Plastic PA speaker cabinets - improving internal bracing & damping

Got a pair of plastic cab PA speakers, peavey impulse 100's, new old stock, paid under $300. Use an older version of the eminence Delta-10A, and a decent compression tweeter. They sound pretty good actually once EQ'd. I will cross these over around 100-150hz for PA use with stereo subs.

I'm looking to beef up the cab a bit, it is plastic. There is internal ribbing for stiffness but the walls themselves are about 1/4". The walls are not as stiff as MDF or ply, but they are very damp, a knuckle rap test gives a very dull thud. There is a bit of an air leak between the baffle and cab, so I will seal that up. There is this plastic wool type material for light stuffing.

I've got plenty of the dynamat with aluminum backing. I'm thinking about at least damping the delta's steel basket and the compression horn, mounting bracket, maybe the compression driver itself. I'm hesitating on damping the walls, since they are already sooooo damp, but since I'm not really feeding them bass, does it matter if the cab is stiff, vs. being damped? Should I brace the baffle, and damp the rest of the cab? Brace the whole cab with slats of ply or aluminum angle?

Your thoughts? Thanks!

---------------------------------------------------------------------------

Update with the final mods and results:

So, I finally got these mostly done and listened to them a bit last night, here is the list of mods:

- Braced the cab with 2 vertical and 2 horizontal plywood braces, interlocked

- Covered 90% of the inside (not the ribs) with strips of dynamat extreme, rubbery bitumen stuff with AL backing

- Replaced the thin plastic rear connector plate with 1/2" plywood, sealed with silicone, mounted the crossover on standoffs, and installed a speakon connector

- Stuffed extensively with 2" thick poly material

- Dynamat on woofer basket and compression tweeter, silicone around woofer/baffle junction on inside

- Sealed baffle to cab with mortite window sealer

- Reversed tweeter polarity vs. factory, tweeter is now in phase with woofer, both have correct phase.

- They weigh a bit over 32lb modified, and look identical to stock aside from the rear plate.

This took around 30 hours of labor, working a couple nights a week on it for a few hours a time. And I'm a bit slow, lol.

I was a bit nervous about how difference this would actually make, considering the time spent and delays to the overall project. As discussed before, they sounded pretty good at low volumes but distortion increased rapidly at higher volumes, clearly due to cabinet vibrations. Well, my fears were unfounded, the improvement is massive. They now image at 110+ db like they did at 90db. They are dynamic, musical and clear/revealing at high volumes and low. Very little vibration can be felt in the cab at high volumes and there seems to be quick decay, no ringing. They actally smoke my venerable Klipsch CF-1's everywhere except for bass below 100hz when used without subs. I'm using an analog PEQ to cut bass to crossover to the subs, these are fed by a full analog chain after the usb interface (DAC) out of a computer.

The swap on the tweeter polarity (and possibly everything else) has made a huge improvement in the frequency response of the speaker, they were waaaay too harsh and sylibant in the upper midrange (around the 2200hz XO), where I was running a major PEQ notch, they were unlistenable without it. Now I have been able to go to basicly a flat eq without particularly bad behavior. The upper-mid lower-treble still has plenty of punch when needed but is not boosted un-naturally. They could possibly do with a bit of a boost in the mid-upper treble.

Only issue I'm picking up on is a subtle nasal quality to vocals on most modern popular music. I can't tell if this is due to a FR issue, or if it's due to the speakers just being very dynamic and bringing it out. I doubt it's induced distortion. The upper midbass on these has a ton of punch when called upon, such as with lower range distorted electric guitar, there may be a bump around 300hz, may take a hair of a cut there. I do have the subs crossed rather high, but don't have any issues with chesty sounding vocals.

Overall I'm extremely happy with how these are turning out so far. I'm trying to put together a portable PA system for house parties, tailgating, etc, that stands apart from normal PA equipment in sound quality, approaching mid-high fi quality. Getting there.

Supporting equipment:

Adcom GFA-555 (mains amp)

Xtant P500A PEQ (mains)

Focusrite 2i2 usb audio interface + computer with FLAC files

2x 15" Dayton Ref HO subs, 150hz 1st order crossover

NU6000DSP (sub amp)

Custom spliter cable

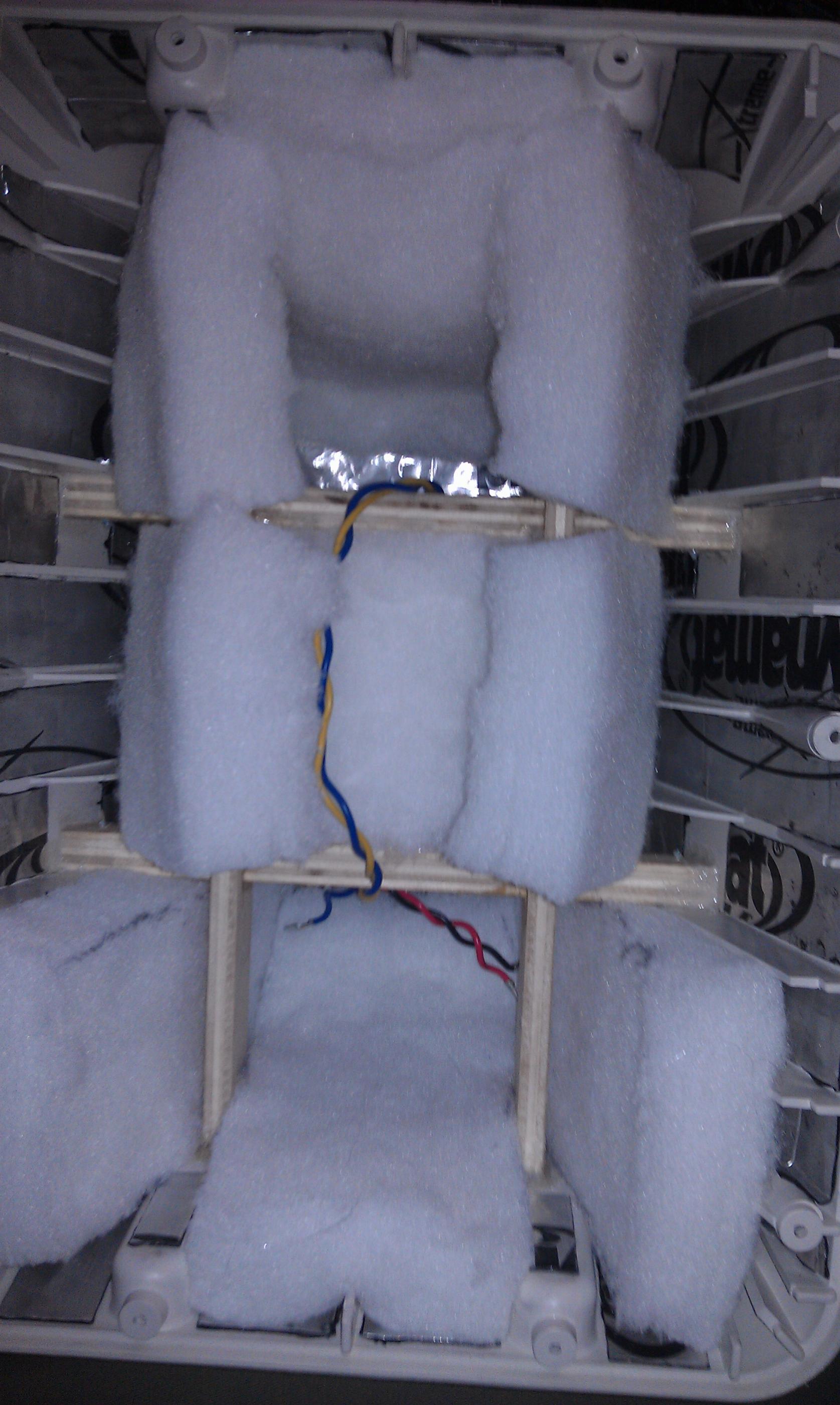

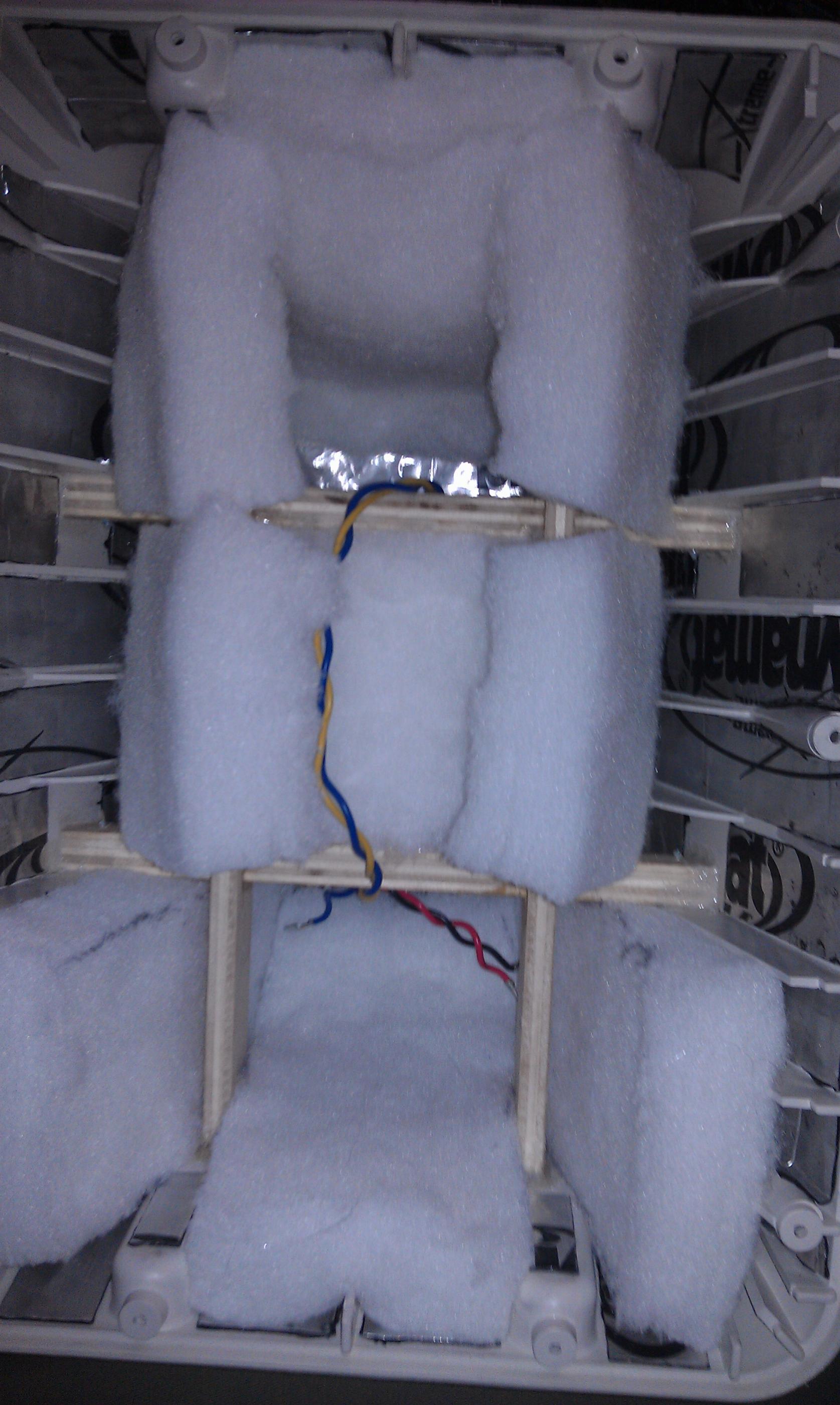

Not a great pic, but you get the idea:

Got a pair of plastic cab PA speakers, peavey impulse 100's, new old stock, paid under $300. Use an older version of the eminence Delta-10A, and a decent compression tweeter. They sound pretty good actually once EQ'd. I will cross these over around 100-150hz for PA use with stereo subs.

I'm looking to beef up the cab a bit, it is plastic. There is internal ribbing for stiffness but the walls themselves are about 1/4". The walls are not as stiff as MDF or ply, but they are very damp, a knuckle rap test gives a very dull thud. There is a bit of an air leak between the baffle and cab, so I will seal that up. There is this plastic wool type material for light stuffing.

I've got plenty of the dynamat with aluminum backing. I'm thinking about at least damping the delta's steel basket and the compression horn, mounting bracket, maybe the compression driver itself. I'm hesitating on damping the walls, since they are already sooooo damp, but since I'm not really feeding them bass, does it matter if the cab is stiff, vs. being damped? Should I brace the baffle, and damp the rest of the cab? Brace the whole cab with slats of ply or aluminum angle?

Your thoughts? Thanks!

---------------------------------------------------------------------------

Update with the final mods and results:

So, I finally got these mostly done and listened to them a bit last night, here is the list of mods:

- Braced the cab with 2 vertical and 2 horizontal plywood braces, interlocked

- Covered 90% of the inside (not the ribs) with strips of dynamat extreme, rubbery bitumen stuff with AL backing

- Replaced the thin plastic rear connector plate with 1/2" plywood, sealed with silicone, mounted the crossover on standoffs, and installed a speakon connector

- Stuffed extensively with 2" thick poly material

- Dynamat on woofer basket and compression tweeter, silicone around woofer/baffle junction on inside

- Sealed baffle to cab with mortite window sealer

- Reversed tweeter polarity vs. factory, tweeter is now in phase with woofer, both have correct phase.

- They weigh a bit over 32lb modified, and look identical to stock aside from the rear plate.

This took around 30 hours of labor, working a couple nights a week on it for a few hours a time. And I'm a bit slow, lol.

I was a bit nervous about how difference this would actually make, considering the time spent and delays to the overall project. As discussed before, they sounded pretty good at low volumes but distortion increased rapidly at higher volumes, clearly due to cabinet vibrations. Well, my fears were unfounded, the improvement is massive. They now image at 110+ db like they did at 90db. They are dynamic, musical and clear/revealing at high volumes and low. Very little vibration can be felt in the cab at high volumes and there seems to be quick decay, no ringing. They actally smoke my venerable Klipsch CF-1's everywhere except for bass below 100hz when used without subs. I'm using an analog PEQ to cut bass to crossover to the subs, these are fed by a full analog chain after the usb interface (DAC) out of a computer.

The swap on the tweeter polarity (and possibly everything else) has made a huge improvement in the frequency response of the speaker, they were waaaay too harsh and sylibant in the upper midrange (around the 2200hz XO), where I was running a major PEQ notch, they were unlistenable without it. Now I have been able to go to basicly a flat eq without particularly bad behavior. The upper-mid lower-treble still has plenty of punch when needed but is not boosted un-naturally. They could possibly do with a bit of a boost in the mid-upper treble.

Only issue I'm picking up on is a subtle nasal quality to vocals on most modern popular music. I can't tell if this is due to a FR issue, or if it's due to the speakers just being very dynamic and bringing it out. I doubt it's induced distortion. The upper midbass on these has a ton of punch when called upon, such as with lower range distorted electric guitar, there may be a bump around 300hz, may take a hair of a cut there. I do have the subs crossed rather high, but don't have any issues with chesty sounding vocals.

Overall I'm extremely happy with how these are turning out so far. I'm trying to put together a portable PA system for house parties, tailgating, etc, that stands apart from normal PA equipment in sound quality, approaching mid-high fi quality. Getting there.

Supporting equipment:

Adcom GFA-555 (mains amp)

Xtant P500A PEQ (mains)

Focusrite 2i2 usb audio interface + computer with FLAC files

2x 15" Dayton Ref HO subs, 150hz 1st order crossover

NU6000DSP (sub amp)

Custom spliter cable

Not a great pic, but you get the idea:

Last edited:

In my view, stiffness matters. It's that Ql factor in the T/S equations. Simply damping resonances still produces losses. However, Peavey certainly has the wherewithal to take this into account in the design, and I don't see how you could design a plastic cabinet without considering losses when tuning it.I'm hesitating on damping the walls, since they are already sooooo damp, but since I'm not really feeding them bass, does it matter if the cab is stiff, vs. being damped?

But since you're not concerned with the bass, I'd put an ear to the cabinet walls (or even better, one of those stick-on guitar transducers (about $35) if you have measurement software) and see how much they really leak. Sound from them could smear the mids a bit.

a piezo guitar pickup is an interesting suggestion which i thought to try when i got a dean markley one. Trouble was that i was itching to try it in the acoustic! A cheap piezo disc could work just as well. Plastic cabs ive seen seem damped and robust, but not that rigid. You could lay up glass or polyester mat, and resin. I would be wary of changing the volume too much though. An underdamped alignment will make its presence known through the midrange as well as the bass, and hi passing is unlikely to remedy this. Reducing the volume too much is going to make the reflex system less damped.

Last edited:

Hi,

IMHO very difficult to improve without a lot of work and damping on the

drivers will have little effect given the lossy cabinet. Any improvement

will add significantly to the cabinet weight and you need to balance

added mass versus added stiffness versus added damping.

This sort of thing might work :

http://www.diyaudio.com/forums/multi-way/221477-sand-liner-diy.html

A completely different tack is expanding building foam, but you need to

practise applying the right small amounts into the spaces and ribs.

Can't see it not working, but its an irreversable process. It will stiffen

the cabinet and being low mass not need additional damping.

Add more stuffing and IMO cut off and block off the two lower ports.

rgds, sreten.

IMHO very difficult to improve without a lot of work and damping on the

drivers will have little effect given the lossy cabinet. Any improvement

will add significantly to the cabinet weight and you need to balance

added mass versus added stiffness versus added damping.

This sort of thing might work :

http://www.diyaudio.com/forums/multi-way/221477-sand-liner-diy.html

A completely different tack is expanding building foam, but you need to

practise applying the right small amounts into the spaces and ribs.

Can't see it not working, but its an irreversable process. It will stiffen

the cabinet and being low mass not need additional damping.

Add more stuffing and IMO cut off and block off the two lower ports.

rgds, sreten.

Use same stuff which used in cars. You can use bitumen pads inside of your cabinets (let me say 4mm). Something like FLEX from Jantzen catalog:Your thoughts? Thanks!

http://jantzen-audio.com/image/accessoreis/Jantzen_Audio_Denmark_-_Damping_materials%5b1%5d.pdf

It will be artwork to make lot of strips and stick them inside

What would work well is semi-rigid(a small amount of flexiblizer) expanding polyurethane foam between the ribs on the back but I think that would take up too much volume in the box. Also attaching bracing would be difficult. I think that damping would be best best as the resonant frequencies are likely controlled by mass not stiffness. A damping compound brushed on the back section as well as the tweeter horn is what I would suggest. A product like acoust-x (Speaker Cabinet Coating - Acoust-X Sound Damping Coating) would work but you might want to use a primer for plastic, the more flexible the better. Don't worry about applying compound in the corners.

Putting some foam tape between the woofer and the cabinet is always good. If you can figure out how to make sure the two halfs of the cabinet seal well that would probably help out as well.

A waterfall plot or spectrograph impulse measurement before and after treatment would really tell you how effective your work was. I'm sure there are a ton of mackie SRM x50 who would benefit from your results. Best of luck and let us know how things go.

-Matt

Putting some foam tape between the woofer and the cabinet is always good. If you can figure out how to make sure the two halfs of the cabinet seal well that would probably help out as well.

A waterfall plot or spectrograph impulse measurement before and after treatment would really tell you how effective your work was. I'm sure there are a ton of mackie SRM x50 who would benefit from your results. Best of luck and let us know how things go.

-Matt

Missed this thread the first time around, but I would go the Bitumin/Dynamat route. It would add both mass and damping and those are the most important things. Stiffness is probably already adequate.

The other important factor is that those little bits of dacron fluff are nothing but placebo stuffing. Absolutely no benefit re. Internal standing waves. As it is vented it needs a good lining of fiberglass and that will make a more immediately audible improvement than even wall damping.

By the way, I'm cleaning up a pair of JBL Control 5 and the polypropylene cabinets are fairly heavy and low Q. Not a bad material choice.

David

The other important factor is that those little bits of dacron fluff are nothing but placebo stuffing. Absolutely no benefit re. Internal standing waves. As it is vented it needs a good lining of fiberglass and that will make a more immediately audible improvement than even wall damping.

By the way, I'm cleaning up a pair of JBL Control 5 and the polypropylene cabinets are fairly heavy and low Q. Not a bad material choice.

David

Last edited:

Thanks guys for the late responses. I have the speakers pulled apart with the front baffles off and the crossovers out. Going to run 2 horizontal cross braces between the sides, this seems to be the most flexable and vibration prone part of the box. Already had a good amount of foil backed dynamat extreme which I will use to damp all internal surfaces including the baffle and horn. I will replace the back plate with 1/2" ply and fit a speakon connector. The baffle will be sealed to the main box with a non-adhesive sealant. I've already posted in another thread that I have some very thick/heavy polyester materal to use for stuffing.

Overall, I'm hoping this will result in more sensitivity in the midbass and midrange, requiring less EQ of the speakers, with overall better clairity and power handling before cabinet distortion sets in.

Will try to take pics and post them in the next few weeks as I get more time to work on the project.

Overall, I'm hoping this will result in more sensitivity in the midbass and midrange, requiring less EQ of the speakers, with overall better clairity and power handling before cabinet distortion sets in.

Will try to take pics and post them in the next few weeks as I get more time to work on the project.

Bump. After staring at these apart for over a month, I've started with the bracing. I've run two cross braces side to side, 3/4" ply about 1" wide. Mounted with hex head #12 sheet metal screws through the ribs, and silicone. Going to need to run some braces to the top and bottom of the box because there is considerable flex there too.

Have also made some 1/2" ply back plates to re-mount the crossover and provide for speakon inputs, considerably more hefty than the thin plastic.

Also noticed that the crossover wires the tweeter in reverse polarity, as is common with 2nd order designs. To me this seems un-needed becasue the recess of the tweeter in the horn should compensate for the phase shift at the 2200hz crossover (1/2 wave = 3.1"). I am going to try the tweeter in phase for sure, I have to do lots of EQ right now to bring up a lull in the midrange. We'll see.

Still have a considerable amount of work to do, but trying to get this system gig ready by the end of Feb.

Have also made some 1/2" ply back plates to re-mount the crossover and provide for speakon inputs, considerably more hefty than the thin plastic.

Also noticed that the crossover wires the tweeter in reverse polarity, as is common with 2nd order designs. To me this seems un-needed becasue the recess of the tweeter in the horn should compensate for the phase shift at the 2200hz crossover (1/2 wave = 3.1"). I am going to try the tweeter in phase for sure, I have to do lots of EQ right now to bring up a lull in the midrange. We'll see.

Still have a considerable amount of work to do, but trying to get this system gig ready by the end of Feb.

Last edited:

not to say those are a PITA to open right ? ( torx ) screw ?

Philips screws, 10 of them screwing the baffle to main box. Not too hard just time consuming, or use power tools.

I would swap polarity on one and listen side by side. If the difference isn't obvious try different listening content, If still not obvious the xover could use adjusting.

Be careful not to block the area directly behind the woofer with the bracing. Also, I would bet that a front to back brace would make the greatest improvement but that is probably hard to implement. Lastly, I suggest using a more rigid adhesive than silicone for braces.

Good luck,

-Matt

Be careful not to block the area directly behind the woofer with the bracing. Also, I would bet that a front to back brace would make the greatest improvement but that is probably hard to implement. Lastly, I suggest using a more rigid adhesive than silicone for braces.

Good luck,

-Matt

I agree that silicone would flex enough that if not for those screws, the brace would be ineffective. Don't neglect the panel damping, ie: the bitumen or similar. This would probably do more than the braces especially to damp that plastic sound that sometimes emanates from bad examples of these types of cabinet.

I wouldn't stress about the tweeter polarity unless you think there is an actual problem. I doubt there is anything to gain from the 'correct' polarity unless you want to measure this up and redesign the crossover.

I wouldn't stress about the tweeter polarity unless you think there is an actual problem. I doubt there is anything to gain from the 'correct' polarity unless you want to measure this up and redesign the crossover.

Thanks guys, the silicone is to prevent buzzing between the braces and cab while having some give, the screws hold them in solid. Will damp the whole thing with dynamat. One brace is bit behind the the woofer vent but there is enough space and i will round it. Will compare test the tweeter wiring.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Plastic speaker cabinets - improving internal bracing & damping