Hi,

I've almost finished a 2-way bass-reflex "boom box". My version has an active crossover, 2 x50W chip amps, Vifa P21WO-39-08 woofer and Vifa XT25TG tweeter.

The original passive enclosure design from 1986 calls for the top, bottom and sides to be lined with 50mm (2 inch) thick medium density "mattress foam". That seems like a lot of volume taken up by foam.

The pics below show the box internal before the top was installed. The stiffeners on the side walls are 50mm, so the suggested foam would be flush with these. The other pic is of some foam I have lying around. It was used as packing for an air rifle, so I doubt it is "acoustic" foam. It is open cell, light weight and would be an 'average' thickness of around 50mm. I have enough of this foam to line the sides.

What do you guys think of the suitability of the foam I have?

Any general comments on lining speaker boxes?

I have no idea why the picture of the painted box is sideways. The original pic isn't and when I go to Manage Attachments the pic is orientated correctly.

I've almost finished a 2-way bass-reflex "boom box". My version has an active crossover, 2 x50W chip amps, Vifa P21WO-39-08 woofer and Vifa XT25TG tweeter.

The original passive enclosure design from 1986 calls for the top, bottom and sides to be lined with 50mm (2 inch) thick medium density "mattress foam". That seems like a lot of volume taken up by foam.

The pics below show the box internal before the top was installed. The stiffeners on the side walls are 50mm, so the suggested foam would be flush with these. The other pic is of some foam I have lying around. It was used as packing for an air rifle, so I doubt it is "acoustic" foam. It is open cell, light weight and would be an 'average' thickness of around 50mm. I have enough of this foam to line the sides.

What do you guys think of the suitability of the foam I have?

Any general comments on lining speaker boxes?

I have no idea why the picture of the painted box is sideways. The original pic isn't and when I go to Manage Attachments the pic is orientated correctly.

Attachments

Last edited:

The foam, if it's open-cell, is probably just fine, though you may decide later to add wadding if the box is too boomy or colored sounding. Some members coupling opposite panels in the box would stiffen it up significantly, damped braces might be just the ticket there. As built, you may find an issue with heat from the active XO- the wood bottom won't act as much heatsinking for the amp nor the rectifier. I might relocate it into a matching stand, with heatsinking on the rear, if I were you. Nice paintjob!

The foam, if it's open-cell, is probably just fine, though you may decide later to add wadding if the box is too boomy or colored sounding. Some members coupling opposite panels in the box would stiffen it up significantly, damped braces might be just the ticket there. As built, you may find an issue with heat from the active XO- the wood bottom won't act as much heatsinking for the amp nor the rectifier. I might relocate it into a matching stand, with heatsinking on the rear, if I were you. Nice paintjob!

Thanks for the quick response. I'll look into damped braces.

I was planning to place a thermocouple probe in the box to assess how warm it gets in there. Since taking the photo I've mounted the rectifier on a heatsink. The chip amps have decent sized heatsinks too and seem to run fairly cool.

The paint will look even better when I've cut and polished it!

Chris,

For damping resonances in speaker cabinets I have used 'cotton waste' under-carpet matting (was often used in soundproofing in cars) which has proved quite effective and is cheap...... see the Bunnings link below. The matting has the odd piece of tinsil on it's surface, possibly the Chinese manufacturers thought they should beautify it to make it more saleable I guess, either way it's easily removed.

Clark Rubber sell a closed cellular foam in large sheets which can be folded over if need be to make up a required thickness.

I've found 'closed cellular foam' to also be very effective in midrange frequency absorption. Bunnings also carry a 'closed cellular foam' which has 'stick on' backing to it which may be more convenient to use.

Wrap&Move 1.8 x 2m Movers Blanket I/N 2610066 | Bunnings Warehouse

P.S If the cabinet is to be a Bass Reflex design, putting the port at the top of the cabinet would go some way in keeping the 'internals' cool. Just a thought.

C.M

For damping resonances in speaker cabinets I have used 'cotton waste' under-carpet matting (was often used in soundproofing in cars) which has proved quite effective and is cheap...... see the Bunnings link below. The matting has the odd piece of tinsil on it's surface, possibly the Chinese manufacturers thought they should beautify it to make it more saleable I guess, either way it's easily removed.

Clark Rubber sell a closed cellular foam in large sheets which can be folded over if need be to make up a required thickness.

I've found 'closed cellular foam' to also be very effective in midrange frequency absorption. Bunnings also carry a 'closed cellular foam' which has 'stick on' backing to it which may be more convenient to use.

Wrap&Move 1.8 x 2m Movers Blanket I/N 2610066 | Bunnings Warehouse

P.S If the cabinet is to be a Bass Reflex design, putting the port at the top of the cabinet would go some way in keeping the 'internals' cool. Just a thought.

C.M

Foam, or other damping, does not take up volume, but increases the apparent volume. Foam thou, is not very good damping material.

For a BR you want to damp at least opposite walls, we use 1/2" recycled cottom felt on all panels. Wool felt, fiberglass insulation, even poly batting are better than foam.

dave

For a BR you want to damp at least opposite walls, we use 1/2" recycled cottom felt on all panels. Wool felt, fiberglass insulation, even poly batting are better than foam.

dave

Some members coupling opposite panels in the box would stiffen it up significantly, damped braces might be just the ticket there.

I just realised the internal photo I posted doesn't show the 50x20 hardwood front-back brace that has since been fitted. I reckon I will still add a side-side brace too.

There's foam and then there's foam. Of all readily available materials acoustic foams from known suppliers are only surpassed by mineral fibers when it comes to damping characteristics. Most other materials just do not come close. Every product sheet and acoustic handbook will confirm this, I really do not understand why one would suggest otherwise.

Hi Chris,

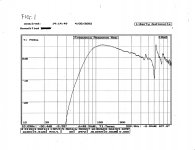

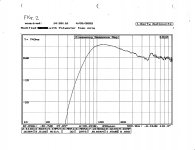

Many years ago I made some near field measurements on a ported 2way similar to yours, both before and after the enclosure was lined with open cell foam. I’ve attached the results showing the difference the open cell foam makes. Fig1 is the unmodified enclosure and Fig2 shows the results of lining the enclosure with 1.5” thick foam.

Unmodified, these speakers sounded boxy, but after the foam was added, the boxy sound completely disappeared.

From other tests that I’ve made, foam is not the best material available, but it is very easy to apply and you shouldn’t have any problems like with fibrous materials that can sag with age and fibres blowing out of the port. It is worth noting though that fibreglass filling may perform better at low frequencies compared to foam, since it can increasing the apparent volume of the enclosure more so than foam.

The dips/peaks in the response shown in Fig1 appear to be significantly reduced with the application of the foam as is evident from Fig2, but there remains a single dip/peak at about 500Hz. I’m not sure what the cause of this was. It could be one of so many sources like an enclosures panel resonance or a resonance of the driver’s suspension/frame etc, but in this particular case, it did not appear to degrade the sound.

I have not tried closed cell foam, since I can’t think of any scientific reason for it being able to reduce the magnitude of standing waves. Hope this is of help.

Peter

Many years ago I made some near field measurements on a ported 2way similar to yours, both before and after the enclosure was lined with open cell foam. I’ve attached the results showing the difference the open cell foam makes. Fig1 is the unmodified enclosure and Fig2 shows the results of lining the enclosure with 1.5” thick foam.

Unmodified, these speakers sounded boxy, but after the foam was added, the boxy sound completely disappeared.

From other tests that I’ve made, foam is not the best material available, but it is very easy to apply and you shouldn’t have any problems like with fibrous materials that can sag with age and fibres blowing out of the port. It is worth noting though that fibreglass filling may perform better at low frequencies compared to foam, since it can increasing the apparent volume of the enclosure more so than foam.

The dips/peaks in the response shown in Fig1 appear to be significantly reduced with the application of the foam as is evident from Fig2, but there remains a single dip/peak at about 500Hz. I’m not sure what the cause of this was. It could be one of so many sources like an enclosures panel resonance or a resonance of the driver’s suspension/frame etc, but in this particular case, it did not appear to degrade the sound.

I have not tried closed cell foam, since I can’t think of any scientific reason for it being able to reduce the magnitude of standing waves. Hope this is of help.

Peter

Attachments

There's foam and then there's foam. Of all readily available materials acoustic foams from known suppliers are only surpassed by mineral fibers when it comes to damping characteristics. Most other materials just do not come close. Every product sheet and acoustic handbook will confirm this, I really do not understand why one would suggest otherwise.

But how does it sound?

Hi Peter,

Thanks for your reply. The 1.5" foam clearly made a large improvement to your speakers.

While foam may not be the best damping material, it certainly seems to make an improvement. It certainly won't hurt to line the sidewalls with the foam I have. I'll start with that and go from there.

Cheers

Thanks for your reply. The 1.5" foam clearly made a large improvement to your speakers.

While foam may not be the best damping material, it certainly seems to make an improvement. It certainly won't hurt to line the sidewalls with the foam I have. I'll start with that and go from there.

Cheers

Foam, or other damping, does not take up volume, but increases the apparent volume.

My understanding is that cabinet damping doesn't increase apparent volume but lowers Qtc- it lacks the shift in Fc that a larger cabinet brings with it, but can damp the response around Fc somewhat.

I've never tested it explicitly, as I tend to prefer oversized cabs anyway, so the damping doesn't really make a big diff to enclosure tuning in those types of enclosures.

I've never tested it explicitly.

I believe it was Nousane (sp?) who did the tests to confirm that damping can make a box appear to be as much as 30% larger.

dave

There are two components to the change though- one is a lower Qtc, the other is a downward shift in Fc, which is what I think falls short compared to a truly larger box. Again, I might be wrong- these rules of thumb are so often inaccurate that it's hard to be sure without doing your own testing. I guess I could just do it eh?

I've had similar results to PLB, I did a bunch of tests years ago with different materials and there was a LARGE difference in effectiveness depending on the foam. I ended up getting a specialty product which has foam as well as mass loaded vinyl in it. see this post http://www.diyaudio.com/forums/mult...materials-what-do-people-use.html#post2193250

The egg crate foam from memory gave similar results to PLB's the soundsorber barrier is in another league This post has a comparison between the eggcrate foam and the soundsorber.. http://www.diyaudio.com/forums/multi-way/153199-enclosure-stuffing-2.html#post1948569

This post has a comparison between the eggcrate foam and the soundsorber.. http://www.diyaudio.com/forums/multi-way/153199-enclosure-stuffing-2.html#post1948569

Tony.

The egg crate foam from memory gave similar results to PLB's the soundsorber barrier is in another league

Tony.

Straight open cell foam is not terribly effective at low freqs...

...there are specs published showing absorption vs. freq.

But otoh, anything is better than nothing, pretty much.

Wool (felt or batting) is generally speaking "top of the food chain".

But there may be newer "foam" products that have higher losses due to added mass in the "cells" of the foam. But I dunno about any in particular, but it sounds plausible.

As far as 30% that seems off, as the usually cited figure is more like 10% best case. I'd not trust much of what Tom Nousaine said, but since he's no longer with us, bet to leave that one where it is.

Regardless, 1/2" of almost anything I know of will only work effectively at fairly high frequencies. Which is still better than having all sorts of stuff never being attenuated inside the cabinet.

Only my opinions and experience.

...there are specs published showing absorption vs. freq.

But otoh, anything is better than nothing, pretty much.

Wool (felt or batting) is generally speaking "top of the food chain".

But there may be newer "foam" products that have higher losses due to added mass in the "cells" of the foam. But I dunno about any in particular, but it sounds plausible.

As far as 30% that seems off, as the usually cited figure is more like 10% best case. I'd not trust much of what Tom Nousaine said, but since he's no longer with us, bet to leave that one where it is.

Regardless, 1/2" of almost anything I know of will only work effectively at fairly high frequencies. Which is still better than having all sorts of stuff never being attenuated inside the cabinet.

Only my opinions and experience.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- How much foam lining for this speaker?