Here is a question that is pregnant to say the least. In unity type horns midrange drivers are entering a conical style horn from somewhere other than the throat. Given theoretically a perfect cone, what are the pitfalls of having a single say 1 inch compression driver enter this way, but as close to the apex as possible and make that nasty turn? Obviously there is a price to pay for this, I do understand this will not be without consequences, my question is can this be done with a single driver ala Econowave? I once owned some VOTT 2 way boxes that did make a 90 albeit from the throat entry and via the horn. After seeing and hearing some unity horns with multiple drivers I'm wondering if it might be possible to enter a conical horn with a single compression driver in this fashion, and yes I do have an extremely good reason for wanting to do this. Am I completely nuts for asking this one?

Last edited:

It's a very interesting box construction idea that will be non resonant by nature and includes the horn. If this idea pans out theoretically I will have something very cool. Another part of it includes corner horn loading the port only. This speaker will have construction simplicity, high efficienty, wide bandwidth.

Thank for the Paraline tip. Because of the use of active xover, I am willing to put up with some fr irregularitys as they will hopefully be tamed by DSP. What I won't give up though, is simplicity and efficiency. This must be a two way, two driver unit. Perhaps 3 way. I once owned an EV speaker that fired the mid driver 180 into a the cab which became the horn. This is what led me to khorns, and a love for efficiency. And this idea rolling in my head for years. I probably have logged thousands of hours in these forums researching this for the last couple of years so I can ask smarter stupid questions 0-:

Oh, yes it will (by nature) be rather, but not exceedingly large and will have RMAF. (That means "real man appeal factor" "Excuse me dear, but I almost thought I heard you say you objected to my speakers?" (-:

This will most certainly be a DIY thing for us not a commercial venture. As soon as I have a practical idea of how best to couple the driver to the conical horn I will post a very simple line drawing. This is a corner speaker that deals with a whole slew of imaging and speaker positioning issues in a practical manner, ideal for home theater and visually stunning ( Thus the "RMAF') ;-)

This will most certainly be a DIY thing for us not a commercial venture. As soon as I have a practical idea of how best to couple the driver to the conical horn I will post a very simple line drawing. This is a corner speaker that deals with a whole slew of imaging and speaker positioning issues in a practical manner, ideal for home theater and visually stunning ( Thus the "RMAF') ;-)

Last edited:

In case you haven't seen it, a long thread about Paralines: http://www.diyaudio.com/forums/multi-way/217298-square-pegs.html

I'm listening to Paralines I built right now mounted to a conical horn/waveguide and they're sounding pretty good. There is a lot of eq required though. There are ideas in that thread about using Paralines for vehicle apps that have the comp driver at a right angle to the waveguide.

I'm listening to Paralines I built right now mounted to a conical horn/waveguide and they're sounding pretty good. There is a lot of eq required though. There are ideas in that thread about using Paralines for vehicle apps that have the comp driver at a right angle to the waveguide.

Paralines are useful for line array and multiple driver use, but are peakier than the same driver mounted on a conical horn.Thank for the Paraline tip.

The offset mid drivers in a Synergy/Unity result in an acoustical high pass filter, a good thing. An acoustical HP on a HF driver is not a good thing

Right angle mounting of a HF driver can be done using the approach Dave Gunness used in the quad HF driver EV MT4 cabinets, (or the dual 1/2MT) but still results in a notch in the response.

Fixed broken quote

Fixed broken quoteParalines are useful for line array and multiple driver use, but are peakier than the same driver mounted on a conical horn.

FWIW if I was to start over I'd stick with the "traditional" Synergy design.

Here is a question that is pregnant to say the least. In unity type horns midrange drivers are entering a conical style horn from somewhere other than the throat. Given theoretically a perfect cone, what are the pitfalls of having a single say 1 inch compression driver enter this way, but as close to the apex as possible and make that nasty turn? Obviously there is a price to pay for this, I do understand this will not be without consequences, my question is can this be done with a single driver ala Econowave? I once owned some VOTT 2 way boxes that did make a 90 albeit from the throat entry and via the horn. After seeing and hearing some unity horns with multiple drivers I'm wondering if it might be possible to enter a conical horn with a single compression driver in this fashion, and yes I do have an extremely good reason for wanting to do this. Am I completely nuts for asking this one?

I think I have some measurements of what happens in my 'Homster' thread. The USD audio horns fire a compression driver straight in a 90 degree bend, about 5cm from the diaphragm.

As you can imagine, this creates a hell of a dip.

A Paraline might work for you, but might be over kill too. The Paraline pulls off four, count 'em FOUR bends by keeping the diameter of the horn so small, the wave can't even form.

But the Paraline *definitely* rolls off the highs a lot. But I'd rather have a nice smooth rolloff of the highs than a big fat dip.

Also check out Bruce Edgar's research on reflectors in horns, the articles are on Volvotreter's site.

At high frequencies a sharp turn is a problem...

An entry into a larger volume from a compression driver, without a smooth transition will also muck with the frequency response, the loading and create diffraction...

A drawing will serve to illustrate the OP's idea better...

btw, there are *no* "non-resonant" enclosures. the best you can do is to reduce the amplitude of HF energy. Unless you use a IB set up... maybe with the back side going outside, or to an anechoic chamber...

_-_-bear

An entry into a larger volume from a compression driver, without a smooth transition will also muck with the frequency response, the loading and create diffraction...

A drawing will serve to illustrate the OP's idea better...

btw, there are *no* "non-resonant" enclosures. the best you can do is to reduce the amplitude of HF energy. Unless you use a IB set up... maybe with the back side going outside, or to an anechoic chamber...

_-_-bear

Had gigs through wknd. I will be throwing up a crude windows paint sketch soon. I feel this is a unique design that might interest many of us. Perhaps the bend can be worked around, but with the bend this thing can be made with 6 pieces total and that *includes* horn and vent. I did not mean to imply this thing won't resonate at all, but I can guarantee you won't find a need for extra bracing.. hmmm while was typing this I realized I might be able enter the horn a the throat without the turn but it will mean the compression driver will not be in side of the structure and must actually cut partially into the mdf, that would not be elegant architecturallly. Now its time to put up a sketch.

Last edited:

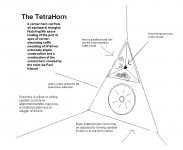

You are right Bear. Ok Here goes nothing, I am posting rough diagram, if we can work this thing out together, I will start a new Thread entitled "The TetraHorn" Where we can perfect this thing. I hope you guys like this, if we can pull this off we will have a speaker that anyone can quickly make, has very high efficiency, can help minimize room reflection problems has the possibility of deep clean bass with low overhead and in general should have some unique merits, both as a home theater speaker and as a recording studio monitor as it is uniquely scalable too. Here goes Pete Leoni's Tetrahorn, may the picking fest begin (-:

Attachments

Now you can see why I initially wanted to do the 90 somewhere near the apex, but on further thought, since this must stand some inches from flush to the wall due to the bass refex vent, is is possible to put the HF driver outside of the tetra box, and have no such turn. Not an elegant solution though one of the compromises I guess.When I was a kid, my mom said, "there are no perfect women, just find you one with a set of flaws that you can live with and hope you she does the same" Mother would have made a fine speaker designer (-:

I was thinking 1" MDF, so the anti diffraction "lip" can simply be carved, another simplification, and since there are so few parts, the non resonant characteristics of heavy MDF would be welcome is this simple design. In fact, I doubt that this one needs anything but glue. I once owned a Grumman Yankee. It was strong as hell and this was a 1970's airplane. I feel that due to the "Bucky Fulleresque" use of equilateral triangles this thing will not be nearly as subject to resonance and shaking apart as a cube-y speaker. Glue should do it. One angle is what all that is needed for panels, and a jig must be built for a table saw. Can someone here figure out the exact angle? I think it is around 54.xxx degrees for the radius (from centroid to the center of any two vertexes) but I don't know the exact figure, and it is not the dihedral of course. My 6th grade education fails me here. (-:

It is worth noting, that the vertical dispersion angle and depth (pattern/throw) of the regular triangular conical waveguide are altered simultaneously simply by resizing the bottom plate of the HF horn and extending to (duh) the front plane of the other two ( made from the top of the "box") It will still remain a symmetrical cone regardless. I would expect there will be sweet spot somewhere and that this should be a point of discussion.This of course, then alters the size of the woofer chamber because of horn displacement, so it gets interesting.

To elaborate:

Vertical angle and throw adjusted by depth/length of horn bottom plate. Horn mechanical cutoff by width (therefore size of mouth) of bottom plate. It's a regular triangle, so all planes fall into symmetry automatically.

A room corner is already an 8th space triangular conical horn, we are stuck with it anyway. I can't see how a triangular conical horn is that much of a drawback, maybe I'm wrong? This idea takes PWK's and extends it to the tweeter horn as well putting the tweeter in the corner eliminating back wash from wall, as it is virtually in the wall. Everything is still horn loaded to a degree, but all folds in horn are gone *except* for VLF bass reflex tuned vent, which will not suffer from folding at all. Not as efficient, but I would bet it could be cleaner in the mids than a K-horn. We now have electronic xovers and inexpensive clean power, luxuries when PWK did the Khorn. What we still need however, is a good portion of the dynamic range offered by horn loading. I feel that these properties make this idea a good compromise and worth exploring, hope you all do as well.

To elaborate:

Vertical angle and throw adjusted by depth/length of horn bottom plate. Horn mechanical cutoff by width (therefore size of mouth) of bottom plate. It's a regular triangle, so all planes fall into symmetry automatically.

A room corner is already an 8th space triangular conical horn, we are stuck with it anyway. I can't see how a triangular conical horn is that much of a drawback, maybe I'm wrong? This idea takes PWK's and extends it to the tweeter horn as well putting the tweeter in the corner eliminating back wash from wall, as it is virtually in the wall. Everything is still horn loaded to a degree, but all folds in horn are gone *except* for VLF bass reflex tuned vent, which will not suffer from folding at all. Not as efficient, but I would bet it could be cleaner in the mids than a K-horn. We now have electronic xovers and inexpensive clean power, luxuries when PWK did the Khorn. What we still need however, is a good portion of the dynamic range offered by horn loading. I feel that these properties make this idea a good compromise and worth exploring, hope you all do as well.

Last edited:

You are right Bear. Ok Here goes nothing, I am posting rough diagram, if we can work this thing out together, I will start a new Thread entitled "The TetraHorn" Where we can perfect this thing. I hope you guys like this, if we can pull this off we will have a speaker that anyone can quickly make, has very high efficiency, can help minimize room reflection problems has the possibility of deep clean bass with low overhead and in general should have some unique merits, both as a home theater speaker and as a recording studio monitor as it is uniquely scalable too. Here goes Pete Leoni's Tetrahorn, may the picking fest begin (-:

Here's my attempt at something similar:

3 driver full range-1.mp4 - YouTube

Basically a corner horn with a triangular mouth. You could also make one with a round mouth that works the same way

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Side entry of compression driver?