high assumption, okay, might be but even the 5g isn't satisfactory at this driver. But it also has to be safe, otherwise the whole ordeal is completely useless. One hole/untreated spot in the surface and it will happen again.

Speakers with an already much higher moving mass react much less on such a treatment btw.

To be honest, I would never use such a treatment to a new driver. The result (protection aswell performance) isn't guaranteed and that's a lot of money which is on the line there. I would simply chose different, non-corrosive cone drivers instead.

I totally agree with you on that one. I suggested earlier different drivers for loudspeakers. But if one wishes the same drivers regardless of possible consequences, then the best way to do is to put theory to the test.

If old drivers are destroyed after let's say 15 years, it can not hurt to try this on new ones because the least it will do, it will slow down the degradation process.

Ofcourse it has to be as thin as possible. I strongly doubt you can apply varnish that precise without any fail in such tight space, how are you applying a perfect single layer on the backside of the cone?

Protect everything with tape and spray it on.

I can not imagine 1g is even possible. If 10g is a too high assumption, okay, might be but even the 5g isn't satisfactory at this driver. But it also has to be safe, otherwise the whole ordeal is completely useless. One hole/untreated spot in the surface and it will happen again.

The thing is that spots didn't happen on the whole cone but on some places. That tells us that the cone is not equally well protected, but it is protected. Adding light spray of diluted lacquer or wax would only make the protection better. The point is to protect the aluminium layer that is applied to the Mg cone. If that holds, no corrosion will occur - that's the theory at least.

Thank you so much for this detailed report. It is simply fantastic that you would take so much time and effort to help someone. Thank you again.

NP, I like to help.

I can see that if the wax or varnish exceeds 2gms or so the whole process makes no sense.

Yes, that's right. Even if my estimation of the added weight would be off by x, it clearly shows what happens, the simulations are very accurate regarding

such things. Everyone should judge for themselves if that's acceptable or not.

b. some experiments with wax and varnish (A4 is about 620cm2 so if I can keep the added weight to under 3gm on the A4 sheet I would be doing great).

Yes, that would mean it's within the usable range. Wax got some downsides though: On the metal surface it can relatively easy be removed, intentionally or unintentionally, i.e. at touches or cleaning. And you can't observe the back side, if the voice coil heats up, it may get removed on some areas without notice, especally on the back side.

Don't forget your mids and rear speakers, they will sooner or later have the same problem.

Oh, another thing, if you use the rears in the 'wrong' way, you should take out the ribbon and re-mount it 90° rotated, that will give you a much better dispersion.

Protect everything with tape and spray it on.

Well, you have to do a lot of taping and you have to be extremely precise with it. But that's not the issue, let's assume you're doing a perfect job on all 11 drivers (2 bass per side, 1 midrange for each side, 3 on the center, one for each rear). The issue is, you have to cover the back of the membrane too! The opening of the basket and the resulting angle to spray it on is very bad for spray painting, you get a very bad angle on to the surface, especally towards the voice coil. And to make things worse, there will be a lot of paint-'fog' landing on the off-side side. Maybe you're a lot better with spray painting than I am but I can't really imagine you're getting a perfect-only-one-layer-varnish surface. Remember, you can't sand it off and you need a perfectly closed surface. And, you can make things a lot worse if you don't work perfectly, a painted spider, voice coil, wires to the voice coil can result in practically a loss of the driver. Like I said, a hell of a work you have to do perfectly for an unsure outcome, high risk and effort for a medicore outcome, which you probably only see in a few years. The thing is, you won't be able to buy the woofers (or the other drivers) forever and if one fails, you can't get a new one, what then? Selling the rest of the painted drivers will be pretty much impossible for a reasonable price, getting a replacement in some years will be problematic too. Really, I very much doubt the new investment and effort is worth it.

The thing is that spots didn't happen on the whole cone but on some places. That tells us that the cone is not equally well protected, but it is protected. Adding light spray of diluted lacquer or wax would only make the protection better. The point is to protect the aluminium layer that is applied to the Mg cone. If that holds, no corrosion will occur - that's the theory at least.

Yes, that's theory. Because you don't know where it will start or if the protection on the new drivers will be better or maybe worse. And even if you do a perfect job and the cone is really stiff, it's under permanent stress and heat (VC, sun, the metal expands) the paint will crack at some point. You can't exactly sand it for better a good, solid 'grip' on the membrane. And a primer isn't possible either because of the weight. It will sooner or later fall off in some spots - Remember, it's constantly vibrating. Please don't say you're repainting these parts. It will possibly happen on the back side and you're not noticing.

Your arguments are good but not far sighted enough IMO. You don't 'only need to protect it a bit better', you need to protect it lasting.

Clamp.

However;-)

If you use a wooden box, counter with/use metal. Screws, profiles. We do listen material-mixes too. More than THD, TMD, frequency-response... Wooden and metal are complement.

But better than wooden and metal: concrete or stone or some composites or so on;-)

Do not forget to clamp;-)

However;-)

If you use a wooden box, counter with/use metal. Screws, profiles. We do listen material-mixes too. More than THD, TMD, frequency-response... Wooden and metal are complement.

But better than wooden and metal: concrete or stone or some composites or so on;-)

Do not forget to clamp;-)

Attachments

Wooden and metal are complement.

Yes.

Metal sounds awesome on wooden boxes.

Clamp.

However;-)

If you use a wooden box, counter with/use metal. Screws, profiles. We do listen material-mixes too. More than THD, TMD, frequency-response... Wooden and metal are complement.

But better than wooden and metal: concrete or stone or some composites or so on;-)

..and (besides the actual truth about these 'facts') how does that help preventing the corrosion?

Yes, that's theory. Because you don't know where it will start or if the protection on the new drivers will be better or maybe worse. And even if you do a perfect job and the cone is really stiff, it's under permanent stress and heat (VC, sun, the metal expands) the paint will crack at some point. You can't exactly sand it for better a good, solid 'grip' on the membrane. And a primer isn't possible either because of the weight. It will sooner or later fall off in some spots - Remember, it's constantly vibrating. Please don't say you're repainting these parts. It will possibly happen on the back side and you're not noticing.

Your arguments are good but not far sighted enough IMO. You don't 'only need to protect it a bit better', you need to protect it lasting.

Old drivers are good enough for testing if it will hold or not. Not testing but only theorizing what could or couldn't work leeds us nowhere. I think that you are too worried about cracking the paint. There are a number of clear coat varnish for Al and Mg. If it holds on to a car rims in heavy conditions, it'll hold on to a cone. I just think that you are too affraid to even think to try it on new speakers of that price range and that's somewhat understandable. But here we have a situation where there are old drivers for testing. If it proves wrong, no harm done because they are already ruined. But if my theory is solid it would solve a problem for Navin and at least a few others.

As for aplying the paint - it's just a matter of right tools and patience. I'm holding Seas L15 in my hands right now and it seems doable. Airbrush can get the job done.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Corrosion SEAS Magnesium Drivers

![IMG_20171224_145128[1].jpg](/community/data/attachments/606/606910-65a02dcaca9d5244e6d07e9787970188.jpg)