Hi,

Yes. he has spent lot of money and is disappointed. that is most probably

because something has gone wrong, and I'm fairly sure its an inadequate

crossover design.

If you want something to be right you have to do it all right, baby steps

don't help IMO, they just confuse the matter, as does poor c/o calculators.

The point about diffraction is not just noise, it is fundamental to quality.

Your not understanding what I'm saying. The diffraction model of the

current baffle with the drivers published curves will give box response.

The steps are all detailed in the links I provided and can be followed one by

one. When finished it would probably end up being near 4th order L/R acoustic

with 2nd order electrical on the bass and 2nd or 3rd order on the treble.

The idea that you won't learn something by going through the modelling

process, is just bizarre, it won't do it for you, you have to work it out

and understand what is going on for meaningful results.

And hopefully realise where something went wrong.

rgds, sreten.

Okay. Have at it.

IMO, there's not much of a dialog going on here- lots of advice and only a few posts from the OP. It's tough to troubleshoot without hearing it, and theory will only get you so far. I've seen sealed systems filled with foam, but not ported systems. A lot of foam could have a real impact on how a ported system sounds, and probably not for the better. Given that the boxes are together, I'd still try to rip out the foam. The Egyptians got the brains out of mummies through the nose, so getting the foam out through the woofer hole should be possible. I'd also experiment with the ports if it's possible to change the tuning or even damp or plug 'em. In general, it's best to make large changes to be sure of what direction to go. Small changes usually lead to much wandering and little certainty. It might be useful to listen to a sweep (easily done with a PC recorded CD) of the low frequencies to see how smooth it is and what room placement does. Bottom line is do something, and do something large enough to determine a direction.

Hi speedie,

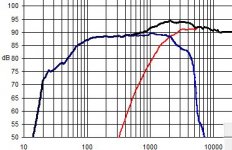

Outcome from a quick simulation: Looks IMO OK in a 22L ported box(No stuffing): See the picture:

b

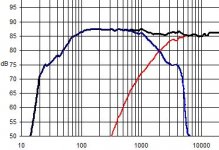

FYI: Adding a more complete simulation slightly stuffed 22L ported box and an attempt (some random cut and past notes) for to examine eventual filter problems using electrical equivalents of the drivers(IB impedances only).

The only real problem I found is if not using a suitable baffle step compensation and if not using a Zobel compensation for the Peerless driver.

The damping material looks to be of closed cell type and should IMO/IME be avoided in any speaker.

b

Attachments

more thought

Seems like my post has stirred up a crossover nightmare

What was used in the design is 16# copper motor winding wire two polyprop caps in a two 2nd order LR combination

C1= 14.6 Uf C2=6.5

L1=0.4 L2 =1.1 Mh

These are numbers derived from X-over pro

As stated earlier I was under the impression that they were bass shy

After some more auditioning they seem to be improving to my ears

as an interesting exercise to me I would like to build the same box configuration in plain MDF and screw panels together then do as has been suggested

Alter the stuffing or attenuating media

Also apply differing crossover combinations and employ the Zobel circuits

Then listen to side by side or A/B and see what sonic differences will be produced

As a side note there is a considerable amount of air movement in and out of the port when more power is applied

Also with my ears near the peerless driver I can also hear more mid coming from the cone area then more to the port and hear lower notes in a bassier tone

Thanks once again speedie

Seems like my post has stirred up a crossover nightmare

What was used in the design is 16# copper motor winding wire two polyprop caps in a two 2nd order LR combination

C1= 14.6 Uf C2=6.5

L1=0.4 L2 =1.1 Mh

These are numbers derived from X-over pro

As stated earlier I was under the impression that they were bass shy

After some more auditioning they seem to be improving to my ears

as an interesting exercise to me I would like to build the same box configuration in plain MDF and screw panels together then do as has been suggested

Alter the stuffing or attenuating media

Also apply differing crossover combinations and employ the Zobel circuits

Then listen to side by side or A/B and see what sonic differences will be produced

As a side note there is a considerable amount of air movement in and out of the port when more power is applied

Also with my ears near the peerless driver I can also hear more mid coming from the cone area then more to the port and hear lower notes in a bassier tone

Thanks once again speedie

Wooha that’s a lot of foam for a small speaker; also, never do the front baffle board.

I used to over load foam in my subs (I did use the same foam as you) big mistake(s), now I don’t use any (or very little) and much happier with the results.

May be too late for this project, but sometimes I line small speakers with lead, and small pieces of 1/2“ to 3/4” foam.

I used to over load foam in my subs (I did use the same foam as you) big mistake(s), now I don’t use any (or very little) and much happier with the results.

May be too late for this project, but sometimes I line small speakers with lead, and small pieces of 1/2“ to 3/4” foam.

hopefully i have posted the correct way

Wooha that’s a lot of foam for a small speaker; also, never do the front baffle board.

I used to over load foam in my subs (I did use the same foam as you) big mistake(s), now I don’t use any (or very little) and much happier with the results.

May be too late for this project, but sometimes I line small speakers with lead, and small pieces of 1/2“ to 3/4” foam.

Yeah, the foam is obstructing the woofer cone pretty badly. it's gotta go.

question

Bjorno

Looking closer at your calculations am I to read them that the tweeter circuit has an 8.84 Uf cap and a 0.72 Mh inductor and the values of R1& R2 are the resistance from these components

Then the woofer circuit has a 1.6Mh inductor using a 6.4 Ohm resistor around the coil (this is zobel component) then in series with another 1.83Mh coil and a 3.46Uf cap.

Now that I have looked and thought a bit more the first question seems silly in respect as there are no R1 R2 components in the woofer area?

So much science!

Cheers speedie

Bjorno

Looking closer at your calculations am I to read them that the tweeter circuit has an 8.84 Uf cap and a 0.72 Mh inductor and the values of R1& R2 are the resistance from these components

Then the woofer circuit has a 1.6Mh inductor using a 6.4 Ohm resistor around the coil (this is zobel component) then in series with another 1.83Mh coil and a 3.46Uf cap.

Now that I have looked and thought a bit more the first question seems silly in respect as there are no R1 R2 components in the woofer area?

So much science!

Cheers speedie

Hi,

I'm out of here, the fundamental problem is being ignored. The OP

does not understand speaker design, or the limitations of X-over pro,

because the latter requires the former, the crossover is simply wrong.

There is so much ill informed conjecture in this thread, most of it from people

it seems who don't have the experience to know what is likely to be wrong.

That is simple, a very poor alleged 2nd order L/R crossover, it isn't.

That is due to a fairly poor software program, and no understanding.

All information on how to do it properly are in my previous links and posts.

rgds, sreten.

I'm out of here, the fundamental problem is being ignored. The OP

does not understand speaker design, or the limitations of X-over pro,

because the latter requires the former, the crossover is simply wrong.

There is so much ill informed conjecture in this thread, most of it from people

it seems who don't have the experience to know what is likely to be wrong.

That is simple, a very poor alleged 2nd order L/R crossover, it isn't.

That is due to a fairly poor software program, and no understanding.

All information on how to do it properly are in my previous links and posts.

rgds, sreten.

Last edited:

Hi,

I'm out of here, the fundamental problem is being ignored. The OP

does not understand speaker design, or the limitations of X-over pro

because the latter requires the former, the crossover is simply wrong.

rgds, sreten.

Why get frustrated now? The guy needs and is asking for some hand holding and just because you feel ignored you scoot away? There are a lot of cooks in the kitchen.

You should have more tenacity than that if you feel you have something to offer and you can establish a good dialog with the builder.

Incidentally, my only difference with you (if we really have a difference) was that I didn't want him to get discouraged trying to drink out of the fire hose.

Stick with it a little more.

Why get frustrated now? The guy needs and is asking for some hand holding and just because you feel ignored you scoot away? There are a lot of cooks in the kitchen.

You should have more tenacity than that if you feel you have something to offer and you can establish a good dialog with the builder.

Incidentally, my only difference with you (if we really have a difference) was that I didn't want him to get discouraged trying to drink out of the fire hose.

Stick with it a little more.

Hi, I'm not frustrated, I'm bored. Too many people with no real idea giving advice, rgds, sreten.

Last edited:

I think that it would be wise to pull that foam out before anything else, as Mr. Hoffman (among others) has suggested several times. The OP has, if I'm reading this correctly, complained about the bass seeming a bit thin. I would disconnect the tweeter and listen to it (along with an SPL meter) using test tone and chart out the steps. If the bass is rolling off too high, then I'd certainly consider ripping that foam completely out, he can replace it with polyfil, or whatever, at a later time. I wouldn't hesitate to take the foam off the front baffle no matter what, it shouldn't even be there.

The crossover isn't even a factor at the lower bass frequencies and by disconnecting the tweeter we can ignore the balancing act with Baffle Step, levels, etc., until the lack of bass is attended to.

I remember a fairly well known professional speaker builder had problems with a design and asked Dan Wiggins to check it out, after he had tried just about everything. Turned out that Dan listened to it, then removed a woofer to find that the cabinet was lined with "Black Hole" foam. He told the designer to rip it out and guess what...problem solved! BTW: That builder was giving away yards and yards of that expensive BH foam the very next week and never used it again.

Best Regards,

TerryO

The crossover isn't even a factor at the lower bass frequencies and by disconnecting the tweeter we can ignore the balancing act with Baffle Step, levels, etc., until the lack of bass is attended to.

I remember a fairly well known professional speaker builder had problems with a design and asked Dan Wiggins to check it out, after he had tried just about everything. Turned out that Dan listened to it, then removed a woofer to find that the cabinet was lined with "Black Hole" foam. He told the designer to rip it out and guess what...problem solved! BTW: That builder was giving away yards and yards of that expensive BH foam the very next week and never used it again.

Best Regards,

TerryO

Last edited:

Hi,

<snip>

There is so much ill informed conjecture in this thread, most of it from people

it seems who don't have the experience to know what is likely to be wrong.

That is simple, a very poor alleged 2nd order L/R crossover, it isn't.

That is due to a fairly poor software program, and no understanding.

<snip>

With respect sreten, without seeing any measurements I would assert that your comments are conjecture as well

Tony.

guys lets all settle down and be a little more relaxed in this issue after all the common ground is music, which sooth the savage beast

i am still a little green in this feild and apoligise if i seem ignorant

i will try as best i can to remove the foam from the front baffle and see if it yeilds better results

i do not have any sound generating software nor an adequate mic for recording sound sweeps

the only real thing is a sound perssure meter, LCR meter,multi meter

the reason that i put these smaller boxes together was for this very reason to over come potential problems in the tower build

all the assistance that is provided is a bonus and i thank one and all reponses

all that have posted selflessly provided more invaluable insight

once again cheers speedie

i am still a little green in this feild and apoligise if i seem ignorant

i will try as best i can to remove the foam from the front baffle and see if it yeilds better results

i do not have any sound generating software nor an adequate mic for recording sound sweeps

the only real thing is a sound perssure meter, LCR meter,multi meter

the reason that i put these smaller boxes together was for this very reason to over come potential problems in the tower build

all the assistance that is provided is a bonus and i thank one and all reponses

all that have posted selflessly provided more invaluable insight

once again cheers speedie

What was used in the design is 16# copper motor winding wire two polyprop caps in a two 2nd order LR combination

C1= 14.6 Uf C2=6.5

L1=0.4 L2 =1.1 Mh

These are numbers derived from X-over pro

As a side note there is a considerable amount of air movement in and out of the port when more power is applied

I can't see any mention of padding resistors for the tweeter but even so, those values are way off the money. If you look at a rough sim (graph below) using your values you can see where the problem exists.

Crossover design is the hardest part to get right in speaker design and would suggest looking around at some existing designs or getting someone like Stones Sound Studio to do a crossover design for a moderate fee.

When designing a crossover you have to consider:

BSC, FR, Overlap behaviour, Tweeter level, Phase (check for a deep reverse null where applicable), Impedance behaviour, Polarity etc.

Port noise is due to under size port diameter causing increased air velocity.

Attachments

Port noise is due to under size port diameter causing increased air velocity.

Too small? If anything it looks too large in the picture (I assume the pip is going to be cut down).

Buts as said before, you really can't be sure until you do measurements.

A demonstration of what i said about -6db crossover point at high frequencies. Here, a -3db crossover level would suppress this 2Khz hole.Here's a DX25 + 830875 combo where I just upgraded the AR series crossover. Have a look at the FR, overlap and mild BSC. It will give some idea where you have to aim.

With respect sreten, without seeing any measurements I

would assert that your comments are conjecture as well

Tony.

Hi, No they are not. that is very lazy argument that is wrong

rgds, sreten.

Hi, No they are not. that is very lazy argument that is wrong.

rgds, sreten.

Welcome back.

Well, wouldn't you want to measure the driver's T/S parameters rather than using the published parameters?

Good crossover design depends on good data, no?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- disappointment