No, it has dried more than one hour (wood glu) so it should be ok.

They look huge compared to my small CA18RLY I got recently. I just hope that I have got some result, it is getting crowded in there if I put in something more, I do not want to stop air flow. I will play my "hate-CD" tomorrow and check (Diana Krall: Live in Paris).

They look huge compared to my small CA18RLY I got recently. I just hope that I have got some result, it is getting crowded in there if I put in something more, I do not want to stop air flow. I will play my "hate-CD" tomorrow and check (Diana Krall: Live in Paris).

Now it has dried, tested that Live in Paris CD and no more resonance from the box itself  . I will give more impressions tonight together with the inside picture. I just hope that this last mod has not destroyed bass performance, but after the quick checking today it seemed fine.

. I will give more impressions tonight together with the inside picture. I just hope that this last mod has not destroyed bass performance, but after the quick checking today it seemed fine.

Some impressions: all together it is a step up in sound quality, that is clear to me. Middle range more clarity but with warmth, bass seem more robust. I also tried with the front panels on, and I like the bass support it gives so they will stay.

I can finally say the speakers are ready, I am very pleased and will enjoy my time with them. I have learned how cabinet rigidity is important, and how to achieve that in my own way. MDF is probably ok if you use solid wood for bracing, but next time I will use birch plywood. My original bracing was also made from MDF since that was what was available, but I can say now that it is not a good idea, use solid pine rod or something similar.

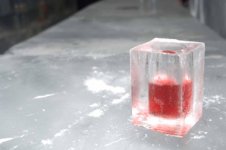

I send this to Salas to help him get cool in hot Athens....

I can finally say the speakers are ready, I am very pleased and will enjoy my time with them. I have learned how cabinet rigidity is important, and how to achieve that in my own way. MDF is probably ok if you use solid wood for bracing, but next time I will use birch plywood. My original bracing was also made from MDF since that was what was available, but I can say now that it is not a good idea, use solid pine rod or something similar.

I send this to Salas to help him get cool in hot Athens....

Attachments

Some impressions: all together it is a step up in sound quality, that is clear to me. Middle range more clarity but with warmth, bass seem more robust. I also tried with the front panels on, and I like the bass support it gives so they will stay.

I can finally say the speakers are ready, I am very pleased and will enjoy my time with them. I have learned how cabinet rigidity is important, and how to achieve that in my own way. MDF is probably ok if you use solid wood for bracing, but next time I will use birch plywood. My original bracing was also made from MDF since that was what was available, but I can say now that it is not a good idea, use solid pine rod or something similar.

I send this to Salas to help him get cool in hot Athens....

Whoever is going to copy this speaker using MDF better follow your bracing guide, pictures tell the tale. The original cabinet is made out of different wood and bracing material. Your cab should be better controlled. Thanks for the ice cube, happy listening. A good project came to its full.

Some bad news I'm afraid, I have noticed another box related problem. The backside opposite the woofer is making a lot of noise, it is obviously that infamous back-bounce pressure. I know understand why it is common to use shelf bracing since it gives more support for the panels. Is it common that speakers has this problem? Maybe if I glue a few rods at the back from side to side and also to the backpanel, it will help. Or I just need a birch plywood box after all.

Like this:

Like this:

Attachments

I will reinforce the back panel with some ribs or rod when I get my energy back, lol.

It is only the part behind the woofer that needs it, higher up and lower down it makes no sound. It is obvious now that if you want to be serious about this speaker and use MDF, you should do some serious bracing. Those drivers deserve it.

It is only the part behind the woofer that needs it, higher up and lower down it makes no sound. It is obvious now that if you want to be serious about this speaker and use MDF, you should do some serious bracing. Those drivers deserve it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- "Tired2way" speaker building.