I’ll start this off by saying that I will never build another system without a wave guide. If there are any downsides, I don’t see them.

EDIT: Before you dismiss this build because of the drivers used, you should take a look at just how much a wave guide lowers distortion (as much as 25db for F2 at 2000hz).

Some arent giving the wave guide's contribution its credit of how much it lowers distortion. Using a cap on any tweeter with a wave guide lowers distortion under the level of a bare 1" dome. I dont have measurement equipment but the way the XT25 is used here counters any statement about its low end distortion. Now that I know how Dave Pellegrene's wave guides sound and how easy they are to attach to many tweeters, I will build a system using the best available parts with no costs cut.

To illustrate for others who aren't aware of Zaph's tests for wave guides added to a tweeter..............

This is the Seas 27-TDFC bare response

This is the lift with a small 6" wave guide (I used a 8" wide for the XT25 = more low end lift)

This is the response with a 3.3 cap on it:

Here is the bare tweeter distortion plot

Here is the distortion plot with guide and cap. The F2 distortion is down by 25db at 2000hz and the response is again flat on the tweeter. Its not just low in frequency. Since the harmonics generate the noise up top that theyre based on, the F2 is down 15db from 6-10k Hz. Whats really interesting is that the higher order distortion is based on whats happening from the low end hiccups and thus the F4 and F5 is sent to the floor on the top of the range. Active crossover uses can use any slope they want countering the phase issues electronically. The roll off approximates an LR2. I dont know how to build passives but if you can then increase the crossover to LR4 from 1800 or so, the low end issues are off the map including the res freq ringing like a bell.

As you can see the resulting response once back to flat has lower distortion by 25db. Once back to flat, I can apply any slope crossover to the lower distortion XT25 as its an active system. The resonant frequency ringing is also lowered over 30db. The dispersion with a wave guide is now wall to wall as the off axis response is not falling off much even at 45 degrees off axis. It also moves the acoustic center back to match your midbass. This post is to show how wave guides improve just about everything.

Since I already owned a DCX2496 for the sub cross, adding another amp for active 2 way mains was pretty cheap taking into account how much higher order crossover costs to build especially when they don’t come out good which is most of mine. For me it’s a matter of pushing buttons and turning a knob. Having the ability of 8th order electrical with phase/time alignment is priceless to me. I can shift frequency and try many slopes so have at it.

This project grew from wanting a better home theater main speaker using two drivers I like very much that I already owned. The RS180 from Dayton is a great mid-bass driver. It has a very clean low end and its really cheap. This system uses a second midbass unit to increase power handling to play louder and cleaner and it negates the need for BSC in the crossover. That makes it a very sensitive speaker. It’s Achilles heal is that it cant play too high in frequency because exciting 3000hz causes 2nd and 3rd harmonics double peaks in the 6-9K range that will have you running for the Tylenol. Zaph used these in his tower speakers crossed at 850 2nd order. By 3400 his RS180s are down 24db, mine are 1700 LR4 so they are also down 24db but by 6000 and 9000 My RS180s and much lower in level so the break up is off the radar. The tweeter I love is the cheap XT25-60 which is superior to the XT25tg30 in every way. Its more efficient, has a cleaner low end, and is only a few dollars more. The XT25 is reference level highs but it also has an Achilles heal that it cant play very low in frequency due to its rising distortion under 2k coupled with an under damped resonant frequency that rings like a bell at 600hz.

These two unlikely mates can work quite well together if you add in one more ingredient: a wave guide. I have so wanted to use the XT25 with a wave guide because it seems to like them. One man who made wave guides more reasonable to use is Dave Pellegrene. His website is located at:

acoustic waveguides

I chose the 8x5 unit for limited vertical but excellent improved horizontal dispersion although I hear no drop in highs standing up as I did with the bare XT25. Horizontal dispersion is wall to wall. I lived with the XT25 for quite some time. Its night and day.

The rear mounting plate that Dave makes which makes it so easy.

The tweeter with its faceplate removed with the Dave supplied studs to bolt up the guide. Make sure you get studs that bottom out in the tweeter body or you will have the stud turn as you try to tighten the nut. Dave sent me out longer ones when I brought the problem to his attention. He was great to deal with.

All together and a little bit of sealant to assure an airtight fit. I know I have one because its a sealed box with movement on one mid bass as I push the other. This is essentially now a $70 tweeter with industry leading dispersion and low disrtion on the low end. The tweeter is 35 as is the wave guide. Its worth every penny.

A secondary benefit is that the wave guide allows a lower crossover point with the same power handling but lower distortion. Moving the crossover point to 1700hz LR4 with a notch on the 600hz res frequency allows a better utilization of the RS180’s abilities within its limitations. The speaker is an active unit but I’m sure others can develop a passive crossover that will make it usable to many. I also use a notch up at the twin peaks. Feel free to comment on the crossover and other areas of improvement if you think it will help others. I’m no guru in this department.

A 3rd benefit is that this waveguide moves the acoustic center back to be near perfect with the RS180. This is a bigger benefit to passive crossovers.

The response with the XT25 and this waveguide. It looks to be about an 10db lift at 2000 so a cap at 6k or so brings it back down along with the distortion. I always use a cap anyway to protect from DC from the amps being active. I still had a slight 3db peak around 3500-4000 so I may try a smaller cap. For now, I just have EQ. This is the Pellegrene Acoustics supplied freq response graph and polar response graph.

The enclosures are standard MDF units that are ¾” thick on the sides and 1.25” thick on the front and rear to allow for counter sinking.

I usually over do the thickness on my cabinets so this time I’m trying to keep it down to a mild 100lbs. The dimensions are 45.5” high not counting the granite bases I had made. My home theater has a 16’ diag screen and I need a higher perspective than some applications of others. I sit about 12 feet from the speakers and vertical dispersion is fine with the tweeters actual position at 38”.

The finish of the cabinets use Dave Pellegrene’s trench method for making butt joints in MDF disappear. The original article for the trench method is here: https://plus.google.com/photos/104034261276506533670/albums/5427401701588472609?banner=pwa

Autobody filler on the trenched seams. I put a beveled edge on so the filler will go to the new routed edge afterward.

Bottom plate to make the speaker appear to be floating over the granite bases. Note the beveled edges and how the trench method moved the seam into the bevel.

Trial fit for counter sinking and here you see my grills that have cutouts for the drivers just behind them. The grills are not very invasive on the sound. I can't hear a difference.

The finish info though is a long time quest for many. In my case I used the trench method to get the seams blended with Rage auto body filler. Its pretty creamy to use compared to others. Avoid Bondo brand. After Rage sets for about 10 mins start getting the big stuff off with 60-80 grit paper. Work on one side at a time. If you let the filler sit for too long it will be a week of sanding to get it smooth. Ignore people telling you to use the softer filler as the main filler. Its not strong. After the trenches are filled I completely covered the entire surface of the speaker with the Rage body filler for a skim coat. It creates a seamless finish more likely to resist showing through the auto quality paint job I planned to do to it. It’s a ton of work but you will get out of it what you put into it. I wasn’t looking to cut corners. Ultimately I decided to use Duratex instead of paint. In a front projection home theater, the reflective paint would be too much light.

A warning on Duratex. It doesnt stick to Zinsser 123 shellac primer well during application. Once dried its fine but it spreads differently and looks like a seam where is none. I used the Zinsser because it was initially going to get an automotive paint finish. My next pair will have that.

Drivers mounted in finished cabinets

Complete with grills on. I had name plates made up for them. I named my 'speaker company' when I was 12...Axis. It was because of off-axis sound.

Granite bases:

Rear shot showing seamless edges. This was the side with all the seams. Once primered, you cant tell its a seam. The trench method works.

Sound: The tweeter dispersion is unreal. The sweet spot is anywhere in the room for highs. It doesn’t seem to roll off even at 60 degrees off axis. Standing anywhere in the room is the same too. Height doesn’t seem to affect dispersion in my application. I use Crown 600XLS amps for the highs and mids. The clip lights blink and the power handling is solid. There is also no sign of strain.

Crossover:

I tried 4th order electrical and 8th order electrical. Once I have the DCX2496 adjust the time alignment/phase, I cant tell a difference 4th/8th at 1700hz. An 8" wide guide would work down to 1700 so I chose that frequency (13560/8). I vary it from 1500 to 2000 and there is no real difference. I stayed wth 4th for the power handling. To cut the top end of the lower midbass, I used a 4.0 iron core inductor and the tweeter has a 4.7 clarity cap on it to level off the rising low end of the waveguide. The width of the baffle really calls for a 450hz cut off for the lower midbass but there was a peak there so I used a bigger inductor. I guess that’s then 5th order electrical on the tweeter? I had non-inverting polarity on the drivers and there was a deep null at the cross that would move if I turned the knob to change the cross freq. Once I had the DCX auto adjust for phase, it was gone. I would have been lost on the build without the Behringer.

My Home theater with a 16 foot diag screen. My subs are 4 15" TC sounds powered by two bridged Peavey 4080hz amps which bench test to 4400watts.

I’m really happy with the results. I would like to replace all my other speakers in my house with waveguide systems. I will go for more sensitivity by finding an 8” midbass for a 1500 cross. I am also thinking about compression drivers if the quality of sound is there. Being able to cross at 1000hz would open up the door to huge possibilities in efficiency with 2 10's or 2 12's. The BMS drivers look good if the SQ is there. Another option is a Geddes speaker kit because a genius already did the work. I had these drivers already so I built this system to experience wave guides first. I'm sold.

Dave Pellegrene get ready for my next order.

Thanks for reading.

EDIT: Before you dismiss this build because of the drivers used, you should take a look at just how much a wave guide lowers distortion (as much as 25db for F2 at 2000hz).

Some arent giving the wave guide's contribution its credit of how much it lowers distortion. Using a cap on any tweeter with a wave guide lowers distortion under the level of a bare 1" dome. I dont have measurement equipment but the way the XT25 is used here counters any statement about its low end distortion. Now that I know how Dave Pellegrene's wave guides sound and how easy they are to attach to many tweeters, I will build a system using the best available parts with no costs cut.

To illustrate for others who aren't aware of Zaph's tests for wave guides added to a tweeter..............

This is the Seas 27-TDFC bare response

This is the lift with a small 6" wave guide (I used a 8" wide for the XT25 = more low end lift)

This is the response with a 3.3 cap on it:

Here is the bare tweeter distortion plot

Here is the distortion plot with guide and cap. The F2 distortion is down by 25db at 2000hz and the response is again flat on the tweeter. Its not just low in frequency. Since the harmonics generate the noise up top that theyre based on, the F2 is down 15db from 6-10k Hz. Whats really interesting is that the higher order distortion is based on whats happening from the low end hiccups and thus the F4 and F5 is sent to the floor on the top of the range. Active crossover uses can use any slope they want countering the phase issues electronically. The roll off approximates an LR2. I dont know how to build passives but if you can then increase the crossover to LR4 from 1800 or so, the low end issues are off the map including the res freq ringing like a bell.

As you can see the resulting response once back to flat has lower distortion by 25db. Once back to flat, I can apply any slope crossover to the lower distortion XT25 as its an active system. The resonant frequency ringing is also lowered over 30db. The dispersion with a wave guide is now wall to wall as the off axis response is not falling off much even at 45 degrees off axis. It also moves the acoustic center back to match your midbass. This post is to show how wave guides improve just about everything.

Since I already owned a DCX2496 for the sub cross, adding another amp for active 2 way mains was pretty cheap taking into account how much higher order crossover costs to build especially when they don’t come out good which is most of mine. For me it’s a matter of pushing buttons and turning a knob. Having the ability of 8th order electrical with phase/time alignment is priceless to me. I can shift frequency and try many slopes so have at it.

This project grew from wanting a better home theater main speaker using two drivers I like very much that I already owned. The RS180 from Dayton is a great mid-bass driver. It has a very clean low end and its really cheap. This system uses a second midbass unit to increase power handling to play louder and cleaner and it negates the need for BSC in the crossover. That makes it a very sensitive speaker. It’s Achilles heal is that it cant play too high in frequency because exciting 3000hz causes 2nd and 3rd harmonics double peaks in the 6-9K range that will have you running for the Tylenol. Zaph used these in his tower speakers crossed at 850 2nd order. By 3400 his RS180s are down 24db, mine are 1700 LR4 so they are also down 24db but by 6000 and 9000 My RS180s and much lower in level so the break up is off the radar. The tweeter I love is the cheap XT25-60 which is superior to the XT25tg30 in every way. Its more efficient, has a cleaner low end, and is only a few dollars more. The XT25 is reference level highs but it also has an Achilles heal that it cant play very low in frequency due to its rising distortion under 2k coupled with an under damped resonant frequency that rings like a bell at 600hz.

These two unlikely mates can work quite well together if you add in one more ingredient: a wave guide. I have so wanted to use the XT25 with a wave guide because it seems to like them. One man who made wave guides more reasonable to use is Dave Pellegrene. His website is located at:

acoustic waveguides

I chose the 8x5 unit for limited vertical but excellent improved horizontal dispersion although I hear no drop in highs standing up as I did with the bare XT25. Horizontal dispersion is wall to wall. I lived with the XT25 for quite some time. Its night and day.

The rear mounting plate that Dave makes which makes it so easy.

The tweeter with its faceplate removed with the Dave supplied studs to bolt up the guide. Make sure you get studs that bottom out in the tweeter body or you will have the stud turn as you try to tighten the nut. Dave sent me out longer ones when I brought the problem to his attention. He was great to deal with.

All together and a little bit of sealant to assure an airtight fit. I know I have one because its a sealed box with movement on one mid bass as I push the other. This is essentially now a $70 tweeter with industry leading dispersion and low disrtion on the low end. The tweeter is 35 as is the wave guide. Its worth every penny.

A secondary benefit is that the wave guide allows a lower crossover point with the same power handling but lower distortion. Moving the crossover point to 1700hz LR4 with a notch on the 600hz res frequency allows a better utilization of the RS180’s abilities within its limitations. The speaker is an active unit but I’m sure others can develop a passive crossover that will make it usable to many. I also use a notch up at the twin peaks. Feel free to comment on the crossover and other areas of improvement if you think it will help others. I’m no guru in this department.

A 3rd benefit is that this waveguide moves the acoustic center back to be near perfect with the RS180. This is a bigger benefit to passive crossovers.

The response with the XT25 and this waveguide. It looks to be about an 10db lift at 2000 so a cap at 6k or so brings it back down along with the distortion. I always use a cap anyway to protect from DC from the amps being active. I still had a slight 3db peak around 3500-4000 so I may try a smaller cap. For now, I just have EQ. This is the Pellegrene Acoustics supplied freq response graph and polar response graph.

The enclosures are standard MDF units that are ¾” thick on the sides and 1.25” thick on the front and rear to allow for counter sinking.

I usually over do the thickness on my cabinets so this time I’m trying to keep it down to a mild 100lbs. The dimensions are 45.5” high not counting the granite bases I had made. My home theater has a 16’ diag screen and I need a higher perspective than some applications of others. I sit about 12 feet from the speakers and vertical dispersion is fine with the tweeters actual position at 38”.

The finish of the cabinets use Dave Pellegrene’s trench method for making butt joints in MDF disappear. The original article for the trench method is here: https://plus.google.com/photos/104034261276506533670/albums/5427401701588472609?banner=pwa

Autobody filler on the trenched seams. I put a beveled edge on so the filler will go to the new routed edge afterward.

Bottom plate to make the speaker appear to be floating over the granite bases. Note the beveled edges and how the trench method moved the seam into the bevel.

Trial fit for counter sinking and here you see my grills that have cutouts for the drivers just behind them. The grills are not very invasive on the sound. I can't hear a difference.

The finish info though is a long time quest for many. In my case I used the trench method to get the seams blended with Rage auto body filler. Its pretty creamy to use compared to others. Avoid Bondo brand. After Rage sets for about 10 mins start getting the big stuff off with 60-80 grit paper. Work on one side at a time. If you let the filler sit for too long it will be a week of sanding to get it smooth. Ignore people telling you to use the softer filler as the main filler. Its not strong. After the trenches are filled I completely covered the entire surface of the speaker with the Rage body filler for a skim coat. It creates a seamless finish more likely to resist showing through the auto quality paint job I planned to do to it. It’s a ton of work but you will get out of it what you put into it. I wasn’t looking to cut corners. Ultimately I decided to use Duratex instead of paint. In a front projection home theater, the reflective paint would be too much light.

A warning on Duratex. It doesnt stick to Zinsser 123 shellac primer well during application. Once dried its fine but it spreads differently and looks like a seam where is none. I used the Zinsser because it was initially going to get an automotive paint finish. My next pair will have that.

Drivers mounted in finished cabinets

Complete with grills on. I had name plates made up for them. I named my 'speaker company' when I was 12...Axis. It was because of off-axis sound.

Granite bases:

Rear shot showing seamless edges. This was the side with all the seams. Once primered, you cant tell its a seam. The trench method works.

Sound: The tweeter dispersion is unreal. The sweet spot is anywhere in the room for highs. It doesn’t seem to roll off even at 60 degrees off axis. Standing anywhere in the room is the same too. Height doesn’t seem to affect dispersion in my application. I use Crown 600XLS amps for the highs and mids. The clip lights blink and the power handling is solid. There is also no sign of strain.

Crossover:

I tried 4th order electrical and 8th order electrical. Once I have the DCX2496 adjust the time alignment/phase, I cant tell a difference 4th/8th at 1700hz. An 8" wide guide would work down to 1700 so I chose that frequency (13560/8). I vary it from 1500 to 2000 and there is no real difference. I stayed wth 4th for the power handling. To cut the top end of the lower midbass, I used a 4.0 iron core inductor and the tweeter has a 4.7 clarity cap on it to level off the rising low end of the waveguide. The width of the baffle really calls for a 450hz cut off for the lower midbass but there was a peak there so I used a bigger inductor. I guess that’s then 5th order electrical on the tweeter? I had non-inverting polarity on the drivers and there was a deep null at the cross that would move if I turned the knob to change the cross freq. Once I had the DCX auto adjust for phase, it was gone. I would have been lost on the build without the Behringer.

My Home theater with a 16 foot diag screen. My subs are 4 15" TC sounds powered by two bridged Peavey 4080hz amps which bench test to 4400watts.

I’m really happy with the results. I would like to replace all my other speakers in my house with waveguide systems. I will go for more sensitivity by finding an 8” midbass for a 1500 cross. I am also thinking about compression drivers if the quality of sound is there. Being able to cross at 1000hz would open up the door to huge possibilities in efficiency with 2 10's or 2 12's. The BMS drivers look good if the SQ is there. Another option is a Geddes speaker kit because a genius already did the work. I had these drivers already so I built this system to experience wave guides first. I'm sold.

Dave Pellegrene get ready for my next order.

Thanks for reading.

Last edited:

Nice build SpinMonster,

I noticed the XT25 you have is an XT25BG60-04. I've not heard of that one. My graphs are with the XT25TG30. I wonder what the difference is?

Anyway the graph that you posted is of my older version. If you recall it took me an extra week to get these to you because I wanted to try the new guide I just developed for the SS D3004 AirCirc with the XT25. It mounted up and performed better then the old version so I've switched to it. the only difference is the adapter plate shape.

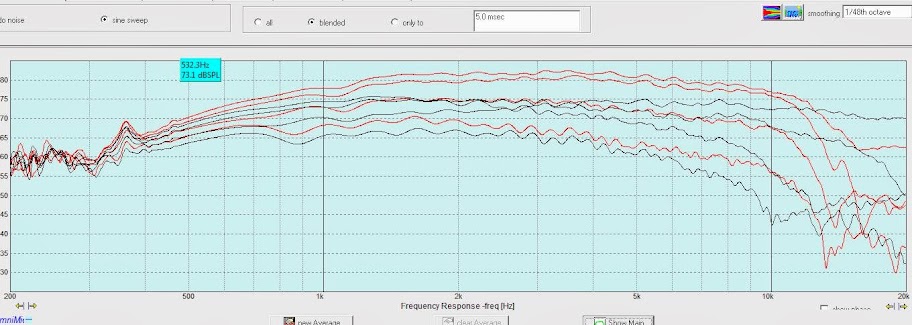

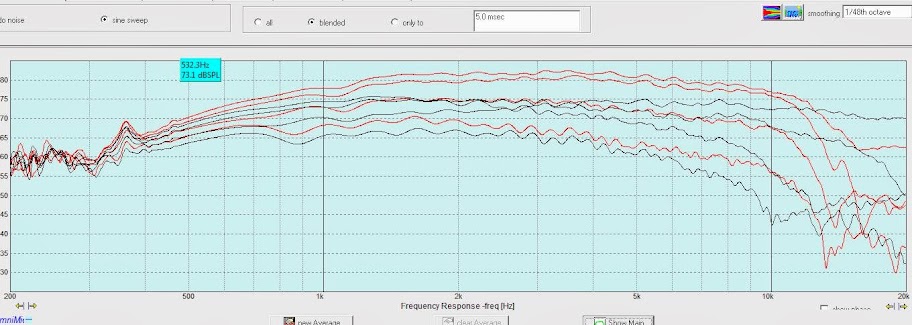

Here are the graphs with the new adapter plate on the XT25TG30 on a 10x14 baffle at 1 meter.

0-90 degrees on the horizontal axis at 10 degree increments.

This is the Flat baffle (black) vs the 8x5 waveguide (red) at 0,30,60 and 90 degrees horizontal axis.

Just curious did you dampen the back side of the guides at all? As I had mentioned there is a measurable difference. Just by applying denim insulation to the backside made a 1 to 1.5 db increase around the 3kHz area on one of my guides. I need to come up with a product that you could pour from the backside into the baffle cut out to stiffen them. Something like thin set or even epoxy would work. Possibly auto body putty? I guess the down side would be that you could no longer remove them.

Anyway glad you like the guides.

Dave

I noticed the XT25 you have is an XT25BG60-04. I've not heard of that one. My graphs are with the XT25TG30. I wonder what the difference is?

Anyway the graph that you posted is of my older version. If you recall it took me an extra week to get these to you because I wanted to try the new guide I just developed for the SS D3004 AirCirc with the XT25. It mounted up and performed better then the old version so I've switched to it. the only difference is the adapter plate shape.

Here are the graphs with the new adapter plate on the XT25TG30 on a 10x14 baffle at 1 meter.

0-90 degrees on the horizontal axis at 10 degree increments.

This is the Flat baffle (black) vs the 8x5 waveguide (red) at 0,30,60 and 90 degrees horizontal axis.

Just curious did you dampen the back side of the guides at all? As I had mentioned there is a measurable difference. Just by applying denim insulation to the backside made a 1 to 1.5 db increase around the 3kHz area on one of my guides. I need to come up with a product that you could pour from the backside into the baffle cut out to stiffen them. Something like thin set or even epoxy would work. Possibly auto body putty? I guess the down side would be that you could no longer remove them.

Anyway glad you like the guides.

Dave

Be careful with studs that bottom out. The steel plate on the tweeter is drilled through and over tightening the bolts can separate the plate from the magnet as it will act as a puller and the screws will push against the magnet in the tapped hole and break the adhesive bond.

Be careful with studs that bottom out. The steel plate on the tweeter is drilled through and over tightening the bolts can separate the plate from the magnet as it will act as a puller and the screws will push against the magnet in the tapped hole and break the adhesive bond.

As in the auto industry, studs bottoming entails nothing more that finger tightening them to be touching and not tool tightening them that they apply any pressure. There is no mechanical pressure being applied to the front plate of the tweeter.

Nice build SpinMonster,

I noticed the XT25 you have is an XT25BG60-04. I've not heard of that one. My graphs are with the XT25TG30. I wonder what the difference is?

Dave

The 60 is a 30 with a second magnet glued to the first one to increase efficiency.

This may work: Speaker Cabinet Coating - Acoust-X Sound Damping CoatingJust curious did you dampen the back side of the guides at all? As I had mentioned there is a measurable difference. Just by applying denim insulation to the backside made a 1 to 1.5 db increase around the 3kHz area on one of my guides. I need to come up with a product that you could pour from the backside into the baffle cut out to stiffen them. Something like thin set or even epoxy would work. Possibly auto body putty? I guess the down side would be that you could no longer remove them.

It would be cool if they had a small sample size like they do with duratex. I like duratex so I would try this.

I use dynamat because I own it already.

Be careful with studs that bottom out. The steel plate on the tweeter is drilled through and over tightening the bolts can separate the plate from the magnet as it will act as a puller and the screws will push against the magnet in the tapped hole and break the adhesive bond.

I cant edit my other response and I just caught what you said.

Studs have nuts that turn independent of the stud. Tightening a bolt isnt the same as a nut on a stud. Turning a bolt pushes the shaft down. Tightening a nut pulls the stud upward and doesnt turn it at all.

The reason a stud has to bottom out is so it doesnt turn as you turn the nut which is exactly what happened as I tried to tighten them. Being too short, the stud would go lower until there were no threads inside the nut and it went flush with the wave guide plate.

The design intent of the extra magnet is to provide shielding of stray magnetic fields, commonly called a bucking magnet. The increase in gain was unintentional, but we'll take whatever we can on that front 🙂The 60 is a 30 with a second magnet glued to the first one to increase efficiency.

I don't believe this is correct.The design intent of the extra magnet is to provide shielding of stray magnetic fields, commonly called a bucking magnet. The increase in gain was unintentional, but we'll take whatever we can on that front 🙂

The dual magnet version of the ring dome tweeter provides extra magnetic energy to increase the sensitivity and to extend the frequency response to above 40kHz. The additional volume from the second magnet also increases the size of the chamber, lowering the resonance frequency.

I don't believe this is correct.

I agree.

The distortion is also lower in the lower range.

The wave guide negates the 40k hz extension because it doesnt boost over 15K although I dont hear a difference in air on the top end vs the bare tweeter. It is by far my favorite tweeter now that 1500 and above is clean from the wave guide. Dispersion is now as good as it gets.

Based on the PMs I'm getting a clarification is in order.

The XT25tg60 is much cleaner on the low end than the XT25tg30. If you look for test for the sonus faber XT25tg61 which is also the same motor as the 60 and the Scan speak 2604/8330 you see the low end being far cleaner. With the wave guide and a cap a 1500 cross with a 440hz res peak is perfectly ok.

Forum members get it in their heads that the XT25tg30 has worse limitations, they dismiss the 60 as the same unit and it isnt. With a wave guide the 60 has none of those limitations.

The XT25tg60 is much cleaner on the low end than the XT25tg30. If you look for test for the sonus faber XT25tg61 which is also the same motor as the 60 and the Scan speak 2604/8330 you see the low end being far cleaner. With the wave guide and a cap a 1500 cross with a 440hz res peak is perfectly ok.

Forum members get it in their heads that the XT25tg30 has worse limitations, they dismiss the 60 as the same unit and it isnt. With a wave guide the 60 has none of those limitations.

Thanks for posting SpinMonster - I know lots of folks have XT25TG30-04s and no projects to use them in.

I don't believe this is correct.

Test it in FEMM, if you have a Hall sensor in your phone (most do) this can be directly measured around the periphery will help you understand the bucking action. Troels Gravesen has tested adding a bucking magnet to boost the spl often getting upwards of a 1.5dB gain. Not huge but better than nothing. The main reason for not much gain is the magnet is on the outside of the magnetic circuit atop of the T pole. Adding a ferrous metal can would help reduce stray fields a bit more. Mu metal should provide best shielding with a bucking magnet.

I'm not asking anyone to simply take my word for it, but am asking to test and read up on the subject.

Based on the PMs I'm getting a clarification is in order.

The XT25tg60 is much cleaner on the low end than the XT25tg30. If you look for test for the sonus faber XT25tg61 which is also the same motor as the 60 and the Scan speak 2604/8330 you see the low end being far cleaner. With the wave guide and a cap a 1500 cross with a 440hz res peak is perfectly ok.

Forum members get it in their heads that the XT25tg30 has worse limitations, they dismiss the 60 as the same unit and it isnt. With a wave guide the 60 has none of those limitations.

It still has rather highish distortion at the low end. The waveguide help reduce this and provides better low end reinforcement. Still to low of a crossover point for my tastes, not that I dislike the 60. It certainly does perform better than the 30 🙂

Face's quote applies to a double magnet speaker that have 2 magnets between metal plates. A bucking magnet is a magnet attacted outside a finished speaker.

A bucking magnet increases Bl by 3%.

A bucking magnet increases Bl by 3%.

The design intent of the extra magnet is to provide shielding of stray magnetic fields, commonly called a bucking magnet. The increase in gain was unintentional, but we'll take whatever we can on that front 🙂

This is absolutely correct by the way. There is some gap flux addition, but the main effect is stray field reduction. The front plate also gets saturated, which reduces flux modulation. It is a Band-Aid however since this technique is an expensive waste of magnet volume.

Why is there a Hall sensor in a cell phone? How can it be used as you indicate?

Face's quote applies to a double magnet speaker that have 2 magnets between metal plates. A bucking magnet is a magnet attacted outside a finished speaker.

A bucking magnet increases Bl by 3%.

Face's post was taken directly from the advertisement literature talking about the goal of the second magnet on the 60. The company's goal was to increase efficiency, lower res freq, and lower distortion. The fact that it reduces stray mag fields in the world of flat panel TVs isnt as important as it once was.

His post along with mine was to explain to Dave Pellegrene what the difference between the 30 and 60 were from the wave guide use perspective because Dave asked in post 2 for a clarification of what the 60 was.

All dave needed to know in terms of wave guides was that the 60 is a 30 with a second magnet on it, therefore the diaphragm and mounting are the same.

It still has rather highish distortion at the low end. The waveguide help reduce this and provides better low end reinforcement. Still to low of a crossover point for my tastes, not that I dislike the 60. It certainly does perform better than the 30 🙂

You arent giving the wave guide's contribution its credit of how much it lowers distortion. Using a cap on any tweeter with a wave guide lowers distortion under the level of a bare 1" dome. I dont have measurement equipment but the way the XT25 is used here counters any statement about its low end distortion. I think the lack of interest in this thread is that people saw the two drivers used and dismissed it as garbage. Maybe it is. All I know is I have a great sounding speaker free of the criticisms of these drivers. I figured it would have people take another look at waveguides. I'm not pushing these drivers. Now that I know how Dave's wave guides sound, I will build a system using the best available parts with no costs cut.To illustrate for others who aren't aware of Zaph's tests for wave guides added to a tweeter..............

This is the 27-TDFC bare response

This is the lift with a small 6" wave guide (I used a 8" wide for the XT25 = more low end lift)

This is the response with a 3.3 cap on it:

Here is the bare tweeter distortion plot

Here is the distortion plot with guide and cap. The F2 distortion is down by 25db at 2000hz.

No way the XT25 with a guide is worse low end distortion above 1700 than any bare tweeter after you reshape the low end to counter for the rising wave guide lift. Above 2500, the XT25's performance is already reference level. Its dispersion with a wave guide for me makes it as good as it gets. For some reason, likely its phase plug, makes it interact better with a wave guide than most tweeters. Once back to a flat response with the 8" guide and cap I used, I can apply any slope curve with active crossing and get a low end that is better than any bare tweeter. The power handling is unreal. I have an extra 10db from the guide so I need a fraction of a watt to hit the same SPL.

People just have it in for the XT25 because they read about its distortion and they dismiss it with generalized statements. Their loss. A wave guide and cap shaing the response back to flat lowers the noise at 2000hz 20db and the resonant frequency ringing in lower by something like 30db.

You cant just pop a 3.3 or 4 cap onto a bare 1" because it would be down 10db in its response in the low end. The 60 with a wave guide used like this is the equal of any 1" dome in distortion....or better.

Last edited:

***I think the lack of interest in this thread is that people saw the two drivers used and dismissed it as garbage.***

I doubt that's the case. It looks like a very nicely thought-out and executed project. What I find especially interesting is that the measurements seem to show that Dave's WG removes the actual problem I've heard from the Vifa and ScanSpeak ring radiators: extremely extremely narrow treble dispersion.

Now that I know how Dave's wave guides sound, I will build a system using the best available parts with no costs cut.

That, by contrast, I suspect that would end up disappointing. Not because it wouldn't be good, but because there wouldn't be much improvement from what you already have. Probably get more people on forums to ooh and aah if you're able to throw out brand names like Audio Technology, Accuton, Scan Revelator, etc, but ultimately speakers really boil down to three things: listening axis FR, dispersion, and output capability. Your current project looks well-sorted for a speaker of that size. I'd say be happy, and add multiple subs. 🙂

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- My first wave guide speaker....lots of pics