You don't have it wrong, but you're in the 'name your poison' region. The filter slopes &c. come into play, as does practicality. MTW potentially (not invariably) may require a taller box or stand which isn't to all tastes (ditto the looks), and it can make construction a PITA as you've discovered. So especially for commercial companies, they may well accept a relatively small sacrifice in the vertical polar for fewer headaches elsewhere.

Thanks, Scottmoose. I was afraid that was the answer. Since I am going for my personal reference monitors, I guess I am going to have to do the waveguide then. It's quite a bit more work but I think the polars will be well worth it - plus I think the horizontal polars for the tweeter will be smoother and more extended for HF's even - so additional benefits all around. This will mean an external Dagger rear chamber and trapezoidal baffle for the B80 which is good from sense that it allows me to play around with other mids easier. Perhaps an all Dayton system with RS100P-8 as paper cone mid. Plus allows me to switch to traditional 2-way (with waveguide) when I want a compact speaker for less time-aligned critical stuff.

I have a couple of these Visaton WG's on hand. If needed, I can also 3d print one to custom specs.

I can also add a positive outward step with an extra baffle thickness booster for the woofer - a la ATC style monitors/Troels Disco 3-way (as shown below). This way, the combo of the step boost and the WG setback bring time alignment a lot closer without needing such a deep WG. It would look cool too.

I have a couple of these Visaton WG's on hand. If needed, I can also 3d print one to custom specs.

I can also add a positive outward step with an extra baffle thickness booster for the woofer - a la ATC style monitors/Troels Disco 3-way (as shown below). This way, the combo of the step boost and the WG setback bring time alignment a lot closer without needing such a deep WG. It would look cool too.

Last edited:

Dave Pellegrene tested several RS28F waveguides installed on a 10.5 X 14" baffle. He has polar plots for the flat baffle, two elliptical waveguides (8" X 4" and 6.5" X 4.5") and a 8" round waveguide HERE. Handy for reference to see what you can expect. He used to sell the waveguides, but I think he quit offering them.

Dave Pellegrene tested several RS28F waveguides installed on a 10.5 X 14" baffle. He has polar plots for the flat baffle, two elliptical waveguides (8" X 4" and 6.5" X 4.5") and a 8" round waveguide HERE. Handy for reference to see what you can expect. He used to sell the waveguides, but I think he quit offering them.

Thanks for the tip. The elliptical is an interesting idea. Provides tighter CTC spacing vertically and plots look smoother. I actually have a 3D model of an elliptical already I could try to print. Round looks more aesthetically pleasing though.

Hi X,

You can certainty pop over my place any time if you want to use the shop.

Test boxes, Baffles, etc.

I'm guessing your less than a hour away.

Looks like you are underway though.

Doug

You can certainty pop over my place any time if you want to use the shop.

Test boxes, Baffles, etc.

I'm guessing your less than a hour away.

Looks like you are underway though.

Doug

Hi Do,

Thanks for the encouragement. Hopefully the second baffle will go faster. I am a little concerned about minimizing center-to-center distances - but there are practicalities like giving enough room for mounting the mid's rear chamber etc. I am estimating the setback of the tweeter is going to be around 2.5in from the baffle front (assuming a -25mm acoustic center on the woofer). The mid should be set back as well - or recessed in a 2in deep waveguide, but it's just not practical given the tight spacing.

I still have another baffle to play with if anyone has strong objections to how the baffle is going so far.

Hi X,

You can certainty pop over my place any time if you want to use the shop.

Test boxes, Baffles, etc.

I'm guessing your less than a hour away.

Looks like you are underway though.

Doug

Thank you for the offer Doug! Very kind of you.

FYI, these were designed for the RS28, but other tweeters will work with them as well. They may be a little large for your application though: SEOS-8? for domes DIY Sound Group

Does is really make sense to use the RS180 as the bottom of a 3-way or wouln't be 8" a better match.

While reading this thread I immediatly though about something like this:

HobbyHifi released a similar kit using the B80:

Vision BS

While reading this thread I immediatly though about something like this:

An externally hosted image should be here but it was not working when we last tested it.

HobbyHifi released a similar kit using the B80:

Vision BS

Burnet,

Thanks for the thought - I had the exact same idea about the mixed vertical horizontal layout of a studio bridge monitor. Certainly could be done andb maybe better polar but would be really not consistent polar. I did not go with 8in woofer because I had RS170P from another project already. Also I have a large 8in woofer monitor already. I was tying to shrink box a bit.

There's also a Focal 3-way with passive rad

Thanks for the thought - I had the exact same idea about the mixed vertical horizontal layout of a studio bridge monitor. Certainly could be done andb maybe better polar but would be really not consistent polar. I did not go with 8in woofer because I had RS170P from another project already. Also I have a large 8in woofer monitor already. I was tying to shrink box a bit.

There's also a Focal 3-way with passive rad

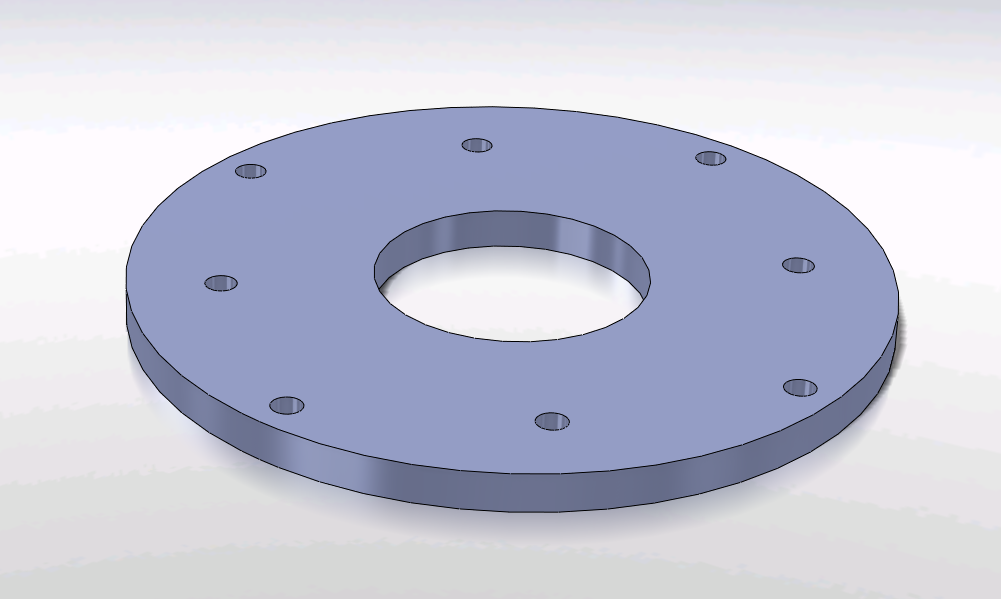

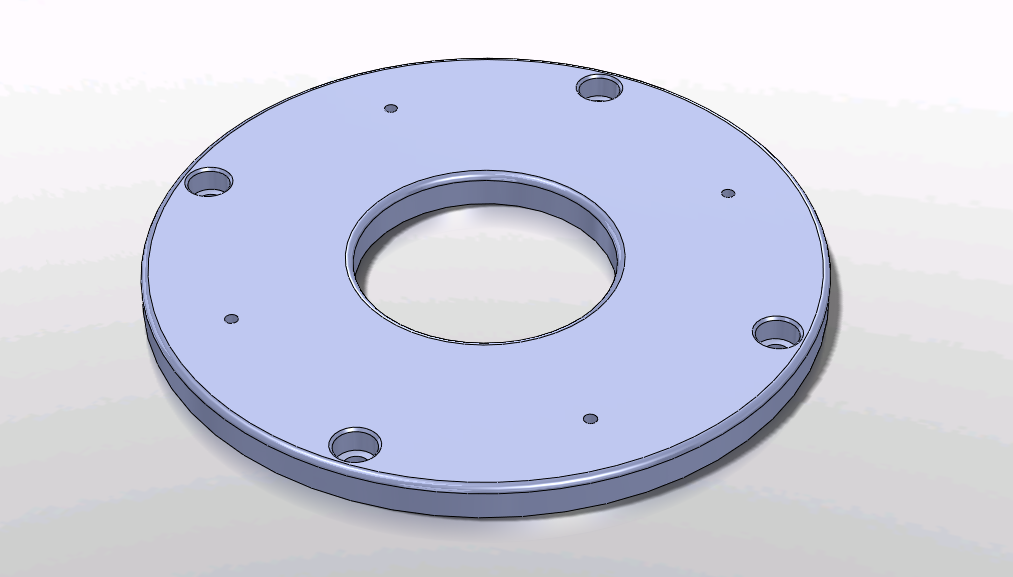

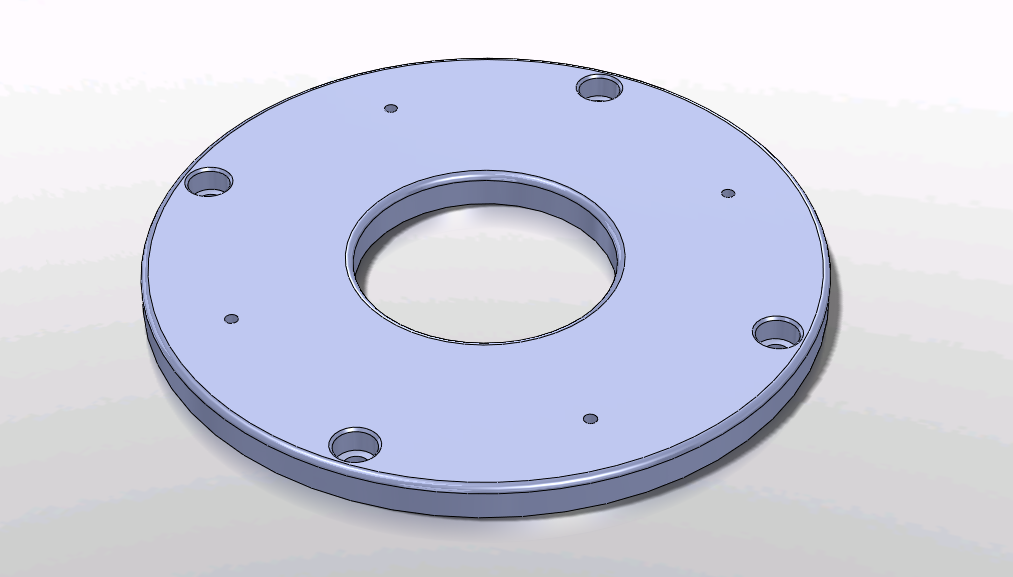

Progress is slow, but managed to make 3d model of RS28F to WG-300 waveguide adapter plate. Now need to print 2 copies. Also glued second flat pack cabinet together.

Next steps:

- redo baffle for WG with router

- cut external trapezoid baffle for mid range

- make Dagger rear chamber for mid

- install and take microphone measurements for XO simulation

Next steps:

- redo baffle for WG with router

- cut external trapezoid baffle for mid range

- make Dagger rear chamber for mid

- install and take microphone measurements for XO simulation

Göran (gornir) already posted a working waveguide design for the RS28F with the Visaton WG148R:

http://www.diyaudio.com/forums/multi-way/263917-scanspeak-2-way-waveguide.html

also on his homepage: www.audioexcite.com Revelation Two ? Monitor WG

http://www.diyaudio.com/forums/multi-way/263917-scanspeak-2-way-waveguide.html

also on his homepage: www.audioexcite.com Revelation Two ? Monitor WG

Thanks for reminding me of Gornir's Revelation Two speaker. I saw that a long time ago. That WG has a nice flat faceplate whereas the one I have has a conical lip that needs to be held in place with an adapter. I suppose I could have gone with a SS Revelator, and used Gornir's design and XO and added a hole-filler mid. That might save me some effort, but where's the fun in that? I really want to try a Revelator some day.

Last edited:

You're welcome. I did see that you've participated in this thread, too.

Correct me if I'm wrong, but doesn't a "filler" driver take away all of the benefits a larger waveguide like the WG300 provides?

I would design your speaker with broad directivity and use something like a 19mm tweeter that couldn't be used with a 6" mid as not being able to be used with a crossover below 3 to 4kHz.

Correct me if I'm wrong, but doesn't a "filler" driver take away all of the benefits a larger waveguide like the WG300 provides?

I would design your speaker with broad directivity and use something like a 19mm tweeter that couldn't be used with a 6" mid as not being able to be used with a crossover below 3 to 4kHz.

Some minor mods to allow adapter to fit better. Turns out the RS28F will have to be attached to the adapter last using wood screws so I needed to make holes smaller in print job. Added some rounded edges and chamfers and conterbore for flush mounting of M4 cap screws to WG. Good thing it was an easy print job and the power of a 3d real model to check fit.

Here is the new model:

Here is progress on boxes - both glued up now. You can see how the WG sort of looks placed where the mid used to go:

Here is the new model:

Here is progress on boxes - both glued up now. You can see how the WG sort of looks placed where the mid used to go:

Attachments

Last edited:

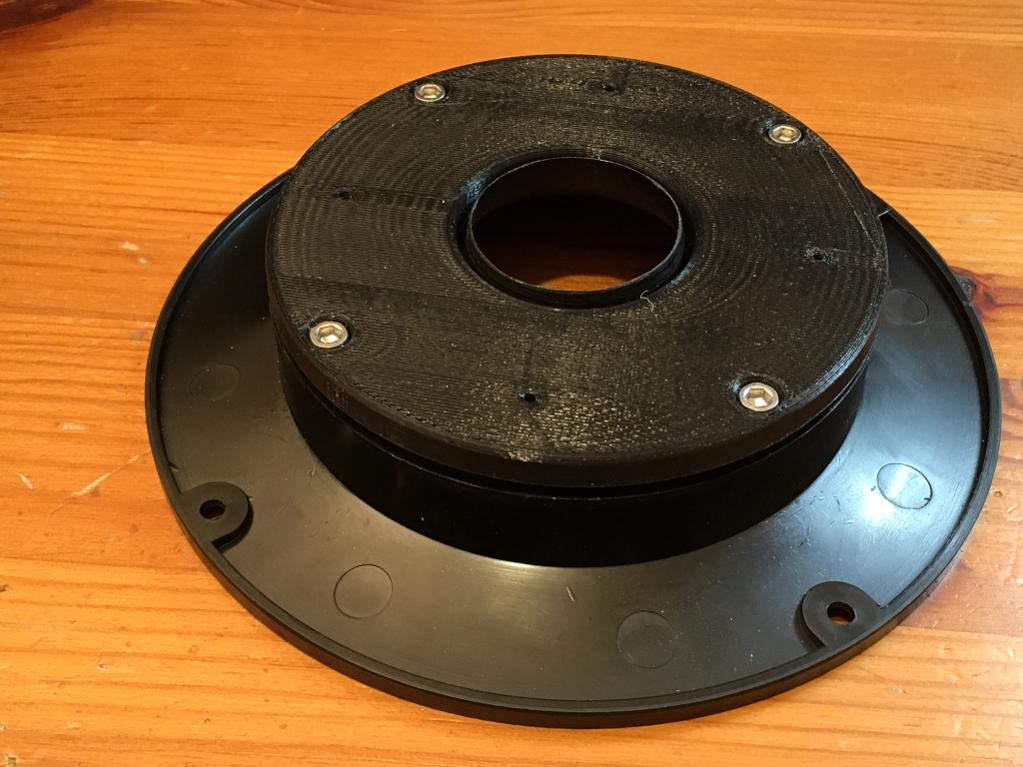

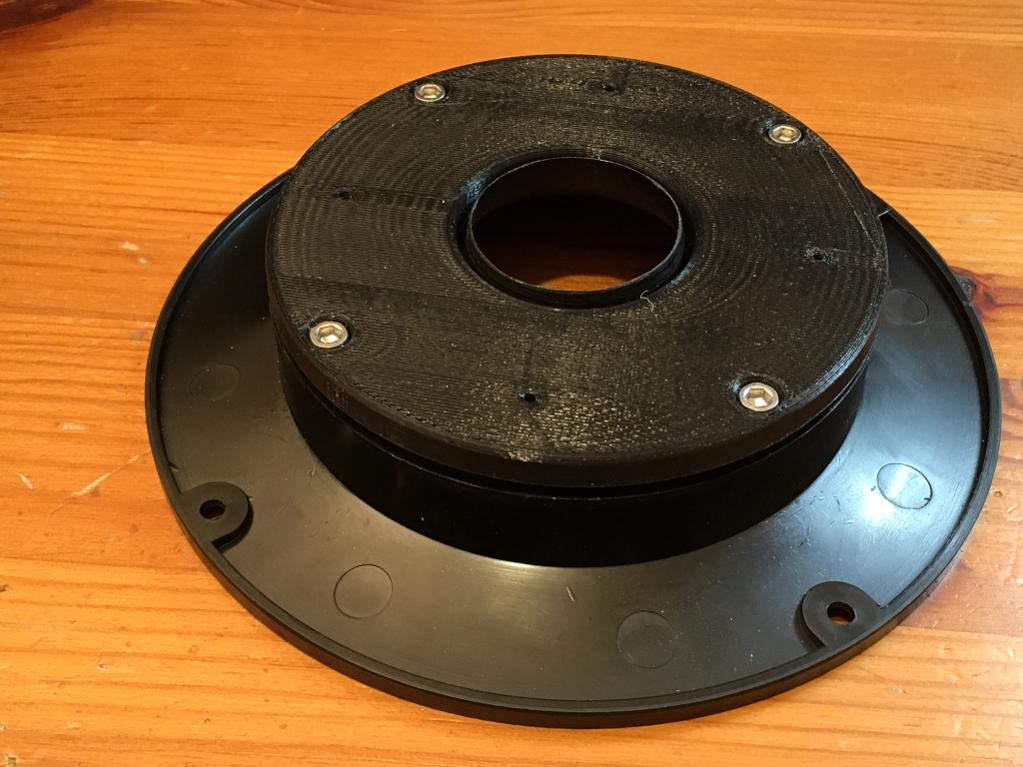

A perfect fit

The 3d printed WG adapter worked out perfectly! Took 90min ea to print. I used an 8-32 tap to re-tap the M4 brass threaded insert on the WG-300. As I have lots of 8-32 socket cap screws on hand. The screws hold the adapter perfectly in place on the WG, and then wood screws with washers clamp the RS28F faceplate down onto the adapter using the supplied RS28F foam gasket for a tight seal and to dampen any vibrations. It all fits together in a neat way.

Adapter screwed onto WG-300 with 8-32 hex head cap screws:

RS28F mounted onto adapter with wood screws:

Finished waveguide and RS28F:

I hope this setup measured well...

The 3d printed WG adapter worked out perfectly! Took 90min ea to print. I used an 8-32 tap to re-tap the M4 brass threaded insert on the WG-300. As I have lots of 8-32 socket cap screws on hand. The screws hold the adapter perfectly in place on the WG, and then wood screws with washers clamp the RS28F faceplate down onto the adapter using the supplied RS28F foam gasket for a tight seal and to dampen any vibrations. It all fits together in a neat way.

Adapter screwed onto WG-300 with 8-32 hex head cap screws:

RS28F mounted onto adapter with wood screws:

Finished waveguide and RS28F:

I hope this setup measured well...

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- RS28F-RS180P-B80 as Hole Filler 3-way