I have a pair of vintage B&W Rock Solids which I really like. I wish to order litz wire for the crossover, but I have no way of knowing what gauge it is. Wires are soldered to the crossover board, and clips are used for the speaker terminals.

I am no expert at determining what gauge, but my guess may be 18? Anyone know what is typically used in small speakers? I will most likely have to order sight unseen.

Also, I wonder where there are better quality terminal clips to get.

Thanks, Gene

I am no expert at determining what gauge, but my guess may be 18? Anyone know what is typically used in small speakers? I will most likely have to order sight unseen.

Also, I wonder where there are better quality terminal clips to get.

Thanks, Gene

Litz wire is great stuff. I've used it for very high Q RF coils for crystal sets, but for speaker coils?? The extra bandwidth Litz might be capable of won't be realized since the role of the inductor is to considerably roll off high frequencies.

To answer your question anyhow, guage of coils will vary considerably. The designer first decides a target DC resistance and then picks wire guage based on that, assuming the resultant cost doesn't get too high. A designer will tyically also make a distinction between woofer series coils and tweeter or mid shunt coils. Woofer series coils will reduce sensitivity if their DCR is too high. I would normally shoot for a DCR of 0.5 to 1 ohms max in those positions. Coils in other locations might be intentionally designed with higher DCR, generally to soften corner Q.

Finally, high inductance coils will require a lot of turns and keeping DCR low will require a very high guage. For that reason designers will feel economic pressure to let the DCR be a little higher than ideal.

Try to resist the temptation to put in mongo coils that knock the DCR way below stock. Again, many coils have a certain DC in place by design and significantly reducing it will alter the system frequency response.

The only coil change that I can imagine that would be an improvement would be to replace an iron core unit with an aircore unit of exactly the same DCR (requiring more turns of a bigger guage). And in most cases I doubt this would be a significant improvment.

David S.

To answer your question anyhow, guage of coils will vary considerably. The designer first decides a target DC resistance and then picks wire guage based on that, assuming the resultant cost doesn't get too high. A designer will tyically also make a distinction between woofer series coils and tweeter or mid shunt coils. Woofer series coils will reduce sensitivity if their DCR is too high. I would normally shoot for a DCR of 0.5 to 1 ohms max in those positions. Coils in other locations might be intentionally designed with higher DCR, generally to soften corner Q.

Finally, high inductance coils will require a lot of turns and keeping DCR low will require a very high guage. For that reason designers will feel economic pressure to let the DCR be a little higher than ideal.

Try to resist the temptation to put in mongo coils that knock the DCR way below stock. Again, many coils have a certain DC in place by design and significantly reducing it will alter the system frequency response.

The only coil change that I can imagine that would be an improvement would be to replace an iron core unit with an aircore unit of exactly the same DCR (requiring more turns of a bigger guage). And in most cases I doubt this would be a significant improvment.

David S.

Using litz wire for audio frequencies is, in my opinion, a waste of money. It only works it's "magic" above the audible range. As for the wire guage question, 18 guage should be fine for the lengths likely to be used inside a speaker cabinet. Speaker "clips" that utilize a spring-loaded push terminal are, to be blunt, usually crap at best. I prefere to use a high quality, (i.e. not cheap) binding post terminal. Beyond that, I'm in full agreement with what Dave said.

Mike

Mike

I agree with both Dave and Michael. I measured frequency responses using different wires, Litz included, and found no significant difference in the audio range. Some argue that there are differences that cannot be measured, but their ears must be far more capable than mine. For crossover or internal enclosure wiring, I doubt you will notice much difference regardless of the gauge of the wire, within reason, as it is a very short run. You might notice a difference in longer runs to the speaker from the amp but like Dave said, keeping the Impedance of the wire to less than .5 to 1 ohms (or if you really are concerned, to less than 10% of the nominal impedance of the loudspeaker) should prevent any audible signal degradation. Jay

Speaker "clips" that utilize a spring-loaded push terminal are, to be blunt, usually crap at best. I prefere to use a high quality, (i.e. not cheap) binding post terminal.

Mike

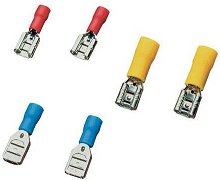

This kind of clip. Something of good quality (if that's possible).

Folks! I just want to use the litz to run from the crossover board to the drivers! Nothing else!

This is what I figured from the first post.

All I've got to say is "if it ain't broke, don't fix it!"...

You're not going to notice any change/improvement from switching out the stock wiring to something else, unless of course there is something physically wrong with the stock wire, such as massive oxidation or fraying, and loose connections.

If they are working fine, then leave them be. If anything, take that money and update the capacitors on the crossover boards instead.

This is what I figured from the first post.

All I've got to say is "if it ain't broke, don't fix it!"...

It is broke. It was rewired with a wrong wire. Though perfectly executed.

You're not going to notice any change/improvement from switching out the stock wiring to something else, unless of course there is something physically wrong with the stock wire, such as massive oxidation or fraying, and loose connections.

Where does one get good sounding quality stock wire? Is there such a thing?

It is broke. It was rewired with a wrong wire. Though perfectly executed.

Where does one get good sounding quality stock wire? Is there such a thing?

Nowhere have you said that the speakers are not working properly. What's "broke" about them and how are they using the wrong wire?

B&W didn't become successful by designing/building junk with bad wiring.

By being younger and over zealous I had created an anomaly without knowing it. Years back when I rewired my speakers with litz I decided to go the full nine yards and to make sure each wire was neatly covered totally with heat shrink, even though litz does not need it. I just learned in another thread from BudP's information that litz should not be surrounded by heat shrink because of the unique reaction of litz to shrink tubing. It will cause a distortion that will effect the sound.

I had read him mentioning an effect concerning litz and heat shrink. It concerned another matter, but alerted me just the same, to the fact that I need to get the tubing off. I have been hearing the effect he mentioned and did not know what caused it.

The shrink tubing I used is on for good. So, I can not salvage the wire. That is why I wish to redo the wiring. Litz always smoothed things out for me. But, what I had done produced something I could not figure out. A sense of over etched detail. According to how it was explained the shrink tubing is the culprit.

The speakers did not sound that way before litzing. So? Here I am. Asking for help in locating a replacement. Its does not have to be litz. For recently I have heard some of newer improved speakers on the market and the wiring they now use is very good. All my speaker cables and interconnects are litz. I found adding the little lengths used in speakers today really does not cause problems as long as its of good quality.

Litz with its unique dielectric quality, when combined with shrink tubing, is an audio no-no. Its alters the sound in a way I would rather be without.

There you have it! Gene

.

I had read him mentioning an effect concerning litz and heat shrink. It concerned another matter, but alerted me just the same, to the fact that I need to get the tubing off. I have been hearing the effect he mentioned and did not know what caused it.

The shrink tubing I used is on for good. So, I can not salvage the wire. That is why I wish to redo the wiring. Litz always smoothed things out for me. But, what I had done produced something I could not figure out. A sense of over etched detail. According to how it was explained the shrink tubing is the culprit.

The speakers did not sound that way before litzing. So? Here I am. Asking for help in locating a replacement. Its does not have to be litz. For recently I have heard some of newer improved speakers on the market and the wiring they now use is very good. All my speaker cables and interconnects are litz. I found adding the little lengths used in speakers today really does not cause problems as long as its of good quality.

Litz with its unique dielectric quality, when combined with shrink tubing, is an audio no-no. Its alters the sound in a way I would rather be without.

There you have it! Gene

.

Last edited:

Where does one get good sounding quality stock wire? Is there such a thing?

Ace Hardware.

I use 16 AWG or lower lamp wire.

The whole trick for wire is having a large enough gauge to handle the current, that is all. The idea that you can use some form of unobtanium element that will improve the sound is as much a myth as Geek mythology.

I am pleased you have discovered this. I too once replaced small gauge wire with something 'better'. I cleanly soldered where there had previously been tarnished finger twisted copper and crud covered joints, then foolishly believed it was the cable diameter that made the difference I heard. That did confuse me for a while afterward when I couldn't reliably reproduce it.

I use the Deoxit cleaner and conditioner on connections that can't be soldered in. Always thought it was very, very odd to use connectors on speakers--the constant vibration sure don't help the integrity of the connection!

Heat sinks, flux, solder and clean connections are your secret sauce that makes it all work.

Heat sinks, flux, solder and clean connections are your secret sauce that makes it all work.

epiphany (hopefully)

does this tell you anything about the alledged cause of the problem, to wit:

I just learned in another thread from BudP's information that litz should not be surrounded by heat shrink because of the unique reaction of litz to shrink tubing. It will cause a distortion that will effect the sound

and your need to eliminate the heat shrink from the Litz wires?

So the contact points (surface conductivity) seems to be the culprit, right??

nothing to do with the litz wire or shrink tubing...

Found a much better solution. Opened up the speakers and had all non-soldered contacts treated with Deoxit (Cramilon). Sounds very nice now. End of search.

does this tell you anything about the alledged cause of the problem, to wit:

I just learned in another thread from BudP's information that litz should not be surrounded by heat shrink because of the unique reaction of litz to shrink tubing. It will cause a distortion that will effect the sound

and your need to eliminate the heat shrink from the Litz wires?

So the contact points (surface conductivity) seems to be the culprit, right??

nothing to do with the litz wire or shrink tubing...

I use the Deoxit cleaner and conditioner on connections that can't be soldered in. Always thought it was very, very odd to use connectors on speakers--the constant vibration sure don't help the integrity of the connection!

Heat sinks, flux, solder and clean connections are your secret sauce that makes it all work.

I suffer from tweeter soldering phobia. Tweetsodphobic.

.

Soldering tweeters is like pulling out into traffic. Once you learn to overcome the initial anxiety, you can do it in your sleep

That may be true. But I do not think the tweeters in my current speakers are still available. These are older speakers. B&W Rock Solid series. Great for high quality desktop.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Crossover wire gauge.