hi all

ive been a few years looking for a 3-way speaker i can build - after first aiming at a german design and later with the help of this forum, i understood that design used bad drivers..

then one helpful member tipped me about Tarkus by paul carmody and after a quick glance, i was sold. this was the speakers i had been looking for..

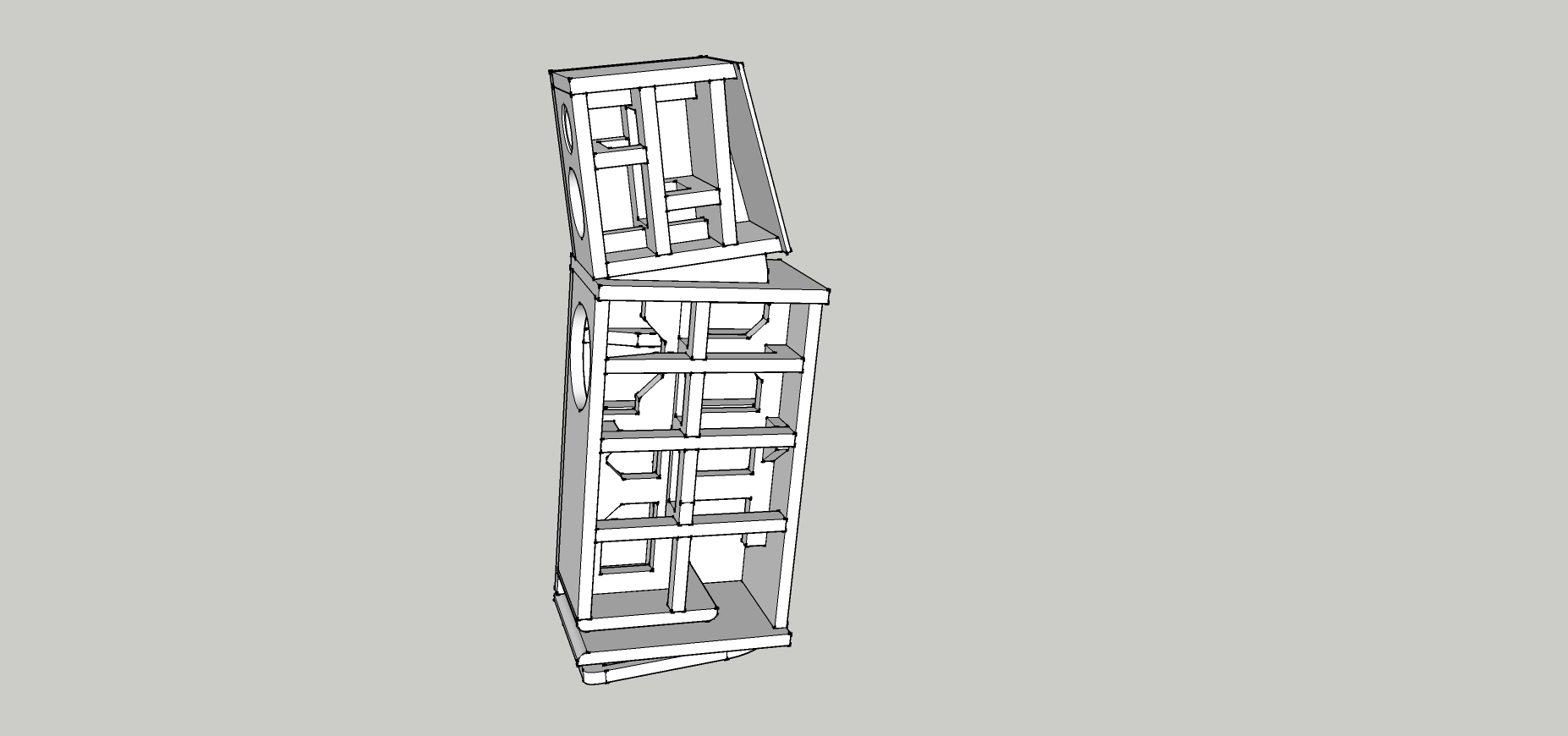

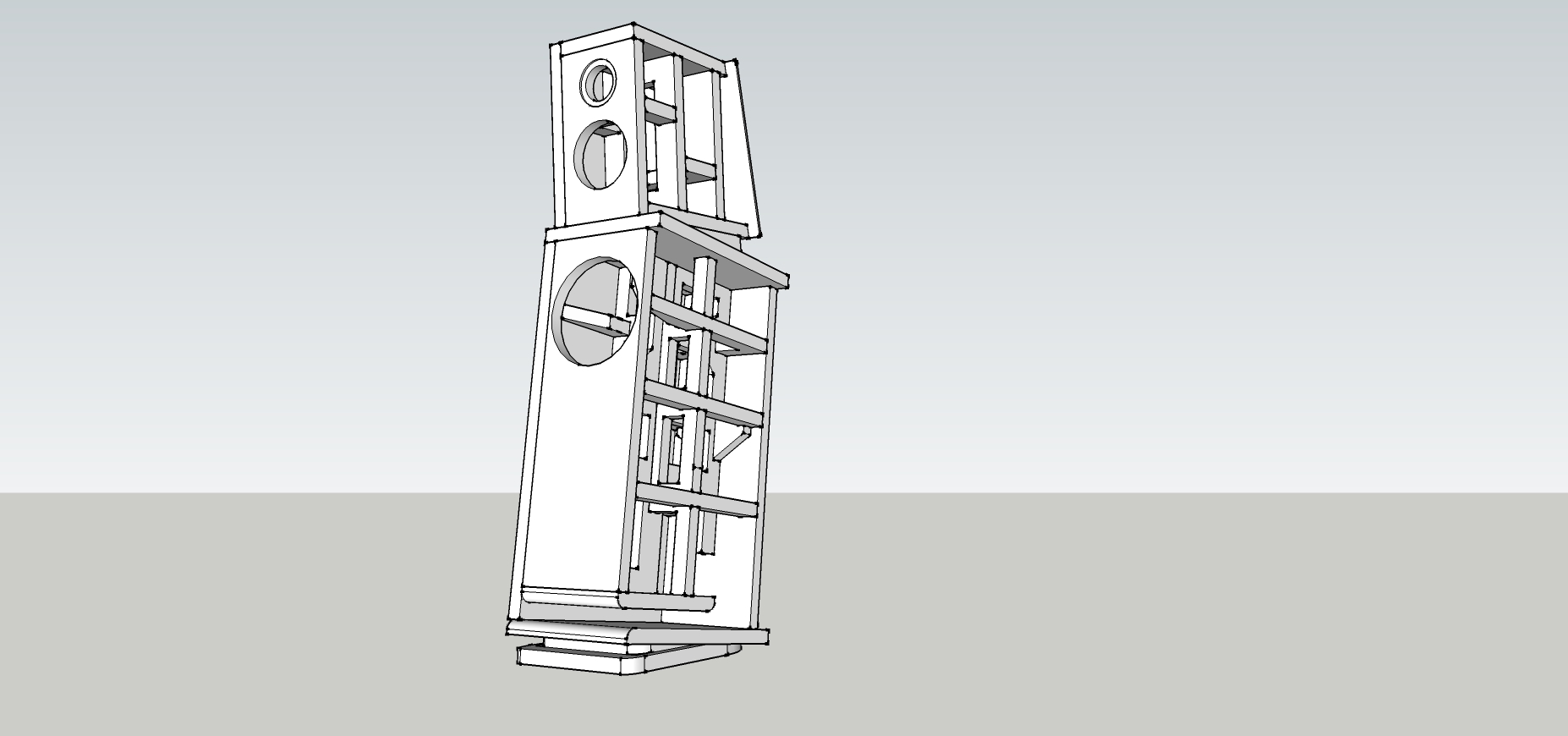

after i had made sure i can find all the components here in europe (thanks again guys!), i started sketching on the build.

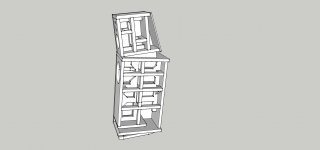

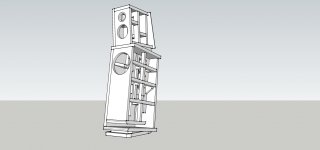

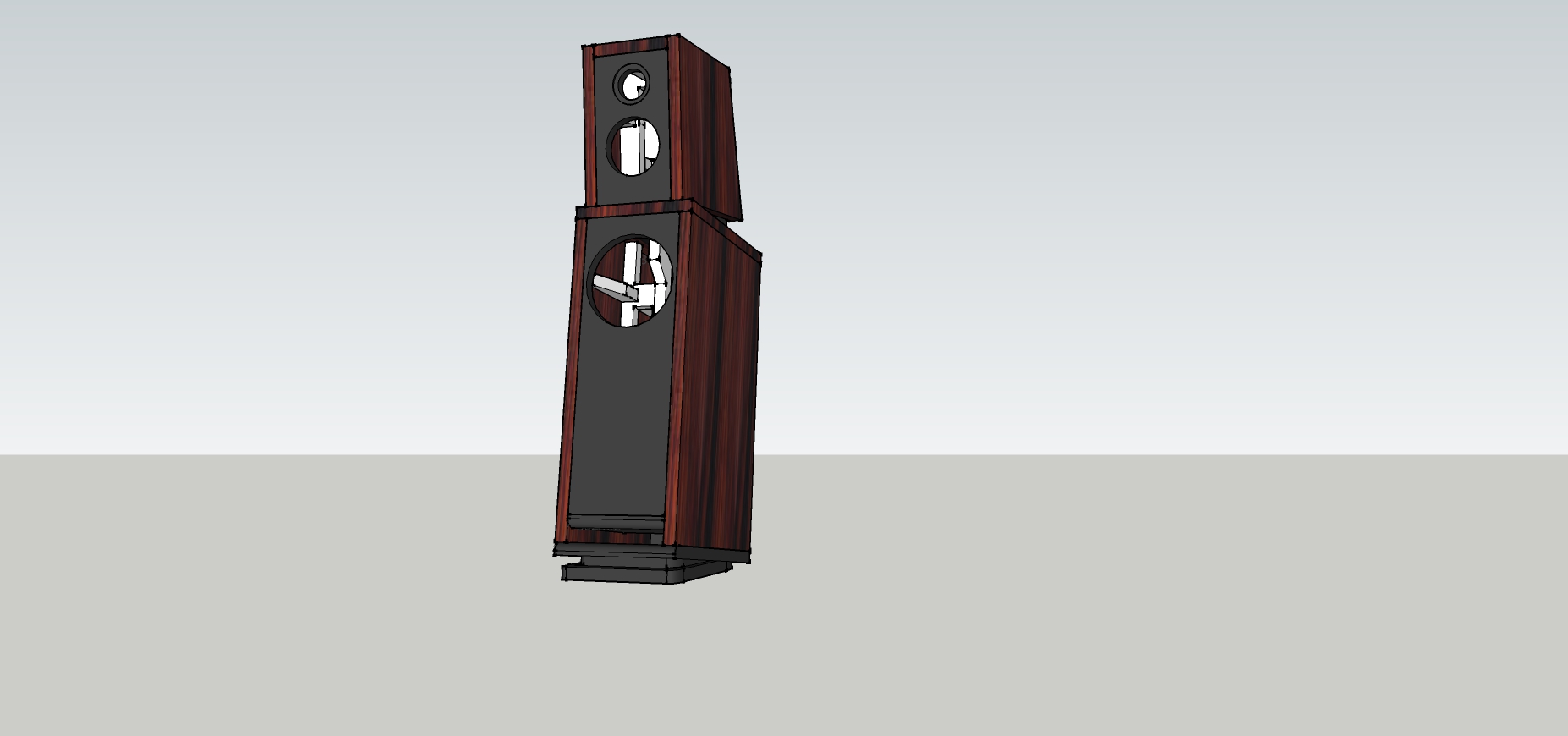

i changed the volume first to allow for bracing, but i also added about 20% more volume to the sub box to get a little bit more deeper bass. also i decided for a rectangular slot vent instead of a tube. the slot vent takes up a fair bit of space on the heigth.

also im planning to do a stand for the speaker, fixing the sub leaned backwards a few degrees (similar to the original but different solution). but also i plan to make a variable stand for the mid/hi box so it can be adjusted from horizontal to about 8º inclination forward. this is since these speakers ended up fairly tall, so for home cinema use, i decided i felt like having the possibility to aim the tweeter towards the couch.

also i added a small compartment in the back of the mid/high box to fit the crossover.

high/mid box has same volume as original (i added only the space needed for the braces)

the subwoofer is now 78,3 liters or 2.75 cubic foot.

outside measures;

total heigth is about 130 cm or 51"

width of subwoofer section is 31cm or 12".

also im thinking of adding wheels to bottom.. not 100% sure about it yet though.. but it would be nice to be able to slide them around a bit if needed... the design above is made using 30mm MDF and it is going to get very heavy.

when watching movies i will use also this subwoofer im going to build recycling 4 sealed 12" subs i have had for 6 years to BR. http://www.diyaudio.com/forums/subwoofers/269904-isocube-project.html

.. i hope i can start soon...

ive been a few years looking for a 3-way speaker i can build - after first aiming at a german design and later with the help of this forum, i understood that design used bad drivers..

then one helpful member tipped me about Tarkus by paul carmody and after a quick glance, i was sold. this was the speakers i had been looking for..

after i had made sure i can find all the components here in europe (thanks again guys!), i started sketching on the build.

i changed the volume first to allow for bracing, but i also added about 20% more volume to the sub box to get a little bit more deeper bass. also i decided for a rectangular slot vent instead of a tube. the slot vent takes up a fair bit of space on the heigth.

also im planning to do a stand for the speaker, fixing the sub leaned backwards a few degrees (similar to the original but different solution). but also i plan to make a variable stand for the mid/hi box so it can be adjusted from horizontal to about 8º inclination forward. this is since these speakers ended up fairly tall, so for home cinema use, i decided i felt like having the possibility to aim the tweeter towards the couch.

also i added a small compartment in the back of the mid/high box to fit the crossover.

high/mid box has same volume as original (i added only the space needed for the braces)

the subwoofer is now 78,3 liters or 2.75 cubic foot.

outside measures;

total heigth is about 130 cm or 51"

width of subwoofer section is 31cm or 12".

also im thinking of adding wheels to bottom.. not 100% sure about it yet though.. but it would be nice to be able to slide them around a bit if needed... the design above is made using 30mm MDF and it is going to get very heavy.

when watching movies i will use also this subwoofer im going to build recycling 4 sealed 12" subs i have had for 6 years to BR. http://www.diyaudio.com/forums/subwoofers/269904-isocube-project.html

.. i hope i can start soon...

Attachments

Last edited:

pete - plywood costs a lot down here in spain. up to 40 euro per m2.. mdf is my only option

richidoo - the top box with the mid and tweeter is separate so when i have built them i will make a test to see if i need to have it tilted or not. the issue is the couch will be quite a bit lower than the tweeter. im just taking precations in case "if needed"

the subwoofers original design is tilted even more backwards. i reduced the angle a bit.

richidoo - the top box with the mid and tweeter is separate so when i have built them i will make a test to see if i need to have it tilted or not. the issue is the couch will be quite a bit lower than the tweeter. im just taking precations in case "if needed"

the subwoofers original design is tilted even more backwards. i reduced the angle a bit.

also im thinking of adding wheels to bottom..

not 100% sure about it yet though.. but it would

be nice to be able to slide them around a bit if

needed... the design above is made using 30mm

MDF and it is going to get very heavy.

Wheels is smart, 30 mm mdf not. You don't need it.

The Tarkus design enables one to optimize cabinet construction to frequency range in consideration. The bass enclosure would have to be stiff with massive use of bracing of all cabinet walls. The mid cabinet would ideally be 'lossy', choose a rather thin plywood (birch?) of 12mm and apply lots of bitumen or other heavy and non-resonant damping sheets on all panels. Think of layers of 10 to 15mm thick. Also, decoupling the unit from the baffle would help here.

Wheels is smart, 30 mm mdf not. You don't need it.

i have only used 30mm mdf when building subwoofers this far and i really like the results. however now when im getting older i really do not feel like carrying 80 kilo speakers around when painting them.

this weekend im going to make other versions of the plans for the Tarkus build and for my subwoofer re-build. ill try with 25mm mdf and ill see how heavy they get calculating the mass per cm3 etc...

markbakk said:The Tarkus design enables one to optimize cabinet construction to frequency range in consideration. The bass enclosure would have to be stiff with massive use of bracing of all cabinet walls. The mid cabinet would ideally be 'lossy', choose a rather thin plywood (birch?) of 12mm and apply lots of bitumen or other heavy and non-resonant damping sheets on all panels. Think of layers of 10 to 15mm thick. Also, decoupling the unit from the baffle would help here.

the drawback is the price here for good birch plywood. its various times more expensive than MDF. as stated before spain unfortunatelly does not have much forrest.. they only produce low quality pine plywood which is so porous (i use it at work - yuk!) it would be un-suitable.

actually in my town i cant even find birch plywood. the only plywood available is of a wood called "Okume" and is used in boat building and has impressive stats regardng resitance to humidity etc but it seems overkill. i have no idea how suitable this would be for speaker building, also it is tremendously expensive. i would need 500 euros worth of plywood per speaker. it is not even realistic...

so - using plywood the cost of material would be atleast 5 times higher... having to add bitumen would increase the price even more.

it sucks but the only realistic option i can find here is MDF.

i have only used 30mm mdf when building subwoofers

this far and i really like the results.

Your boxes are braced to death, need not more than 19 mm

and woofers are designed for surface mounting anyway. If there

is anything worth a little thought, then it's the amount of box

stuffing.

TM box is definitely more critical and wouldn't hurt to check

by measuring. A formula for calculating standing wave frequency:

fr=172/inner dimension in meters

I suggest, if you already have not decided so, get an unexpensive

measurement mic and learn to measure with free software

(ARTA, Holm Impulse, REW).

Take care of your health while building.

yeah i bet 19mm is probably enough  i already made modified plans for 25mm mdf, and i can make plans for 22mm and 19mm mdf to. 19mm mdf is so cheap i can add even more bracing if its needed.

i already made modified plans for 25mm mdf, and i can make plans for 22mm and 19mm mdf to. 19mm mdf is so cheap i can add even more bracing if its needed.

stuffing? Pauls recomendations for this build say no stuffing besides egg-crate foam in the bass cabinet, and the TM-cabinet stuffed full.

my plan was to fill the TM with 1 to 1,5 or even 2 packs of sonofil in each enclosure. no foam.

in the bass cabinets i thought id cover with foam everything i can (spaces between bracing) and what ever i can of the bracing too. also i was going to put in the remaining sonofil in the top/back loosely.

i have a very cheap mic. i doubt its good enough for measuring but i will give it a try later on

but i will give it a try later on

if i understood the standing wave formula..

front and back is 20cm wide, space is 25 cm deep. height is 34cm

standing waves would be at;

20cm=860Hz

25cm=682Hz

34cm=505Hz

stuffing? Pauls recomendations for this build say no stuffing besides egg-crate foam in the bass cabinet, and the TM-cabinet stuffed full.

my plan was to fill the TM with 1 to 1,5 or even 2 packs of sonofil in each enclosure. no foam.

in the bass cabinets i thought id cover with foam everything i can (spaces between bracing) and what ever i can of the bracing too. also i was going to put in the remaining sonofil in the top/back loosely.

i have a very cheap mic. i doubt its good enough for measuring

if i understood the standing wave formula..

front and back is 20cm wide, space is 25 cm deep. height is 34cm

standing waves would be at;

20cm=860Hz

25cm=682Hz

34cm=505Hz

Hi,

With such extensive bracing just lightly stuff,

(about half the density of the TM) the top two

rear and the front two bottom of the bass

cabinet, leave the rest bare.

Foam lining is only really applicable to bassmids

in a vented two way design, and you can still

lightly stuff the area behind the main driver,

keeping the stuffing away from the port area.

rgds, sreten.

With such extensive bracing just lightly stuff,

(about half the density of the TM) the top two

rear and the front two bottom of the bass

cabinet, leave the rest bare.

Foam lining is only really applicable to bassmids

in a vented two way design, and you can still

lightly stuff the area behind the main driver,

keeping the stuffing away from the port area.

rgds, sreten.

Last edited:

Some general thoughts

Your bracing is overkill I believe. Or you are concern of that bottom port design?

I thought that Carmody's design was about sealed box? Haven't seen it for a while...

Anyway, 19mm MDF is more than adequate even if you reduce bracing. It is better and more healthier way to purchase MDF already cut and if necessary CNC processed . Stick to drilling holes for joints, otherwise you will need some sort of surgical masque. MDF dust is super nasty stuff. It is not made of wood only, it has some adhesives.

Then that box, don't alter its volume. Carmody stated that his intention was to make speaker for guitar and rhythm RnR music. So he tuned them toward bass range i think.

So reduce bracing and be very cautious of foam to wrap them into. Egg foam on the walls and synthetic wool inside to 'enlarge' volume. No 'cheap tricks' on Xover. That 10 incher woofer is not easy to tame. You have to cut it very very low, 150Hz I'd say and maybe lower if possible...but its not. Pair of these are collecting dust on the shelf for more than year in my workshop.

Your bracing is overkill I believe. Or you are concern of that bottom port design?

I thought that Carmody's design was about sealed box? Haven't seen it for a while...

Anyway, 19mm MDF is more than adequate even if you reduce bracing. It is better and more healthier way to purchase MDF already cut and if necessary CNC processed . Stick to drilling holes for joints, otherwise you will need some sort of surgical masque. MDF dust is super nasty stuff. It is not made of wood only, it has some adhesives.

Then that box, don't alter its volume. Carmody stated that his intention was to make speaker for guitar and rhythm RnR music. So he tuned them toward bass range i think.

So reduce bracing and be very cautious of foam to wrap them into. Egg foam on the walls and synthetic wool inside to 'enlarge' volume. No 'cheap tricks' on Xover. That 10 incher woofer is not easy to tame. You have to cut it very very low, 150Hz I'd say and maybe lower if possible...but its not. Pair of these are collecting dust on the shelf for more than year in my workshop.

Hi,

With such extensive bracing just lightly stuff,

(about half the density of the TM) the top two

rear and the front two bottom of the bass

cabinet, leave the rest bare.

Foam lining is only really applicable to bassmids

in a vented two way design, and you can still

lightly stuff the area behind the main driver,

keeping the stuffing away from the port area.

rgds, sreten.

the bass box in this design from paul carmody crosses over at about 400 hz

the bass box in this design from paul carmody crosses over at about 400 hz

Hi, And ? That implies what ? rgds, sreten.

Some general thoughts

Your bracing is overkill I believe. Or you are concern of that bottom port design?

I thought that Carmody's design was about sealed box? Haven't seen it for a while...

Anyway, 19mm MDF is more than adequate even if you reduce bracing. It is better and more healthier way to purchase MDF already cut and if necessary CNC processed . Stick to drilling holes for joints, otherwise you will need some sort of surgical masque. MDF dust is super nasty stuff. It is not made of wood only, it has some adhesives.

Then that box, don't alter its volume. Carmody stated that his intention was to make speaker for guitar and rhythm RnR music. So he tuned them toward bass range i think.

So reduce bracing and be very cautious of foam to wrap them into. Egg foam on the walls and synthetic wool inside to 'enlarge' volume. No 'cheap tricks' on Xover. That 10 incher woofer is not easy to tame. You have to cut it very very low, 150Hz I'd say and maybe lower if possible...but its not. Pair of these are collecting dust on the shelf for more than year in my workshop.

hello

the Woofer box is vented. Paul used a tube. the vent doesnt show on his drawings, but if you read the text it is clear. he recommends a 10cm diameter tube of 34 cm length or so

i know mdf contains phenol formaldehyde resin glue (formaldehyde based) and i have a proper 3M gasmask

i have both an indoor workshop and a covered big open aired "garage" where i build bigger projects.

i am of course going to get most of the wood cut at the vendor, mostly because of transport issues, working alone the 240cmx205 cm sheets are impossible to manage.

im not going to get it cnc milled since its very expensive, and i can do it myself with my router.

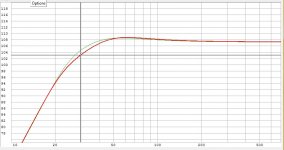

the box maintains same tuning as in his design. i only added some more volume. i have read everything Paul has written that i could find concerning this design and he clearly states in his build thread on part express the box volume can be changed a bit with no greater influence.

he also states this design as adecuate for hip hop etc or as i interpret it, most bass heavy music.

plotting the extra volume i added does not make much difference either.

red original, green the added volume.

it only ads one miserable dB at 30 Hz

i dont get what you mean with "no cheap tricks on the crossover" ? everything is as close as possible to the original...

Attachments

Hi, And ? That implies what ? rgds, sreten.

hello

the vented enclosure with the 10" woofer will play from 420Hz downwards as in Pauls design. so imho afaik the woofer is playing mid bass. so i follows pauls advice on the foam on the walls... in the woofer enclosure.

Last edited:

P is not a guru. He is not right about everything.

rgds, sreten.

i dont think i have written anywhere i think he is a guru

please understand me right

im merely saying im building the enclosure as he designed it, with a few small mods since i like woodwork (the bracing..)

although im still happy for any input regarding this build about cost efficient improvements... as long as i can understand it

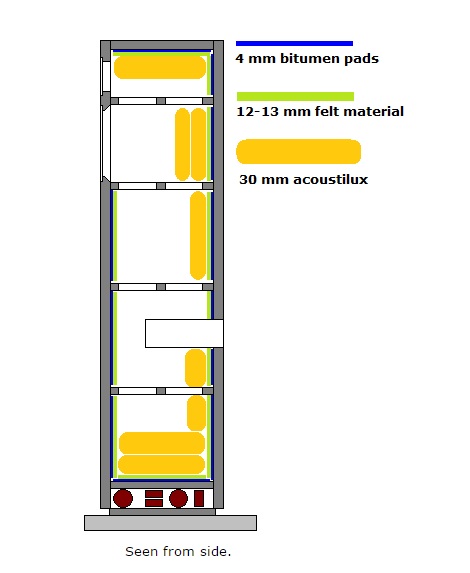

i have a hard time explaining so i will post a link instead to troels site;

Cabinet-damping

the inspiration i had more or less for the damping is the image about halfway down on the link above. although im not going to use bitumen, but the placement of the Sonofill is more or less how i wanted to do it

Cabinet-damping

the inspiration i had more or less for the damping is the image about halfway down on the link above. although im not going to use bitumen, but the placement of the Sonofill is more or less how i wanted to do it

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- building the TARKUS