I'm looking into building a midrange enclosed and have been looking at dealing with internal reflections. Absorption and reflection seem to be the options.

What if I used rows and rows of (say 2cm) wooden balls lining the internal surfaces? That should shatter the rearward sound into fairly random waves that shatter again on the next impact

Assuming I take into account the lost cabinet volume does that sound at all workable/useful?

What if I used rows and rows of (say 2cm) wooden balls lining the internal surfaces? That should shatter the rearward sound into fairly random waves that shatter again on the next impact

Assuming I take into account the lost cabinet volume does that sound at all workable/useful?

That can work but the hard surfaces balls still reflect energy. You want absorption and non parallel wall reflection. Balls of same size may have reflections of same wavelength that interfere and make a resonance. Mr Clean Magic Erasors are same as BASF sound absorption phenolic foam.

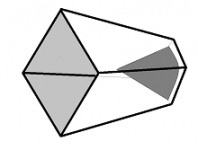

Non parallel wall Dagger (3 sided tall pyramid) stuffed progressively with fiberglass is excellent. Very neutral and no coloration. More infor here:

http://www.diyaudio.com/forums/multi-way/287609-what-do-you-put-sealed-midrange-enclosure.html

It's used on my reference speakers:

http://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-ref-monitor.html

Non parallel wall Dagger (3 sided tall pyramid) stuffed progressively with fiberglass is excellent. Very neutral and no coloration. More infor here:

http://www.diyaudio.com/forums/multi-way/287609-what-do-you-put-sealed-midrange-enclosure.html

It's used on my reference speakers:

http://www.diyaudio.com/forums/full-range/273524-10f-8424-rs225-8-fast-ref-monitor.html

Perhaps steal some ideas from B&W's raindrop shape? Oval or pentagonic transsection is better than round or square.

http://bwgroupsupport.com/downloads/reference/bw/800_Development_Paper.pdf

http://bwgroupsupport.com/downloads/reference/bw/800_Development_Paper.pdf

Thanks for taking the time to reply guys.

I've thought about non equal pyramids, both square and triangular. The B&W housing has always interested me too, ever since I owned a pair of the CDM1 NT monitor with the seperate tweeter housing.

I may well be having a serious physics failure, but as far as my brain can tell a sound wave hitting a sphere cant produce a straight reflection and energy that is reflected will be disturbed by other reflections coming from other parts of the same sphere and even more so by reflections from other surrounding spheres.

I think of firing water from a hose at a hard soccer ball. There will be a somewhat circular pattern of reflection. But if you then place that ball in the middle of 9 balls arranged as a square and then fire water at the same place and angle at the first time, the similar reflections (spray patterns) of water will interfere with each other.

Considering that the rear wave will be just that, a wave and not be a point source (like the hose illustration) and all 4 internal walls will be covered in spheres, won't the sheer volume of of non linear reflections reduce the sound to nearly nought?

I'm kind of thinking anechoic chamber behind the driver. Is too much dispersion a bad thing?

But like I said, I sometimes have a tenuous relationship with physics

I've thought about non equal pyramids, both square and triangular. The B&W housing has always interested me too, ever since I owned a pair of the CDM1 NT monitor with the seperate tweeter housing.

I may well be having a serious physics failure, but as far as my brain can tell a sound wave hitting a sphere cant produce a straight reflection and energy that is reflected will be disturbed by other reflections coming from other parts of the same sphere and even more so by reflections from other surrounding spheres.

I think of firing water from a hose at a hard soccer ball. There will be a somewhat circular pattern of reflection. But if you then place that ball in the middle of 9 balls arranged as a square and then fire water at the same place and angle at the first time, the similar reflections (spray patterns) of water will interfere with each other.

Considering that the rear wave will be just that, a wave and not be a point source (like the hose illustration) and all 4 internal walls will be covered in spheres, won't the sheer volume of of non linear reflections reduce the sound to nearly nought?

I'm kind of thinking anechoic chamber behind the driver. Is too much dispersion a bad thing?

But like I said, I sometimes have a tenuous relationship with physics

Last edited:

A loudpeaker enclosure is like a room, it has internal modes (long wavelength) and multiple reflections of first to multiple orders (short wavelength). A random shape and non-parallel walls fight against modes and wall lining and stuffing against reflections.

Try this http://amroc.andymel.eu/ or some other simulation. some of them even accept other than rectangular area.

Try this http://amroc.andymel.eu/ or some other simulation. some of them even accept other than rectangular area.

Last edited:

Yup, non parallel walls, always. Reduced intetnal nodes, which is most critical.

Also worth noting that a lot of cheap foams and filler are pretty crap, if you want to absorb the energy go for 100% natural wool. It's expensive but last time I saw any real world data it was still leaps and bounds above anything else available.

Also I tend to use an inverted "wedge" shape behind my drivers, in the hope that any reflections go into the damping on the sides of the box rather than straight back into the driver cone itself. Unfortunately I don't have suitable gear to produce conclusive evidence of the effectiveness of that

Did you see the old school B&W 800 series? then had what looked like the walls or an anechoic chamber on the back of the cabinets, I presume it must have worked or they wouldn't have done it in the first place. Don't know whether they preferred the nautilus concept or it wasn't marketable, or a combination of both... plus nautilus is cheaper to manufacture, so you do the math

Also worth noting that a lot of cheap foams and filler are pretty crap, if you want to absorb the energy go for 100% natural wool. It's expensive but last time I saw any real world data it was still leaps and bounds above anything else available.

Also I tend to use an inverted "wedge" shape behind my drivers, in the hope that any reflections go into the damping on the sides of the box rather than straight back into the driver cone itself. Unfortunately I don't have suitable gear to produce conclusive evidence of the effectiveness of that

Did you see the old school B&W 800 series? then had what looked like the walls or an anechoic chamber on the back of the cabinets, I presume it must have worked or they wouldn't have done it in the first place. Don't know whether they preferred the nautilus concept or it wasn't marketable, or a combination of both... plus nautilus is cheaper to manufacture, so you do the math

Damping cabinet air resonances is a trivial matter. You can deal with

these with different materials, glass wool being very efficient at suppresing

low frequencies. Wool stuff, poly fibers work too. No problem. Non parralel

walls is worthwile effort to make something different than usual monkey coffins.

Greater concern ought to be steered towards lowering cabinet panel resonances

which is something not widely practiced in DIY circles. Easier said than

done. Preventing speaker unit vibrations from getting to baffle is the first task, then

from passing to the other panels, then damping the walls with usual bitumen

pads or constrained layer damping. You can calculate on months of work to get

decent improvements over typical thick panel boxes.

these with different materials, glass wool being very efficient at suppresing

low frequencies. Wool stuff, poly fibers work too. No problem. Non parralel

walls is worthwile effort to make something different than usual monkey coffins.

Greater concern ought to be steered towards lowering cabinet panel resonances

which is something not widely practiced in DIY circles. Easier said than

done. Preventing speaker unit vibrations from getting to baffle is the first task, then

from passing to the other panels, then damping the walls with usual bitumen

pads or constrained layer damping. You can calculate on months of work to get

decent improvements over typical thick panel boxes.

I guess Lojzek was concerned about outer walls resonating and emitting sound? On contrary to his opinion, I believe that diy-cabinets are generally munh better than commercial ones in this respect. These internal modes and cabinet resonances affect mainly midrange say 200-2000Hz

The problem with these is how to analyze a real cabinet. The usual way is to make nearfield (½cm) measurements in infinite baffle and in the cabinet. But how many of us really do these, I haven't seen any documented! Not even myself!

The problem with these is how to analyze a real cabinet. The usual way is to make nearfield (½cm) measurements in infinite baffle and in the cabinet. But how many of us really do these, I haven't seen any documented! Not even myself!

BB or MDF sandwiches with sorbothane sheets is an extremely good speaker material. Recently, Perceval found that a stone cutter in Taiwan can make speaker cabinets out of onyx for him. In addition to being acoustically inert - they look beautiful. The price was reasonable from what he says. Probably not that way in other parts of the world. Stone cabinets sound like an ideal way to make cabinets dead sounding. If you have access to it.

The problem with wood balls is that you need to consider wavelengths. Reflections off different parts of the surface will vary in phase like you say but 2cm balls can only give you variation of 2cm. That's one half wavelength at 8600Hz, so it won't do much of anything below that frequency. Probably not a lot of 8kHz+ energy would be flowing out past your midrange or woofer cones normally even without varying the surface inside the box.

Thanks for all the input so far!

So far I'm getting:

Conventional box with well thought out stuffing

Irregular pyramid box stuffed to get progressively denser toward the apex

As my wood working kit is limited, how about a progressively stuffed wedge (3 normal box sides and 1 diagonal to create the taper) and then insert the wedge into a slightly bigger box filled with sand to kill any external vibrations?

Would an irregular 3 sided pyramid be better?

So far I'm getting:

Conventional box with well thought out stuffing

Irregular pyramid box stuffed to get progressively denser toward the apex

As my wood working kit is limited, how about a progressively stuffed wedge (3 normal box sides and 1 diagonal to create the taper) and then insert the wedge into a slightly bigger box filled with sand to kill any external vibrations?

Would an irregular 3 sided pyramid be better?

BB or MDF sandwiches with sorbothane sheets is an extremely good speaker material. Recently, Perceval found that a stone cutter in Taiwan can make speaker cabinets out of onyx for him. In addition to being acoustically inert - they look beautiful. The price was reasonable from what he says. Probably not that way in other parts of the world. Stone cabinets sound like an ideal way to make cabinets dead sounding. If you have access to it.

There was a company in the 90s used to make there cabs out of slate. Slate audio, can't seem to find much about them online.

There have been some other efforts too, mostly soupstone as material

But here some wasted potential...

A bit more ambitious project http://www.avsforum.com/forum/86-ul...00/1327408-amazing-stone-speakers-making.html

[/IMG]

[/IMG]

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

But here some wasted potential...

An externally hosted image should be here but it was not working when we last tested it.

A bit more ambitious project http://www.avsforum.com/forum/86-ul...00/1327408-amazing-stone-speakers-making.html

Last edited:

How about if I bought these as my wood working skills are lacking?

https://www.ebay.co.uk/itm/351287108858

Square pyramid with a curve should be very nice! I can strengthen from the outside with battens and then a skin. Sand filling the resulting cavity should make for a dead box. Then stuffing the internals

I'm using a 10inch mid btw

https://www.ebay.co.uk/itm/351287108858

Square pyramid with a curve should be very nice! I can strengthen from the outside with battens and then a skin. Sand filling the resulting cavity should make for a dead box. Then stuffing the internals

I'm using a 10inch mid btw

Working on Daniel Hertz copies?

Nah. More go, less show

How about a sand-filled cone glued in the bottom of the pot, to reduce backwave? Volume might get too small though...

I like that idea! I'll work on the volume. There are larger versions available!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Internal reflection control