I just received my 60 Aurasound NS3-194-16A 3" from Madisound today.

Upon inspection they look like nifty drivers, but have raised a question.

My box of 50, plus a second box of 10 loose ones, have both a mixed bag of similar looking drivers. ALmost half/half.

First driver: terminal has a red stamped "A" like character. cone/former junction has a yellow colored glue on it. Motor tagged: AS3-75-16FR

Second Driver: terminal has no inking. cone/former junction has a black glue on it, and appears to not be as tall as the other driver. motor marked the same.

two drivers have slightly different colored motor metal.

Is this correct? does this line up with every one else's experience?

Upon inspection they look like nifty drivers, but have raised a question.

My box of 50, plus a second box of 10 loose ones, have both a mixed bag of similar looking drivers. ALmost half/half.

First driver: terminal has a red stamped "A" like character. cone/former junction has a yellow colored glue on it. Motor tagged: AS3-75-16FR

Second Driver: terminal has no inking. cone/former junction has a black glue on it, and appears to not be as tall as the other driver. motor marked the same.

two drivers have slightly different colored motor metal.

Is this correct? does this line up with every one else's experience?

Kaholi

All of my NS3 is as the first you describe, except I canot find any yellow glue..?

But they are all the same.

SOOO!

My ALU e closures has come back from the machine shop and been anodizised.

These are for the vifa drivers and will NOT fill teh bill of beeing "stupid cheap"! Not at all.

Aluminium working, espascially when prototypng, is very expensive..

Here are some pictures.

They should be self explainable, but ask away if in doubt.

Koldby

All of my NS3 is as the first you describe, except I canot find any yellow glue..?

But they are all the same.

SOOO!

My ALU e closures has come back from the machine shop and been anodizised.

These are for the vifa drivers and will NOT fill teh bill of beeing "stupid cheap"! Not at all.

Aluminium working, espascially when prototypng, is very expensive..

Here are some pictures.

They should be self explainable, but ask away if in doubt.

Koldby

Attachments

Wow!

Very nice anodized aluminum enclosures! I've been messing with scrap wood to figure out how to cut bezels and learned my Roto Zip only goes down to 83mm holes and I need 76mm.

So I'm back to the hole saw and attempting to figure out how to bevel the holes to prevent diffraction. The weather has turned nasty so I have time to think this one out.

The CNC aluminum bezels would look great but might be a little out of my price range.

Very nice anodized aluminum enclosures! I've been messing with scrap wood to figure out how to cut bezels and learned my Roto Zip only goes down to 83mm holes and I need 76mm.

So I'm back to the hole saw and attempting to figure out how to bevel the holes to prevent diffraction. The weather has turned nasty so I have time to think this one out.

The CNC aluminum bezels would look great but might be a little out of my price range.

Wesayso:

Thanks. I cannot divide into smaller compartments, because the drivers has to be pushed in from top or buttom. I have mounted self adhesive damping aspahlt ( the kind you use in cars) on the inside side and back walls to dampen the resonances in the alu. And I plan to make a wood piece in the hole length , with holes in , a little larger than the inside width, so it will be in tension (not the right word) between the walls to further damp the sides.

gmcalabria:

Thanks. What do you mean by "driver edge treatment"?

18hurtz:

Why not use a router to make the bezel?

You can get special router bits for just that purpose.

That was what I used.

I even made the holes with the router, but the holesaw will be fine.

Koldby

Thanks. I cannot divide into smaller compartments, because the drivers has to be pushed in from top or buttom. I have mounted self adhesive damping aspahlt ( the kind you use in cars) on the inside side and back walls to dampen the resonances in the alu. And I plan to make a wood piece in the hole length , with holes in , a little larger than the inside width, so it will be in tension (not the right word) between the walls to further damp the sides.

gmcalabria:

Thanks. What do you mean by "driver edge treatment"?

18hurtz:

Why not use a router to make the bezel?

You can get special router bits for just that purpose.

That was what I used.

I even made the holes with the router, but the holesaw will be fine.

Koldby

Can't wait to hear/read what it sounds like. I understand your problem with the kind of mounting you have. I do like it though, the drivers beeing mounted from the rear.

I think you allready had everything anodised. Otherwise I'd suggest beveling the inner mounting fixture as well to let the speakers breathe at the back side.

Did you use self damping asphalt? If you havent put it in yet consider using the butyl type damping materials. It is superior to the asphalt in more than one way.

I think you allready had everything anodised. Otherwise I'd suggest beveling the inner mounting fixture as well to let the speakers breathe at the back side.

Did you use self damping asphalt? If you havent put it in yet consider using the butyl type damping materials. It is superior to the asphalt in more than one way.

Last edited:

I'm building test boxes with 4 drivers each--that way I can measure how the frequency response changes from 4 to 8.

The 3 inch hole saw is a perfect cut and for the quicky test boxes, a 83mm C to C distance (3.25") provide plenty of strength for rear mounting.

For the main speakers, I'll use 1/2" plywood to make the bezel then laminate another piece of 1/2" ply over it for a 1" or 24mm bezel thickness. The narrow sealed box for the 3" is 1/2" ply so I just have to router out around 15mm of thickness at the front. My 3/8ths round over bit is too large to perform that function but if I mount it in the Roto Zip, I can lift it up to limit how far out it cuts. I'll find the right balance.

The weather has switched back to winter so no more wood working for another week or so, I'll play around with the test boxes while winter rages.

The 3 inch hole saw is a perfect cut and for the quicky test boxes, a 83mm C to C distance (3.25") provide plenty of strength for rear mounting.

For the main speakers, I'll use 1/2" plywood to make the bezel then laminate another piece of 1/2" ply over it for a 1" or 24mm bezel thickness. The narrow sealed box for the 3" is 1/2" ply so I just have to router out around 15mm of thickness at the front. My 3/8ths round over bit is too large to perform that function but if I mount it in the Roto Zip, I can lift it up to limit how far out it cuts. I'll find the right balance.

The weather has switched back to winter so no more wood working for another week or so, I'll play around with the test boxes while winter rages.

Wesayso:

You are right, the mountring plate ougth to have a bevel as well, but it is only 6 mm thick so it is not a big issue , I think.

Greg:

I only asked the alu- workshop to bevel the holes so there would be no sharp edges. The material is only 4 mm so there is no horn/waveguide function here.

18 Hurts:

Winter?

18 C below zero here between 4. and 5. feb.

Koldby

You are right, the mountring plate ougth to have a bevel as well, but it is only 6 mm thick so it is not a big issue , I think.

Greg:

I only asked the alu- workshop to bevel the holes so there would be no sharp edges. The material is only 4 mm so there is no horn/waveguide function here.

18 Hurts:

Winter?

18 C below zero here between 4. and 5. feb.

Koldby

Going to take 10 or so of the closest matched drivers I have out of the set and do some experiments.

2 control drivers, 8 variations on modifications.

damar resin in linseed oil, damar resin in linseed with beeswax, damar resin in beeswax,

standard mod podge, (note damar resin not damar varnish)

Each with differing levels of coating thickness (ie layer count).

We'll see what sort of cone breakups and resonances we can modify.

2 control drivers, 8 variations on modifications.

damar resin in linseed oil, damar resin in linseed with beeswax, damar resin in beeswax,

standard mod podge, (note damar resin not damar varnish)

Each with differing levels of coating thickness (ie layer count).

We'll see what sort of cone breakups and resonances we can modify.

That would be interesting,

Since the weather has ice forming on the ground, my speaker experiments have stalled due to cold. Later next week at the earliest to start construction of the bezels and get on track again.

I do have the test boxes with 8 drivers operating, those little guys have more bass than I expected. Listening by ear, running 8 of them gives a flatter frequency response than 4 drivers so I'm hoping 21 of them will continue the trend. Pondering dropping the crossover to the woofer lines from 400 to 350 or 300Hz depending on final readings.

Kahooli, do you think just treating the dust cap would ease the huge spike at 9 KHz? I'll be crossing to the tweeter line at 6 KHz but if a little glue and a paint brush smooths that out, all the better.

Looking forward to your results.

Since the weather has ice forming on the ground, my speaker experiments have stalled due to cold. Later next week at the earliest to start construction of the bezels and get on track again.

I do have the test boxes with 8 drivers operating, those little guys have more bass than I expected. Listening by ear, running 8 of them gives a flatter frequency response than 4 drivers so I'm hoping 21 of them will continue the trend. Pondering dropping the crossover to the woofer lines from 400 to 350 or 300Hz depending on final readings.

Kahooli, do you think just treating the dust cap would ease the huge spike at 9 KHz? I'll be crossing to the tweeter line at 6 KHz but if a little glue and a paint brush smooths that out, all the better.

Looking forward to your results.

I really have no intuition as to what areas will affect which frequencies. the first round will be full coatings. I'll be applying them with the same style of brush, and a potters wheel to spin them. the driver will spin on its axis, the brush will be stroked linearly from center to edge. That's the plan at least. I could do the coatings in stages as well. dust cap only then full driver. cone only then full driver on others. We'll see. If I expand the study I can always buy more drivers.

IF I had to guess the damping of the wax/damar/linseed finish will greatly reduce the high frequency of this driver.

IF I had to guess the damping of the wax/damar/linseed finish will greatly reduce the high frequency of this driver.

Going to take 10 or so of the closest matched drivers I have out of the set and do some experiments.

2 control drivers, 8 variations on modifications.

damar resin in linseed oil, damar resin in linseed with beeswax, damar resin in beeswax,

standard mod podge, (note damar resin not damar varnish)

Each with differing levels of coating thickness (ie layer count).

We'll see what sort of cone breakups and resonances we can modify.

That sort of experimentation can be very enjoyable. I did similar experiments starting about 20 years ago and it certainly gave me a good idea of what worked and what didn't work.

Keep accurate records and measure each variable, one at a time.

Best Regards,

TerryO

Going to take 10 or so of the closest matched drivers I have out of the set and do some experiments.

2 control drivers, 8 variations on modifications.

damar resin in linseed oil, damar resin in linseed with beeswax, damar resin in beeswax,

standard mod podge, (note damar resin not damar varnish)

Each with differing levels of coating thickness (ie layer count).

We'll see what sort of cone breakups and resonances we can modify.

I'd be really interested in seeing what seems to act as a light-weight stiffener; since I'm using my NS3's as midranges only, I don't think that I have many of the same resonance issues that you guys will. The NS525s though have an awful soft dustcap that appears to have been designed to collapse and pop on hard bass hits. I guess that I could find a stiffer/rounder dust cap and replace, but I don't want to do that with 32 drivers.

Greg

I'd be really interested in seeing what seems to act as a light-weight stiffener; since I'm using my NS3's as midranges only, I don't think that I have many of the same resonance issues that you guys will. The NS525s though have an awful soft dustcap that appears to have been designed to collapse and pop on hard bass hits. I guess that I could find a stiffer/rounder dust cap and replace, but I don't want to do that with 32 drivers.

Greg

There is a thread about the Pioneer BOFU 8" full-range with wizzer cone and how they would use various coatings and the end results. One of the coatings was a 50/50 mix of Elmers glue and water that worked quite well. Coating the dust cap made it stiffer and would cut the highs.

I'll be using mine for mids and cross to tweeters at 6KHz, just interested if the dust cap trick cuts the spike at 9KHz. Maybe stiffening the dust cap on those 5.25" Auras would solve the popping issue? Since they are being used for bass duties and not a full range, it should not have any downsides.

My father fixed a rip in his Altecs (many years ago) with finger nail polish and the repair lasted for at least 25 years. Not sure if that would solve the soft dust cap issue or make things worse if the dust cap is vented--just throwing that out there.

There is a thread about the Pioneer BOFU 8" full-range with wizzer cone and how they would use various coatings and the end results. One of the coatings was a 50/50 mix of Elmers glue and water that worked quite well. Coating the dust cap made it stiffer and would cut the highs.

I'll be using mine for mids and cross to tweeters at 6KHz, just interested if the dust cap trick cuts the spike at 9KHz. Maybe stiffening the dust cap on those 5.25" Auras would solve the popping issue? Since they are being used for bass duties and not a full range, it should not have any downsides.

My father fixed a rip in his Altecs (many years ago) with finger nail polish and the repair lasted for at least 25 years. Not sure if that would solve the soft dust cap issue or make things worse if the dust cap is vented--just throwing that out there.

Interesting. Worth a try for $.50. Just gotta get a few extra testers.

My brother who's been in this hobby before he bought his EPI100's new has always used rubber cement for torn drivers, at least tears near the cap or the surround. Maybe really light application across the cone would work too. I'd imagine you'd have to dilute the rubber cement in order to get it to apply thin and soak into the paper fibers.

I should try nail polish also: I'd really like a nice shade of pink on my dust cap. Actually, it's probably a good compound since it's designed to be a stiff layer on top of the nail. Adding weight would lower the Fs too... It'd also risk the 3dB woofer advantage over the mids, which is a problem since I planned to design the lower x-over and cabinet width at the same frequency and use the 3dB as BSC. If I go passive...

Greg

For rips, try Golden Harvest Latex Wallpaper Border Adhesive (GH-50) and a small patch of tissue paper (left over from Christmas?) to bridge the tear and give a bit more surface area for the adhesive. A base coat followed by a thin coat or two to wet out and seal the repair is sufficient. Let it set up for a a couple of days and you're good to go.

For surrounds, use hospital gauze (like your Mom used for cut fingers) instead of the tissue paper and apply the GH, then followed by the gauze, using a brush to work the gauze into the base coat of adhesive. Let it cure overnight and then another light coating of GH and a couple of days more to set up. I've repaired high excursion subwoofer drivers this way and never experienced a failure. I have a woofer that had a rip in the foam surround repaired this way 15 (or 16?) years ago and it's still working fine.

This was just one of the many audio tips, tricks and tweaks that Ed Heath developed on the old "Bass List."

Best Regards,

TerryO

For surrounds, use hospital gauze (like your Mom used for cut fingers) instead of the tissue paper and apply the GH, then followed by the gauze, using a brush to work the gauze into the base coat of adhesive. Let it cure overnight and then another light coating of GH and a couple of days more to set up. I've repaired high excursion subwoofer drivers this way and never experienced a failure. I have a woofer that had a rip in the foam surround repaired this way 15 (or 16?) years ago and it's still working fine.

This was just one of the many audio tips, tricks and tweaks that Ed Heath developed on the old "Bass List."

Best Regards,

TerryO

Hi Again

The aura sound NS3 are now put to work in the basment Theatre and they are doing a superb job there. <for the money they are very good sounding and certanly fills the bill of being a "Stupid Cheap Line array".

But...

The Vifa is quite another story!

They are truely High End stuff.

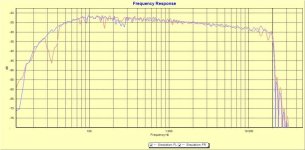

The two graphs below are measured in the listening position 3 m away.

The Vifa graph is the raw uncorrected response and Vifa2 is after Audiolense has done its magic.

They make a very good soundstage, have terrific transient response, are tonally neutral an above all they are very musical sounding speakers.

I have been in this game for many years, starting out in 1975 with Quad els57 with RTR 15 spheric tweeters and KEF b139 TL sub. electronic XO with tube amps for ELS and Dynaco stereo 400 as sub. amp.

I have , among others, owned Tympany 1D, Audiostatic ELS, as importer i Denmark of ProAc a lot of their speakers a DIY fullranhe true ribbon speaker and heard numerus other systems.

And these Vifa lines is up among the best and I believe , with the right sub (I am thinking 2 or 4 18" Infinit Baffle) and perhaps a ribbon super tweeter (2 m long) , that they will surpass tem all!!

Bold words yes, but tey are so good IMHO!!!

Koldby

The aura sound NS3 are now put to work in the basment Theatre and they are doing a superb job there. <for the money they are very good sounding and certanly fills the bill of being a "Stupid Cheap Line array".

But...

The Vifa is quite another story!

They are truely High End stuff.

The two graphs below are measured in the listening position 3 m away.

The Vifa graph is the raw uncorrected response and Vifa2 is after Audiolense has done its magic.

They make a very good soundstage, have terrific transient response, are tonally neutral an above all they are very musical sounding speakers.

I have been in this game for many years, starting out in 1975 with Quad els57 with RTR 15 spheric tweeters and KEF b139 TL sub. electronic XO with tube amps for ELS and Dynaco stereo 400 as sub. amp.

I have , among others, owned Tympany 1D, Audiostatic ELS, as importer i Denmark of ProAc a lot of their speakers a DIY fullranhe true ribbon speaker and heard numerus other systems.

And these Vifa lines is up among the best and I believe , with the right sub (I am thinking 2 or 4 18" Infinit Baffle) and perhaps a ribbon super tweeter (2 m long) , that they will surpass tem all!!

Bold words yes, but tey are so good IMHO!!!

Koldby

Attachments

I'll be using the ns3 line as a mid range as well. They have increasing distortion figures below 400Hz, so I'll be crossing them in around 600-950, and I'll be crossing onto the tweeter line before they beam and comb too much. So with response peaks at 9k in the stop band, not even an octave above 6k, they'd have to be notched out for an even response. If I can smooth out the 2-4k range with it it'd be much better. as well.

I'm starting out active filtered via my computer dsp to model them.

I'm starting out active filtered via my computer dsp to model them.

- Home

- Loudspeakers

- Multi-Way

- Stupid Cheap Line Array