3d is pourous so there could be some rear wave interference through the adapter

The porous 3d thing is only an issue if one does not properly set the process settings for the fused filament fabrication (FFF). I tell the 3d printing software to make 3 solid fused layers for all solid boundaries. It is airtight and watertight. Internally it is a porous 30% fill factor 3d mesh to save materials and time. External shells are all solid fused.

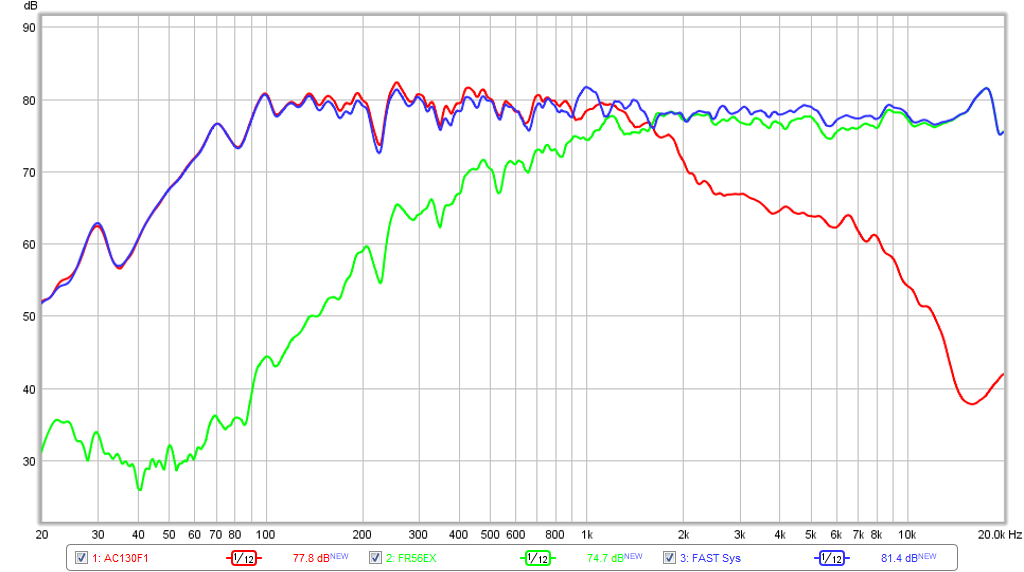

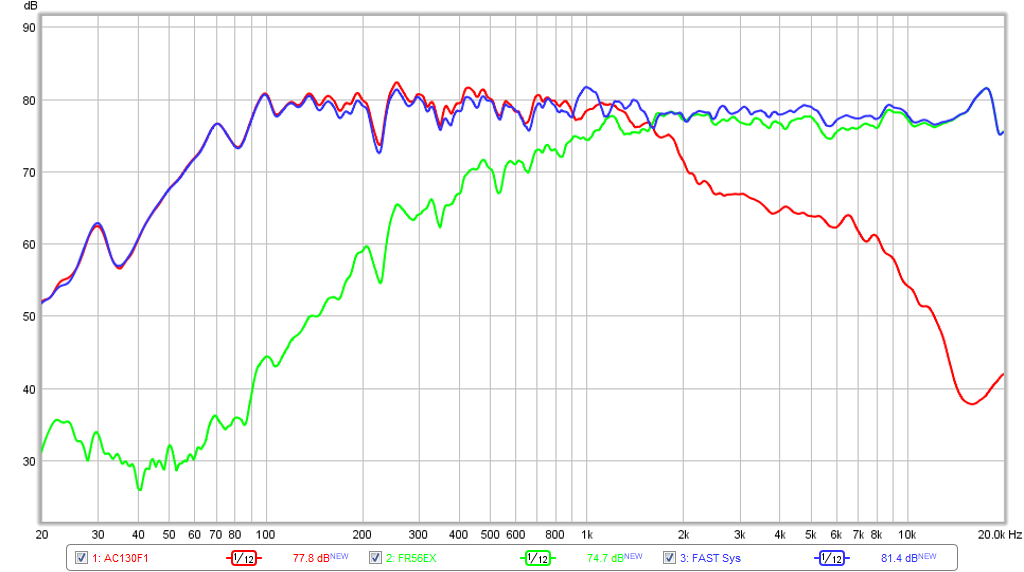

Effect of foam, felt, and polyfill in chamber

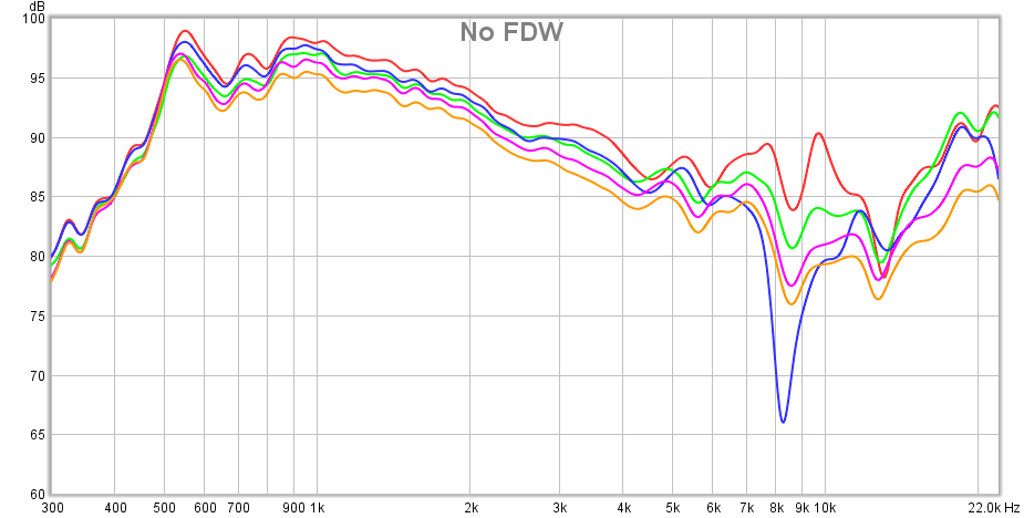

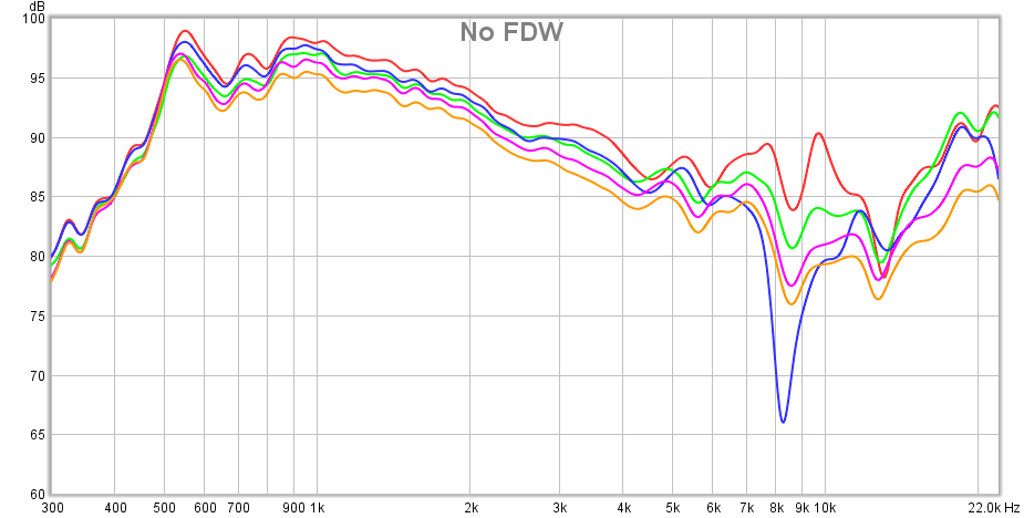

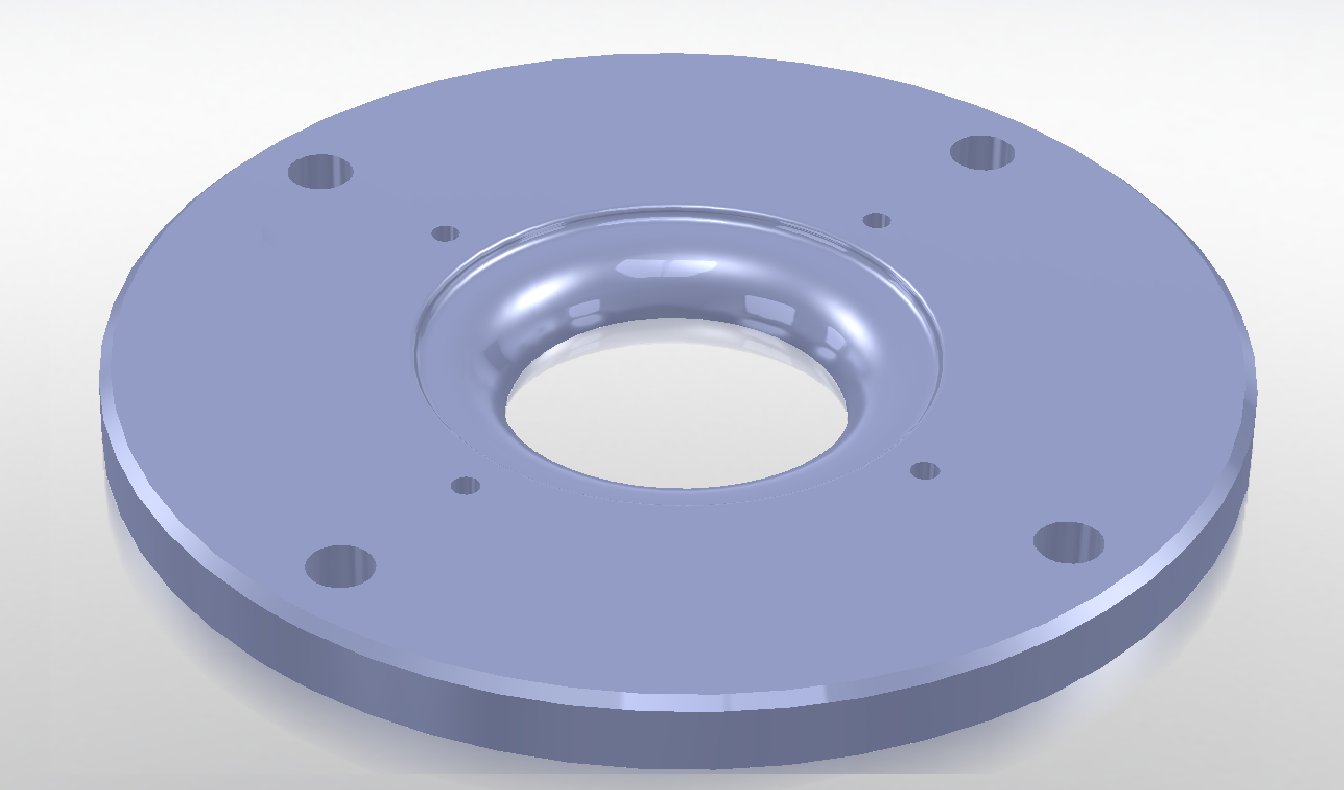

The baseline is nothing in the chamber or bare (red).

I made a small 2mm thick ring of open cell grey foam that I stuck in between the gap created by the adapter and the surround. That was the worst notch (blue).

Then I made a felt rim gasket (green) that extended about 3mm into the area where the surround is from the outer sealed perimeter, that produced the smoothest response - similar to how Bushmeister did it.

Then on top of the felt rim gasket (magenta), I added a small ball of polyfill to fill the chamber where the cone is but not beyond the throat. The smoothed out the IR but it made the notch a little deeper.

Finally, I added even more polyfill (orange) beyond the throat and about 2in out into the main waveguide. This attenuated the sound level some and seemed to smooth out the IR even more. In the frequency response space though, the felt rim gasket seems to be best.

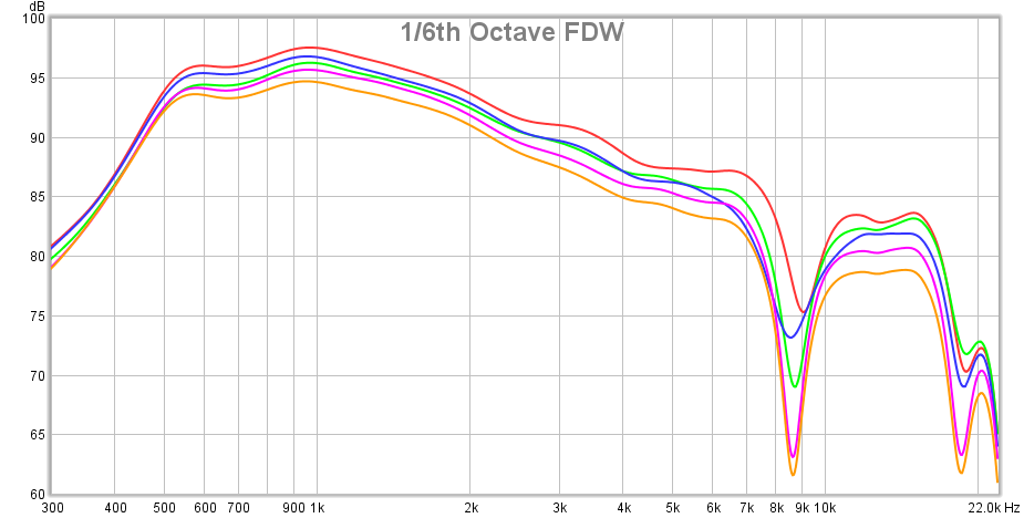

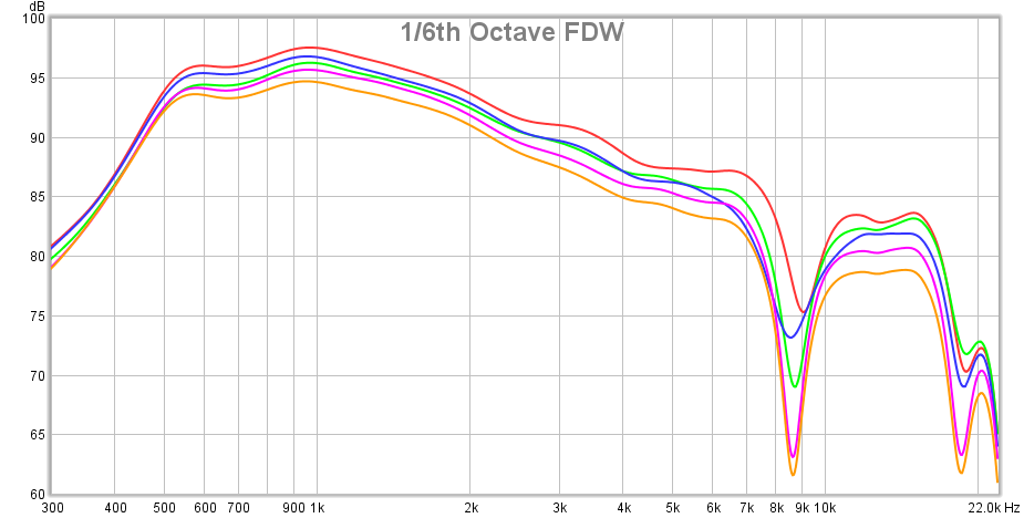

However, if we look at all of these with 1/6th octave frequency dependent window (FDW), it would appear that the bare chamber (red) is best.

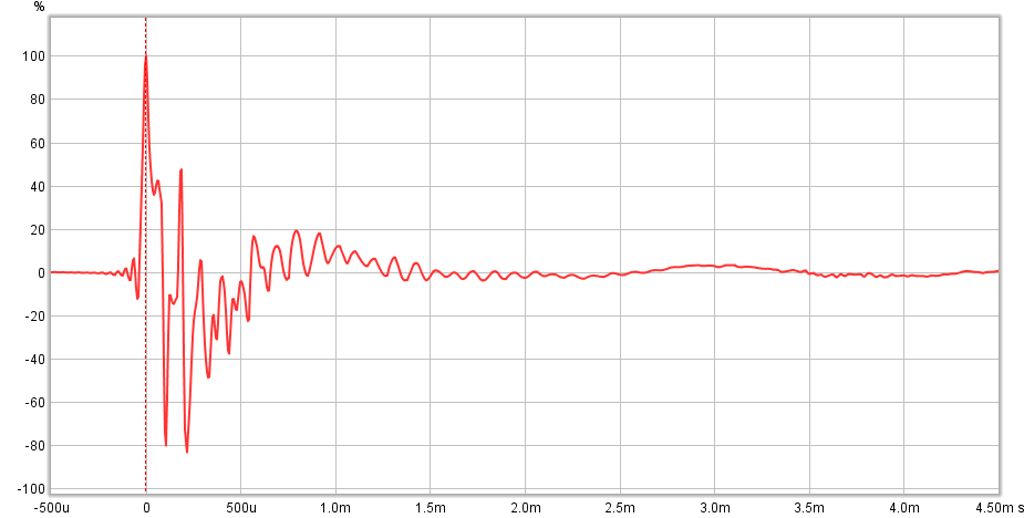

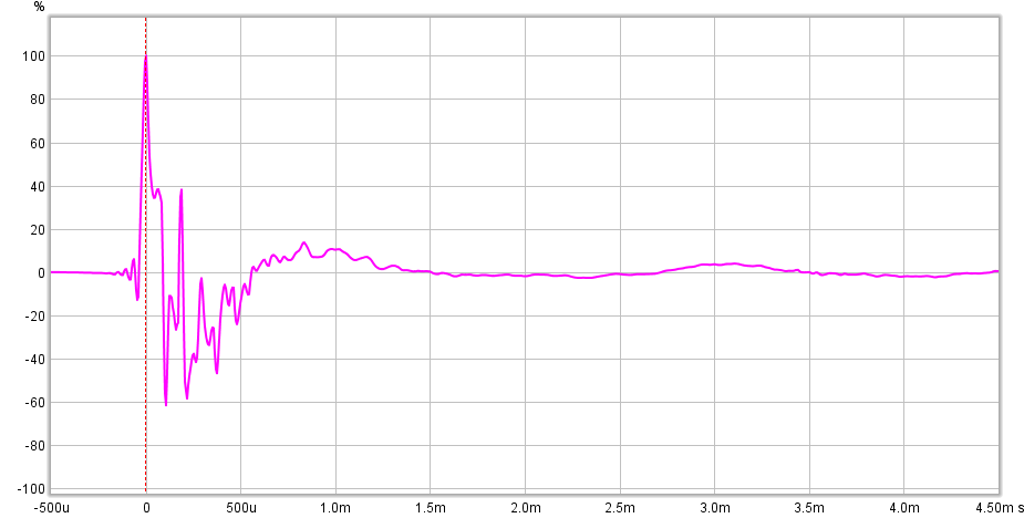

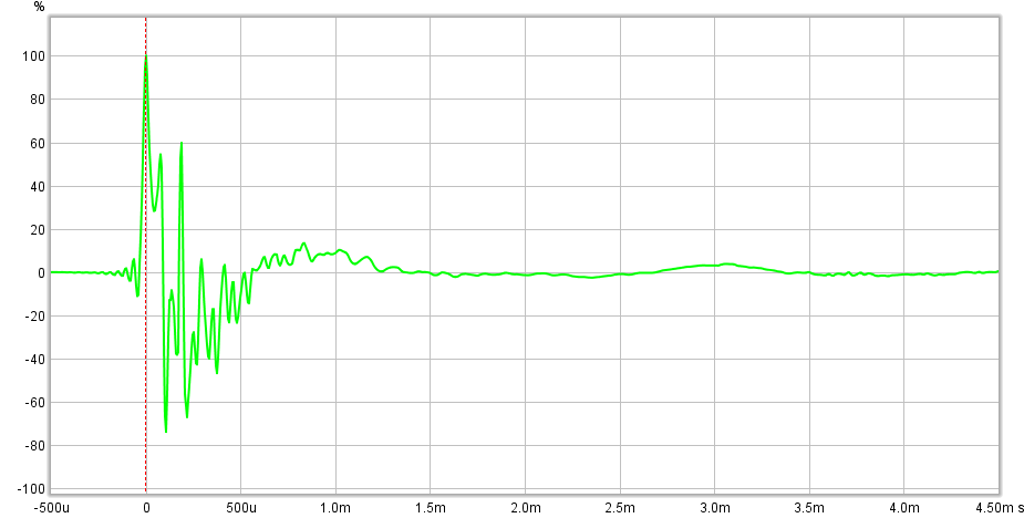

Here is the impulse response for the bare chamber:

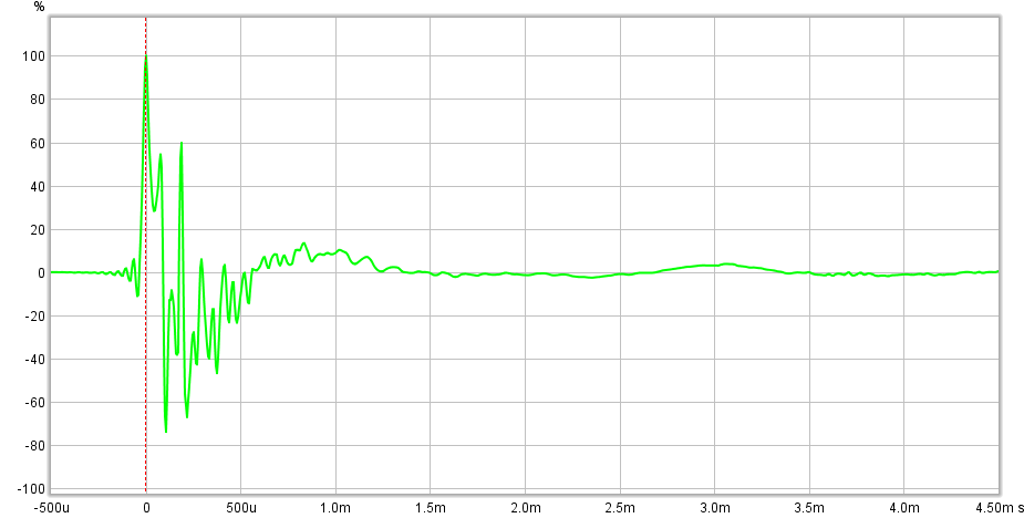

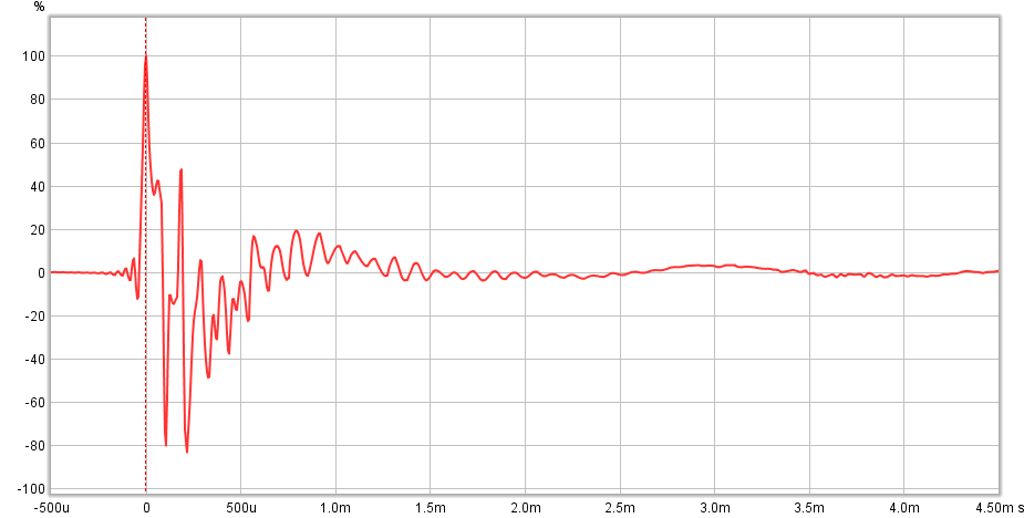

IR for the felt rim chamber:

Ir for the felt rim chamber with poly ball:

I am wondering if some of this is the WG ringing itself. It is rather thin ABS plastic and when I tap on it with my knuckles it rings like a bell sound. Covering the whole horn with latex caulking or Bondo would probably not be a bad idea.

All of this ringing action, I fear, are echoes inside the front chamber. Perhaps it need to be as thin as possible?

The baseline is nothing in the chamber or bare (red).

I made a small 2mm thick ring of open cell grey foam that I stuck in between the gap created by the adapter and the surround. That was the worst notch (blue).

Then I made a felt rim gasket (green) that extended about 3mm into the area where the surround is from the outer sealed perimeter, that produced the smoothest response - similar to how Bushmeister did it.

Then on top of the felt rim gasket (magenta), I added a small ball of polyfill to fill the chamber where the cone is but not beyond the throat. The smoothed out the IR but it made the notch a little deeper.

Finally, I added even more polyfill (orange) beyond the throat and about 2in out into the main waveguide. This attenuated the sound level some and seemed to smooth out the IR even more. In the frequency response space though, the felt rim gasket seems to be best.

However, if we look at all of these with 1/6th octave frequency dependent window (FDW), it would appear that the bare chamber (red) is best.

Here is the impulse response for the bare chamber:

IR for the felt rim chamber:

Ir for the felt rim chamber with poly ball:

I am wondering if some of this is the WG ringing itself. It is rather thin ABS plastic and when I tap on it with my knuckles it rings like a bell sound. Covering the whole horn with latex caulking or Bondo would probably not be a bad idea.

All of this ringing action, I fear, are echoes inside the front chamber. Perhaps it need to be as thin as possible?

Attachments

-

FR58EX-LTH142-No-EQ-0.5-NO-FDW-Felt-Foam-Poly.png96.8 KB · Views: 635

FR58EX-LTH142-No-EQ-0.5-NO-FDW-Felt-Foam-Poly.png96.8 KB · Views: 635 -

FR58EX-LTH142-No-EQ-0.5m-6-FDW-Felt-Foam-Poly.png99.8 KB · Views: 638

FR58EX-LTH142-No-EQ-0.5m-6-FDW-Felt-Foam-Poly.png99.8 KB · Views: 638 -

FR58EX-LTH142-No-EQ-0.5-Polyball-IR.png43.9 KB · Views: 619

FR58EX-LTH142-No-EQ-0.5-Polyball-IR.png43.9 KB · Views: 619 -

FR58EX-LTH142-No-EQ-0.5-Felt-Rim-IR.png52.4 KB · Views: 641

FR58EX-LTH142-No-EQ-0.5-Felt-Rim-IR.png52.4 KB · Views: 641 -

FR58EX-LTH142-No-EQ-0.5-Bare-IR.png55 KB · Views: 625

FR58EX-LTH142-No-EQ-0.5-Bare-IR.png55 KB · Views: 625

Last edited:

Horns arrived P. Audio PH-2723 PH-4528 one of each and if one of them works will get a partner. Have 2" entrance and hope will partner with 10F/TC9 because have them else order SB65/FR88.

Attachments

Those look really nicely made Byrtt. The material appears to be thicker and denser than my LTH142. Almost like high density polyethylene with glass fiber filler.

Thanks also think they look nice for low cost GBP £25/32 and plenty of material to have cylinder bored : )

But will really need all the guidance i can get if serious mod is needed, for me they look like weltersys land and glad he contribute alot here.

SEOS guides look more anti diffraction streamlined for hifi but lets see if they bad then nothing to loose and they can get some clay or epoxy in corners.

Regarding mouting plane plywood for woofer especially the small one is practically in it has plane top and bottom all way from throat to mouth, where big one has little under bow but not too bad.

Have 4 woofer that even they new had them more than a decade, 4x SPH-210 8" PP cone and they looks good when modeled in they without stuffing only need 10,55 liter in sealed to be Q 0,7 82,5Hz so hope if horn works these will do MW job.

But will really need all the guidance i can get if serious mod is needed, for me they look like weltersys land and glad he contribute alot here.

SEOS guides look more anti diffraction streamlined for hifi but lets see if they bad then nothing to loose and they can get some clay or epoxy in corners.

Regarding mouting plane plywood for woofer especially the small one is practically in it has plane top and bottom all way from throat to mouth, where big one has little under bow but not too bad.

Have 4 woofer that even they new had them more than a decade, 4x SPH-210 8" PP cone and they looks good when modeled in they without stuffing only need 10,55 liter in sealed to be Q 0,7 82,5Hz so hope if horn works these will do MW job.

Last edited:

Wowzers!

I love the way the idea that sporned this thread has resulted in a multinational effort to perfect it with different drivers and horns - in a way this is a little like the the on-line collaboration that results in the SEOS waveguides!

Well done guys! It will be a rush to see who completes first - my guess is X with his foam-core skills!

Brytt - love the choices and the backdrop - I am a big snow fan!

I love the way the idea that sporned this thread has resulted in a multinational effort to perfect it with different drivers and horns - in a way this is a little like the the on-line collaboration that results in the SEOS waveguides!

Well done guys! It will be a rush to see who completes first - my guess is X with his foam-core skills!

Brytt - love the choices and the backdrop - I am a big snow fan!

Last edited:

Brytt - love the choices and the backdrop - I am a big snow fan!

LOL, I thought those were beach chairs on sand 😀

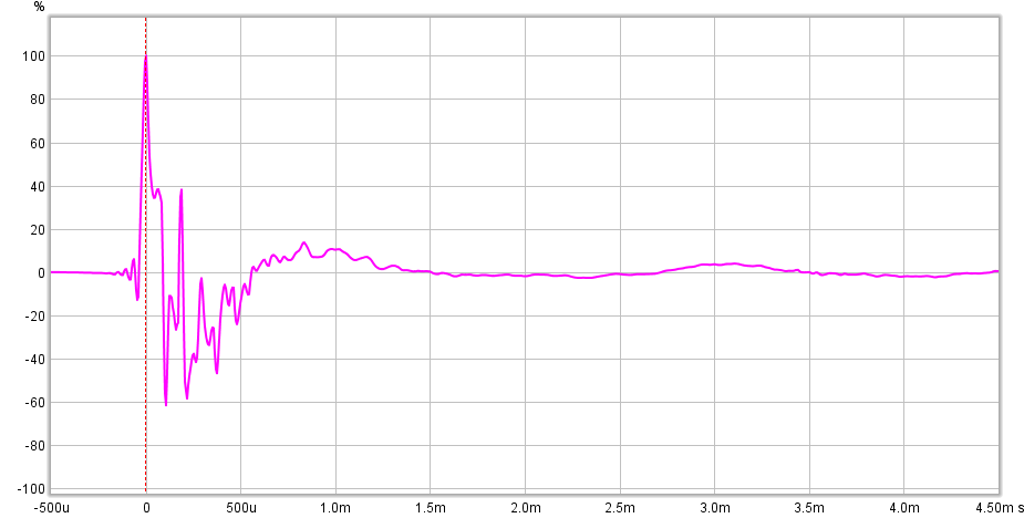

Perhaps a shallower adapter plate will work better?

Attachments

Last edited:

Run an impedance sweep and let's see if we can't find a wiggle centered at the notch frequency. Maybe the driver needs to be loaded? Fountek doesn't mention their measurment conditions but does mention a small sealed chamber in the driver notes.

Fountek graphs shows a slight impedance wiggle and dip at 9.5khz or so but nothing as deep as you're getting. Someone over at PE forum measured it and said the response graphs looked nothing like Founteks either......and also mentioned a nasty ring centered at the breakup. I'd put that driver on a flat baffle and remeasure of you haven't already. PE still trying to get rid of em on close out I believe.

Fountek graphs shows a slight impedance wiggle and dip at 9.5khz or so but nothing as deep as you're getting. Someone over at PE forum measured it and said the response graphs looked nothing like Founteks either......and also mentioned a nasty ring centered at the breakup. I'd put that driver on a flat baffle and remeasure of you haven't already. PE still trying to get rid of em on close out I believe.

Last edited:

Wowzers!

I love the way the idea that sporned this thread has resulted in a multinational effort to perfect it with different drivers and horns - in a way this is a little like the the on-line collaboration that results in the SEOS waveguides!

Well done guys! It will be a rush to see who completes first - my guess is X with his foam-core skills!

Brytt - love the choices and the backdrop - I am a big snow fan!

The international collaboration has been very fun and inspirational. It makes the work go faster when you see others doing it too.

Bushmeister, how does it sound playing music now that you have the Harsch XO dialed in? Did you listen to percussion test tracks? Live recorded jazz trios are good.

Google Fountek fr58ex images......that dip is NASTY in third party flat baffle measurements and there's a horrendous 3rd order peak that looks like a tsunami on a CSD. I think that driver's a wash X.

Wowzers!

I love the way the idea that sporned this thread has resulted in a multinational effort to perfect it with different drivers and horns - in a way this is a little like the the on-line collaboration that results in the SEOS waveguides!

Well done guys! It will be a rush to see who completes first - my guess is X with his foam-core skills!

Brytt - love the choices and the backdrop - I am a big snow fan!

Agree and hope when your build have survived proof of concept, that SEOS release a BMXT1464 and they shall not hear a bad word if they also release a 62mm throat for TC9/TG9/10F.

On the country so fair beautiful area around here, although we 72 meters above sea we can't skiing even we fluctuate around minus 10-25º these days because Denmark is flat as a pancake. Actual i spoiled the landscape a bit because that field is rapeseed and five deer eat there every day, but they ran when i come with my weird hardware and start photo session.

LOL, I thought those were beach chairs on sand 😀 .....

Ha ha you right and no hard feelings know everything is bigger in US, trees trucks etc even normal cityes have more population than my hole country, and that B&O in last model fitted whoopee 15x drivers is not normal here : )

In Netherlands B&O is just small number, down there they have 50x drivers

.

.I have used the FR58EX in a FAST before and never saw the dip at 9k. There is a peak at 9k with this driver.

The fact that the depth of the notch responds to different damping schemes and that 9k corresponds to 1.5in half wave cancellation distance tells me it is geometry based.

The fact that the depth of the notch responds to different damping schemes and that 9k corresponds to 1.5in half wave cancellation distance tells me it is geometry based.

Looking those scary plots mayhem13 points to comes to think around CHN70 and that again remind me xrk971 you have A7.3 and it has build in acoustic shelving high on axis (datasheet says out to 32kHz), under hung surround to fill with foam, and for a tweeter a dreaming 4,2mm Xmax with 71Hz Fs.

Last edited:

"Chamber" with horn loaded speakers traditionally refers to the compression chamber, you have not mentioned the compression chamber volume or damping material used in it, but seem to be writing about the throat transitional section.The baseline is nothing in the chamber or bare (red).

I made a small 2mm thick ring of open cell grey foam that I stuck in between the gap created by the adapter and the surround. That was the worst notch (blue).

However, if we look at all of these with 1/6th octave frequency dependent window (FDW), it would appear that the bare chamber (red) is best.

I am wondering if some of this is the WG ringing itself. It is rather thin ABS plastic and when I tap on it with my knuckles it rings like a bell sound. Covering the whole horn with latex caulking or Bondo would probably not be a bad idea.

All of this ringing action, I fear, are echoes inside the front chamber. Perhaps it need to be as thin as possible?

Your various attempts at smoothing the throat transitional area (which would be occupied by a phase plug in a traditional compression driver, reducing problems inherent in the "full range" beaming piston range) have resulted in a serious reduction of sensitivity, twice as much power would be required to overcome the drop, and excursion would rise by 50%.

The aspects of the throat transitional area require an iterative approach, as each change can result in different polar characteristics, simply looking at the on axis response tells only part of the story- fairly deep, high Q holes can be fixed with EQ, but if the off axis response does not track, the EQ creates worse problems. Beware of using much smoothing when making iterative decisions, looking at "trees" rather than "forests" is important when considering tradeoffs.

That is why I suggested comparing the original flange with a standoff (the cereal box gasket would provide an adequate air seal) to compare with your deeper throat transitional adapter- if my results are indicative of the various problems, your horn will then will have better sensitivity than your "red" results, and only a single deep notch that will remain largely the same off axis, so is correctable.

The chart below shows the various iterations I have tried thus far, which should be indicative of results with horns not using an undercut (pinched) throat.

Art

Attachments

I have used the FR58EX in a FAST before and never saw the dip at 9k. There is a peak at 9k with this driver.

The fact that the depth of the notch responds to different damping schemes and that 9k corresponds to 1.5in half wave cancellation distance tells me it is geometry based.

Maybe a consistency issue?.......Fountek FR58EX

Here's the thread from PE where a few people did some testing. I'd stick it on a flat baffle before any further trial and error. I've come across LOTS of consistency issues with drivers in the past......even Scans.

A cereal box gasket or a foam core standoff does not provide enough purchase for the driver mounting screws. As the flange is steel, I cannot mount directly to it. The four bolts that hold the flange to the horn actually line up with the driver screw holes but they are a larger size. I could enlarge the holes on the bezel and use the flange bolts to hold the driver in place. The cone and surround is about 2.1in dia and that has to go down to 1.4in dia. So you are suggesting that let the cone push all that air sideways and through the throat with a sharp corner. I have to imagine the rounded corner is better. I agree adding damping polyfill is not a viable solution but was checking to see if they would have an effect on the echoes.

Maybe a consistency issue?.......Fountek FR58EX

Here's the thread from PE where a few people did some testing. I'd stick it on a flat baffle before any further trial and error. I've come across LOTS of consistency issues with drivers in the past......even Scans.

I pulled the driver from that speaker project with the measurement shown so I know it should be well behaved.

1) That is exactly the same ratio of the TC9 3" cone and surround mating to a 2" throat as my project, 2.1/1.4 = 3/2. The dip frequency simply is also raised according to the throat/cone diameter difference.1)The cone and surround is about 2.1in dia and that has to go down to 1.4in dia.

2)So you are suggesting that let the cone push all that air sideways and through the throat with a sharp corner.

3)I have to imagine the rounded corner is better.

2) Yes, my tests so far have found that to have the least compromises.

One thing to consider is that very high frequencies are similar to light waves in that they reflect off surfaces like ray tracing at the angle of incidence, so an extended rounded throat adapter results in multiple reflection paths between the cone and throat. Without the deep roundover, the gap between the cone and the flange is small enough for the HF waves to diffract around, though this still results in a path length difference, and resultant cancellation.

3) I rounded the aluminum flange on one of my Maltese horn to 1/8" round, the response was almost indistinguishable from the hard edge version.

As a temporary test, you could simply use clamps to hold the compression chamber/driver on to the standoff ring between the driver and horn flanges.

Tomorrow I will be making compression chambers which will allow the TC9 drivers to be rear mounted, which will allow a single surround clearance ring around the driver. This will will minimize the percentage of the cone that must diffract into the throat, I expect the HF dip may reduce to less than 4 dB.

The sketch below shows the plan, which could also be applied to your horn. The sketch shows the chamber depth a bit short, a .25 liter chamber keeps excursion at Xmax with rated power below 250 Hz.

Will report back when the tests are done, hopefully by this time tomorrow should be able to test the quad array.

Art

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn