I use ferrofluid and have tested a lot of variants...

The best audio quality are without ferrofluid, but I use it to center the voice coil so it is needed. Soon I will test out a minimalistic spider design that have only one mission -> center the voice coil. If I used the variant with stiffer cloth surround I can avoid the ferrofluid / spider, but with the silk surround some centering are required.

A mission -> to center the voice coil.

I once had the idea of using one layer of a voice coil with two sections and with a center tap, one section up north and the other one going up south (using the magnetic pole designations); with a small amount of DC running permanently it would center the voice coil.

I once made a woofer where I took out the spider, used strings; and a cloth surround. - - The voice coil would go to the outside of its extension when playing hard. Rather annoying. But I never implemented this idea (no winfding machine).

The extra layer could be very small wire.

A mission -> to center the voice coil.

I once had the idea of using one layer of a voice coil with two sections and with a center tap, one section up north and the other one going up south (using the magnetic pole designations); with a small amount of DC running permanently it would center the voice coil.

I once made a woofer where I took out the spider, used strings; and a cloth surround. - - The voice coil would go to the outside of its extension when playing hard. Rather annoying. But I never implemented this idea (no winfding machine).

The extra layer could be very small wire.

With the voice coils and magnet systems I already have then a minimal spider are the only other way..

However I have made design plans for both magnet systems and voice coils that will center without magnetic oil or spiders, but I do not know if I will spend the time and money to make prototypes and evaluate.

RayCtech, That sound very interesting and would love to see how you would do that. Is it a multi coil syatem. If you don't have any commercial interests in it, would you share your idea with us in more details.

In a couple of months time I will do some work with dynamic drivers and build the minimalistic spider prototypes and also review the spider less design variants. If then I discover an easy way to implement and evaluate one of the spider less designs I may be able to tell more.

Just a small update. I did decided to go back and try making a cone from Depron after experimented with a variety of material. The reason for this is that Depron is very light weighted and stiff material and it has some good damping qualities.

I made the cone by pressing two hot forms with the Depron in between, it took some tryes to get the temperature right. The temperature should bee 150-160°C, maybe a little bit higher. The cone is made in one pcs.

The cone you see is 6” and the cone is made in one pcs. the weighs is only 1,6 gram, that's hard to beat. I did mount a voice coil on it and it work fine. But I need more time to figure out if it's a keeper.

Take care

I made the cone by pressing two hot forms with the Depron in between, it took some tryes to get the temperature right. The temperature should bee 150-160°C, maybe a little bit higher. The cone is made in one pcs.

The cone you see is 6” and the cone is made in one pcs. the weighs is only 1,6 gram, that's hard to beat. I did mount a voice coil on it and it work fine. But I need more time to figure out if it's a keeper.

Take care

Attachments

Last edited:

Thanks Hentai, Yes your are right I did try Depron (polystyrene foam) before, But thanks to you, this forum and a lot of experimenting I think I can pull it of now. In this one I used a larger areal to connect the cone and the voice coil, it is like a small some what flat wizzer where the centre cone is glued on. Also I am using my own voice coil, I used a standard replacement coil in the first try.

I am using slow curing epoxy glue with micro balloons (200 micron glass balloons), this makes the glue very hard. The Depron is slightly sanded to make a good grip for the glue.

One thing I have notes with the Depron cone is the high frequency respond at a angle, it doesn’t seems to be very directional as the other cones I made. Maybe it's because of the way the cone is spilt and the con is relative flat.

But due to the low weight of the cone I need to find a way to make a spider, with a very high suspension in order to get a descent low resonant frequency. Maybe I should try to make one of Depron...

Take Care

I am using slow curing epoxy glue with micro balloons (200 micron glass balloons), this makes the glue very hard. The Depron is slightly sanded to make a good grip for the glue.

One thing I have notes with the Depron cone is the high frequency respond at a angle, it doesn’t seems to be very directional as the other cones I made. Maybe it's because of the way the cone is spilt and the con is relative flat.

But due to the low weight of the cone I need to find a way to make a spider, with a very high suspension in order to get a descent low resonant frequency. Maybe I should try to make one of Depron...

Take Care

Hey Hentai,

I just wanted to let you know I took you're advise. I put great plains audio 416-8b drivers in my bass horns. There suspension is much softer then the other drivers I was using. Qts is .32 instead of .2. There also of an underhung design. I was worried at first because the bl is a bit low. But I was very happy with the results when I put the 2 I had into one of the bass horns. So much so that I then had to buy 2 more, LOL.

Ive been wanting to let you know. Just kept forgetting to tell you.

Keep up the good work guys.

Nick

I just wanted to let you know I took you're advise. I put great plains audio 416-8b drivers in my bass horns. There suspension is much softer then the other drivers I was using. Qts is .32 instead of .2. There also of an underhung design. I was worried at first because the bl is a bit low. But I was very happy with the results when I put the 2 I had into one of the bass horns. So much so that I then had to buy 2 more, LOL.

Ive been wanting to let you know. Just kept forgetting to tell you.

Keep up the good work guys.

Nick

Hi Frank,

Great experience with Depron. Very useful info you brought to the table. I would say as a simple and straight forward change is to switch the foam surround with a cloth one. That foam has more weight than the cone itself I'm sure.

Hi Nick,

Happy to hear you like the change. Enjoy the music.

Great experience with Depron. Very useful info you brought to the table. I would say as a simple and straight forward change is to switch the foam surround with a cloth one. That foam has more weight than the cone itself I'm sure.

Hi Nick,

Happy to hear you like the change. Enjoy the music.

The weight of the surroundings weight is 4.2 gram so you are absolutely right Hentia. But I haven’t been to successful in making a cloth surrounding, that is why I am using the foam surrounding.

The trouble starts when I make the cloth airtight by coating it, then the weight is getting to high. If only I could find a place where I could buy them, and if there weight is lower, then I would be happy to switch.

I am thinking of making the cone and surrounding in one piece, still using Depron but it a bit trickier because the thickness of the material must varies throughout the cone length. 3D print could solve this and I am trying to find someone that can print it for a fair price.

Take care

The trouble starts when I make the cloth airtight by coating it, then the weight is getting to high. If only I could find a place where I could buy them, and if there weight is lower, then I would be happy to switch.

I am thinking of making the cone and surrounding in one piece, still using Depron but it a bit trickier because the thickness of the material must varies throughout the cone length. 3D print could solve this and I am trying to find someone that can print it for a fair price.

Take care

Thanks Hentai, Yes your are right I did try Depron (polystyrene foam) before, But thanks to you, this forum and a lot of experimenting I think I can pull it of now. In this one I used a larger areal to connect the cone and the voice coil, it is like a small some what flat wizzer where the centre cone is glued on. Also I am using my own voice coil, I used a standard replacement coil in the first try.

I am using slow curing epoxy glue with micro balloons (200 micron glass balloons), this makes the glue very hard. The Depron is slightly sanded to make a good grip for the glue.

One thing I have notes with the Depron cone is the high frequency respond at a angle, it doesn’t seems to be very directional as the other cones I made. Maybe it's because of the way the cone is spilt and the con is relative flat.

But due to the low weight of the cone I need to find a way to make a spider, with a very high suspension in order to get a descent low resonant frequency. Maybe I should try to make one of Depron...

Take Care

When bonding, try mixing a thin epoxy with silica. That way you get a trixotopic adhesive, with the best of both worlds.

If you don't have a suitable epoxy or silica let me know, and I'll send you a bit of each.

Magura

The weight of the surroundings weight is 4.2 gram so you are absolutely right Hentia. But I haven’t been to successful in making a cloth surrounding, that is why I am using the foam surrounding.

The trouble starts when I make the cloth airtight by coating it, then the weight is getting to high. If only I could find a place where I could buy them, and if there weight is lower, then I would be happy to switch.

I am thinking of making the cone and surrounding in one piece, still using Depron but it a bit trickier because the thickness of the material must varies throughout the cone length. 3D print could solve this and I am trying to find someone that can print it for a fair price.

Take care

A cloth surround may not be that hard to make light. If you use a soft type of epoxy to seal it/shape it, and dilute the epoxy adequately, I think you'll get what you want.

Magura

The weight of the surroundings weight is 4.2 gram so you are absolutely right Hentia. But I haven’t been to successful in making a cloth surrounding, that is why I am using the foam surrounding.

The trouble starts when I make the cloth airtight by coating it, then the weight is getting to high. If only I could find a place where I could buy them, and if there weight is lower, then I would be happy to switch.

I am thinking of making the cone and surrounding in one piece, still using Depron but it a bit trickier because the thickness of the material must varies throughout the cone length. 3D print could solve this and I am trying to find someone that can print it for a fair price.

Take care

If you were making 8" drivers I could have sent you some complete membranes with silk surround. Total weight 8 gram with voice coil (including wiring). I can put one without voice coil on the scale and check..

I have also multi layer cones (20 gram total), and cloth surrounds in different shapes and stiffnesses. Actually the cone size are slightly larger than standard 8" - I do not remember exactly without checking the drawings, but ca. 8 - 10 millimeter greater diameter.

Thanks for your offers guys but I am pretty much got what I need, it would bee nice with a silk surrounding that fit my cone...

Take care

I made drawings for my surround and had a tool made and then the factory made a series of silk surrounds with slightly different coatings etc..

As I have done the same for cones and dust caps (drawings and made tools) - the factory delivers complete and finished surround / cone assemblies. I could have had them mount also my custom designed and built voice coils, but then shipping sizes would have been enormous...

The tool costs are so high that it needs to be produced thousands of items to get the unit cost down, but I ordered only 100 - 200 pcs of each variant, and I have only finished 20 complete drivers so my unit price pr. driver are quite high

However I started by making cones, surrounds, dust caps, voice coils and magnet systems by hand / manually, and when I had some prototypes performing - I then made drawings and had the parts produced by making tools and professionally made by companies that had the best equipment.

RayCtech, Are you starting a business, It's sounds like that is what you are doing... Yes making tools cost and you often have to order large numbers. I'm sure I am not the only one that would like to see some of your work, will you share it with us.

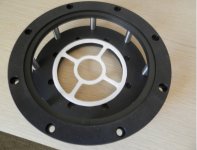

I just finished my first take on a Depron spider, and it's looking good. Weight is between 0.4-0.5 gram and the suspension seems very soft. I know there should be more than four joints, but it is the first try .

.

Take care

I just finished my first take on a Depron spider, and it's looking good. Weight is between 0.4-0.5 gram and the suspension seems very soft. I know there should be more than four joints, but it is the first try

Take care

Attachments

Last edited:

RayCtech, Are you starting a business, It's sounds like that is what you are doing... Yes making tools cost and you often have to order large numbers. I'm sure I am not the only one that would like to see some of your work, will you share it with us.

I just finished my first take on a Depron spider, and it's looking good. Weight is between 0.4-0.5 gram and the suspension seems very soft. I know there should be more than four joints, but it is the first try.

Take care

Your spider looks good, but I could not use it as my 8" have 30 millimeter peak to peak movement...

Posted some info regarding the 8" in 2009 in this thread http://www.diyaudio.com/forums/full-range/156251-alnico-s-8-inch-4.html#post2006142

Made also some basket less versions - CNCed Corian baffles.

Have now prepared some baskets and will in a couple of months time build some new 8" with the minimalistic spider and some new AMTs and can post some pictures then.

Attachments

Last edited:

With the voice coils and magnet systems I already have then a minimal spider are the only other way..

However I have made design plans for both magnet systems and voice coils that will center without magnetic oil or spiders, but I do not know if I will spend the time and money to make prototypes and evaluate.

Hi RayCtech,

I did already make two models with magnetic centering like you mention (two directions winding) but... radial centering with ferrofluid. I found out this is not a good way, to much damping (was unable to apply the point of critical damping). Overdamped resulted in a not open stereofield, missed some "sparkle" in the music. Thinking of a solution for magnetic centering (axial and radial). But didn't found a (good) solution yet. The axial centering works very well so this is a good basis to go for (very lineair). Some help for the radial centering would be very much appreciated. If you have questions about my design please ask.

Cheers,

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker