With a 5" mid/woofer, you won't get get any appreciable bass. Maybe that is what you want but I don't think I would ever be satisfied with anything that won't go a bit loud when you might like it.

My first build was a project speaker in a now defunct Australian electronics hobby magazine; a tow way with 8" and 1" Vifa's, now both obsolete. While I liked them, it wasn't until I made one active that I found something much better. When I converted them to three way actives, I found a really good system.

With many good drivers around, together with DSP such as the miniDSP and class D amps, a reasonably low cost and good set of speakers is not all that difficult to achieve, even for a first time builder, more so with an engineering background.

Abs (listening to Harry Manx right now)

My first build was a project speaker in a now defunct Australian electronics hobby magazine; a tow way with 8" and 1" Vifa's, now both obsolete. While I liked them, it wasn't until I made one active that I found something much better. When I converted them to three way actives, I found a really good system.

With many good drivers around, together with DSP such as the miniDSP and class D amps, a reasonably low cost and good set of speakers is not all that difficult to achieve, even for a first time builder, more so with an engineering background.

Abs (listening to Harry Manx right now)

My mistake - I forgot to calculate for 2 speakers. Doh.

Also hadn't heard about 2m=farfield SPL's before. That's helpful. Thanks sreten.

http://www.pispeakers.com/ssdm_99.pdf

Hi,

The above is a good read if your into that sort of thing.

Also covers the effect of directivity on near / far field.

rgds, sreten.

Hi,

FWIW whilst I can see the appeal of the ZD5 I'd say you'd

need some experience to know that they are the right

speakers for you. And whilst it has the best drivers at

reasonable cost Zaph had measured at the time, some

drivers do approach the Scanspeaks at lower cost.

In terms of a speaker design the ZD5 is a bit extreme,

rather than a consummate all rounder. Like I said

earlier using a 11L Vas driver in 14L for sealed and

25L vented is not ideal, your accepting compromise

just to use that little extra the 5" driver provides.

However pretty much, a good 6.5" driver is a better

choice that a 5" for an all round speaker, and far

more suitable for an up to 30L tall thin floorstander.

Note that PC's line of Totem clones started off with

the VIC-20, which used a Scanspeak 8545K and

in the TRS-80 design he basically suggests that

it really doesn't provide the extra performance to

justify its extra cost compared to other options.

The Amiga is high value. TBH at extra cost

I really like the look of the ZX Spectrum :

https://sites.google.com/site/undefinition/zx-spectrum

YMMV but I think its a less compromised design than

the ZD5 and a better allrounder. One thing for sure IMO

is it has what I would call a nice bass alignment, tight

and deep, with a room friendly rounded bass roll-off.

However the general idea of a planar tweeter really has to

appeal a lot as the Neo 3 is not a very high value tweeter.

Zaph|Audio

rgds, sreten.

FWIW whilst I can see the appeal of the ZD5 I'd say you'd

need some experience to know that they are the right

speakers for you. And whilst it has the best drivers at

reasonable cost Zaph had measured at the time, some

drivers do approach the Scanspeaks at lower cost.

In terms of a speaker design the ZD5 is a bit extreme,

rather than a consummate all rounder. Like I said

earlier using a 11L Vas driver in 14L for sealed and

25L vented is not ideal, your accepting compromise

just to use that little extra the 5" driver provides.

However pretty much, a good 6.5" driver is a better

choice that a 5" for an all round speaker, and far

more suitable for an up to 30L tall thin floorstander.

Note that PC's line of Totem clones started off with

the VIC-20, which used a Scanspeak 8545K and

in the TRS-80 design he basically suggests that

it really doesn't provide the extra performance to

justify its extra cost compared to other options.

The Amiga is high value. TBH at extra cost

I really like the look of the ZX Spectrum :

https://sites.google.com/site/undefinition/zx-spectrum

YMMV but I think its a less compromised design than

the ZD5 and a better allrounder. One thing for sure IMO

is it has what I would call a nice bass alignment, tight

and deep, with a room friendly rounded bass roll-off.

However the general idea of a planar tweeter really has to

appeal a lot as the Neo 3 is not a very high value tweeter.

Zaph|Audio

rgds, sreten.

Last edited:

very interesting , could you please list your cross over parametres?

watt of the resisters, and awg of the inductors.

thanks.

watt of the resisters, and awg of the inductors.

thanks.

Hello,

I am building a similar design (same drivers) but from Troels Gravesen, called Ellam XT.

Ellam-XT

Maybe you could check these. Crossover is simpler. Use cheaper component for the filter, Troels usually use usually very expensive components.

As a first project, I would recommand something cheaper.

For instance in french forums (HCFR) you have a few hitmaker which maybe are not discussed here :

DA990 (Peerless SDS134+Vifa DX25) :

An externally hosted image should be here but it was not working when we last tested it.

Enceinte 2 voies haute-fidélité | alexaudio

I have made one of these. Cost +/-130€ (110£)

There is also a floor standing version of these (crossover is different):

Gavroche :

Gavroche DX - Just DIY It !

Another project which have much success is Prima (Scanspeak 18w4434+D2608 91300) cost +/- 280€ (230£):

An externally hosted image should be here but it was not working when we last tested it.

Prima - Just DIY It !

You can adress your questions to the designers of these, they speak English. Troels Gravesen also answer Emails.

For DA990 and Prima, there is a French site which folow the kits and they can also do it for you :

speaker-kits wil audio - WilAudio

I also do my shopping there or at Europe-audio (NL).

Funny - the biggest thing concerning me if I decide to build the ZD5s - how to get a decent finish on those rounded corners.

No hope. If you make rounded corners, you must paint them. Veneering round cornesr is beyond our skill as far as you have to use the same sheet to cover side and faceplate.

That is also why you should consider a "cheap" design. You have to learn a bit before doing a 800€ design. You must learn to work with the rooter. Maybe you will have to make the equipment to make circles with the rooter yourself. After that, you will have to learn to have a descent finish just with paint. And if you want you can give veneering a try.

The little design I gave you "DA990" is really very clever and was developped by a professionnal (Recital Audio who sells speaker from 5000€ to 20000€.

qingcai said:very interesting , could you please list your cross over parametres?

watt of the resisters, and awg of the inductors.

thanks.

You mean for the Ellam XT device from Troels Gravesen?

Everything is listed there.

I just ordered ordinary capacitors poly there are no big values there.

For coils, the important one is the 1.2mH. I used non ferite cored 1 mm (3$) but you could try a air core 1.6mm (20$).

The tricky one is the 3 mH which could be expensive. But for this usage anything can do. You just have to be sure that the internal resister of coils+ the serial resister give a total of 9.2 ohms. I took a cored one 0.63mm + 8.2 ohm serial resister (nothing more is needed there.)

Interesting thing also for this design is that you can upgrade to a 3 way with the same drivers :

Ellam-FLEX-3W

For DA990 and Prima designs, refer to the BOM of Wilaudio.com (the site works also in English), BOM there were approved by designers.

The little design I gave you "DA990" is really very clever and was developped by a professionnal (Recital Audio who sells speaker from 5000€ to 20000€.

I wouldn't build a speaker with a crossover at 990Hz that's using a conventional tweeter. The DX25 can sustain a 2KHz LR4 crossover but not a full octave lower without limiting SPL or increasing distortion. See here: Zaph|Audio

The reasoning that the designer put for the crossover point is ridiculous (my rough translation): between 500Hz and 1KHz the frequency response of the Peerless rise from 83dB to 86.5dB (+3.5dB), and this rise could be a problem for the tonal balance if not taken into account. Unfortunately a conventional crossover is not able to solve this problem <snip>.

Frankly, this is the baffle step effect and can be simply compensated by using an appropriate coil. See for example here: Zaph|Audio specifically the transfer function graph: http://www.zaphaudio.com/audio-speaker17-modeled-transferfunction.gif

Ralf

This is not my design. I can just say that it work very well and that we have built more than fifty of these and everybody is happy with them. Nobody seems to have burn a tweeter yet.

The cross over point is very low. In the floorstanding device "Gavroche" (other designer), they took the crossover point higher (1800hz) and they seem to keep the same overal quality and tonal balance. Anyway, the limitation of this speaker is the woofer in term of power.

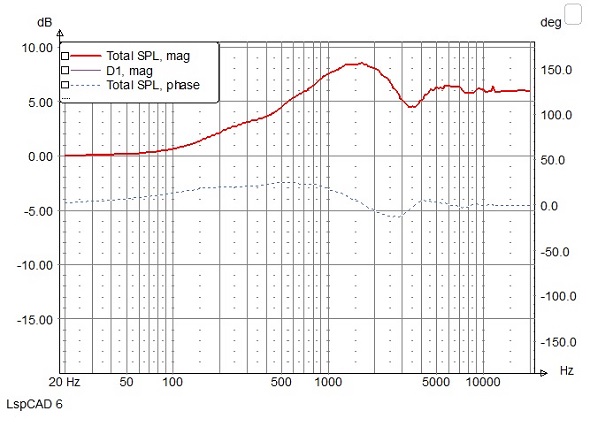

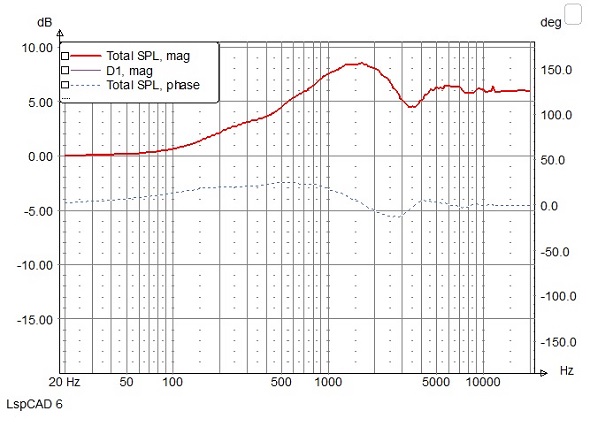

Distorsion seems low and not comming frow the tweeter :

The floorstanding device was first developped with the XT25 which is better on the paper but was far less good in real.

I will not discuss further the technical aspects of this speaker. Just say it is a realy good one and we are a lot to say so.

The cross over point is very low. In the floorstanding device "Gavroche" (other designer), they took the crossover point higher (1800hz) and they seem to keep the same overal quality and tonal balance. Anyway, the limitation of this speaker is the woofer in term of power.

Distorsion seems low and not comming frow the tweeter :

The floorstanding device was first developped with the XT25 which is better on the paper but was far less good in real.

I will not discuss further the technical aspects of this speaker. Just say it is a realy good one and we are a lot to say so.

Enceinte 2 voies haute-fidélité | alexaudio

Hi,

The above is a fine example of a halfbaked design. I cannot

see any attempt to address far field baffle step issues. It

might work well as a desktop nearfield at the limited

volumes needed not pushing the tweeter too hard.

Gavroche DX - Just DIY It !

The above floorstanding version has the baffle step

problem illustrated as plain as day on the page, and

then goes on to absolutely nothing about it, except

for compensation of the hump > 1KHz.

If its not clear for a bassmid that does 86dB into half space, the resulting

speaker should be under 83dB say 82dB for the broad sensitivity.

Refusal to "further discuss" half baked design is pointless.

Both designs only address the typical baffle step hump

and ignore the general bafflestep transition that occurs.

However they are cheap and cheerful, and many commercial

speakers (especially AV) do exactly the same so its not terrible.

Same with the more "boombox" bass alignments.

Neither version would remotely compete with the Amiga.

rgds, sreten.

Its quite clear you can massage the hump into a 4th order

acoustic rolloff around 2KHz with some x/o design skills,

and avoid the major issues of the tweeter, as in the Amiga.

Hi,

The above is a fine example of a halfbaked design. I cannot

see any attempt to address far field baffle step issues. It

might work well as a desktop nearfield at the limited

volumes needed not pushing the tweeter too hard.

Gavroche DX - Just DIY It !

The above floorstanding version has the baffle step

problem illustrated as plain as day on the page, and

then goes on to absolutely nothing about it, except

for compensation of the hump > 1KHz.

If its not clear for a bassmid that does 86dB into half space, the resulting

speaker should be under 83dB say 82dB for the broad sensitivity.

Refusal to "further discuss" half baked design is pointless.

Both designs only address the typical baffle step hump

and ignore the general bafflestep transition that occurs.

However they are cheap and cheerful, and many commercial

speakers (especially AV) do exactly the same so its not terrible.

Same with the more "boombox" bass alignments.

Neither version would remotely compete with the Amiga.

rgds, sreten.

Its quite clear you can massage the hump into a 4th order

acoustic rolloff around 2KHz with some x/o design skills,

and avoid the major issues of the tweeter, as in the Amiga.

Last edited:

I am okay with a router - not a problem there.

As for veneering, I am re-covering my tired old Kef 35s this week. I did consider cutting my own veneer, but decided to cheat by buying the iron-on stuff. I am looking forward to seeing the finished result, and learing from any mistakes made.

As for thinking I was going to be able to veneer rounded cornes in 3 dimensions - dont worry. I know better than that.

I realise that simply sanding a radius is difficult when knocking down a paint finish. Too easy to sand in a flat or a ripple.

As for veneering, I am re-covering my tired old Kef 35s this week. I did consider cutting my own veneer, but decided to cheat by buying the iron-on stuff. I am looking forward to seeing the finished result, and learing from any mistakes made.

As for thinking I was going to be able to veneer rounded cornes in 3 dimensions - dont worry. I know better than that.

I realise that simply sanding a radius is difficult when knocking down a paint finish. Too easy to sand in a flat or a ripple.

A distortion graph without the methodology used to produce it is meaningless.Distorsion seems low and not comming frow the tweeter

But all this talk is meaningless, because the OP is after a quality stand mount sound and the Peerless 830656 IMHO doesn't fit the bill. Make no mistakes, the Peerless is high value for the money, in fact I built a speaker with this woofer paired to a Vifa BC25TG15-04 tweeter (search here on diyaudio) and it sounds good. After building it I found a design from Cattaneo Acoustics and ASE with the same pair of drivers on the vifa.de site. The design is not on this site anymore but can be found here: http://www.nordic-audio.de/doku.php/magazin/startairkit_3r

The peerless goes pretty low considering its size.

A stand mount design that can be reused as a floor stand and doesn't need a subwoofer is here: CA18RLY/22TAF-G

Ralf

The CA18RLY/22TAF-G looks like a well documented project, and I do like the option of floorstanding or stand mounted, but I still have the same concern - would it be an upgrade from my Kef Q35s, or just different?

How would they compare against the Amigas?

How would they compare against the Amigas?

Funny - the biggest thing concerning me if I decide to build the ZD5s - how to get a decent finish on those rounded corners.

Yes, the round-overs are typically done on the baffle and then those are usually painted. The cabinets can still be veneered though, like the 1st picture below for eg. You could possibly think about using a 45 degree, straight cut chamfer instead of the round-over which although difficult can be veneered. I believe the round-over is a tiny bit better in terms of diffraction but I'm not at all sure that you would ever notice the difference.

I think at least 3 other possibilities exist too. The first is to cut the baffle smaller and then use 1/2" quarter round around the baffle edges but I personally don't care for that look at all.

Another method is to use real hardwood instead of mdf or plywood for the baffle, round-over the edges and then stain it a nice matching color to the cabs (second picture below - though aesthetically, I don't really like that combination much either). Some will warn that real wood may be prone to cracking which may or may not be true depending on the type of wood used and the humidity levels where you live. It may help to glue it to mdf backing - although I'm not really sure about that and then the real wood would need to be on all outside edges too. You might also need a planer and a joiner too depending on the wood you use, like this person did - Anarchy/Dayton TM build (see about page 3 or 4 I think). A variation would be something like the 3rd picture which is a lamination of bamboo plywood I think. Again, I think a darker stain wood be in order.

Lastly, I've seen some good results using vinyl wrap films that go on with a heat gun and bend and stretch without a problem. A carbon fiber pattern is perhaps used most often for baffles but some wood patterns look surprisingly good. See here for eg, Vinyl Wrap Films | Carbon Fiber Vinyl | Wood Grain Vinyl.

Attachments

I do like the combination of light and dark wood. I have often mixed dark walnut and maple in the past.

I have a 6" planer and surface so that would not be a problem, but would not use real wood for front as I would be concerned about it 'ringing' (if that is the right term).

I think trying to veneer a chamfer is probably a bit too ambitious, so for now, I will keep to painting if that is the way I go.

I have a 6" planer and surface so that would not be a problem, but would not use real wood for front as I would be concerned about it 'ringing' (if that is the right term).

I think trying to veneer a chamfer is probably a bit too ambitious, so for now, I will keep to painting if that is the way I go.

I do like the combination of light and dark wood. I have often mixed dark walnut and maple in the past.

I have a 6" planer and surface so that would not be a problem, but would not use real wood for front as I would be concerned about it 'ringing' (if that is the right term).

Make sure you read through that speaker's thread then. There is some very good info in there especially about finishing methods.

In terms of ringing, there are ways around that (not that I'm sure it would even be an issue with hardwoods to start off with). But I was going to suggest a thicker baffle than 3/4" anyway. So here you could use something like 3/4" of real wood as the outside baffle (with rounded edges) and then glue that up to a 1/2" or 3/4" panel of MDF or good quality plywood that would sit inside the cabinet. Extend the cabinet depth the extra 1/2" or 3/4" to maintain the same internal volume and make sure the internal cut-out around the driver is well chamfered. That will be one dead front baffle. And there is something to be said for the aesthetics of a natural wood grain front baffle.

You could also take that a step further and make a constrained layer laminate by using a visco-elastic glue or similar that stays soft after drying which helps to absorb vibrations and sound. Or another trick is to attach the front baffle to the rear baffle with threaded rods. Crank those up and now the front baffle is under tension and is even less likely to ring. This is the method that I used for my build. It also has the advantage of doing the same thing to the side walls when you use curved sides. And you have access to the inside of the speaker at any time without any unsightly screws on the front.

I think trying to veneer a chamfer is probably a bit too ambitious, so for now, I will keep to painting if that is the way I go.

If you are going to be working with some veneer with your Kef's anyways and if you have a little bit left over, why don't you try veneering the face and some chamfers on a scrap piece of wood or 2 and find out. You might surprise yourself. I've only done a little bit of veneering so I'm no expert, but when you stop to think about it, there really isn't that much difference between veneering a 90 degree edge and a 45 degree one. Cut and sand both of them. Tape on 1 side can be your friend. Or maybe someone more experienced can add more?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- First build - considering ZD5.