I respectfully disagree about tweeter polarity being moot. Like I said if switching it doesn't make a big difference the phase difference is probably near 90deg. Signal delay, change in spacing/depth, and adjusting filters are some tools to make up that 90deg where switching the polarity will really make an obvious change.

Turbo: I definitely understand wanting to avoid rattle. that is one of the main problems with the yorkville's I've used. Multiway cabinets are a challenge as you need to provide stiffness and mass/damping to tame cabinet resonances. Do let us know if you have any result with the tweater.

-Matt

Turbo: I definitely understand wanting to avoid rattle. that is one of the main problems with the yorkville's I've used. Multiway cabinets are a challenge as you need to provide stiffness and mass/damping to tame cabinet resonances. Do let us know if you have any result with the tweater.

-Matt

I respectfully disagree about tweeter polarity being moot. Like I said if switching it doesn't make a big difference the phase difference is probably near 90deg. Signal delay, change in spacing/depth, and adjusting filters are some tools to make up that 90deg where switching the polarity will really make an obvious change.

Turbo: I definitely understand wanting to avoid rattle. that is one of the main problems with the yorkville's I've used. Multiway cabinets are a challenge as you need to provide stiffness and mass/damping to tame cabinet resonances. Do let us know if you have any result with the tweater.

-Matt

From what I understand, the tweeter being wired out of phase on 2nd order xo is only prefered when the drivers are time/physically aligned. The tweeters on these are a good 3-4" back from the woofers, which should be roughly equivalent to a 180 deg phase shift at the 2200hz. Obviously, either configuration is far from perfect, so I feel it's worth trying one vs. the other. Also, I just don't like the idea of running any driver out of phase.

In stock configuration the cabinets are quite badly noticeble as volume increases, much worse than any decent hifi speaker.

I don't think anyone has said polarity isn't important. The crossover may be good, bad or otherwise, but the one thing about it you should mostly expect from a reputable manufacturer is that the polarity is the preferred one. At this stage, not too much else is certain.

turbodawg, there can be delay between a cone making sound and the signal that drives the voice coil. This delay means phase change. This says something about what connecting the red wire to the red terminal will or will not get you. Of course what matters is the phase of the sound itself. It's OK to design a crossover with the polarity at whatever it has to be to achieve this.

To deal with the tweeter set back from the woofer, the crossover wants to vary the amount of phase difference between the drivers at higher or lower frequencies. This could be done using a higher slope on one of the drivers, eg: mixing 1st and 4th order filters. Often it is cheaper to avoid the higher order filters so sometimes these kinds of speakers use a compromise that sounds OK. Sometimes the response can be a little peaky.

Neither polarity will be perfect, but that doesn't necessarily mean wrong either. Besides, for every two waves that meet in phase, somewhere else the same two waves will be out of phase, and everywhere in-between. The room is full of all these when a crossover occurs.

turbodawg, there can be delay between a cone making sound and the signal that drives the voice coil. This delay means phase change. This says something about what connecting the red wire to the red terminal will or will not get you. Of course what matters is the phase of the sound itself. It's OK to design a crossover with the polarity at whatever it has to be to achieve this.

To deal with the tweeter set back from the woofer, the crossover wants to vary the amount of phase difference between the drivers at higher or lower frequencies. This could be done using a higher slope on one of the drivers, eg: mixing 1st and 4th order filters. Often it is cheaper to avoid the higher order filters so sometimes these kinds of speakers use a compromise that sounds OK. Sometimes the response can be a little peaky.

Neither polarity will be perfect, but that doesn't necessarily mean wrong either. Besides, for every two waves that meet in phase, somewhere else the same two waves will be out of phase, and everywhere in-between. The room is full of all these when a crossover occurs.

I don't think anyone has said polarity isn't important. The crossover may be good, bad or otherwise, but the one thing about it you should mostly expect from a reputable manufacturer is that the polarity is the preferred one. At this stage, not too much else is certain.

turbodawg, there can be delay between a cone making sound and the signal that drives the voice coil. This delay means phase change. This says something about what connecting the red wire to the red terminal will or will not get you. Of course what matters is the phase of the sound itself. It's OK to design a crossover with the polarity at whatever it has to be to achieve this.

To deal with the tweeter set back from the woofer, the crossover wants to vary the amount of phase difference between the drivers at higher or lower frequencies. This could be done using a higher slope on one of the drivers, eg: mixing 1st and 4th order filters. Often it is cheaper to avoid the higher order filters so sometimes these kinds of speakers use a compromise that sounds OK. Sometimes the response can be a little peaky.

Neither polarity will be perfect, but that doesn't necessarily mean wrong either. Besides, for every two waves that meet in phase, somewhere else the same two waves will be out of phase, and everywhere in-between. The room is full of all these when a crossover occurs.

Excellent points. Considering that the baffle/box junction leaks air in the stock configuration and there is major buzzing when running test tones under 100hz, I have little faith in the design of the crossover. I think it's pretty close to being an off the shelf 2nd order plus tweeter padding, which dictates an out of phase tweeter, I doubt it's been extensively optimised. Putting it in phase has a very reasonable possiblity of being better. I will make a crossover schematic before I button them up.

These speakers use pretty good drivers in a pretty good cabinet with a pretty robust looking crossover, however they seem to have not been optimised extensively like you would expect from a hifi speaker.

Last edited:

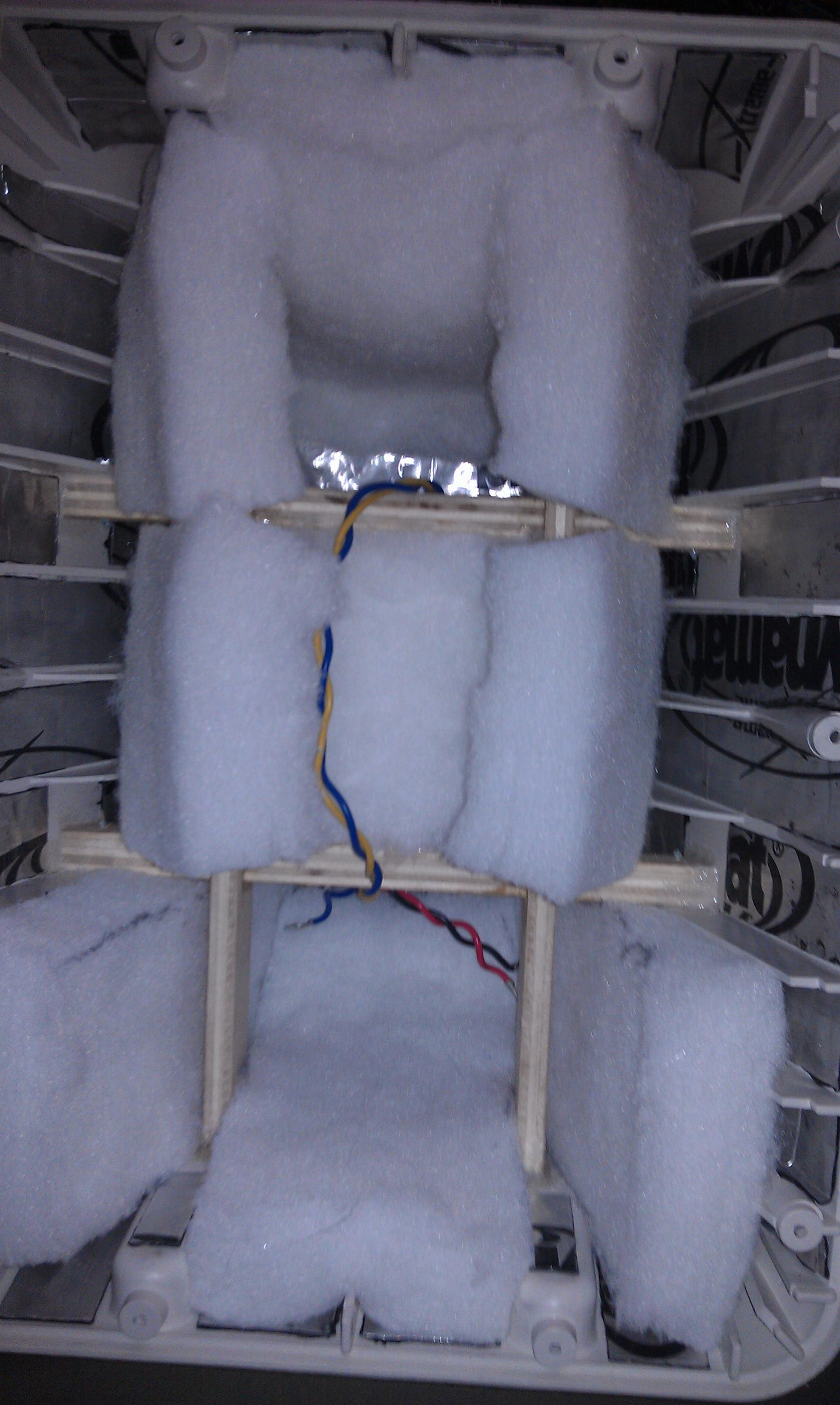

So, I finally got these mostly done and listened to them a bit last night, here is the list of mods:

- Braced the cab with 2 vertical and 2 horizontal plywood braces, interlocked

- Covered 90% of the inside (not the ribs) with strips of dynamat extreme, rubbery bitumen stuff with AL backing

- Replaced the thin plastic rear connector plate with 1/2" plywood, sealed with silicone, mounted the crossover on standoffs, and installed a speakon connector

- Stuffed extensively with 2" thick poly material

- Dynamat on woofer basket and compression tweeter, silicone around woofer/baffle junction on inside

- Sealed baffle to cab with mortite window sealer

- Reversed tweeter polarity vs. factory, tweeter is now in phase with woofer, both have correct phase.

- They weigh a bit over 32lb modified, and look identical to stock aside from the rear plate.

This took around 30 hours of labor, working a couple nights a week on it for a few hours a time. And I'm a bit slow, lol.

I was a bit nervous about how difference this would actually make, considering the time spent and delays to the overall project. As discussed before, they sounded pretty good at low volumes but distortion increased rapidly at higher volumes, clearly due to cabinet vibrations. Well, my fears were unfounded, the improvement is massive. They now image at 110+ db like they did at 90db. They are dynamic, musical and clear/revealing at high volumes and low. Very little vibration can be felt in the cab at high volumes and there seems to be quick decay, no ringing. They actally smoke my venerable Klipsch CF-1's everywhere except for bass below 100hz when used without subs. I'm using an analog PEQ to cut bass to crossover to the subs, these are fed by a full analog chain after the usb interface (DAC) out of a computer.

The swap on the tweeter polarity (and possibly everything else) has made a huge improvement in the frequency response of the speaker, they were waaaay too harsh and sylibant in the upper midrange (around the 2200hz XO), where I was running a major PEQ notch, they were unlistenable without it. Now I have been able to go to basicly a flat eq without particularly bad behavior. The upper-mid lower-treble still has plenty of punch when needed but is not boosted un-naturally. They could possibly do with a bit of a boost in the mid-upper treble.

Only issue I'm picking up on is a subtle nasal quality to vocals on most modern popular music. I can't tell if this is due to a FR issue, or if it's due to the speakers just being very dynamic and bringing it out. I doubt it's induced distortion. The upper midbass on these has a ton of punch when called upon, such as with lower range distorted electric guitar, there may be a bump around 300hz, may take a hair of a cut there. I do have the subs crossed rather high, but don't have any issues with chesty sounding vocals.

Overall I'm extremely happy with how these are turning out so far. I'm trying to put together a portable PA system for house parties, tailgating, etc, that stands apart from normal PA equipment in sound quality, approaching mid-high fi quality. Getting there.

Supporting equipment:

Adcom GFA-555 (mains amp)

Xtant P500A PEQ (mains)

Focusrite 2i2 usb audio interface + computer with FLAC files

2x 15" Dayton Ref HO subs, 150hz 1st order crossover

NU6000DSP (sub amp)

Custom spliter cable

Not a great pic, but you get the idea:

- Braced the cab with 2 vertical and 2 horizontal plywood braces, interlocked

- Covered 90% of the inside (not the ribs) with strips of dynamat extreme, rubbery bitumen stuff with AL backing

- Replaced the thin plastic rear connector plate with 1/2" plywood, sealed with silicone, mounted the crossover on standoffs, and installed a speakon connector

- Stuffed extensively with 2" thick poly material

- Dynamat on woofer basket and compression tweeter, silicone around woofer/baffle junction on inside

- Sealed baffle to cab with mortite window sealer

- Reversed tweeter polarity vs. factory, tweeter is now in phase with woofer, both have correct phase.

- They weigh a bit over 32lb modified, and look identical to stock aside from the rear plate.

This took around 30 hours of labor, working a couple nights a week on it for a few hours a time. And I'm a bit slow, lol.

I was a bit nervous about how difference this would actually make, considering the time spent and delays to the overall project. As discussed before, they sounded pretty good at low volumes but distortion increased rapidly at higher volumes, clearly due to cabinet vibrations. Well, my fears were unfounded, the improvement is massive. They now image at 110+ db like they did at 90db. They are dynamic, musical and clear/revealing at high volumes and low. Very little vibration can be felt in the cab at high volumes and there seems to be quick decay, no ringing. They actally smoke my venerable Klipsch CF-1's everywhere except for bass below 100hz when used without subs. I'm using an analog PEQ to cut bass to crossover to the subs, these are fed by a full analog chain after the usb interface (DAC) out of a computer.

The swap on the tweeter polarity (and possibly everything else) has made a huge improvement in the frequency response of the speaker, they were waaaay too harsh and sylibant in the upper midrange (around the 2200hz XO), where I was running a major PEQ notch, they were unlistenable without it. Now I have been able to go to basicly a flat eq without particularly bad behavior. The upper-mid lower-treble still has plenty of punch when needed but is not boosted un-naturally. They could possibly do with a bit of a boost in the mid-upper treble.

Only issue I'm picking up on is a subtle nasal quality to vocals on most modern popular music. I can't tell if this is due to a FR issue, or if it's due to the speakers just being very dynamic and bringing it out. I doubt it's induced distortion. The upper midbass on these has a ton of punch when called upon, such as with lower range distorted electric guitar, there may be a bump around 300hz, may take a hair of a cut there. I do have the subs crossed rather high, but don't have any issues with chesty sounding vocals.

Overall I'm extremely happy with how these are turning out so far. I'm trying to put together a portable PA system for house parties, tailgating, etc, that stands apart from normal PA equipment in sound quality, approaching mid-high fi quality. Getting there.

Supporting equipment:

Adcom GFA-555 (mains amp)

Xtant P500A PEQ (mains)

Focusrite 2i2 usb audio interface + computer with FLAC files

2x 15" Dayton Ref HO subs, 150hz 1st order crossover

NU6000DSP (sub amp)

Custom spliter cable

Not a great pic, but you get the idea:

Attachments

Last edited:

The swap on the tweeter polarity (and possibly everything else) has made a huge improvement in the frequency response of the speaker, they were waaaay too harsh and sylibant in the upper midrange (around the 2200hz XO), where I was running a major PEQ notch, they were unlistenable without it. Now I have been able to go to basicly a flat eq without particularly bad behavior. The upper-mid lower-treble still has plenty of punch when needed but is not boosted un-naturally. They could possibly do with a bit of a boost in the mid-upper treble.

Only issue I'm picking up on is a subtle nasal quality to vocals on most modern popular music. I can't tell if this is due to a FR issue, or if it's due to the speakers just being very dynamic and bringing it out.

The polarity swap was not necessarily correct, and is probably causing a ragged or inconsistent response around the crossover. The fact that you prefer less output in that region would mean that the crossover would benefit from your own adjustments but rather than swapping the polarity, you could try other things like reducing the capacitance to the tweeter or increasing the inductance to the woofer a little.

The polarity swap was not necessarily correct, and is probably causing a ragged or inconsistent response around the crossover. The fact that you prefer less output in that region would mean that the crossover would benefit from your own adjustments but rather than swapping the polarity, you could try other things like reducing the capacitance to the tweeter or increasing the inductance to the woofer a little.

I've put in a very mild low-q cut around 1500hz which seems to have cured the nasality, and a good low-q boost around 6000-8000hz which seems to brought up the treble hotness the right amount and improved top end detail. Much happier than before with the EQ required.

Exactly. The way to go is take out the crossover. Screw the speaker back together with tweeter and woofer wired up separately through the reflex port.The polarity swap was not necessarily correct, and is probably causing a ragged or inconsistent response around the crossover. The fact that you prefer less output in that region would mean that the crossover would benefit from your own adjustments but rather than swapping the polarity, you could try other things like reducing the capacitance to the tweeter or increasing the inductance to the woofer a little.

Then you can play the two drivers alone and together, swap polarity, watch what happens. Change parts of the filters, all without opening the box.

When you like the sound, take a break. Come back next day. Listen again. It is so much easyer. That's how the pros do it.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Plastic speaker cabinets - improving internal bracing & damping