Re: Yes, nice tractix

Thank you for the compliment. It's a very nice sounding horn. But the good thing is the way the stand supports the horn. It's easy to make and would probably work for your tractrix horns too.

taotao said:Hey carpenter,

nice big horn. I guess something like you build, I'll do, too.

It must be moveable and stable (and of course, should look nice

Thank you.

Olaf

Thank you for the compliment. It's a very nice sounding horn. But the good thing is the way the stand supports the horn. It's easy to make and would probably work for your tractrix horns too.

Hi

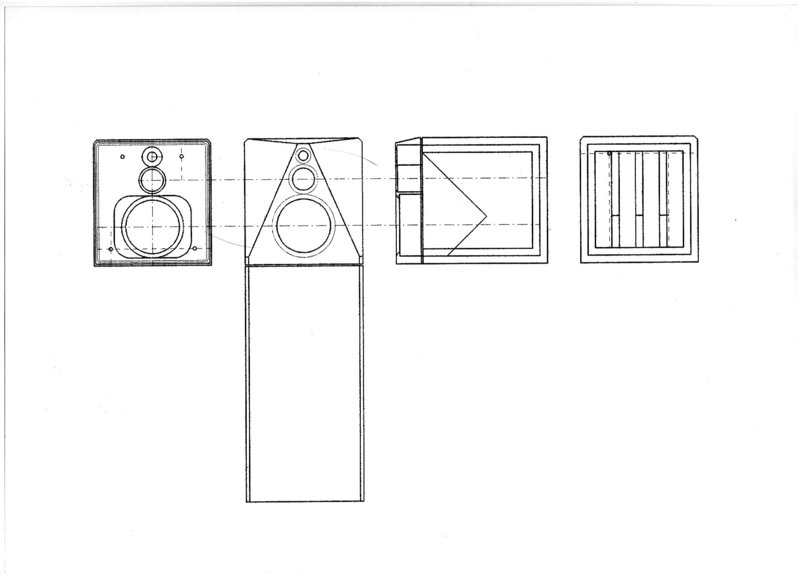

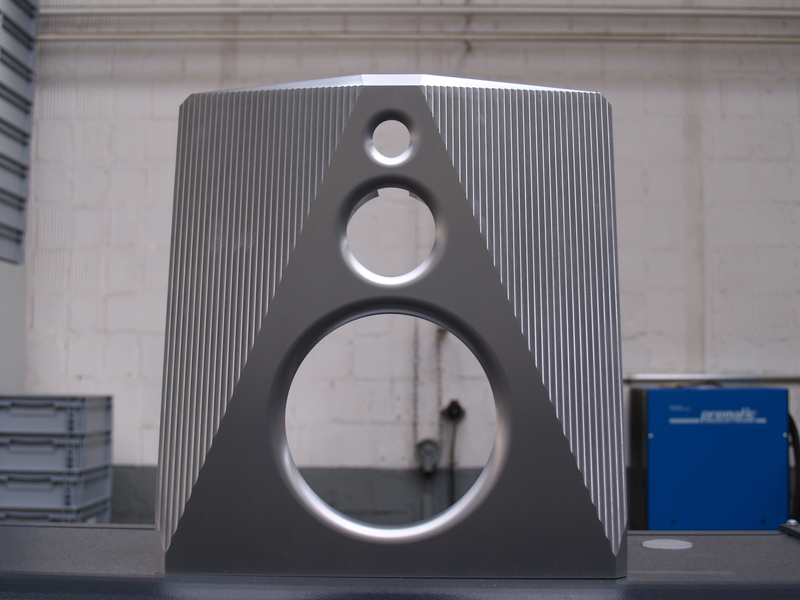

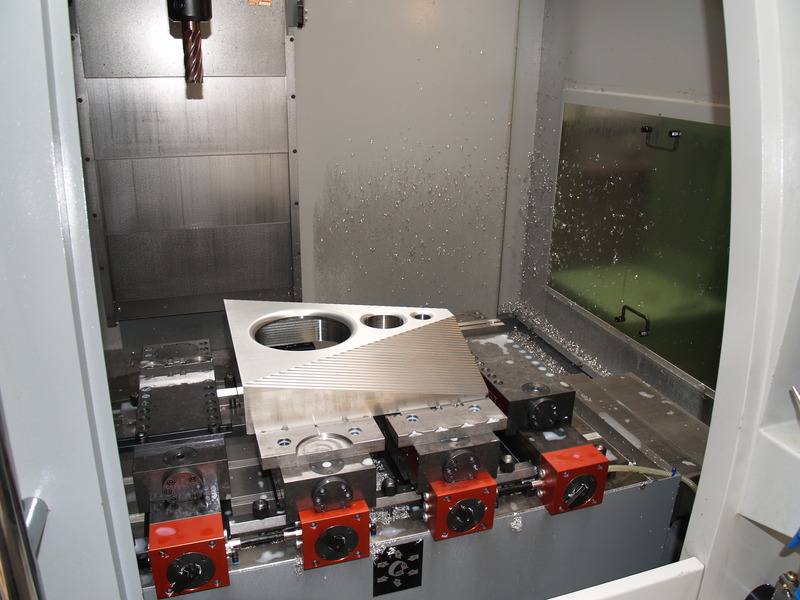

My new system

Digital aktiv 4 Way

more pics and description

http://www.diy-hifi-forum.de/forum/showthread.php?p=7353#post7353

Gustav

My new system

Digital aktiv 4 Way

more pics and description

http://www.diy-hifi-forum.de/forum/showthread.php?p=7353#post7353

Gustav

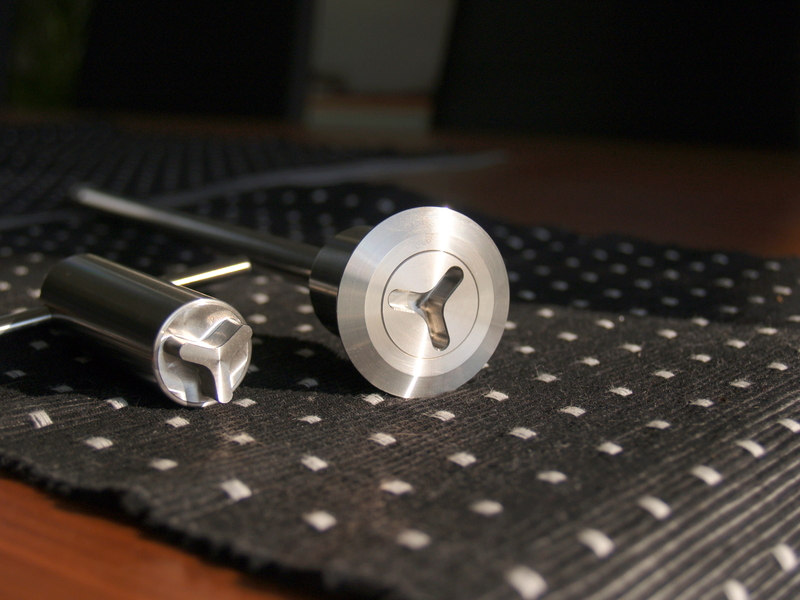

maxlorenz said:I want that machine tool for Xmas!!!

Charming speakers indeed.

Regards,

M

Max,

I haven't seen any posts from you in a while, is everything OK?

As for the tools, I'll take any duplicates that Santa leaves you by mistake.

Best Regards,

TerryO

Dear TerryO,

It is very kind of you.

Everything is very OK.

The pandemia led me little energy to DIY...

Appart a little secret project that takes the rest of my spare time

I'll share if it goes OK.

Best wishes,

M

Max, I haven't seen any posts from you in a while, is everything OK?

It is very kind of you.

Everything is very OK.

The pandemia led me little energy to DIY...

Appart a little secret project that takes the rest of my spare time

I'll share if it goes OK.

Best wishes,

M

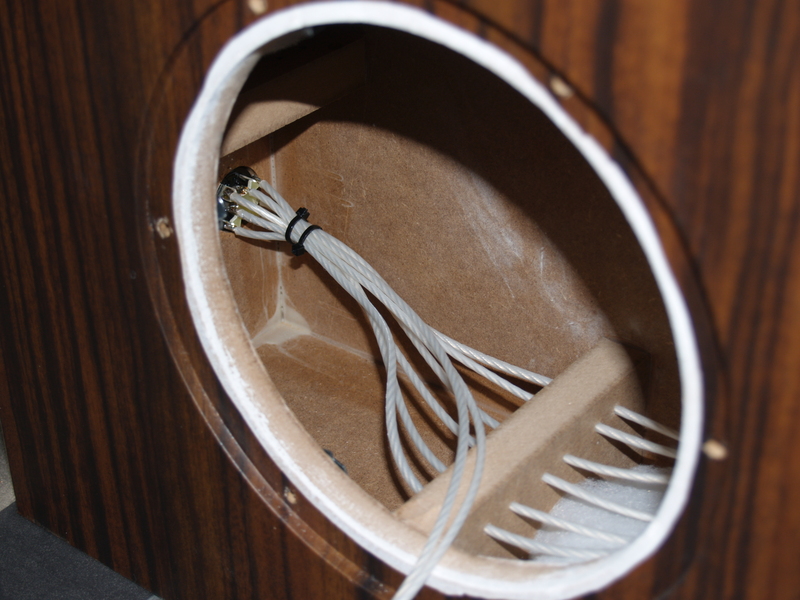

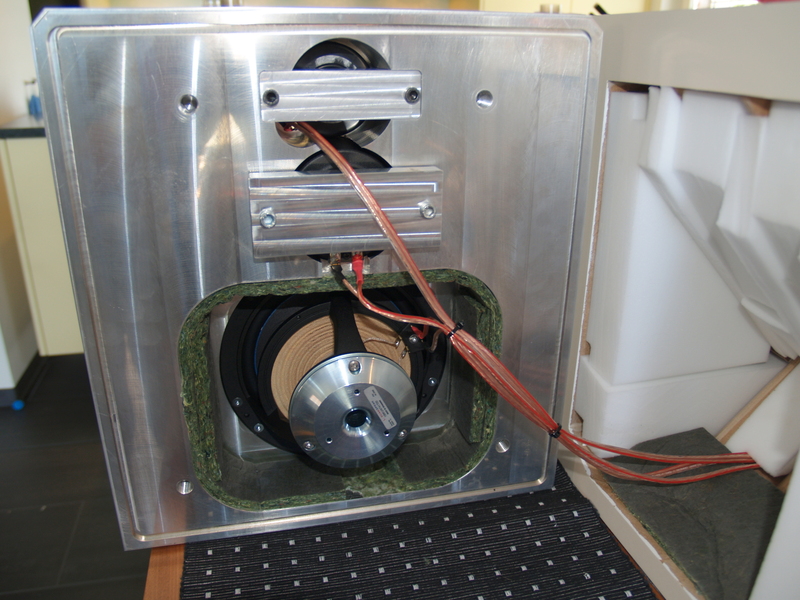

Here's my build: All-Seas 3-way construction using CD22RN4X for bass, CA18RLY for mids and the DXT tweeter. The mid is mounted in an acoustic resistance enclosure for cardioid radiation pattern. Crossover frequencies are 130 Hz LR24 and 2000 Hz LR12. The basses have their own amplifiers so the speaker is half-active.

Attachments

cnclld said:... The mid is mounted in an acoustic resistance enclosure for cardioid radiation pattern...

Very interesting, can you elaborate a little more? Thank you!

DorinD said:

Very interesting, can you elaborate a little more? Thank you!

The idea is to use the driver's back wave and attenuate and delay it to get the desired radiation pattern. This is done by the acoustical resistance in the ports on the sides on the speaker. The ports are damped with felt on the insides and their area is about 1*Sd. The enclosure is about 10 liters which I'm told might be a little large. I still get about 15 dB back attenuation trough the mid's operation range with this.

Technically this is the same as variovents and such. The only differences are in the ratios of acoustical component values. More theory can be found in the AES paper 4979 by Juha Backman: Theory of Acoustical Resistance Enclosures.

Acoustical resistance enclosures for polar pattern control is also used in commercial speakers by Amphion and Gradient in their largest floor standers.

cnclld said:

The idea is to use the driver's back wave and attenuate and delay it to get the desired radiation pattern. This is done by the acoustical resistance in the ports on the sides on the speaker. The ports are damped with felt on the insides and their area is about 1*Sd. The enclosure is about 10 liters which I'm told might be a little large. I still get about 15 dB back attenuation trough the mid's operation range with this.

Technically this is the same as variovents and such. The only differences are in the ratios of acoustical component values. More theory can be found in the AES paper 4979 by Juha Backman: Theory of Acoustical Resistance Enclosures.

Acoustical resistance enclosures for polar pattern control is also used in commercial speakers by Amphion and Gradient in their largest floor standers.

It's a more precise positioning of aperiodic "vents" to achieve the radiation pattern you want.

Aperiodic venting was first used to *decrease* enclosure volume

The best performance however is with large enclosure volumes where most of the system compliance relies on the driver and not the pressure from the enclosure. (..you can over-do this however if the system Qtc is much below .5. - where it becomes over-damped sounding depending on the pairing amplifier.) It's then further enhanced by adding mechanical resistance to the in box resonance (fb) of the driver - achieving: more linear mass controlled operation at and near resonance, decreasing phase departure and group delay, and decreasing impedance (..moving it closer to the driver's average). The disadvantage is an even more declining freq. response near and below fb when compared to a sealed system.

ScottG said:

It's a more precise positioning of aperiodic "vents" to achieve the radiation pattern you want.

There's more to it than vent positioning. The vent area, positioning, enclosure size and the amount of resistance in the ports all have their effect on the radiation pattern. In short, directional enclosures must be smaller and have less resistive ports than low-frequency enclosures to have enough output from the ports across the whole frequency range to control directivity.

I recommend the AES paper by Backman I referred to earlier. It is an interesting read.

- Home

- Loudspeakers

- Multi-Way

- System Pictures & Description