Hi

I have been trying to find another way to make spider suspension, and I came up with this.......Please feel free to comment.

I see no sideways stability

and might produce 'spring sound'

why not just use simple 'threads' ?

should go on the sides of the voice coil, and not in the middle like you show it

You are absolutely correct Hentai, the spring system also have a weight, but it is very low compeered to standard spiders... The spider I had in mind weigh 1.9 gr, I did make one my self and it weight 1.3 gr. For the same size.

I did a calculation on the weight for a four spring system, using 0.3 mm spring wire with one loop and a total length of 30mm. The weight was cal. From a steel weight of 7.84gr. /cu.cm.

The total weight for four spring is 89 micro grams. If I got it right....of course the will bee some extra weight due to the glue, but all in all it can bee made much lighter than a standard spider.

Tinitus, The reason I don't use a simple thread is that thread has to bee able to stretch a bit, when it is moving up and down. This will wear the thread over time, but other than that it is a great idea. You will have sideways stability if you don't make the loops to big. It is not my attention to make the spring to go inside the voice coil, it is only a quick sketch I made.

Anders, that is one nice solution.... I relay like it, and it confirms that the spring system works.

Take care

I did a calculation on the weight for a four spring system, using 0.3 mm spring wire with one loop and a total length of 30mm. The weight was cal. From a steel weight of 7.84gr. /cu.cm.

The total weight for four spring is 89 micro grams. If I got it right....of course the will bee some extra weight due to the glue, but all in all it can bee made much lighter than a standard spider.

Tinitus, The reason I don't use a simple thread is that thread has to bee able to stretch a bit, when it is moving up and down. This will wear the thread over time, but other than that it is a great idea. You will have sideways stability if you don't make the loops to big. It is not my attention to make the spring to go inside the voice coil, it is only a quick sketch I made.

Anders, that is one nice solution.... I relay like it, and it confirms that the spring system works.

Take care

Last edited:

Hi Nick,

yes i had that suspicion and also that you need to change the central pole piece or it would saturate under field coil.

if you draw a sketch there might be some solutions we can come up with.

Hi Hentai,

Changing the center pole. Was the easy part. I even bought the material fir the center pole. My issue was strictly a clearance issue.

I originally consulted Steve Schell on this, he suggested I use 12l14 steel. It has a very low carbon. J analyzed the material jbl used. It had .2% carbon. 12l14 has .15.

I'm going to use the same material for the poles on the 2440's. I'd love to use something like 1001or 1005 but I have not been able to find it. But Steve say the 12l14 works fine for this application.

Nick

Hi Nick, yea 1214 can be good if you can't find at least 1010 which is almost a standard nowadays.

1010 has more iron in it even though carbon percentage is about the same.

Hi Hentai,

The fact that I live practically in Houston Texas means there are quite a few metal suppliers. I could probably find it by making a few calls. These places are just so expensive. I've bought all my materials from an online site called speedy metals. There prices are good. But no 1010.

I'll probably start looking for some 1010 in the near future for the 2440's.

Nick

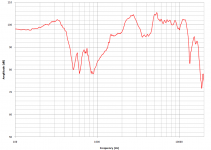

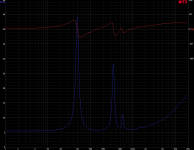

This weekend i tried to find the cause of the 1khz peak in impedance. I've seen this peak in other fullrange drivers more or less proeminent so as i said before my belief was that it was caused by transition between main cone and whizzer, just like a crossover in a 2 way system usually causes a bump in the impedance.

To test it i added a small spider between main cone and voice coil former to increase the compliance inbetween. Even so i chose a pretty stiff spider so that the main cone can move.

In the pictures attached you can see what i mean.

From the impedance curve it is clear how the xover point between two cones changed. The higher compliance moved the peak lower in frequency as expected and in the 1kHz region impedance is clean.

Measuring the frequency response shows the bandwith of the two cones. While firmly decoupled from main cone response goes beyond 10kHz but no much of a real gain compared to previous versions.

The lighter voice coil was used with a measured inductance of 0.4mH.

One of the reason why i find Frank's design of voice coil former and whizzer as one very interesting.

To test it i added a small spider between main cone and voice coil former to increase the compliance inbetween. Even so i chose a pretty stiff spider so that the main cone can move.

In the pictures attached you can see what i mean.

From the impedance curve it is clear how the xover point between two cones changed. The higher compliance moved the peak lower in frequency as expected and in the 1kHz region impedance is clean.

Measuring the frequency response shows the bandwith of the two cones. While firmly decoupled from main cone response goes beyond 10kHz but no much of a real gain compared to previous versions.

The lighter voice coil was used with a measured inductance of 0.4mH.

One of the reason why i find Frank's design of voice coil former and whizzer as one very interesting.

Attachments

FWIW I use 12L14 for my centerpoles.

The main reason for its popularity is mechanical, not magnetic.

It has micro "bubbles" of lead floating in the crystal structure (the lead is not chemically alloyed but sits there unmixed) which help machinability *a lot*.

1) lead drops provide "break points" so shavings break in short easy to handle pieces

2) soft lead acts as a kind of solid lubricant.

It reduces friction and heat

While SAE1008/1010 steel is magnetically better, it's soft and pliable (for a steel, of course) and you get messy long curly shavings which clutter the workspace.

Also if you work turning long bars in automatic high speed lathes, *sometimes* the tool bit "bites" too much and breaks.

So to play it safe, you have to lower speed

Besides, for high production the actual cutting tip is a small carbide insert attached to a larger regular steel part, and the joint is not exactly impact resistant.

The main reason for its popularity is mechanical, not magnetic.

It has micro "bubbles" of lead floating in the crystal structure (the lead is not chemically alloyed but sits there unmixed) which help machinability *a lot*.

1) lead drops provide "break points" so shavings break in short easy to handle pieces

2) soft lead acts as a kind of solid lubricant.

It reduces friction and heat

While SAE1008/1010 steel is magnetically better, it's soft and pliable (for a steel, of course) and you get messy long curly shavings which clutter the workspace.

Also if you work turning long bars in automatic high speed lathes, *sometimes* the tool bit "bites" too much and breaks.

So to play it safe, you have to lower speed

Besides, for high production the actual cutting tip is a small carbide insert attached to a larger regular steel part, and the joint is not exactly impact resistant.

Frank found a mistake on the voice coil spreadsheet in the formula for the total number of turns. Thanks Frank.

Attached is the modified version.

<snip>

Hentai let me know if you want me to remove the older version of the spreadsheet or even replace it with this one. (Send me a PM)

Thread is awesome as always. Nick and I are friends and go back quite some ways - from the days when he lived up here.

Hi Jmfahley,

I've very familiar with the metallurgical properties of 12l14. I've been running a metallurgical research lab for 2 years. And I have been in the field of metallurgy for close to 15 years. But I am not a metallurgical though. I don't want to be. Working on my electrical engineering degree.

The lathe I'm using is an old manual southbend tool room lathe. Its small but its the only lathe we have at work. But it functions quite well.

It has more capabilities then I do as a machinist, . But I'm learning. And yes it uses carbide inserts for cutting.

. But I'm learning. And yes it uses carbide inserts for cutting.

Nick

I've very familiar with the metallurgical properties of 12l14. I've been running a metallurgical research lab for 2 years. And I have been in the field of metallurgy for close to 15 years. But I am not a metallurgical though. I don't want to be. Working on my electrical engineering degree.

The lathe I'm using is an old manual southbend tool room lathe. Its small but its the only lathe we have at work. But it functions quite well.

It has more capabilities then I do as a machinist,

Nick

FWIW I use 12L14 for my centerpoles.

The main reason for its popularity is mechanical, not magnetic.

It has micro "bubbles" of lead floating in the crystal structure (the lead is not chemically alloyed but sits there unmixed) which help machinability *a lot*.

1) lead drops provide "break points" so shavings break in short easy to handle pieces

2) soft lead acts as a kind of solid lubricant.

It reduces friction and heat

While SAE1008/1010 steel is magnetically better, it's soft and pliable (for a steel, of course) and you get messy long curly shavings which clutter the workspace.

Also if you work turning long bars in automatic high speed lathes, *sometimes* the tool bit "bites" too much and breaks.

So to play it safe, you have to lower speed

Besides, for high production the actual cutting tip is a small carbide insert attached to a larger regular steel part, and the joint is not exactly impact resistant.

- Home

- Loudspeakers

- Multi-Way

- Project Ryu - DIY Field Coil Loudspeaker