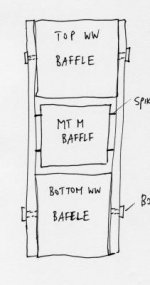

Please consider the following design:

The man behind this design recommeds that the MTM baffle be isolated from the top WW and bottom WW. Obveously this raute was not taken here, in my openion for aethstetic reasons, and more importantly, for simplicity in manufacturing, as this is supposed to be a mass-produced product, despite the fact that "mass-produced" is a relative term. I am contimplating using a set of 4 ten inch drivers from the Seas Excell line on top and on bottom, and running them from 40 Hz to 120 Hz. With this in mind, should I make an attempt at an isolated MTM baffle (which by the way uses eight inch mids) or just keep it simple, and go for one ridgid yet lossy (is that an oxymoron) board to house the 7 drivers?

At first, this seems like a simple choice: just do it and get it over with. But when you start looking at different methods of isolating one baffle from the other, it is just not straight forward. This is why I am looking for recommendations on how, or if, this should be done.

One particular option came to mind, and I have no idea if it will fly. I was thinking about using many rubber band type, or more like bungee cord type loops to suspend the MTM from the WW=WW frame. They can be attached on all sides, and can be made rather tense. The only question is, will this result in loss of enargy as desired, or just become a set of complex vibrating strings and cause quite a mess? If not cords, then what king of material can be used? And how can it all be attached together? Many Thanks!!!

The man behind this design recommeds that the MTM baffle be isolated from the top WW and bottom WW. Obveously this raute was not taken here, in my openion for aethstetic reasons, and more importantly, for simplicity in manufacturing, as this is supposed to be a mass-produced product, despite the fact that "mass-produced" is a relative term. I am contimplating using a set of 4 ten inch drivers from the Seas Excell line on top and on bottom, and running them from 40 Hz to 120 Hz. With this in mind, should I make an attempt at an isolated MTM baffle (which by the way uses eight inch mids) or just keep it simple, and go for one ridgid yet lossy (is that an oxymoron) board to house the 7 drivers?

At first, this seems like a simple choice: just do it and get it over with. But when you start looking at different methods of isolating one baffle from the other, it is just not straight forward. This is why I am looking for recommendations on how, or if, this should be done.

One particular option came to mind, and I have no idea if it will fly. I was thinking about using many rubber band type, or more like bungee cord type loops to suspend the MTM from the WW=WW frame. They can be attached on all sides, and can be made rather tense. The only question is, will this result in loss of enargy as desired, or just become a set of complex vibrating strings and cause quite a mess? If not cords, then what king of material can be used? And how can it all be attached together? Many Thanks!!!

roddyama said:From a pratical standpoint, I think it's 6 of one and a half dozen of the other. That said, if I were to make this system, I would make the tower in 3 sections, with the top and bottom being the same.

Any ideas on the specifics of how these would stack together? I am starting to think that some high loss O rings between drivers and baffle may be sufficient, something like .25 inches of rubber...

I got into this dicussion a while back. IMO, the drivers should be solidly mounted to the baffle. That provides some stability by giving the cones of the drivers some mass to work against.amo said:

Any ideas on the specifics of how these would stack together? I am starting to think that some high loss O rings between drivers and baffle may be sufficient, something like .25 inches of rubber...

In your case, I would make the upper and lower boxes exactly the same, and the middle box would have the same size foot print. You can than use rubber or neoprene between the boxes. Each box can be bolted to the adjacent box. The bolts can be mounted in the boxes using the type of methods used in automotive supensions (hard rubber grommets).

roddyama said:

I got into this dicussion a while back. IMO, the drivers should be solidly mounted to the baffle. That provides some stability by giving the cones of the drivers some mass to work against.

In your case, I would make the upper and lower boxes exactly the same, and the middle box would have the same size foot print. You can than use rubber or neoprene between the boxes. Each box can be bolted to the adjacent box. The bolts can be mounted in the boxes using the type of methods used in automotive supensions (hard rubber grommets).

Fortunately, these are not boxes, as this one is an open baffle design (check out the image to the right). This makes things much simpler.

Sorry Amo. I'm not much of a di-pole sort-of guy. But here's a thought. You could make one sub-baffle that is the full height of the tower. Than make 3 main baffles that mount to the front of the sub-baffle. The upper and lower main baffles would be solidly mounted to the sub-baffle, and the center main baffle (with the MTM) would be isolated with a layer of rubber.

By building it in 3 sections, you make it easier to ship and transport, can use smaller package as well.

Gasket and O-rings coupling drivers to the panel effect the sound. I found that neoprene, cork or some other soft materials are no good for bass and one or two layers of rubber was best. You might try the thick O-rings, but I would recommend experimenting.

I noticed that often cones are used between enclosures stack on ea other. Here's my open baffle speaker, and although different from yours you might use some ideas. The pedestal is a box filled with sand. The lower bass folded baffle is bolted to it. I used 2 x1" aluminum bars to attach the top baffle and the MTM is resting on the bottom bass cabinet. Initially I was using sort of isolation sheet, but later found that 2 drill bits laying flat do better isolation. If the shape was different, the MTM baffle could also be attached to aluminum bars with spikes (on sides) by producing tension with bolts attaching top and bottom bass baffles.

Gasket and O-rings coupling drivers to the panel effect the sound. I found that neoprene, cork or some other soft materials are no good for bass and one or two layers of rubber was best. You might try the thick O-rings, but I would recommend experimenting.

I noticed that often cones are used between enclosures stack on ea other. Here's my open baffle speaker, and although different from yours you might use some ideas. The pedestal is a box filled with sand. The lower bass folded baffle is bolted to it. I used 2 x1" aluminum bars to attach the top baffle and the MTM is resting on the bottom bass cabinet. Initially I was using sort of isolation sheet, but later found that 2 drill bits laying flat do better isolation. If the shape was different, the MTM baffle could also be attached to aluminum bars with spikes (on sides) by producing tension with bolts attaching top and bottom bass baffles.

Attachments

Quote: IMO, the drivers should be solidly mounted to the baffle. That provides some stability by giving the cones of the drivers some mass to work against.

This is exactly right. Ever hold a woofer in your lap while it was doing its business and notice it's just not that impressive? It's because, like turning a bolt in space, the basket of the woofer is as likely to move as the cone is; thus, there's very little displacement, and thus, very little sound. I have some Radio Shack 8" full-rangers that I just hated because I put them in a "high-loss" situation where the baskets were moving all the time. They sounded horrible. I put the same drivers in a dipole config, and suddenly they came to life, giving decent bass response (for a full-range anyway) and that wonderful dipole "in-your-face" rock sound.

Keep those baskets securely in place. Otherwise, you're just wasting displacement volume.

This is exactly right. Ever hold a woofer in your lap while it was doing its business and notice it's just not that impressive? It's because, like turning a bolt in space, the basket of the woofer is as likely to move as the cone is; thus, there's very little displacement, and thus, very little sound. I have some Radio Shack 8" full-rangers that I just hated because I put them in a "high-loss" situation where the baskets were moving all the time. They sounded horrible. I put the same drivers in a dipole config, and suddenly they came to life, giving decent bass response (for a full-range anyway) and that wonderful dipole "in-your-face" rock sound.

Keep those baskets securely in place. Otherwise, you're just wasting displacement volume.

I think he is asking about resiliently mounting only the MTM part, and keeping the WW/WW baffles rigid for sure.

If I were attempting this design, I wouldn't resiliently mount the MTM baffle to the WW/WW baffles at all... if the WW/WW baffle is vibrating, you would still induce vibration into the MTM baffle, only it would be somewhat damped by the hysteresis damping of the isolation used. And man, you really wouldn't want the isolation + MTM baffle to have a natural frequency anwhere in the MTM's useable range... would hate for the MTM baffle to hit a resonance.

Instead, try something like this:

- Very solid (and likely heavy) base.

- Vertical rails on each side to mount the WW/WW baffles to - may require depth bracing as well.

- A second set of rails, perhaps inset from the WW/WW rails, to which the MTM baffle is attached - no vibration induced from WW/WW baffle, and much easier to address natural frequency.

- No mechanical connection at all between MTM and WW/WW baffles except through the base, which should effectively isolate the two baffles.

With some nice woodworking (or otherwise), the gap between the three baffles could be quite small, with a negligible impact on dipole path. Even a very soft gasket between the two wouldn't do any harm, so long as the connection between MTM baffle and the base is very rigid and the gasket very elastic.

Just a few thoughts.

If I were attempting this design, I wouldn't resiliently mount the MTM baffle to the WW/WW baffles at all... if the WW/WW baffle is vibrating, you would still induce vibration into the MTM baffle, only it would be somewhat damped by the hysteresis damping of the isolation used. And man, you really wouldn't want the isolation + MTM baffle to have a natural frequency anwhere in the MTM's useable range... would hate for the MTM baffle to hit a resonance.

Instead, try something like this:

- Very solid (and likely heavy) base.

- Vertical rails on each side to mount the WW/WW baffles to - may require depth bracing as well.

- A second set of rails, perhaps inset from the WW/WW rails, to which the MTM baffle is attached - no vibration induced from WW/WW baffle, and much easier to address natural frequency.

- No mechanical connection at all between MTM and WW/WW baffles except through the base, which should effectively isolate the two baffles.

With some nice woodworking (or otherwise), the gap between the three baffles could be quite small, with a negligible impact on dipole path. Even a very soft gasket between the two wouldn't do any harm, so long as the connection between MTM baffle and the base is very rigid and the gasket very elastic.

Just a few thoughts.

Peter Daniel said:By building it in 3 sections, you make it easier to ship and transport, can use smaller package as well.

Gasket and O-rings coupling drivers to the panel effect the sound. I found that neoprene, cork or some other soft materials are no good for bass and one or two layers of rubber was best. You might try the thick O-rings, but I would recommend experimenting.

I noticed that often cones are used between enclosures stack on ea other. Here's my open baffle speaker, and although different from yours you might use some ideas. The pedestal is a box filled with sand. The lower bass folded baffle is bolted to it. I used 2 x1" aluminum bars to attach the top baffle and the MTM is resting on the bottom bass cabinet. Initially I was using sort of isolation sheet, but later found that 2 drill bits laying flat do better isolation. If the shape was different, the MTM baffle could also be attached to aluminum bars with spikes (on sides) by producing tension with bolts attaching top and bottom bass baffles.

I was actually considering using metal rods for support, but your idea of using thick solid metal bars really makes sence! It will add much needed mass to the whole thing. Can you please elaborate on your idea of attaching the baffle with spikes? I am not sure what you mean by producing tension with bolts in this particular case. This is defenantly good!

Thanks.

mcp said:For the MTM, I would prefer 5" or 4 1/2" instead of 8". It should also be isolated from the 10s.

Up untill very recently, I would agree with you. In fact, I was just going over this on my walk. However, studying Linkwitz's site really opened my eyes. I do not have the theory down enough to repeat it here, but for this application 8 in is the way to go. I was looking at the driver distortion data, and this is the only area that would not compare well with smaller drivers, between 1000 and 1400 hz (cross over point). However, I will be using 4 of these things, so the distortion levels should be LOW!

I based my idea on Pagode rack system. It got very good reviews as sounding well: http://www.finite-elemente.de/d,,tests.html You might try do more search for better pics:

http://www.finite-elemente.de/english/news-archiv.html

Here, how I would use it in baffle mounting. By tightning top and bottom bolts on WW baffles, you will also create pressure on spikes located in MTM baffle and by careful adjustment of those spikes they would create sort of isolation between baffle and rails. I kinda think about it myself, as I think the time has come to modify my speakers

http://www.finite-elemente.de/english/news-archiv.html

Here, how I would use it in baffle mounting. By tightning top and bottom bolts on WW baffles, you will also create pressure on spikes located in MTM baffle and by careful adjustment of those spikes they would create sort of isolation between baffle and rails. I kinda think about it myself, as I think the time has come to modify my speakers

Attachments

RHosch said:I

- No mechanical connection at all between MTM and WW/WW baffles except through the base, which should effectively isolate the two baffles.

Do you mean the vertical rails instead of the base? Are you refering to the entire thing as the base here? I have been consumed by this design all day. I can not come up with a ballance of not transfering energy from one baffle to another, and having a solid mount for the baffle, so that the "xmax is not waisted" so to speak...

Marble or even granite would be something else! Perhaps a few slabs will make it into the design of the base. I do not want to complicate this any further, although stone would be way cool.navin said:yup now if you could buldthose sides out of marble slabs.....

I keep thinking about this and looking at the links, but can not understand wether the spikes would provide enough tention? to keep the entire baffle from vibrating. After all, we want to dampen yet have a solid enough mount... I am not sure. As far as the frame, for some reason I though I could make the entire thing of solid metal rails. Then I came to the hardware store and realized the they ring like bells when lightly tapped. So that idea was trashed. I guess laminated MDF is the way to go for the frame/rails... Maybe birch?Peter Daniel said:I based my idea on Pagode rack system. It got very good reviews as sounding well: http://www.finite-elemente.de/d,,tests.html You might try do more search for better pics:

http://www.finite-elemente.de/english/news-archiv.html

Here, how I would use it in baffle mounting. By tightning top and bottom bolts on WW baffles, you will also create pressure on spikes located in MTM baffle and by careful adjustment of those spikes they would create sort of isolation between baffle and rails. I kinda think about it myself, as I think the time has come to modify my speakers

amo said:

Do you mean the vertical rails instead of the base? Are you refering to the entire thing as the base here? I have been consumed by this design all day. I can not come up with a ballance of not transfering energy from one baffle to another, and having a solid mount for the baffle, so that the "xmax is not waisted" so to speak...

I probably wasn't very clear in my description. What I was suggesting, and by no means do I think it would be straightforward to accomplish, was a very rigid and heavy base plate (foundation), and separate attachment of each baffle to this base. The upper and lower WW baffles could be coupled together (i.e., mounted to the same "rails" or framing system), but the MTM baffle should have its own rigid connection to the base, and the baffles (MTM and WW/WW) should be isolated from on another (or, simply, not connected).

You're right... making the upper WW baffle rigid isn't a trivial task considering you don't have the typical box structure to offer geometrical stiffness, and this is compounded by the additional complexity of isolating the MTM baffle. But... it's the best way to accomplish the isolation you seek.

Any mounting of the MTM baffle to the WW/WW baffle is going to induce vibration into the MTM baffle, unless your isolation had an excursion capability of several millimeters (being conservative - you do have a pretty large moving mass at a pretty sizeable moment arm distance from the base), and you could fanagle the resonance to be out of the range of both baffles (e.g., above 20kHz or below 20Hz...). Not an easy task at all - I think separate connections to the base would be more plausible.

Of course, you can always just go the route of one super-rigid baffle.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Materials advice needed