I was interested in the TriTrix MTM TL combo kit sold by Parts Express... added it to the cart.... OMG why are they charging me $121 shipping! I also had a few gripes about the box so I have decided to purchase the speaker kit and build the enclosure myself. My father has access to a CNC router so this shouldn't be too difficult ( I have made 3 car sub-woofer enclosures using this CNC machine when I was younger and more annoying ).

Changes:

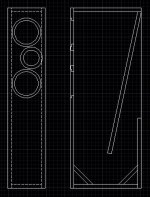

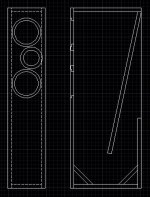

This is my new design:

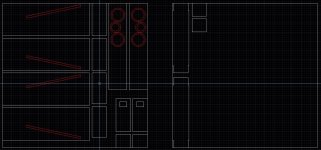

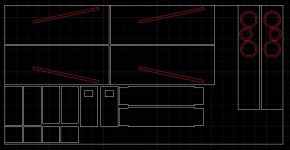

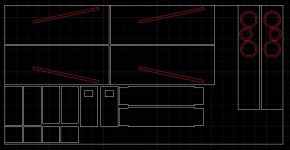

Sheet cut layout:

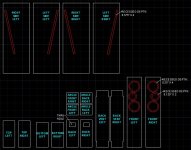

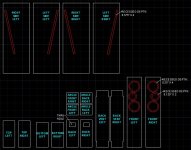

Parts with notes:

I plan to use biscuits and glue to attach the sides together. I will likely use some screws in place of using a ton of clamps I don't own yet.

I hope to get the wood cut sometime this week and I will be sure to include pictures of that process.

I am open to anyone's opinions and/or suggestions.

Changes:

- I didn't like the rough edges of the MDF facing the front

- Also not a huge fan of MDF... I will be using baltic birch plywood

- Added a cutout for the terminals

- Only put a routered slot in for the angled back piece

This is my new design:

Sheet cut layout:

Parts with notes:

I plan to use biscuits and glue to attach the sides together. I will likely use some screws in place of using a ton of clamps I don't own yet.

I hope to get the wood cut sometime this week and I will be sure to include pictures of that process.

I am open to anyone's opinions and/or suggestions.

Sounds like you're improving the design. WRT BB ply, the preferred choice is either void free 11 or 13 ply 19 mm, which is usually only available in 5 x 5 ft sheets and not the furniture grade 4 x 8 ft sheets sold in 'big box' stores, etc., since it normally has voids that can audibly 'squeak'/'creak' under pressure.

The preferred super stiff BB ply requires few screws to clamp it sufficiently, so no need to unduly weaken the joints by screwing it down like it was particleboard/MDF. If you're really paranoid about joint strength, then glue in some scrap wood rabbit blocks.

GM

The preferred super stiff BB ply requires few screws to clamp it sufficiently, so no need to unduly weaken the joints by screwing it down like it was particleboard/MDF. If you're really paranoid about joint strength, then glue in some scrap wood rabbit blocks.

GM

Ah! 5x5! Thank you so much! I will be modifying my sheet layout...Sounds like you're improving the design. WRT BB ply, the preferred choice is either void free 11 or 13 ply 19 mm, which is usually only available in 5 x 5 ft sheets and not the furniture grade 4 x 8 ft sheets sold in 'big box' stores, etc., since it normally has voids that can audibly 'squeak'/'creak' under pressure.

The preferred super stiff BB ply requires few screws to clamp it sufficiently, so no need to unduly weaken the joints by screwing it down like it was particleboard/MDF. If you're really paranoid about joint strength, then glue in some scrap wood rabbit blocks.

GM

I will also be sure not to over do it with the screws.

Thanks for your input!

You're welcome! Hmm, OK, just to be clear, the proper BB ply is available to some folks in ~ 4 x 8 ft sheets, but at least in the USA it appears to be quite rare. For sure, I haven't had any luck finding any in the greater metro Hotlanta area, though I haven't looked in over a decade now, so you may want to ask your local 'big box' store to check its supplier to see if any can be had at a per sq-ft price comparable to the 5 x 5 ft sheets. Try PlyMart also if it's not your local store's 'go-to' place for special order plywoods.

GM

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- First Post - Redesigned TriTrix Enclosure