Yeah, the milos are a little boomy in comparison, but they are also more full and I can play all sorts of music with them, and they remind me of what I heard at concerts, because I probably have heard them at some point.

Just a different type of sound. The horns have attack and detail. Less bass with the drivers that I tested, and the one that had bass, was weird. It's good that you still argue for horns below 100Hz, then I will continue my endeavour.

The big rectangular exponential flare bass / mid bass horns I am making are now in my system on test for tuning before finishing.

From workshop

I have been experimenting with driver chamber volumes

and damping too. From very damped to less.

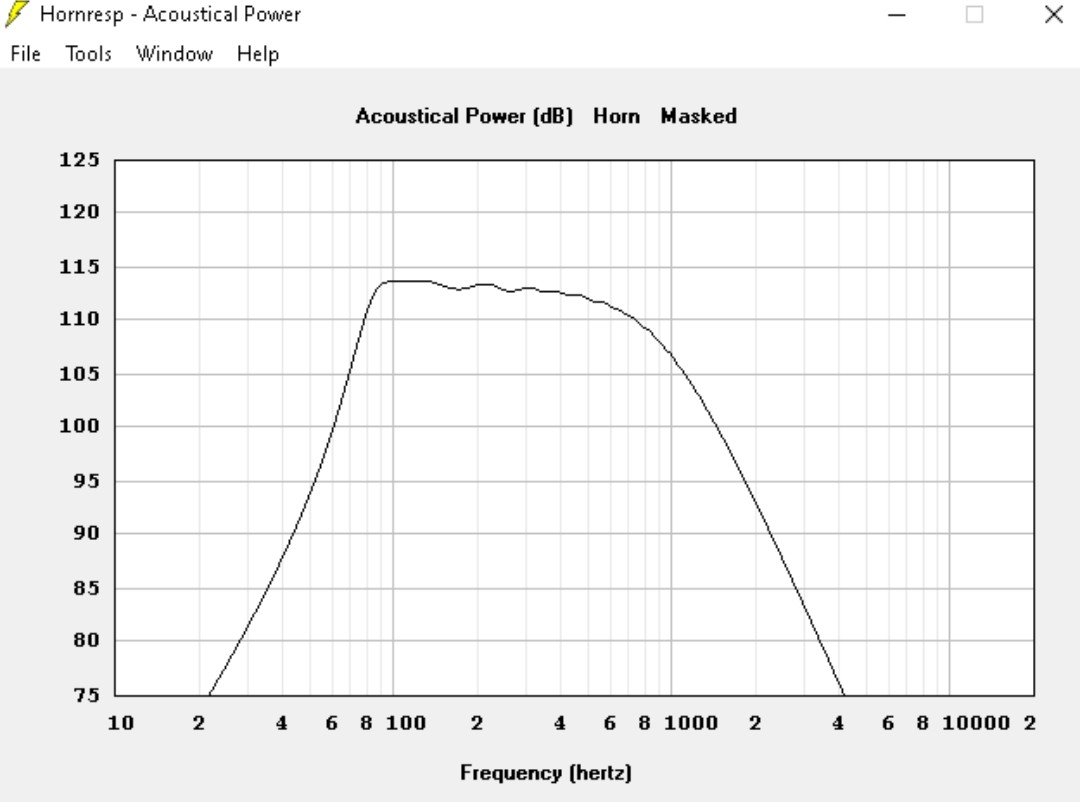

These are long at 1.4m including driver chamber, being smooth exponential they modelled very well down to 80Hz and smooth beyond 500Hz.

These are long at 1.4m including driver chamber, being smooth exponential they modelled very well down to 80Hz and smooth beyond 500Hz.

So how do they sound;

"Just fine actually. I've just put them in, aligned them and not changed anything on the DSP set up - X/O etc and am having a listen.

Deep piano is fantastic! In general there is a tad more snap/punch and weight than mine (greater compression than I have on might I expect, and the length).

Nice detail and subtlety, no problems in the room or any resonance - birch ply rules!!! Plus that curve is so strong and rigid I can't see it being an issue at domestic / even Scalford Saturday night levels...

They work just laying on the floor. I could really reduce my stack height with them quite dramatically - another 30cm or so.

That might be good for cohesion in my room, but It doesn't standout as a problem / something I need to address.

will have a play with the X/O points and slopes now and a measure."

In home system / room

From workshop

I have been experimenting with driver chamber volumes

and damping too. From very damped to less.

These are long at 1.4m including driver chamber, being smooth exponential they modelled very well down to 80Hz and smooth beyond 500Hz.

These are long at 1.4m including driver chamber, being smooth exponential they modelled very well down to 80Hz and smooth beyond 500Hz.So how do they sound;

"Just fine actually. I've just put them in, aligned them and not changed anything on the DSP set up - X/O etc and am having a listen.

Deep piano is fantastic! In general there is a tad more snap/punch and weight than mine (greater compression than I have on might I expect, and the length).

Nice detail and subtlety, no problems in the room or any resonance - birch ply rules!!! Plus that curve is so strong and rigid I can't see it being an issue at domestic / even Scalford Saturday night levels...

They work just laying on the floor. I could really reduce my stack height with them quite dramatically - another 30cm or so.

That might be good for cohesion in my room, but It doesn't standout as a problem / something I need to address.

will have a play with the X/O points and slopes now and a measure."

In home system / room

Last edited:

I like the mellow sound I got from your previous horn. You don't feel this longer horn is too intense?

It is horses for courses. I need more time with these to see.

The shorter, bigger mouth ones are as you say a little more mellow. Toward passive rad / horn. These are all horn.

I am always careful about initial reactions... different is not always an upgrade but I like the punch of these. Ginger Bakers drum solo on the Toad track (Reunion at the Albert hall) sounded fantastic...

At the end of the day it's building what you are happiest with isn't it.

I've played with driver chamber volume this afternoon and optimised. Also EQ'd in Najda for room modes so a proper listening session can be held this evening

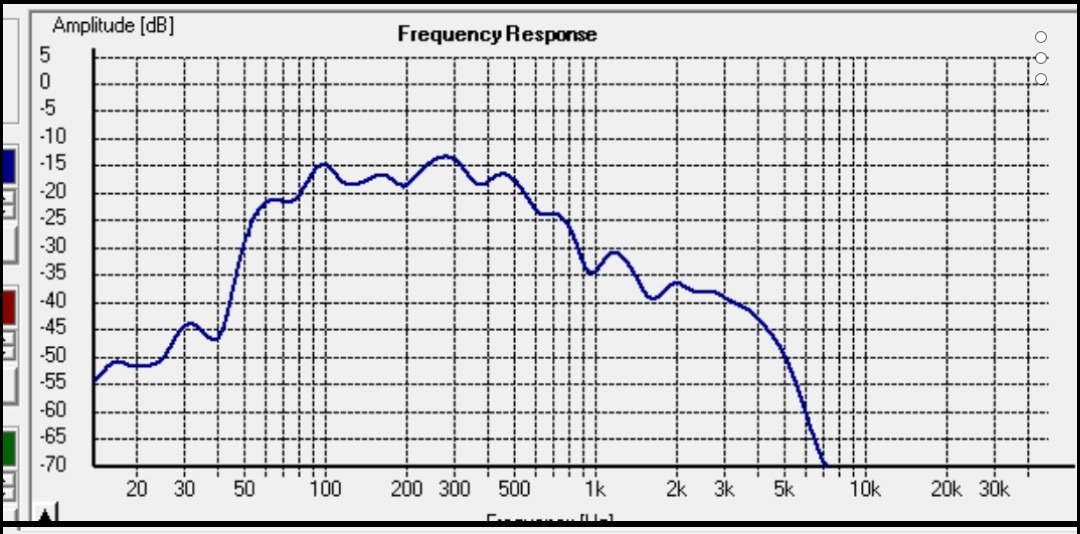

Here is a measurement in room

There's a bit of room suck out below 100Hz or so on the right hand one. I always have this in my room.

Using my Najda DSP X/O I will level them (using PEQ cuts only, boosting the vol as necessary) and cross them where suits best to the integrate with the sub bass.

IMO this is where DSP X/O's really win, by being able to manage what you have to work with in the real world so well.

There's a bit of room suck out below 100Hz or so on the right hand one. I always have this in my room.

Using my Najda DSP X/O I will level them (using PEQ cuts only, boosting the vol as necessary) and cross them where suits best to the integrate with the sub bass.

IMO this is where DSP X/O's really win, by being able to manage what you have to work with in the real world so well.

Last edited:

They seem to have a nice boost around 100Hz. I was almost able to mimic this snare drum snap the other day by applying an EQ boost where the horn would otherwise boost it. It sounded not as impressive but more balanced. Maybe I had too much horn boost, or the opposite. With a midbass 12" that does 80Hz in a ported 74L box, the horn sounded like I had connected a wah-wah pedal to it.

Last edited:

They seem to have a nice boost around 100Hz. I was almost able to mimic this snare drum snap the other day by applying an EQ boost where the horn would otherwise boost it. It sounded not as impressive but more balanced. Maybe I had too much horn boost, or the opposite. With a midbass 12" that does 80Hz in a ported 74L box, the horn sounded like I had connected a wah-wah pedal to it.

I forgot to say I used a non hornloaded Meyer Milo 120 replica. Still waiting to hear the Eminence kappa for myself.

I forgot to say I used a non hornloaded Meyer Milo 120 replica. Still waiting to hear the Eminence kappa for myself.

Several of us here in the UK rate the Kappa A in 12 or 15" form for mid bass duties. It is cheap and performs well.

Several of us here in the UK rate the Kappa A in 12 or 15" form for mid bass duties. It is cheap and performs well.

I like the fact that it has a pure paper cone. And that sensitivity is unusual in a driver. JBL drivers I have tried had an almost dead tone with very rigid paper. I hope the kappas are more musical.

Nice! Question - in just aspect of rectangular versus round do you feel there is a difference in the range you are using the midbass horns?

Thanks!

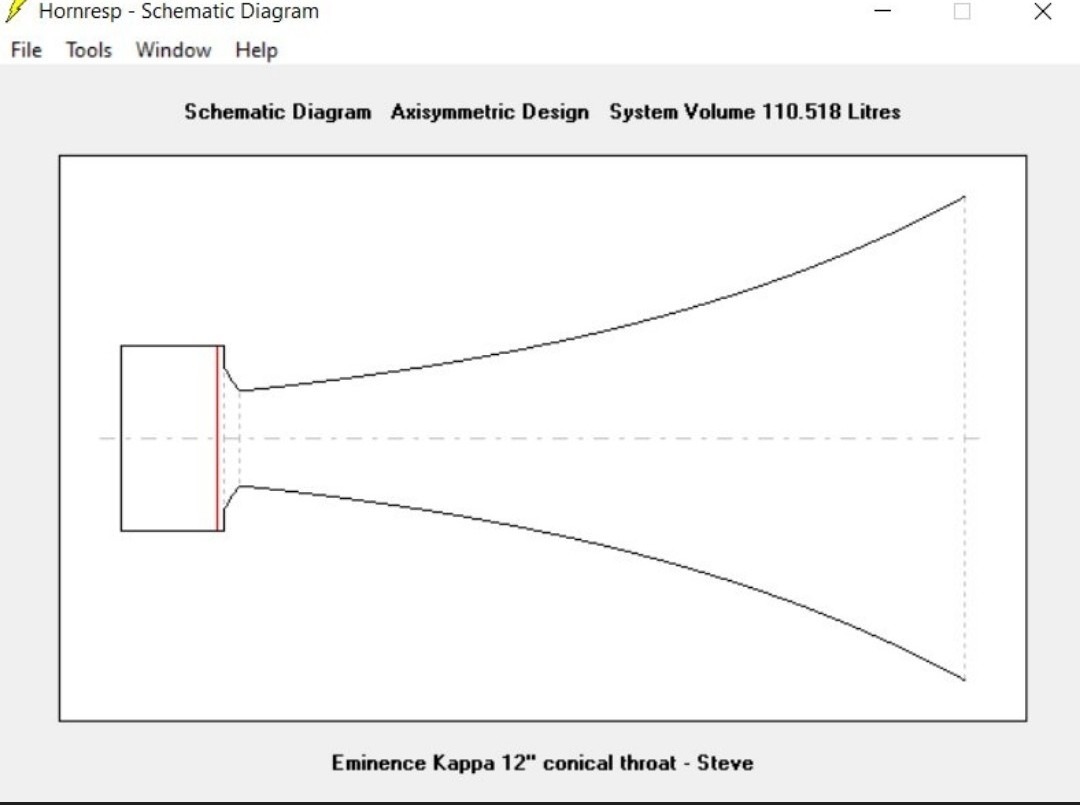

I don't think it round vs rect in this case. More longer and narrower throat VS shorter and wider throat.

The rect being longer plays lower by quite a bit as Hornresp predicted - also holds flatter for longer into 400-500Hz.

Hornresp does not care if it round or rect or square, just throat, length and mouth. Then you output the plans either for round, rect or square and chop wood

However in room there may be difference if that is what you mean.

I'm listening to some fairly intense English folk at the moment - John Renbourn and Co. and its a very full well complimented, melodic mid bass sound. The upper mid bass is strong, sweet and well formed with this type of music.

I like the fact that it has a pure paper cone. And that sensitivity is unusual in a driver. JBL drivers I have tried had an almost dead tone with very rigid paper. I hope the kappas are more musical.

Boohoo,

, I've got a nice pair of JBL 2220H's coming to try - Can always move them on if they don't cut the mustard...

, I've got a nice pair of JBL 2220H's coming to try - Can always move them on if they don't cut the mustard...Yes, no doubt like cabs / musical instruments things can get too over damped and rigid.

I've been listening to various music on these long horns and I like them! So much so... I'm planning at least to adapt my pair of round shorter bass horns, to be like these...

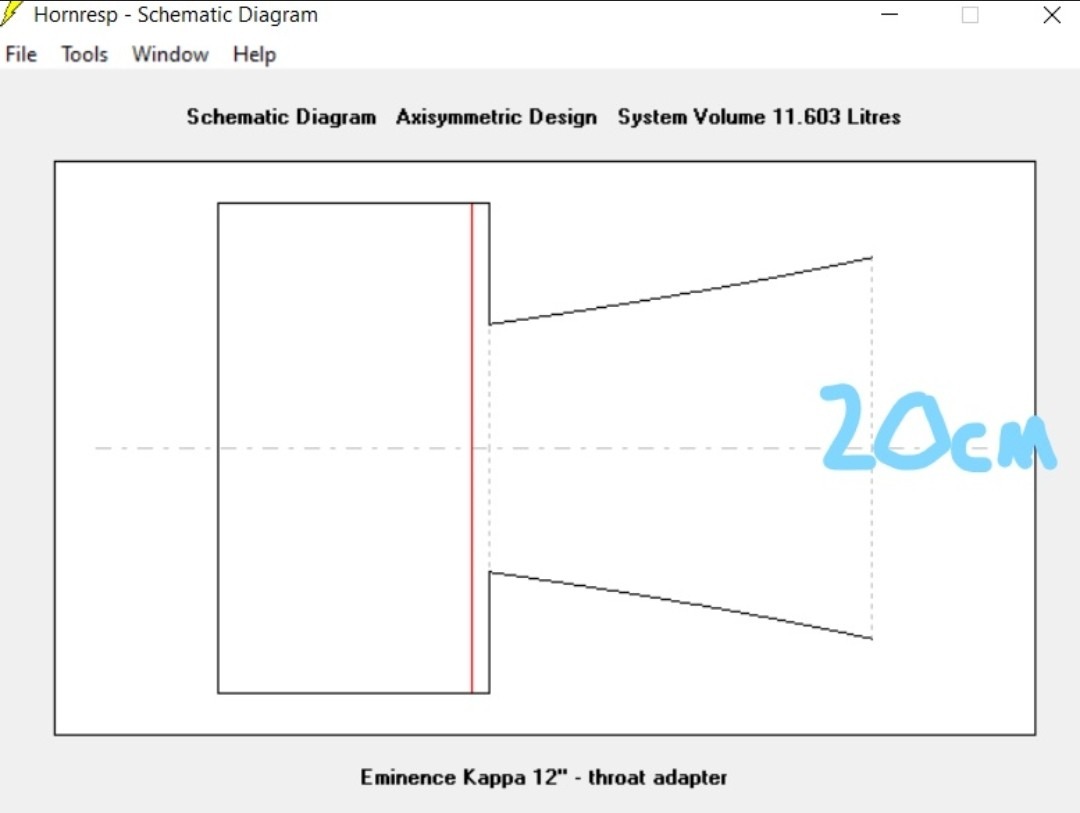

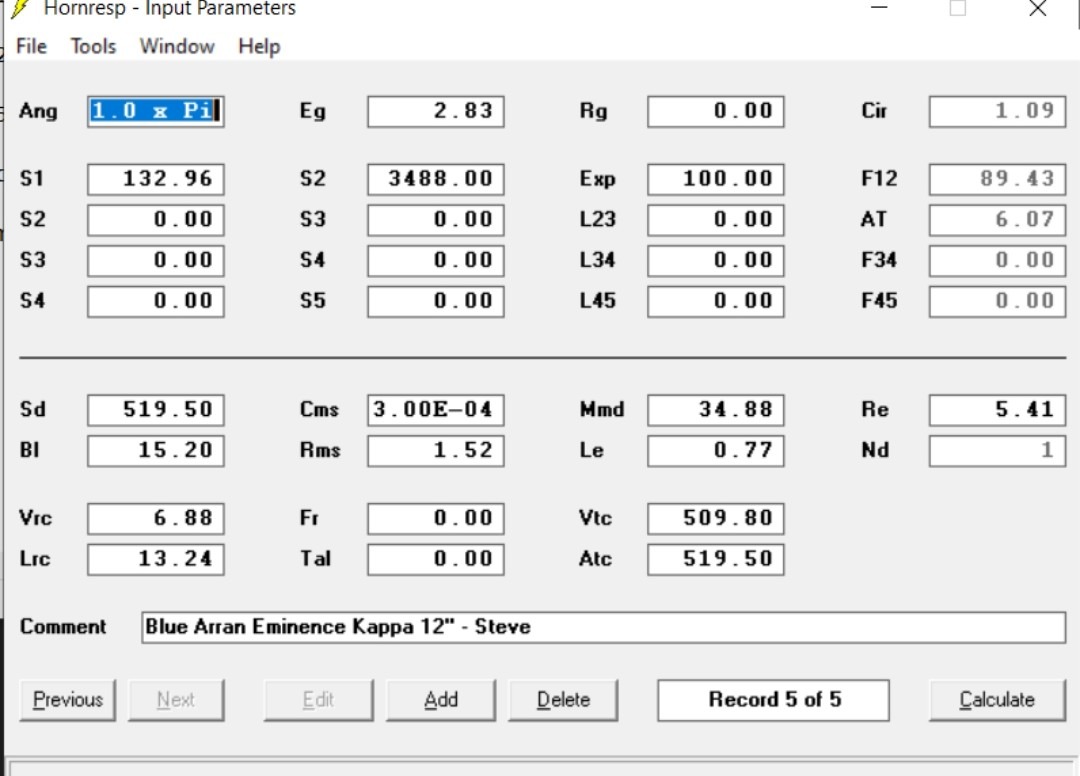

Hornresp to the rescue. An exponential flare 30cm long with 172sqcm throat and 314sqcm opening will fit right in

Gives

A few (lots of) rings of birch ply to cut / glue up and as it is small enough, I can easily turn it on my big lathe.

Hornresp to the rescue. An exponential flare 30cm long with 172sqcm throat and 314sqcm opening will fit right in

Gives

A few (lots of) rings of birch ply to cut / glue up and as it is small enough, I can easily turn it on my big lathe.

Last edited:

I've been listening to various music on these long horns and I like them! So much so... I'm planning at least to adapt my pair of round shorter bass horns, to be like these...

Hornresp to the rescue. An exponential flare 30cm long with 172sqcm throat and 314sqcm opening will fit right in

A few (lots of) rings of birch ply to cut / glue up and as it is small enough, I can easily turn it on my big lathe.

So you will just add more rings starting from the throat? I thought what you liked about this horn was when you opened up the throat to 20cm by removing rings. Now you want to add rings? Ambivalent about our horns, are we?

Also, adding length destroys the profile a little. You will probably need to remove a few ring close to your existing throat.

I agree that the difference between round and square is probably exaggerated.

Last edited:

Hindsight is a wonderful thing. I'm definitely learning about mid bass as I go .

.

There probably is no right or wrong answer either.

I was coming from the 1m conical. I was used to that sound. The original exponential sizing was with a bigger throat than modelled perfectly.

I went the way of opening it up to get to the sound I was used to.

Had I gone the add ore rings and narrow the throat approach, I might have liked back then but I was in conical sizing / thinking mode at the time. Exponentials are no doubt a bit different.

Now I have tasted the narrower / longer option. All good learning.

I will definitely swap between the two a few times to confirm my hearings and what I like...

These are more Rock oriented I think.

Another thing to add - not sure it makes much difference but I was using fixed X/O slope passives when I first tried the round exponentials... That was on 2nd order with Zobels etc..., I now use 4th order on the low X/O and some correction. Do you think that would have an impact in what I am perceiving.

re the profile - nothing a bit of 2 pack filler and my drum sander with a course belt won't fix

There probably is no right or wrong answer either.

I was coming from the 1m conical. I was used to that sound. The original exponential sizing was with a bigger throat than modelled perfectly.

I went the way of opening it up to get to the sound I was used to.

Had I gone the add ore rings and narrow the throat approach, I might have liked back then but I was in conical sizing / thinking mode at the time. Exponentials are no doubt a bit different.

Now I have tasted the narrower / longer option. All good learning.

I will definitely swap between the two a few times to confirm my hearings and what I like...

These are more Rock oriented I think.

Another thing to add - not sure it makes much difference but I was using fixed X/O slope passives when I first tried the round exponentials... That was on 2nd order with Zobels etc..., I now use 4th order on the low X/O and some correction. Do you think that would have an impact in what I am perceiving.

re the profile - nothing a bit of 2 pack filler and my drum sander with a course belt won't fix

Last edited:

Hindsight is a wonderful thing. I'm definitely learning about mid bass as I go.

There probably is no right or wrong answer either.

I was coming from the 1m conical. I was used to that sound. The original exponential sizing was with a bigger throat than modelled perfectly.

I went the way of opening it up to get to the sound I was used to.

Had I gone the add ore rings and narrow the throat approach, I might have liked back then but I was in conical sizing / thinking mode at the time. Exponentials are no doubt a bit different.

Now I have tasted the narrower / longer option. All good learning.

I will definitely swap between the two a few times to confirm my hearings and what I like...

re the profile - nothing a bit of 2 pack filler and my drum sander with a course belt won't fix

I came from a Goto S-150 replica that was shortened to have a 4" throat. It worked until about 200Hz and everything below 200Hz was very wimpy. And using a midbass driver that played lower than say a Fane Studio 8M, did not work because it was below what the horn was made for. The bassy midbass would just sound garbled. At 200-350Hz it had a nice boost. Maybe too much boost, because I found my replica of your horn so relaxing to listen to in comparison. Your round horn is not like my Meyer Milo 120 replicas either because the milos have no hornloading at all and sound actually very boring, but they fill the room with sound in a way that no horn can. I will probably follow and make a few extra rings. Not maybe to be used to 80Hz with the Kappa, but with something even sweeter sounding, that rolls off above 150Hz. Below 150Hz the Milos should take care of business. There will be a lot of overlapping but midbass is complicated and I will leave it at that.

But I have not gotten over the drums I heard, despite their unbalanced sound. With a better suited driver - who knows!

Last edited:

I think rectangular is the way to go because they couple with the floor better and can have a lower profile to stack the upper range of the horn array and still keep the upper horns near ear level. Also a lot easier for most people to build.

Deep horns have a tendency to sound great IME, I have some that are over 50" deep with a 4" throat. They do beam more in their upper range and that can be good or bad. lately I have gone back to short horns and in my system they work and sound better and are also easier to get aligned with the midrange. I find deep horns work best with smaller 8 or 10" drivers and the short horns best with 12 or 15s.

another thing that's real beneficial with rectangular bass horns is building a strong enclosure around them and filling them with sand. In the case of the horns I have now it made a huge difference in bass and midrange detail, clarity and dynamics. Definitely worth the time to build the box and buy the sand.

Deep horns have a tendency to sound great IME, I have some that are over 50" deep with a 4" throat. They do beam more in their upper range and that can be good or bad. lately I have gone back to short horns and in my system they work and sound better and are also easier to get aligned with the midrange. I find deep horns work best with smaller 8 or 10" drivers and the short horns best with 12 or 15s.

another thing that's real beneficial with rectangular bass horns is building a strong enclosure around them and filling them with sand. In the case of the horns I have now it made a huge difference in bass and midrange detail, clarity and dynamics. Definitely worth the time to build the box and buy the sand.

I think rectangular is the way to go because they couple with the floor better and can have a lower profile to stack the upper range of the horn array and still keep the upper horns near ear level. Also a lot easier for most people to build.

Deep horns have a tendency to sound great IME, I have some that are over 50" deep with a 4" throat. They do beam more in their upper range and that can be good or bad. lately I have gone back to short horns and in my system they work and sound better and are also easier to get aligned with the midrange. I find deep horns work best with smaller 8 or 10" drivers and the short horns best with 12 or 15s.

another thing that's real beneficial with rectangular bass horns is building a strong enclosure around them and filling them with sand. In the case of the horns I have now it made a huge difference in bass and midrange detail, clarity and dynamics. Definitely worth the time to build the box and buy the sand.

Interesting stuff!

I will test the floor loading thing by being able to compare round and rect in same setup.

The sand think sounds like a good idea and can be down quite tastefully I think around the horn and with a lid. Good job the floor is a massive slab of concrete

- Home

- Loudspeakers

- Multi-Way

- 5 way horn speaker system project - tapped, bass, mids and tweeter passive active