Inspired by this document 7100-waveguide I wanted to adapt the Monacor WG-300 waveguide to a Vifa DX25 tweeter. Using the Troels' method it seems a pretty easy task, but the only problem I see is that the tweeter is not really secured to the waveguide, as it is screwed onto a disc which is then sort of glued onto the waveguide. So I bought the waveguides but never started the project.

Then I came across this link: CNC Adapterplatte – Heißmann Acoustics, and this is (almost) what I wanted. After many measurements I realized that I could make a slightly different adapter which needs only the removal of the plastic faceplate of the tweeter.

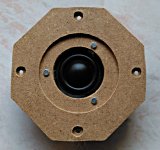

I had some small pieces of 3mm MDF lying aroung, and this with some screws is all what is needed. Ideally I had to cut two 120 mm diameter discs (not smaller than 116 mm anyway), but my pieces were 117 mm in width so for ease of construction I cut them square and then cut the corners away. On one the internal hole is 46-47 mm in diameter, and in the other is 70-72 mm. A picture:

The other 4 holes are on a 104 mm diameter, and is best to make them before the internal hole. On the left you need a 4 mm bit, and on the right a 8 mm bit. What I found is that the screw holes are well centered on the waveguide, unfortunately not the plastic holders (8 mm in diameter), so I had to enlarge those holes. Here are the two discs mounted and glued together in place, the right screws are M4x16:

The last work was to make 3 more holes needed to connect the tweeter to the adapter. The only method I found was to fit the screws on the tweeter (without faceplate), paint the points and fit the waveguide, and then make the holes where the paint is. Here is a picture of the combo tweeter-adapter, the right screws are M3x12, longer than the ones fitted on the tweeter:

This combo can then be mounted on the waveguide:

The last image shows how good the fit is, but I had to work on the end of the throat, because it wasn't parallel to the front of the waveguide (second bad point on my two samples).

I expect it to perform exactly as shown in the Heissmann Acoustics page (so very good), but will see when I have the time to build a test enclosure.

Ralf

Then I came across this link: CNC Adapterplatte – Heißmann Acoustics, and this is (almost) what I wanted. After many measurements I realized that I could make a slightly different adapter which needs only the removal of the plastic faceplate of the tweeter.

I had some small pieces of 3mm MDF lying aroung, and this with some screws is all what is needed. Ideally I had to cut two 120 mm diameter discs (not smaller than 116 mm anyway), but my pieces were 117 mm in width so for ease of construction I cut them square and then cut the corners away. On one the internal hole is 46-47 mm in diameter, and in the other is 70-72 mm. A picture:

The other 4 holes are on a 104 mm diameter, and is best to make them before the internal hole. On the left you need a 4 mm bit, and on the right a 8 mm bit. What I found is that the screw holes are well centered on the waveguide, unfortunately not the plastic holders (8 mm in diameter), so I had to enlarge those holes. Here are the two discs mounted and glued together in place, the right screws are M4x16:

The last work was to make 3 more holes needed to connect the tweeter to the adapter. The only method I found was to fit the screws on the tweeter (without faceplate), paint the points and fit the waveguide, and then make the holes where the paint is. Here is a picture of the combo tweeter-adapter, the right screws are M3x12, longer than the ones fitted on the tweeter:

This combo can then be mounted on the waveguide:

The last image shows how good the fit is, but I had to work on the end of the throat, because it wasn't parallel to the front of the waveguide (second bad point on my two samples).

I expect it to perform exactly as shown in the Heissmann Acoustics page (so very good), but will see when I have the time to build a test enclosure.

Ralf

Attachments

Someone made a 3D print file for the adapter, it was intended to fit the ring radiator from Vifa but it uses the same flange, just search around.

Troels did fill the WG-300 with something to stiffen it, I do it too as they`re rather flimsy and cheapish so some good amount of silicone always helps The disc is then mounted with bolts to the metalized inserts of the WG-300 and then you can screw the tweeter from the back to the disc (I usually use plywood for this disc, 8mm).

The disc is then mounted with bolts to the metalized inserts of the WG-300 and then you can screw the tweeter from the back to the disc (I usually use plywood for this disc, 8mm).

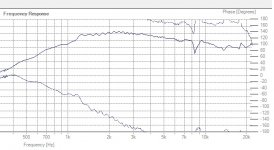

I am just working on a project using a rather good Polish engineered/built tweeter with has similar dome shape (maybe a bit more convex) as the DX25 and it has a good dip at around 8.5Khz which is a reflection in the throat. The dome shape is not optimal for this waveguide, try a ring radiator or a tweeter that has flatter diaphragm. Besides the dip - textbook performance (I`ve attached on-axis only but off-axis is superb too) which makes it easy for a single cap to equalize and achieve a low 4th order with a simple crossover (usually with a 2nd order electrical).

Troels did fill the WG-300 with something to stiffen it, I do it too as they`re rather flimsy and cheapish so some good amount of silicone always helps

I am just working on a project using a rather good Polish engineered/built tweeter with has similar dome shape (maybe a bit more convex) as the DX25 and it has a good dip at around 8.5Khz which is a reflection in the throat. The dome shape is not optimal for this waveguide, try a ring radiator or a tweeter that has flatter diaphragm. Besides the dip - textbook performance (I`ve attached on-axis only but off-axis is superb too) which makes it easy for a single cap to equalize and achieve a low 4th order with a simple crossover (usually with a 2nd order electrical).

Attachments

I even posted on that thread, but at that time I was interested in the simpler Troels' approach. Thank you to remind me the 3D print, but anyway, my method is for anyone who owns a router.Someone made a 3D print file for the adapter, it was intended to fit the ring radiator from Vifa but it uses the same flange, just search around.

If you look at the following image, the adapter is not really secured to the WG-300, and the tweeter is only secured to the adapter, and this is the reason I eventually discarded this simpler idea.Troels did fill the WG-300 with something to stiffen it, I do it too as they`re rather flimsy and cheapish so some good amount of silicone always helps The disc is then mounted with bolts to the metalized inserts of the WG-300 and then you can screw the tweeter from the back to the disc (I usually use plywood for this disc, 8mm).

I expect my sample to give the same performance seen here, as I'm using the same common tweeter, so no 8KHz dip until 45 degree off axis: Test Peerless DX25TG09-04 (Vifa XD-270 F/4) am Waveguide WG-300 – Heißmann AcousticsI am just working on a project using a rather good Polish engineered/built tweeter with has similar dome shape (maybe a bit more convex) as the DX25 and it has a good dip at around 8.5Khz which is a reflection in the throat. The dome shape is not optimal for this waveguide, try a ring radiator or a tweeter that has flatter diaphragm.

Ralf

Hi,

I believe Troels has done this for the pic only, otherwise it should be secured with bolts. The WG300 is made out of ABS plastic which is notorious for its resistance to bonding (its usually welded with a heatgun and ABS rods). If he really left it this way, lol

Yours adapter looks good, measurements show this tweeter can be well used with a proper wg attachment, thanks for the links.

I believe Troels has done this for the pic only, otherwise it should be secured with bolts. The WG300 is made out of ABS plastic which is notorious for its resistance to bonding (its usually welded with a heatgun and ABS rods). If he really left it this way, lol

Yours adapter looks good, measurements show this tweeter can be well used with a proper wg attachment, thanks for the links.

I’m not sure you can mate easily the Visaton waveguide to the DX25, what I showed here was the Monacor waveguide.

Anyway, I don’t remember having done something special to remove the faceplate from the tweeter, after removing the screws maybe a careful effort with a knife is all what is needed.

Ralf

Anyway, I don’t remember having done something special to remove the faceplate from the tweeter, after removing the screws maybe a careful effort with a knife is all what is needed.

Ralf

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.