Hi im trying to flatten some quilted maple veneer that is a little rippled, ive looked on you tube, and seen whatthat they spray the veneer with watwater.And then sandwich between to pieces of mdf, which I tryed overnight. With my surprise it looks worse. What else can I do.

IIRC, the veneer needs to be sprayed with a mixture of water and rubbing alcohol, the one that contains some lanonin or similar.

Then, the veneer sheets needs to be sandwitched with kitchen tissue paper and then between sheets of mdf or plywood and then pressed (weights or woodworker's screws).

You need to remove them after every few hours (2-4) to replace the tissue with fresh ones and repeat the pressure cycle.

Then, the veneer sheets needs to be sandwitched with kitchen tissue paper and then between sheets of mdf or plywood and then pressed (weights or woodworker's screws).

You need to remove them after every few hours (2-4) to replace the tissue with fresh ones and repeat the pressure cycle.

Flattening veneer takes a long time.. You can use a veneer softener and press it with paper towels on both sides of the veneer.. The trick is to have the moisture escape when it's pressed flat, so you need to change out the paper towels two or three times a day..I've done this with 1mm maple veneer with very strong ripples and it took 1 week..

After wasting time flattening rippled veneer I discovered that you don't need to flatten it.. This is assuming that you are gluing the veneer on a flat surface using clamps.. Then simply spray both side of veneer with water mist, press veneer to the glued substrate and let it dry..

There is a little more to it. Type of glue used with a special roller and techniques like clamp in center first and move out to the edges etc etc...

I give you many more tips if you're interested... Perfect Veneer application becomes a very simple job, after a little practice with the right tools and the correct instructions..

After wasting time flattening rippled veneer I discovered that you don't need to flatten it.. This is assuming that you are gluing the veneer on a flat surface using clamps.. Then simply spray both side of veneer with water mist, press veneer to the glued substrate and let it dry..

There is a little more to it. Type of glue used with a special roller and techniques like clamp in center first and move out to the edges etc etc...

I give you many more tips if you're interested... Perfect Veneer application becomes a very simple job, after a little practice with the right tools and the correct instructions..

Last edited:

Thanks Joel. So if I were to clamp.How many clamps could I get away with using. Or use as many as i possibly can.. biggest piece to be clamped is 22" x 18".Flattening veneer takes a long time.. You can use a veneer softener and press it with paper towels on both sides of the veneer.. The trick is to have the moisture escape when it's pressed flat, so you need to change out the paper towels two or three times a day..I've done this with 1mm maple veneer with very strong ripples and it took 1 week..

After wasting time flattening rippled veneer I discovered that you don't need to flatten it.. This is assuming that you are gluing the veneer on a flat surface using clamps.. Then simply spray both side of veneer with water mist, press veneer to the glued substrate and let it dry..

There is a little more to it. Type of glue used with a special roller and techniques like clamp in center first and move out to the edges etc etc...

I give you many more tips if you're interested... Perfect Veneer application becomes a very simple job, after a little practice with the right tools and the correct instructions..

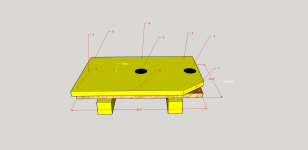

You should use 9 clamps for that size.. Is the piece a flat board or is it a box?

The sketch shows a board and the order of clamping and this will insure that you wont trap a veneer fold.. The glue should be even spread and not to much glue.. To much glue can create a ridge from pocket of glue..

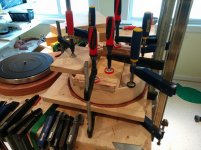

This is the method I use for speaker boxed

The clamp has a rotational force, so you want to stop that action...

For smaller Pieces, I'm favouring pressing the substrate into the veneer that is laying on a thick board..

The sketch shows a board and the order of clamping and this will insure that you wont trap a veneer fold.. The glue should be even spread and not to much glue.. To much glue can create a ridge from pocket of glue..

This is the method I use for speaker boxed

The clamp has a rotational force, so you want to stop that action...

For smaller Pieces, I'm favouring pressing the substrate into the veneer that is laying on a thick board..

Attachments

You should use 9 clamps for that size.. Is the piece a flat board or is it a box?

The sketch shows a board and the order of clamping and this will insure that you wont trap a veneer fold.. The glue should be even spread and not to much glue.. To much glue can create a ridge from pocket of glue..

This is the method I use for speaker boxed

The clamp has a rotational force, so you want to stop that action...

For smaller Pieces, I'm favouring pressing the substrate into the veneer that is laying on a thick board..

Joel yes its a speakercabinet. Looks like the root I'll have to take. Many thanks

Paul, Keep going. It a real pain in the #$%

With glass I would think there is less breathing, hence, less drying than with wood .. Towels are absorbing but for a really good system drying should happen while veneer is flattened.. By now you should notice progress and veneer should be a little flatter?

I had a plan(that I didn't execute)where I would use a sheet of wood or metal with holes so the moisture can escape while flat.. I believe the towels would not be needed with this method..

With glass I would think there is less breathing, hence, less drying than with wood .. Towels are absorbing but for a really good system drying should happen while veneer is flattened.. By now you should notice progress and veneer should be a little flatter?

I had a plan(that I didn't execute)where I would use a sheet of wood or metal with holes so the moisture can escape while flat.. I believe the towels would not be needed with this method..

Paul, Keep going. It a real pain in the #$%

With glass I would think there is less breathing, hence, less drying than with wood .. Towels are absorbing but for a really good system drying should happen while veneer is flattened.. By now you should notice progress and veneer should be a little flatter?

I had a plan(that I didn't execute)where I would use a sheet of wood or metal with holes so the moisture can escape while flat.. I believe the towels would not be needed with this method..

Ok Joel I'll give it a go. Many thanks

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- flattening veneer