Speaking about EV DH1A's, I had a look at four specimens that were pulled from MTH-2 cabs. The drivers mouth opening measured 32mm across. That is a little short of 1,3", not 1,4" as reported by Art previously in this thread. In actual fact what I measured was the hole in the round flat (~1,5 mm thick) gasket of the driver. I didn't want to start fiddling with it just yet, so I don't know what is going on under that gasket.

We were hoping to mate these to some eighteensound XT1464 horns, which have a 1,4" throat. Any comments on this?

We were hoping to mate these to some eighteensound XT1464 horns, which have a 1,4" throat. Any comments on this?

Bob4,

The EV MTA-22 spec sheet does claim a 1.3 inch entrance.

The gasket may be undersized compared to the throat exit.

I no longer have any EV DH1AMT drivers or EV MTA-22, but still have a few adapters made by my father on his lathe to mate those drivers to a standard 2" (1.94") horn entrance, and they measure a taste over 35mm on the driver side.

I am fairly certain that was the correct dimension for the throat exit for the 1991 vintage DH1AMT drivers, as it was duplicated with calipers.

The XT1464 horn entrance is 35.5mm, or 36mm, depending on what part of the spec sheet you look at ;^).

If your driver's exit is only 32mm, it would be best to make a transition flange to avoid a discontinuity between it and the horn you mate it to. That said, a perimeter step of 1.75mm going to a larger horn throat will not cause reflections, while "choking down" would.

Art

The EV MTA-22 spec sheet does claim a 1.3 inch entrance.

The gasket may be undersized compared to the throat exit.

I no longer have any EV DH1AMT drivers or EV MTA-22, but still have a few adapters made by my father on his lathe to mate those drivers to a standard 2" (1.94") horn entrance, and they measure a taste over 35mm on the driver side.

I am fairly certain that was the correct dimension for the throat exit for the 1991 vintage DH1AMT drivers, as it was duplicated with calipers.

The XT1464 horn entrance is 35.5mm, or 36mm, depending on what part of the spec sheet you look at ;^).

If your driver's exit is only 32mm, it would be best to make a transition flange to avoid a discontinuity between it and the horn you mate it to. That said, a perimeter step of 1.75mm going to a larger horn throat will not cause reflections, while "choking down" would.

Art

Hello Art,

thank you very much for the swift reply! I suspect it may just be a wrong gasket cutout size. THe MTH2 datasheet says 1,375, which would only be half a millimeter off. Curiously, I forgot to measure the throat of the horn adaptor. Let's see what I can find out next time.

thank you very much for the swift reply! I suspect it may just be a wrong gasket cutout size. THe MTH2 datasheet says 1,375, which would only be half a millimeter off. Curiously, I forgot to measure the throat of the horn adaptor. Let's see what I can find out next time.

went back to have a look at the DH1a's. Remembered to bring my Caliper, but forgot the heat gun this time. Hence I couldn't soften up the glue, and decided not to rip off the gasket. instead I inspected the inside of the driver with the aid of a flashlight. Although the gasket seemed to be slightly undersized, it was only by a small margin.

I measured the throats of the bisecting adaptor, and came up with 33 mm. That would make it a hair under 1,3" wide.

In the best case (XT1464 throat diameter=35,5mm) I would be looking at a 1,25 mm discontinuity. unfortunately I don't really have any means to design, let alone build adaptors. I'm not sure what flare rate the driver has at the mouth exit. I have a hunch that the adaptor piece would become too short to be practical. Have to look up the old JBL adaptor piece that goes between 035 and 2350, can't remember the part number.....

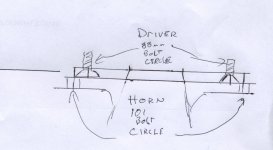

if that wasn't enough, another problem emerged, the mounting thread placement. They are arranged at a diameter of 88mm, while the XT1464 has holes spaced at 102mm.

Just looking at pictures and the construction diagrams, I'm confident that additional, matching holes could be drilled into the throat flange.

Drilling new holes and tapping threads into the comp drivers themselves is not really an option, again due to not having facilities and tools for the process.

alas, what to do? Would it be worth a shot to try our luck with the DH1A & XT1464 without adaptors? Opinions?

I measured the throats of the bisecting adaptor, and came up with 33 mm. That would make it a hair under 1,3" wide.

In the best case (XT1464 throat diameter=35,5mm) I would be looking at a 1,25 mm discontinuity. unfortunately I don't really have any means to design, let alone build adaptors. I'm not sure what flare rate the driver has at the mouth exit. I have a hunch that the adaptor piece would become too short to be practical. Have to look up the old JBL adaptor piece that goes between 035 and 2350, can't remember the part number.....

if that wasn't enough, another problem emerged, the mounting thread placement. They are arranged at a diameter of 88mm, while the XT1464 has holes spaced at 102mm.

Just looking at pictures and the construction diagrams, I'm confident that additional, matching holes could be drilled into the throat flange.

Drilling new holes and tapping threads into the comp drivers themselves is not really an option, again due to not having facilities and tools for the process.

alas, what to do? Would it be worth a shot to try our luck with the DH1A & XT1464 without adaptors? Opinions?

Last edited:

Bob,I measured the throats of the bisecting adaptor, and came up with 33 mm. That would make it a hair under 1,3" wide.

In the best case (XT1464 throat diameter=35,5mm) I would be looking at a 1,25 mm discontinuity. unfortunately I don't really have any means to design, let alone build adaptors. I'm not sure what flare rate the driver has at the mouth exit.

if that wasn't enough, another problem emerged, the mounting thread placement. They are arranged at a diameter of 88mm, while the XT1464 has holes spaced at 102mm.

Just looking at pictures and the construction diagrams, I'm confident that additional, matching holes could be drilled into the throat flange.

Would it be worth a shot to try our luck with the DH1A & XT1464 without adaptors? Opinions?

You are overthinking the problem, "flare rate" for an adapter only 5-7mm thick is basically a straight line connecting two circles, easily made with a few minutes of filing.

The adapter can be made from aluminum plate using a drill, bits of the bolt diameter, countersink bits, a circle cutter, and a half round bastard file.

The adapter will allow both the horn and driver to be used "as is" with no additional holes drilled in either.

Mark the centerpoint and bolt circles with a compass/caliper divider on the aluminum plate.

To avoid measurement errors, a sheet of paper and the side of a pencil lead brushing over the existing driver and horn bolt holes can be used to make transfer templates for the bolt hole positions.

Drill & countersink the 88mm & 102 mm mounting bolt holes on opposite sides.

Using the circle cutter, drill the center hole to the exact diameter of the driver exit. Use the half round bastard file to expand it to the exact size of the horn mouth. If you don't have a smoother file, use sandpaper around a dowel or piece of tube to smooth the entry.

The scale diagram below shows how little material needs to be filed out for the worst case of a 33mm driver to 36mm horn.

Cheers,

Art

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- High Frequency Compression Driver Evaluation