DTQWTII by Troels Gravesen from Argentina

Hello everyone :

I have finally begun to build this great project Troels Gravesen. I read many favorable reviews for great sound the same, I hope not disappoint my expectations.

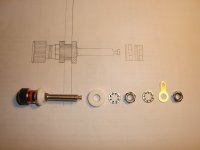

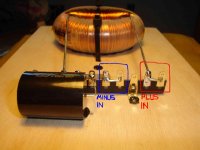

I mounted the tweeter waveguide, reinforced the crossovers and I had to make a mounting plate for binding post

I will continue to report progress as the construcccion.

Regards

Hello everyone :

I have finally begun to build this great project Troels Gravesen. I read many favorable reviews for great sound the same, I hope not disappoint my expectations.

I mounted the tweeter waveguide, reinforced the crossovers and I had to make a mounting plate for binding post

I will continue to report progress as the construcccion.

Regards

Attachments

-

006.jpg191 KB · Views: 2,760

006.jpg191 KB · Views: 2,760 -

25 Finalizado definitivo .jpg436.2 KB · Views: 445

25 Finalizado definitivo .jpg436.2 KB · Views: 445 -

24 retrabrajado con angulos redondeados 077.jpg392 KB · Views: 394

24 retrabrajado con angulos redondeados 077.jpg392 KB · Views: 394 -

13 bis binding post y aislantes .jpg530.2 KB · Views: 424

13 bis binding post y aislantes .jpg530.2 KB · Views: 424 -

09 bis .jpg148.4 KB · Views: 495

09 bis .jpg148.4 KB · Views: 495 -

01 Borneras .jpg524.2 KB · Views: 2,523

01 Borneras .jpg524.2 KB · Views: 2,523 -

15 Aislación resistencias sin uso.jpg260.5 KB · Views: 2,584

15 Aislación resistencias sin uso.jpg260.5 KB · Views: 2,584 -

Xover graves 035.JPG204.5 KB · Views: 2,605

Xover graves 035.JPG204.5 KB · Views: 2,605 -

Bobina graves 044.jpg235.2 KB · Views: 2,666

Bobina graves 044.jpg235.2 KB · Views: 2,666 -

Seccion medios y agudos, recableado wac coils 077.jpg377.8 KB · Views: 577

Seccion medios y agudos, recableado wac coils 077.jpg377.8 KB · Views: 577

Last edited:

Nicely organized build you have here.....One observation if you will...I see you have mounted your power-resistors directly onto your board. Have you calculated the power you will be dissipating thru those resistors? Myself, I would tend to mount them up off the board to get an unobstructed airflow around them...it just might degrade the RTV you've used to secure them,.....Depends entirely on how much they warm up of course.....Reworking a project is always a PITA...

_____________________________________________________Rick..........

_____________________________________________________Rick..........

Richard Ellis :

Hola, le contesto en español, y luego lo pegaré traducido por Google para el foro, me será mucho más fácil responderle y aclarar el punto. No tengo buen dominio del inglés.

Como puede ver, las resistencias tienen una disipación térmica de 10 watts. Está sobradamente calculado por el diseñador de la red de cruce, que además usa el mismo procedimiento, todos sus trabajos ( y son muchos ) van con los componentes pegados directamente sobre el tablero de madera.

No toman demasiada temperatura, aún a muy altos niveles de sonido ( SPL )

Por otro lado, el pegamento utilizado es caucho de siliconas. La misma es un gran aislante eléctrico y térmico. Soporta muy altas temperaturas. 150 grados o más, dependiendo de la calidad de la misma.

Dicoinsa S.L. Manufacturas Silicona

Gracias de todas formas por el consejo, es bienvenido.

Saludos

As you can see, the resistors have a thermal dissipation of 10 watts. It is amply [/ I] calculated by the designer of the crossover, which also uses the same procedure, all his works (and many) go with the components glued directly on the wooden board.

They do not take too hot, even at very high sound levels (SPL)

Moreover, adhesives is silicone rubber. It is a great power and thermal insulation. Supports very high [/ I] temperatures. 150 degrees or more, depending on the quality thereof.

*

Dicoinsa S.L. Manufacturas Silicona

Thanks anyway for the tip, is welcome.

Regards

Hola, le contesto en español, y luego lo pegaré traducido por Google para el foro, me será mucho más fácil responderle y aclarar el punto. No tengo buen dominio del inglés.

Como puede ver, las resistencias tienen una disipación térmica de 10 watts. Está sobradamente calculado por el diseñador de la red de cruce, que además usa el mismo procedimiento, todos sus trabajos ( y son muchos ) van con los componentes pegados directamente sobre el tablero de madera.

No toman demasiada temperatura, aún a muy altos niveles de sonido ( SPL )

Por otro lado, el pegamento utilizado es caucho de siliconas. La misma es un gran aislante eléctrico y térmico. Soporta muy altas temperaturas. 150 grados o más, dependiendo de la calidad de la misma.

Dicoinsa S.L. Manufacturas Silicona

Gracias de todas formas por el consejo, es bienvenido.

Saludos

As you can see, the resistors have a thermal dissipation of 10 watts. It is amply [/ I] calculated by the designer of the crossover, which also uses the same procedure, all his works (and many) go with the components glued directly on the wooden board.

They do not take too hot, even at very high sound levels (SPL)

Moreover, adhesives is silicone rubber. It is a great power and thermal insulation. Supports very high [/ I] temperatures. 150 degrees or more, depending on the quality thereof.

*

Dicoinsa S.L. Manufacturas Silicona

Thanks anyway for the tip, is welcome.

Regards

Hello :

I finished trim plates box. 45 degree angles are very delicate, so I protected with masking tape.

I finished trim plates box. 45 degree angles are very delicate, so I protected with masking tape.

Attachments

-

Placas terminadas 053.jpg207.8 KB · Views: 291

Placas terminadas 053.jpg207.8 KB · Views: 291 -

Protección cortes a 45 grados 057.jpg267.2 KB · Views: 285

Protección cortes a 45 grados 057.jpg267.2 KB · Views: 285 -

Cortes a 90 grados 040.jpg134.1 KB · Views: 298

Cortes a 90 grados 040.jpg134.1 KB · Views: 298 -

Cortes a 90 grados 032.jpg167.8 KB · Views: 290

Cortes a 90 grados 032.jpg167.8 KB · Views: 290 -

Cortes 90 grados 026.jpg167.9 KB · Views: 303

Cortes 90 grados 026.jpg167.9 KB · Views: 303 -

Sierra circular 017.jpg274.1 KB · Views: 334

Sierra circular 017.jpg274.1 KB · Views: 334 -

Cortes a 45 grados 016.jpg321.7 KB · Views: 362

Cortes a 45 grados 016.jpg321.7 KB · Views: 362 -

Cortes a 45 grados 015.jpg257.5 KB · Views: 550

Cortes a 45 grados 015.jpg257.5 KB · Views: 550

I have also completed the construction of accessory recommended by Troels holes for drivers. It will be very useful, especially to trim the waveguide tweeter.

Attachments

Friends :

Winter begins to feel here.

The leaves are tinged with yellow and fall.

But every year the cold lasts less.

Climate change has come and it seems that does not stop. We want to do?

Some time ago a lizard has appeared around here, is not typical of this region, every night looking for hot, puzzled ....

Sorry off topic, regards.

Winter begins to feel here.

The leaves are tinged with yellow and fall.

But every year the cold lasts less.

Climate change has come and it seems that does not stop. We want to do?

Some time ago a lizard has appeared around here, is not typical of this region, every night looking for hot, puzzled ....

Sorry off topic, regards.

Attachments

Friends :

Winter begins to feel here.

The leaves are tinged with yellow and fall.

But every year the cold lasts less.

Climate change has come and it seems that does not stop. We want to do?

Some time ago a lizard has appeared around here, is not typical of this region, every night looking for hot, puzzled ....

Sorry off topic, regards.

Really? Climate is always changing...you know like the four seasons....

Climategate 2.0: New E-Mails Rock The Global Warming Debate - Forbes

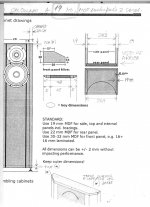

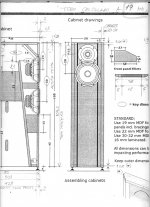

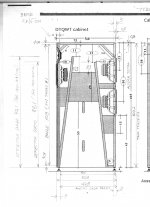

DtqwtII by Troels Gravesen from Argentina

Hello

I was looking for hardwood for lath fronts.

I got a call here crapia wood.

I think look good with black front, as seen in this photo Troels website.

TQWT- Cabinet for JA8008

One of these straps had a small crack, I've glued, anyway will not be, will go on the inside of the baffle.

Now I must do to avoid diffraction profile, and then go gluing with two 15 mm plates, so will for the rear panel.

It is 30 mm instead of 22 mm. So I recalculated the external dimensions to the internal volume remains unaltered.

DTQWT-cabs

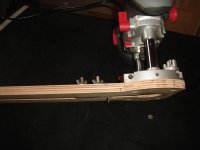

And then using the router, it is my first time ....... ......

Hello

I was looking for hardwood for lath fronts.

I got a call here crapia wood.

I think look good with black front, as seen in this photo Troels website.

TQWT- Cabinet for JA8008

One of these straps had a small crack, I've glued, anyway will not be, will go on the inside of the baffle.

Now I must do to avoid diffraction profile, and then go gluing with two 15 mm plates, so will for the rear panel.

It is 30 mm instead of 22 mm. So I recalculated the external dimensions to the internal volume remains unaltered.

DTQWT-cabs

And then using the router, it is my first time ....... ......

Attachments

This is a joke, right? Forbes is your go-to source for climate science?Really? Climate is always changing...you know like the four seasons....

Climategate 2.0: New E-Mails Rock The Global Warming Debate - Forbes

If you visit the excellent sites from NOAA and NASA you'll see how dramatic the heating of the climate system really is.

I have seen the completion of Alberto,

TQWT-Alberto

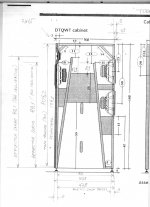

..and decided to do the same at the top and bottom. So changing the dimensions of the front panel of the box, so I attached the corrected measures.

The arrangement of the lath is ready.

Regards.

TQWT-Alberto

..and decided to do the same at the top and bottom. So changing the dimensions of the front panel of the box, so I attached the corrected measures.

The arrangement of the lath is ready.

Regards.

Attachments

-

Tirante lijado 013.jpg193.1 KB · Views: 234

Tirante lijado 013.jpg193.1 KB · Views: 234 -

Tirante encolado 010.jpg177 KB · Views: 929

Tirante encolado 010.jpg177 KB · Views: 929 -

DtqwtII front and rear 3 cm - 3 de 3 .jpg450.9 KB · Views: 945

DtqwtII front and rear 3 cm - 3 de 3 .jpg450.9 KB · Views: 945 -

DtqwtII - front and rear 3 cm - 2 de 3 .jpg557.4 KB · Views: 1,003

DtqwtII - front and rear 3 cm - 2 de 3 .jpg557.4 KB · Views: 1,003 -

DtqwtII - front and rear 3 cm - 1 de 3 .jpg378.3 KB · Views: 1,052

DtqwtII - front and rear 3 cm - 1 de 3 .jpg378.3 KB · Views: 1,052 -

dtqwt-alberto-2.jpg42.1 KB · Views: 1,065

dtqwt-alberto-2.jpg42.1 KB · Views: 1,065

When you finish, how many hours of work will have been invested?

Troels has a lot of great looking projects... But so do other people. What made you decide on this one?

Where I live (Australian south coast), there has been a similar climate and species shift - we get tropical birds here now. The grape harvest has shifted by four weeks over a 30 year period, which is pretty startling.

Troels has a lot of great looking projects... But so do other people. What made you decide on this one?

Where I live (Australian south coast), there has been a similar climate and species shift - we get tropical birds here now. The grape harvest has shifted by four weeks over a 30 year period, which is pretty startling.

When you finish, how many hours of work will have been invested?

Troels has a lot of great looking projects... But so do other people. What made you decide on this one?

Yes, are many hours of work, but also of gratification. I like to do all kinds of work, and I've built several audio boxes above. So it is not the first, but certainly the last by the size and quality of the components. I have a good tube amp with not too much power - by today's standards - and this project is ideal. A good match, I hope.

I appreciate your other comments, thanks.

I attached pictures of bonding plates back panels.

Attachments

-

Paneles traseros terminados 001.jpg239.5 KB · Views: 195

Paneles traseros terminados 001.jpg239.5 KB · Views: 195 -

Encolado rear panel 067.jpg265.3 KB · Views: 181

Encolado rear panel 067.jpg265.3 KB · Views: 181 -

Encolado rear panel 047.jpg405.1 KB · Views: 222

Encolado rear panel 047.jpg405.1 KB · Views: 222 -

Encolado rear panel 042.jpg380.5 KB · Views: 224

Encolado rear panel 042.jpg380.5 KB · Views: 224 -

Encolado rear panel 039.jpg407.5 KB · Views: 187

Encolado rear panel 039.jpg407.5 KB · Views: 187 -

Encolado rear panel 038.jpg375.8 KB · Views: 189

Encolado rear panel 038.jpg375.8 KB · Views: 189 -

Encolado rear panel 037.jpg180.6 KB · Views: 202

Encolado rear panel 037.jpg180.6 KB · Views: 202 -

Encolado rear panel 033.jpg209.9 KB · Views: 224

Encolado rear panel 033.jpg209.9 KB · Views: 224 -

Paneles traseros terminados 004.jpg175.3 KB · Views: 208

Paneles traseros terminados 004.jpg175.3 KB · Views: 208

Last edited:

Thanks for posting the pics. I really enjoy looking at others builds as it can often give you new ideas for future projects. My next build will likely be a Troels design as I hear good things about them. I will watch your build with interest and look forward to your review when you fire them up.

@ academia50

Nice looking build. From the drawings it "appears" as if the mid driver isn't isolated from the bass drivers airflow. Is this how it is, & if so why ?

*

@ jcandy et al

You missed the Real point with the Forbes link ! It's not Forbes that matters, but the data that has been Faked about so called "Man made global warming" climate change etc by people @ that UK university & others, as Proved in the leaked emails ! NASA & others are no angels either, as they are also involved in hiding & faking data ! These are not just anyones opinions, or mine, but provable Facts. It's criminal

Comments from Piers

Welcome Scroll down for details etc

Science and Public Policy More real data & info

Nice looking build. From the drawings it "appears" as if the mid driver isn't isolated from the bass drivers airflow. Is this how it is, & if so why ?

*

@ jcandy et al

You missed the Real point with the Forbes link ! It's not Forbes that matters, but the data that has been Faked about so called "Man made global warming" climate change etc by people @ that UK university & others, as Proved in the leaked emails ! NASA & others are no angels either, as they are also involved in hiding & faking data ! These are not just anyones opinions, or mine, but provable Facts. It's criminal

Comments from Piers

Welcome Scroll down for details etc

Science and Public Policy More real data & info

Thanks for posting the pics. I really enjoy looking at others builds as it can often give you new ideas for future projects. My next build will likely be a Troels design as I hear good things about them. I will watch your build with interest and look forward to your review when you fire them up.

Thank you for giving us your opinion.

Indeed, the front and rear drivers are provided by the air inside the enclosure, here's the explanation.

You have a new design, MKIII, with a single 12-inch driver in exchange two of 10 inches.

I will do an extensive critique when they are finished, promised

DTQWT-mkII

" DTQWT is in principle a 2-way with integrated subwoofers, thus no high-pass filter on the main front driver. This has the indisputable advantage of not needing any series capacitors, which would be excessively expensive if of good quality and sonically inferior to no caps, no matter how good the caps are.

Loading a horn helps keeping front driver membrane in place due to high acoustic impedance compared to a vented enclosure or open baffle and this is further assisted by the mode of action of all drivers.

DTQWT features an 8" front driver and two 10" rear mounted drivers, all connected with positive polarity. They are placed opposite to one another and the rear drivers are fed through a huge coil, thus only adding weight to the lower octaves. All drivers load a center horn and you may ask whether the large bass drivers won't have an impact on the front driver from sharing the same center horn and the answer is yes - and this is intentional. Air goes where pressure is low, thus when the rear bass drivers move inwards, they will push air into the large center horn and by doing so they will suck air from the front horn and pull in the membrane of the front driver. Obviously the front driver will do the same thing for the bass drivers.

By fine-tuning expansion of front, center and rear horns while measuring impedance, a balance can be found allowing the best possible power handling of the main front driver. The subjective experience from this is a cleaner midrange, distortion has been lowered (see measurements below) at high SPLs and yes - we have more bass. In fact a lot more bass compared to TQWT. The typical quality of the bass from a horn is quite different from conventional high mass/low efficiency bass drivers in small vented enclosures. The DTQWT delivers deep, dynamic and dry bass without the typical vented enclosure overhang."

@ academia50

Nice looking build. From the drawings it "appears" as if the mid driver isn't isolated from the bass drivers airflow. Is this how it is, & if so why ?

I was confused, sorry

Thanks, I think my answer to irext you may be interested.

Do not comment more on climate change here, please.

My lizard has died accidentally electrocuted, I think we still do that with humans and i tremble ....

Last edited:

- Home

- Loudspeakers

- Multi-Way

- DTQWTII from Argentina