Hi

I am planning to build a front loaded midbass horn (100 - 500 hz) with curved sides/profile.

I do understand that the horn must be reasonably stiff, and also non-resonancing. However, provided the material meet those criterias; can the material be relatively thin and/or light? For instance a single 4 mm thick sheet of ply, properly braced on the outside, and also damped on the outside with bitumen.

(My question is based on an assumption that the horn's function is to make impedanse in front of the driver, and also couple the air, but if the horn fill those functions, then everything is ok horn-wise. Or must the sides be quite think/massive to prevent "midbass sound" from escaping through the sides of the horn in stead of out the mouth? Sorry for the bad explanation...)

Best regards

Gisle

I am planning to build a front loaded midbass horn (100 - 500 hz) with curved sides/profile.

I do understand that the horn must be reasonably stiff, and also non-resonancing. However, provided the material meet those criterias; can the material be relatively thin and/or light? For instance a single 4 mm thick sheet of ply, properly braced on the outside, and also damped on the outside with bitumen.

(My question is based on an assumption that the horn's function is to make impedanse in front of the driver, and also couple the air, but if the horn fill those functions, then everything is ok horn-wise. Or must the sides be quite think/massive to prevent "midbass sound" from escaping through the sides of the horn in stead of out the mouth? Sorry for the bad explanation...)

Best regards

Gisle

IF you keep the horn light and stiff then it's resonances Will be above 500 Hz and then you really do not need damping. I plan to use 5.6mm board (used for subflooring) IT is really stiff and way cheaper then plywood. The Swedish brand Masonite may be available in Beatiful Norway as well

Audiodidakt,

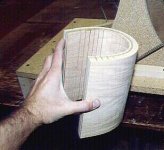

I built a pair of mid bass horns ( 75hz - 450hz ) using "wiggle board" which is a bendable plywood 3/8" thick. I used 4 layers per wall and used oak veneer on the inside and oak wainscot on the outside. As djn suggested, I made 4 ribs of 3/4" plywood with an exponential curve profile and bent / glued the 4 layers together. Since I am not a professional worker, I did lots of research on the proper glue to use for this project including going to a few wood working shows to ask the professionals. Their suggestion on the proper glue was almost universal--" DO NOT USE YELLOW WOOD GLUE ( Titebond etc.) use Unibond 800 2 part epoxy as the normal wood glues "creep" and absorb moisture. I am sure you have similar epoxy glues on your side of the pond so that is the advice I am passing on to you. My curved horn sides came out great--they are super stiff and maintained the exact profile when released from the clamps. Epoxy glue was also much preferred over contact cement when adding veneer to curved surfaces by the same pro wood workers. Good luck with your project.

I built a pair of mid bass horns ( 75hz - 450hz ) using "wiggle board" which is a bendable plywood 3/8" thick. I used 4 layers per wall and used oak veneer on the inside and oak wainscot on the outside. As djn suggested, I made 4 ribs of 3/4" plywood with an exponential curve profile and bent / glued the 4 layers together. Since I am not a professional worker, I did lots of research on the proper glue to use for this project including going to a few wood working shows to ask the professionals. Their suggestion on the proper glue was almost universal--" DO NOT USE YELLOW WOOD GLUE ( Titebond etc.) use Unibond 800 2 part epoxy as the normal wood glues "creep" and absorb moisture. I am sure you have similar epoxy glues on your side of the pond so that is the advice I am passing on to you. My curved horn sides came out great--they are super stiff and maintained the exact profile when released from the clamps. Epoxy glue was also much preferred over contact cement when adding veneer to curved surfaces by the same pro wood workers. Good luck with your project.

Base Horn Construction Issues

Wood sheet products are the most cost effective materials to use.

Obtaining high material stiffness is key to setting wall resonant frequencies above HF limit of the horn.

For a smooth transition from round to rectangular section in the high pressure throat/neck region of the horn, salami slice construction from routed sheet stock is a convenient construction method. When the steps are sanded off, a smooth, rigid, curvilinear transition emerges that provides a base of adequate stiffness for mounting the driver, back-box and horn bell.

For the horn bell/mouth segment, kerfing and bending plywood panels may prove useful in keeping horn weight manageable while retaining a reasonable degree of stiffness.

Regards,

WHG

N.B.:

See an aesthetic bass horn example of salami-slice construction at

Contendo Reference - Aries Cerat

For kerf technology, see the attached files.

Wood sheet products are the most cost effective materials to use.

Obtaining high material stiffness is key to setting wall resonant frequencies above HF limit of the horn.

For a smooth transition from round to rectangular section in the high pressure throat/neck region of the horn, salami slice construction from routed sheet stock is a convenient construction method. When the steps are sanded off, a smooth, rigid, curvilinear transition emerges that provides a base of adequate stiffness for mounting the driver, back-box and horn bell.

For the horn bell/mouth segment, kerfing and bending plywood panels may prove useful in keeping horn weight manageable while retaining a reasonable degree of stiffness.

Regards,

WHG

N.B.:

See an aesthetic bass horn example of salami-slice construction at

Contendo Reference - Aries Cerat

For kerf technology, see the attached files.

Attachments

I'm all for designing my own gear, but I would make a test horn first to ensure your design is good before building a really nice pair. As for gluing up thin laminates. The best thing to do is vacuum forming which once you read up in it you'll find it is easier to do them messing with clamps and such.

Thanks both whgeiger and djn!

The Contendo was intrigueing. I am begining to wonder whether the 2220 driver is not the driver for me. The Contendo uses an 8" for midbass, and John Inlow has also made a 135 hz horn with an 8". However, both of these has an upper limit far above where I am aiming at. I am aiming at apx. 400 hz, where a JMLC 200t-horn takes over the action. Anyone with an advice as to driver for a horn covering 500-100ish hz?

The Contendo was intrigueing. I am begining to wonder whether the 2220 driver is not the driver for me. The Contendo uses an 8" for midbass, and John Inlow has also made a 135 hz horn with an 8". However, both of these has an upper limit far above where I am aiming at. I am aiming at apx. 400 hz, where a JMLC 200t-horn takes over the action. Anyone with an advice as to driver for a horn covering 500-100ish hz?

Addenda

Recommend that performance extend octave above and below the pass-band set by your c/o points. You need latitude in setting these points when voicing the horn/driver components of your system. WHG

Follow Keele's design regimen.

http://www.xlrtechs.com/dbkeele.com...Preprint) - LF Horn Design Using TS Paras.pdf

Your horn specification is close to a design addressed by Klipsch.

See Beranek (1) for a comparison of straight vs. folded versions.

Reference (1) Acoustics, 1993, pp 282-284

https://monoskop.org/images/f/f1/Beranek_Leo_L_Acoustics_no_OCR.pdf

Regards,

WHG

Thanks both whgeiger and djn!

The Contendo was intrigueing. I am begining to wonder whether the 2220 driver is not the driver for me. The Contendo uses an 8" for midbass, and John Inlow has also made a 135 hz horn with an 8". However, both of these has an upper limit far above where I am aiming at. I am aiming at apx. 400 hz, where a JMLC 200t-horn takes over the action. Anyone with an advice as to driver for a horn covering 500-100ish hz?

Recommend that performance extend octave above and below the pass-band set by your c/o points. You need latitude in setting these points when voicing the horn/driver components of your system. WHG

Follow Keele's design regimen.

http://www.xlrtechs.com/dbkeele.com...Preprint) - LF Horn Design Using TS Paras.pdf

Your horn specification is close to a design addressed by Klipsch.

See Beranek (1) for a comparison of straight vs. folded versions.

Reference (1) Acoustics, 1993, pp 282-284

https://monoskop.org/images/f/f1/Beranek_Leo_L_Acoustics_no_OCR.pdf

Regards,

WHG

Anyone with an advice as to driver for a horn covering 500-100ish hz?

I'm interested in this too, although don't know enough to make recommendations. Yet, have you gone through member PMA! thread called "my DIY horn setup" or a name along those lines? The thread is long but he's now building a midbass horn with what I think was Precision Devices drivers.

Another design to check is Volvotreter's website and his build thread over at AudioAsylum.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Material to build midbass horn