I have Kairos, stand-mount, two ways. The designer Jeff Bagby called for window braces, with one vertical brace up the middle and a crossing horizontal brace through the middle between the drivers.

I thought I'd try something "better," so I did a lot of corner braces, with 3/4" x 3/4" sticks about 5" long cut with 45s on each end, glued in kitty corner about 3" apart across all the corners. This made the max unbraced span anywhere in the box less than 3". I also added 3 crossbraces from side to side. Double thickness baffle, all russian BB construction. The box still resonantes at 140hz. People have previously suggested that it is just room modes, but I have moved the speakers to new position on different wall and the same sound persists. It is definitely the boxes singing along. I have the same problem with the bass boxes I built for these, similar bracing style, which is obviously ineffective, or worse.

I proposed using double walled sand box technique in another thread, but it was suggested sand box is not the best choice for this, although I have read sand is excellent at higher freqs? Why is sand box not appropriate for a small speaker?

So how do I build a small, bookshelf size 2 way speaker box that is dead quiet? Matrix style bracing? Or just use bagby's box design duh! Seemed like it had less bracing than mine, but different application.

Thanks for any opinions.

Rich

I thought I'd try something "better," so I did a lot of corner braces, with 3/4" x 3/4" sticks about 5" long cut with 45s on each end, glued in kitty corner about 3" apart across all the corners. This made the max unbraced span anywhere in the box less than 3". I also added 3 crossbraces from side to side. Double thickness baffle, all russian BB construction. The box still resonantes at 140hz. People have previously suggested that it is just room modes, but I have moved the speakers to new position on different wall and the same sound persists. It is definitely the boxes singing along. I have the same problem with the bass boxes I built for these, similar bracing style, which is obviously ineffective, or worse.

I proposed using double walled sand box technique in another thread, but it was suggested sand box is not the best choice for this, although I have read sand is excellent at higher freqs? Why is sand box not appropriate for a small speaker?

So how do I build a small, bookshelf size 2 way speaker box that is dead quiet? Matrix style bracing? Or just use bagby's box design duh! Seemed like it had less bracing than mine, but different application.

Thanks for any opinions.

Rich

The box still resonantes at 140hz.

That is awfully low for a panelresonance on a well-braced box.

Checked with a mechics stethescope and a signal generator?

dave

That is awfully low for a panelresonance on a well-braced box.

Checked with a mechics stethescope and a signal generator?

dave

Hi Dave

I check the resonant notes I hear in music on the piano. A good example is Jaoa Gilberto singing Corcovado, the whole melody is within half octave right in the resonance zone. One note particularly bad at 140Hz. Tenor range vocals most noticeable. Lower and higher notes sound clean.

A well braced box? Maybe by weight,

Quip, thanks. The volume of my braces is comparable to the original design window brace, plus my crossovers are external and I have no reflex port installed. So I think I am net plus on the volume compared to the original design.

Basically, its just a 8w x 15h x 13d interior box with slanted front. How best to brace it? Stressed panels? fill it full of cement?

I can cut it open to replace the existing braces with the original design braces, but I thought I would make a bigger box anyway to lower the Q for sealed. So I'm exploring potentially more exotic and better performing constructions than the stock 3/4" MDF box with two 1/2" thick MDF intersecting window braces. Ideas?

So how do I build a small, bookshelf size 2 way speaker box that is dead quiet?

Thanks for any opinions.

Rich

I'm not a fan a bracing at all (it usually doesn't do much), at least as most people brace.

If you are going to do it though, I usually pick out "random" points on the panels (connecting parallel walls) and use a dowels (1/4") screwed (with pre-drilling for those screws) - that seems to work best, and for the most part it does so without adding much air-flow restriction. The thinner the cabinet panels are, the better this works.

Note: both the smaller connection point (1/4") and the "randomness" are necessary. It needs to be a tight "point" on the panel pulling the other panel inwards (fractionally), but tightly. (..the dowels should be just a little short of spanning the distance from wall to wall.) If it pulls the panel to where there is a small indentation, don't worry - just use wood filler to smooth out the exterior. I'd use at least 3 dowels between each parallel wall grouping (..maybe 5 for the side walls, but no more). For the slant baffle of the Kairos I'd probably use wiring tensioning instead (..same idea as the dowels, just using wire to pull the baffle inward to rear wall and keep the connection points small for each wire). With respect to the "randomness" you don't want to "center" the connection point on the panel - each connection needs to be off-center from the panel and each other and shouldn't be to close to the edges of the panel.

With respect to having a quiet loudspeaker:

You can still do a box within a box construction (thin wall for each), and fill the space between the boxes with a very soft high loss viscoelastic foam. Take care not to leave any voids when pumping the foam between the two boxes.

IF you need to dampen interior panels you can use the bracing method I just mentioned, OR you can line the wall interior with a lossy adhesive and some heavy "panels" (adjusting the depth of the box to accommodate the loss in volume). A heavy "panel" might be some 1/2" steel plate. Perhaps Green Glue as the adhesive - modestly applied (1/16" thick) across the entire surface of one side of the steel plate that's to be glued to the interior panel.

On the exterior box consider a 1/4" brass plate for both driver's connection to the baffle. It shouldn't span the entire baffle, perhaps 8" square for the midbass and another smaller panel for the tweeter. Only the tweeter's brass connection plate should have a lossy decoupling from the exterior box (green glue), the midbass's brass plate should have a fairly rigid (and thinly applied) glue when connecting to the exterior box. A scroll saw or saber saw with a metal cutting blade should make cutting the brass fairly easy (..though a machinist doing it would be easier still.) Ex. Enough brass for both cabinets:

C260 Brass Sheet (1/4) .250" x 11" x 18" - Mill Finish

Despite all the above (which goes well beyond the "normal"), Dave's advice is a "sound" starting point.

Like this?

Yes. Place the tip on the cabinet and then pull it off. If the sound level decreases you have a resonance at that spot on the cabinet. Try all over the cabinet.

If you want to know the frequency use a signal generator as source (downloadable software). I usually just use music unless i have a serious problem (rarely the case).

dave

Make a double box.

Inner box from baltic-birch that is not too thick, something like 9mm. Then make outer box from mdf/hdf or baltic-birch 15-18mm.

Make the box sizes that there is about 5mm space between them.

Then shoot Greenglue into the outerbox randomly, and then place the innerbox. Use some spacers to hold the innerbox in correct place, not touching the outerbox. Should be that the only thing what keeps the boxes together is the glue and the front plate.

Case of Green Glue Noiseproofing Compound - 12 Tubes - Wood Glues - Amazon.com

Inner box from baltic-birch that is not too thick, something like 9mm. Then make outer box from mdf/hdf or baltic-birch 15-18mm.

Make the box sizes that there is about 5mm space between them.

Then shoot Greenglue into the outerbox randomly, and then place the innerbox. Use some spacers to hold the innerbox in correct place, not touching the outerbox. Should be that the only thing what keeps the boxes together is the glue and the front plate.

Case of Green Glue Noiseproofing Compound - 12 Tubes - Wood Glues - Amazon.com

I built the same speakers, modified the bracing also. Haven't noticed any resonances, but now I want to do some measurements, have you done any? Sounds like you overbuilt the boxes, surprised a difference in bracing would make that much difference. I like Scott's idea of tightening panels down on the cross braces, a little tension might raise the resonant frequency.

The design is a little weird, calls for different materials (mdf and bb) in different thicknesses. Maybe he knew just what was needed, but it seems he used what he had lying around. I doubt that anyone has built it exactly by the plans. The stock bracing doesn't seem like anything special either.

I'm with Dave, more research before rebuilding. Can you feel the panels vibrating? Maybe put some clamps on them, like you were gluing the sides on and see how they sound. It's sure to at least change the resonance. Curious what you find out.

..or just make it like Jeff has it designed

The design is a little weird, calls for different materials (mdf and bb) in different thicknesses. Maybe he knew just what was needed, but it seems he used what he had lying around. I doubt that anyone has built it exactly by the plans. The stock bracing doesn't seem like anything special either.

I'm with Dave, more research before rebuilding. Can you feel the panels vibrating? Maybe put some clamps on them, like you were gluing the sides on and see how they sound. It's sure to at least change the resonance. Curious what you find out.

Make the box sizes that there is about 5mm space between them.

Then shoot Greenglue into the outerbox randomly, and then place the innerbox.

Thanks na

I have built a couple speakers with layers of wood laminated together with Green glue. It does deaden the mid and HF vibes very well. I think 5mm gap is too thick, since GG damps via panels the sheering motion of the GG, so thinner layer concentrates the sheering action. I try to cover as much area as possible.

I recently built 85 liter bass boxes this way with 19mm ply outer layer and 19mm MDF inner layer, total coverage of GG between, 1/16" thick. Generous corner stick bracing also applied inside. It sounds dead to the knock, but LF resonances are still present on music. On another speaker, planet10's and Scottmoose's Maiko2, I laminated 3/4" MDF sheets to the outside of the speaker side walls. It really cut down the vibes and made a nice improvement. I usually use a couple staples at the outer corners to hold it in place since GG isn't structural.

Based on my previous experience using GG in speakers, if I were to build another GG box, I would use multiple layers (at least 3) of 1/4" (6mm?) plywood with GG coats between (1/8" notch trowel,) then add crossbracing members to the inside to bulge the panels outward adding tension to the panels. This raises the resonance freq making it easier for GG to damp. I don't think I would do this for a bass box though, which I think should be stiffer to resist bulging for cleaner bass impact.

na said:..or just make it like Jeff has it designed

That is probably the wisest advice!

I want to do some measurements, have you done any?

Not really. But I'll try to run it today to see if there is a FR hump at my perceived resonant freq. Good idea, thanks.

Sounds like you overbuilt the boxes, surprised a difference in bracing would make that much difference.

Me too. I thought I was making it better, but maybe not. I will do some more testing before I make any changes.

I like Scott's idea of tightening panels down on the cross braces, a little tension might raise the resonant frequency.

I haven't read his post yet, but I am looking forward to it. I know dave is also a proponent of stressed panels to raise resonant freq above the resonant range of the material. That's why he recommends BB because it stretches well, unlike MDF which flows over time losing tension.

The design is a little weird, calls for different materials (mdf and bb) in different thicknesses. Maybe he knew just what was needed, but it seems he used what he had lying around. I doubt that anyone has built it exactly by the plans. The stock bracing doesn't seem like anything special either.

I think Jeff's own Kairos boxes are pre-veneered 3/4" MDF. His boxes don't exactly match the CAD design sent by Meniscus, but he says the diff is negligible. His simple window bracing is what I see in comercial speakers which are relatively quiet. It divides the panels into roughly 8 inch squares, but maybe key is the cross bracing which links opposite sides together to reduce bulging across the panel, whereas my stick braces allow waves to move through the panel like a spine of bones or ribs. Mine lacks the batten stiffening effect of window bracing. But previous use of battens on much bigger boxes taught me battens are a waste of glue.

I'm with Dave, more research before rebuilding. Can you feel the panels vibrating? Maybe put some clamps on them, like you were gluing the sides on and see how they sound. It's sure to at least change the resonance. Curious what you find out.

I can get a stethoscope from local parts store for $10. I will also try listening to them on the floor nearfield rather than on stands to eliminate the possibility of floor bounce or ceiling mode.

I can feel slight vibrations from the box when it is playing LF, but I have not felt it when deliberately exciting the resonant freq. I will try clamping the sides, good idea thanks Alan!

Yes. Place the tip on the cabinet and then pull it off. If the sound level decreases you have a resonance at that spot on the cabinet. Try all over the cabinet.

If you want to know the frequency use a signal generator as source (downloadable software). I usually just use music unless i have a serious problem (rarely the case).

dave

OK thanks. I'll get a steth this morning. I also found this interesting article about using stethoscope on speakers.

I use WinISD beta for free signal generator. Or in this case "Corcovado."

I'm not a fan a bracing at all (it usually doesn't do much), at least as most people brace.

If you are going to do it though, I usually pick out "random" points on the panels (connecting parallel walls) and use a dowels (1/4") screwed (with pre-drilling for those screws) - that seems to work best, and for the most part it does so without adding much air-flow restriction. The thinner the cabinet panels are, the better this works.

Note: both the smaller connection point (1/4") and the "randomness" are necessary. It needs to be a tight "point" on the panel pulling the other panel inwards (fractionally), but tightly. (..the dowels should be just a little short of spanning the distance from wall to wall.) If it pulls the panel to where there is a small indentation, don't worry - just use wood filler to smooth out the exterior. I'd use at least 3 dowels between each parallel wall grouping (..maybe 5 for the side walls, but no more). For the slant baffle of the Kairos I'd probably use wiring tensioning instead (..same idea as the dowels, just using wire to pull the baffle inward to rear wall and keep the connection points small for each wire). With respect to the "randomness" you don't want to "center" the connection point on the panel - each connection needs to be off-center from the panel and each other and shouldn't be to close to the edges of the panel.

I understand the concept. But I worry that tensioning the box walls will just drive the resonance higher in freq, albeit quieter in amplitude, still allowing it to be audible in the midrange, since the woofer crosses to tweeter at 1900Hz. I will apply some clamping experiments to the box today to see if tensioning has a positive effect. Thanks

With respect to having a quiet loudspeaker:

You can still do a box within a box construction (thin wall for each), and fill the space between the boxes with a very soft high loss viscoelastic foam. Take care not to leave any voids when pumping the foam between the two boxes.

Do you mean solid memory foam cut to size, or you mean a 2 part liquid polyurethane foam like this?

IF you need to dampen interior panels you can use the bracing method I just mentioned, OR you can line the wall interior with a lossy adhesive and some heavy "panels" (adjusting the depth of the box to accommodate the loss in volume). A heavy "panel" might be some 1/2" steel plate. Perhaps Green Glue as the adhesive - modestly applied (1/16" thick) across the entire surface of one side of the steel plate that's to be glued to the interior panel.

Porcelain tile is good for this. Heavy, glueable, extremely stiff, cheap. That was one idea I had to try to salvage the current Kairo boxes, to glue on thick porcelain tiles to the exterior surfaces with PL construction adhesive, or I guess tile cement would be better, either latex or thinset mortar to add stiffening and mass to tame the wild ring.

On the exterior box consider a 1/4" brass plate for both driver's connection to the baffle. It shouldn't span the entire baffle, perhaps 8" square for the midbass and another smaller panel for the tweeter. Only the tweeter's brass connection plate should have a lossy decoupling from the exterior box (green glue), the midbass's brass plate should have a fairly rigid (and thinly applied) glue when connecting to the exterior box. A scroll saw or saber saw with a metal cutting blade should make cutting the brass fairly easy (..though a machinist doing it would be easier still.) Ex. Enough brass for both cabinets:

C260 Brass Sheet (1/4) .250" x 11" x 18" - Mill Finish

What function does the brass plate for the mid driver serve? A stiffer baffle? I always thought that a cast aluminnum driver basket was a good stiffener of the baffle near the driver's location. Not enough?

The Satori tweeter has a two part flange construction that decouples the tweeter from the box automagically.

Despite all the above (which goes well beyond the "normal"), Dave's advice is a "sound" starting point.

Yes, it is, and I will do some more investigating before I ruin the existing boxes or start building something new.

No sand box for midrange? I have read that it is ideal for midrange. No? Sand actually seems like a pretty simple method, compared to stressed panels or chemical foam injections!

Thanks everybody. I'll post later what I find out.

Last edited:

I did put 3 clamps per speaker, side to side. No difference.

I opened 4 windows in the corners behind the speakers, that might have helped some.

I listened to speakers outside to eliminate the room effects. Cello solo track sounds fine inside and out. Gerry Mulligan barisax sounds mildly resonant inside and clean outside. Corcovado vocals sound resonant inside and less resonant outside.

Could be that the speakers are quiet, and there is some mic proximity effect on the pop/jazz recordings, I'll listen to them w/cans.

That all points to the room, but I never noticed anything like this in years of many different speakers, in different positions. Maybe it's the engineered wood joist floor resonance. I will try a different pair of speakers in the room - cheap ported infinity 2ways.

I am off to buy a stethoscope.

I opened 4 windows in the corners behind the speakers, that might have helped some.

I listened to speakers outside to eliminate the room effects. Cello solo track sounds fine inside and out. Gerry Mulligan barisax sounds mildly resonant inside and clean outside. Corcovado vocals sound resonant inside and less resonant outside.

Could be that the speakers are quiet, and there is some mic proximity effect on the pop/jazz recordings, I'll listen to them w/cans.

That all points to the room, but I never noticed anything like this in years of many different speakers, in different positions. Maybe it's the engineered wood joist floor resonance. I will try a different pair of speakers in the room - cheap ported infinity 2ways.

I am off to buy a stethoscope.

No resonance is audible through the stethoscope. I can't hear any louder sound when I touch the probe anywhere on the box. I can hear it magnifying the probe contact clicks in both ears. I can hear tone if I touch the surround.

I did a sweep 100-200Hz which covers the problem area while feeling the box on both sides. A slight vibe is felt throughout but it stayed same amplitude.

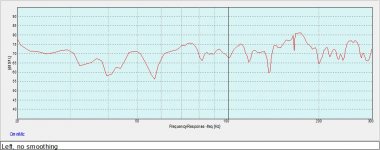

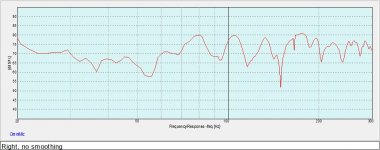

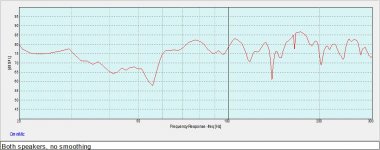

But at the listening seat the perceived SPL during that sweep changes drastically up and down.

So it appears I have been tricked by the room once again. I'll work with speaker placement, room treatment, etc.

Thanks to everyone for the advice and help!

Rich

I did a sweep 100-200Hz which covers the problem area while feeling the box on both sides. A slight vibe is felt throughout but it stayed same amplitude.

But at the listening seat the perceived SPL during that sweep changes drastically up and down.

So it appears I have been tricked by the room once again. I'll work with speaker placement, room treatment, etc.

Thanks to everyone for the advice and help!

Rich

Attachments

I can't hear any louder sound when I touch the probe anywhere on the box.

What about the stands?

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Kairos cabinet