Good questions. I'm not an expert in this area, so please guide me if I get too deep in the forest...

neither am I, but I think the waveguide will make the 8" 'appear' bigger, and thus lower its optimal 'xo point', maybe

hmm, and I do not know exactly, but I expect a coax mounted tweeter will need a somewhat higher xo point, due to the less than optimal horn load

but maybe your waveguide will improve the tweeter load, and make a lower xo point possible

might need a little fiddle back and forth to find the best xo

neither am I, but I think the waveguide will make the 8" 'appear' bigger, and thus lower its optimal 'xo point', maybe

might need a little fiddle back and forth to find the best xo

A shallow horn like that, or like these in the link, has more effect than one might expect. In any horn system, the crossover will have to accommodate /eq the raw response to be flat and in the ones in the picture (uses an 8 inch coax) the gain over a direct radiator begins around 120Hz. This eq also means for a given sound level, there is less power going to the driver than if one had the direct radiating case and so one has less distortion as well etc.

The driver in the SH100 has a rear mounted compression driver and so the cone is part of the horn. As a result, one wants the new added horn flare to match up with the line projected by a straight edge lying on the cone body (no discontinuity in angle, minimum discontinuity in area).

Indeed you will need to get the crossover right, in fact it is the clash between the hf and cone driver that is the downfall of the coax driver in general, very few mate hf/lf sections mate well acoustically to form a single source in time and space. Being so closely coupled that clash can be more pronounced than in a multi-way system where the sources are farther apart radiate fully independently.

Best,

Tom Danley

https://www.google.com/search?q=dan...fficial&client=firefox-a&channel=np&source=hp

Thanks, Tom, Tinitus & others, I appreciate your advice very much.

I am trying to match up the cone and horn flares as well as possible. I don’t have the coax drivers yet, but my friend has an equivalent 18Sound bass driver from which I took measurements, thus I was able to design the shape of the horn.

I am also aware that there will be quite much work in designing the crossover. I will do as Tinitus said; fiddle back and forth systematically, until I have found the best parameters. Let’s see if I’m going to cope all the challenges.

SH100 indeed is a very interesting loudspeaker. I must admit that the outcome of my project will look like SH100 quite much. I haven’t had an opportunity to hear SH100 yet but I would very much like to.

Other inspiration to this project has been Tannoy DC8i. I had an opportunity to hear this system and their sound was pretty much what I like.

Thanks,

Erkki

I am trying to match up the cone and horn flares as well as possible. I don’t have the coax drivers yet, but my friend has an equivalent 18Sound bass driver from which I took measurements, thus I was able to design the shape of the horn.

I am also aware that there will be quite much work in designing the crossover. I will do as Tinitus said; fiddle back and forth systematically, until I have found the best parameters. Let’s see if I’m going to cope all the challenges.

SH100 indeed is a very interesting loudspeaker. I must admit that the outcome of my project will look like SH100 quite much. I haven’t had an opportunity to hear SH100 yet but I would very much like to.

Other inspiration to this project has been Tannoy DC8i. I had an opportunity to hear this system and their sound was pretty much what I like.

Thanks,

Erkki

I have a pair of these in my achives...Kef Q30.

They need some tweaking, no hope of doing 120dBA, but at low to medium levels they do some things very pleasantly.

Dan.

Nice speakers indeed. How you're going to tweak them?

About the polyester fabric method you mentioned; it was suggested here that elliptical mouth shape could be superior to rectangular, so I might make an elliptical waveguide using the fabric method.

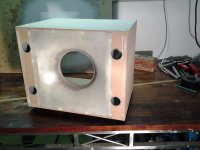

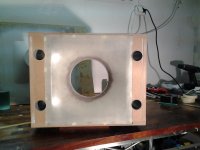

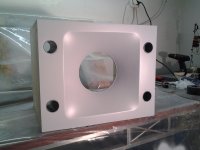

Here are some new pictures... It was a bit difficult to cut the opening for the driver precisely to the center. I made the openings to the last two waveguides during molding:

A disc is attached precisely to the center. Epoxy-microballoon mixture and cloth is laminated around the disc...

...and now there is an opening exactly in the center. Driver support must be attached later.

Is it possible to design passive xo just by using jeff bagsby spreadsheet to get close to SH100 phase response?

I guess it would. The xo will be passive and I must do some research in order to find a good starting point. However, SH100 and this are different and the driver is different. Thus, I do not know how this appproach would work

Thanks! I'll start building the enclosures tomorrow. I am considering if I should build a prototype or two before the final version. Perhaps I should test different volumes and port size and try to match the tuning with the gain caused by waveguide.

I can paint the prototypes purple but that colour has very bad effect on WAF...

I can paint the prototypes purple but that colour has very bad effect on WAF...

Perhaps I should test different volumes and port size and try to match the tuning with the gain caused by waveguide.

I uppose there will be quite a gap between wg boost and BR boost! You will have baffle step "deficiency" there too. Piece of cake for dsp, but passive???

Thanks for comments, Juhazi and Winslow. Yes, there will be many parameters and I begin to realize this isn't as easy project as I supposed..

The testing enclosure is almost ready. Its volume and port lengths can be varied so I can play with the BR tuning. I still need to study what would be the best approach to optimize all the required parameters... LspCAD or other tool, that's certainly what I need. Dsp is also an option.

The testing enclosure is almost ready. Its volume and port lengths can be varied so I can play with the BR tuning. I still need to study what would be the best approach to optimize all the required parameters... LspCAD or other tool, that's certainly what I need. Dsp is also an option.

I can paint the prototypes purple but that colour has very bad effect on WAF...

Get her very dark sunglasses?

LOL, Your product looks good, really good.Painting while waiting the drivers... Looks like an old television with exploded tube

View attachment 392308

You have given me some ideas.

I reckon that a really easy way of making horns and flares would be to stretch a cloth across that box like yours, and setting overall positions/shape geometry with a temporary central disc/shape, and then doping that cloth to create a rigid form, ready for back filling with polyester resin/glass fibre.

Custom straight flares really easily.

Dan.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Two-way coaxial loudspeakers with molded waveguides