New Bass Horns

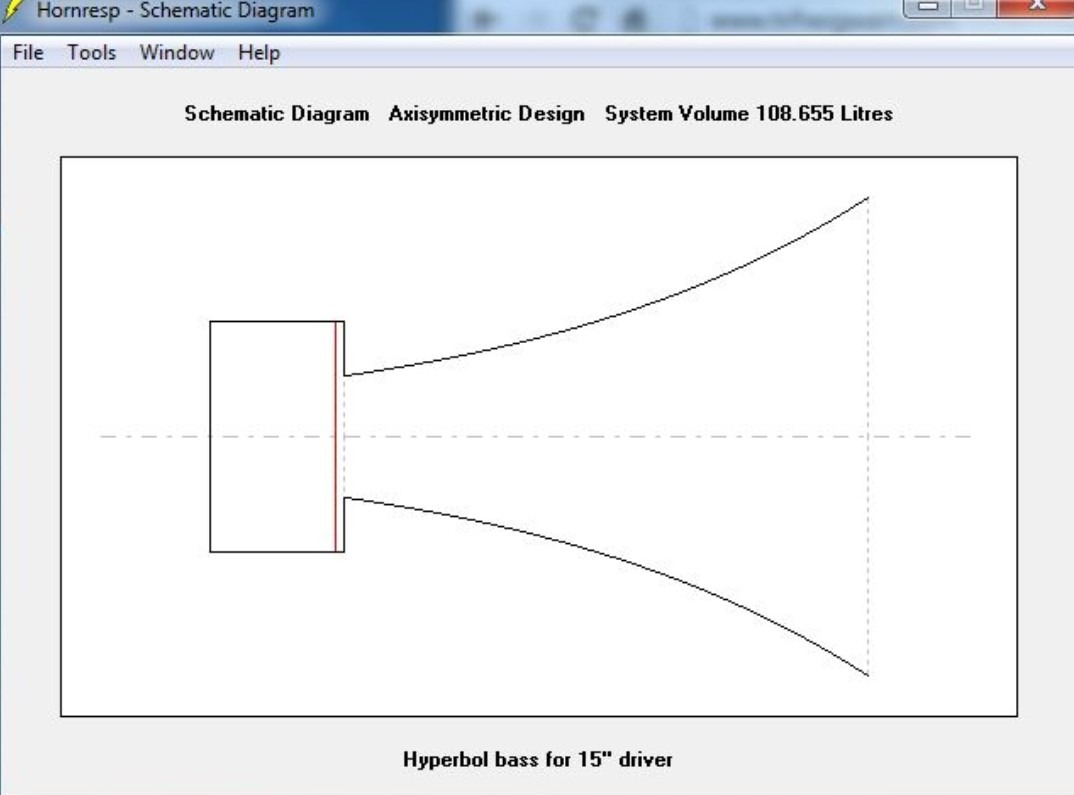

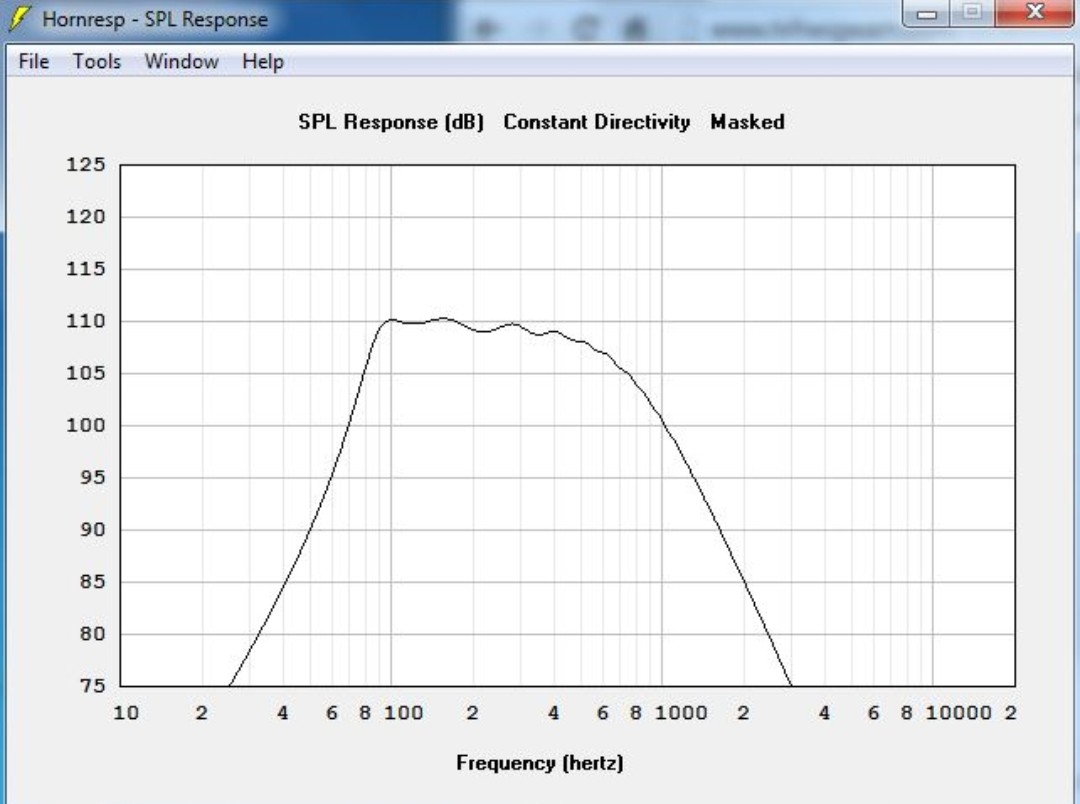

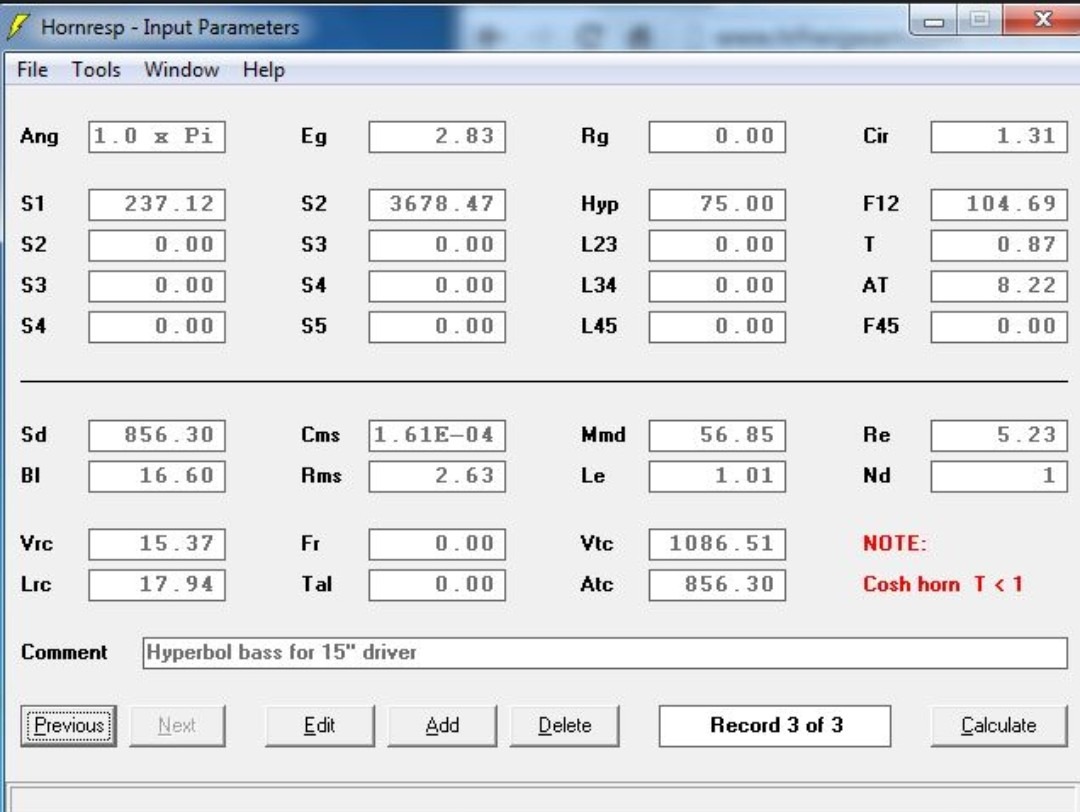

Some playing with Hornresp and it's System Design and using the current Eminence Kappa 15A's (I really like their sound), and I get

This is interesting as the freq resp is flatter and has only about 66cm mouth diameter and about 92cm in depth including back chamber.

If it works anything like the current conical horn I have it will be a winner + I can drop the overall height of my rig by around 24cm.

As before, I plan to use these crossing at 100Hz and 330Hz.

I will try and use a large flat bed printer I can borrow some time on at work, on which I will print out the curve I need and use that to make a template to guide the inner curve as I machine it.

The size of the throat means I can easily get my small angle grinder with suitable wood cutting disc in to shape it.

Tomorrow I will start planning / making the horn rotation platform and probably start cutting rings to laminate together

This project will not be a plug I can use to make GRP but around 1" thick birch ply one off horns.

Let the fun begin...

Some playing with Hornresp and it's System Design and using the current Eminence Kappa 15A's (I really like their sound), and I get

This is interesting as the freq resp is flatter and has only about 66cm mouth diameter and about 92cm in depth including back chamber.

If it works anything like the current conical horn I have it will be a winner + I can drop the overall height of my rig by around 24cm.

As before, I plan to use these crossing at 100Hz and 330Hz.

I will try and use a large flat bed printer I can borrow some time on at work, on which I will print out the curve I need and use that to make a template to guide the inner curve as I machine it.

The size of the throat means I can easily get my small angle grinder with suitable wood cutting disc in to shape it.

Tomorrow I will start planning / making the horn rotation platform and probably start cutting rings to laminate together

This project will not be a plug I can use to make GRP but around 1" thick birch ply one off horns.

Let the fun begin...

Last edited:

I made the horn spinner today.

I knew I had a nice big 360 deg castor base with wheel that had a good quality close tolerance bearing, big plate mounting one side and the large rubber wheel the other. Removed the wheel and a little but of birch ply cutting and drill and I had an adjustable angle spinner that can easily take my weight. I think the castor was spec'd at 150Kg each wheel.

I made up a couple of pulleys on the lathe and a simple belt drive from my hand drill was fine for spinning the wife round on - yes, shes a game lass at times.

Then I though the cheap pillar drill I have would actually make a nice platform and provide some mass.

A few bits more birch ply and its all on a stable base that I can stand on. Perhaps some bags of sand or cement on the edges once I am ready.

So, envisage a spinning roughed out, birch ply, sandwiched horn spinning at just the right speed and gentle application of the cutting disc on an angle grinder - gonna be a piece of cake Famous last words...

Rings are a nice job for the weekday evening - do a few each evening and see how we get on.

I knew I had a nice big 360 deg castor base with wheel that had a good quality close tolerance bearing, big plate mounting one side and the large rubber wheel the other. Removed the wheel and a little but of birch ply cutting and drill and I had an adjustable angle spinner that can easily take my weight. I think the castor was spec'd at 150Kg each wheel.

I made up a couple of pulleys on the lathe and a simple belt drive from my hand drill was fine for spinning the wife round on - yes, shes a game lass at times.

Then I though the cheap pillar drill I have would actually make a nice platform and provide some mass.

A few bits more birch ply and its all on a stable base that I can stand on. Perhaps some bags of sand or cement on the edges once I am ready.

So, envisage a spinning roughed out, birch ply, sandwiched horn spinning at just the right speed and gentle application of the cutting disc on an angle grinder - gonna be a piece of cake Famous last words...

Rings are a nice job for the weekday evening - do a few each evening and see how we get on.

Last edited:

Steve,I made the horn spinner today.

So, envisage a spinning roughed out, birch ply, sandwiched horn spinning at just the right speed and gentle application of the cutting disc on an angle grinder - gonna be a piece of cake Famous last words...

Rings are a nice job for the weekday evening - do a few each evening and see how we get on.

Reminds me of a Leslie I made several years ago.

I don't have a lathe, used a cove bit on a router and spun the rings on a drill press.

It originally used a very long horn, replaced that with 4 x5".

It really spins fast in high gear and high motor speed !

Art

Attachments

That looks interesting. Love the sound.

How fast do you rotate? The web says anything from 40 to 400rpm. The gearing on yours looks pretty high?

I've not had much time for the project in the workshop the last couple of days, but I am measuring up / calculating the number of rings I will need etc.

Then I can start cutting out ring upon ring upon ring...

How fast do you rotate? The web says anything from 40 to 400rpm. The gearing on yours looks pretty high?

I've not had much time for the project in the workshop the last couple of days, but I am measuring up / calculating the number of rings I will need etc.

Then I can start cutting out ring upon ring upon ring...

Steve,

Reminds me of a Leslie I made several years ago.

I don't have a lathe, used a cove bit on a router and spun the rings on a drill press.

It originally used a very long horn, replaced that with 4 x5".

It really spins fast in high gear and high motor speed !

Art

Mine is built for speed. Normal middle pulley Leslie High rotor low speed is 40 RPM, high speed is 400 RPM, I'd guess mine goes from about 200 to 600 rpm.That looks interesting. Love the sound.

How fast do you rotate? The web says anything from 40 to 400rpm. The gearing on yours looks pretty high?

I've not had much time for the project in the workshop the last couple of days, but I am measuring up / calculating the number of rings I will need etc.

Then I can start cutting out ring upon ring upon ring...

At the highest speed, the motor (from a 14" fan) is overworked and gets hot pretty fast...

Exponential Bass horns on the go

After some plotting and working out, I needed 32 rings of 24mm birch ply. This gave 76.8cm - near enough to the 75 horn resp is telling me.

Jig sawing them out uses much less wood and less mess than a router. The mess comes later

With 3 pieces of ply I could cut all the rings I needed, ever reducing following the Hyperbolic curve.

I revolved the piece letting the jig saw follow the plot line.

All rings cut and peering into the ring mass while gluing. Some clamps and weights and plenty of PVA squeezed out.

The horn lathe was a bit of a disaster. Not really stable enough and hard to get at the right speed.

It would have been fine if I was doing a plug (cutting the outer surface for GRF and had another bearing at the front. Needing to get inside preludes that.

So a really coarse grit on the a big drum sander and lots of power sanding.

So far I've done about half way down the horn on a first pass. Easy enough to get accurate even in coarse mode. I have the throat area to do. Further in but less area to cover. It's best done with the horn standing up. Perhaps another evenings work.

I might use the horn lathe again for light final skim and probably have human helper powering it

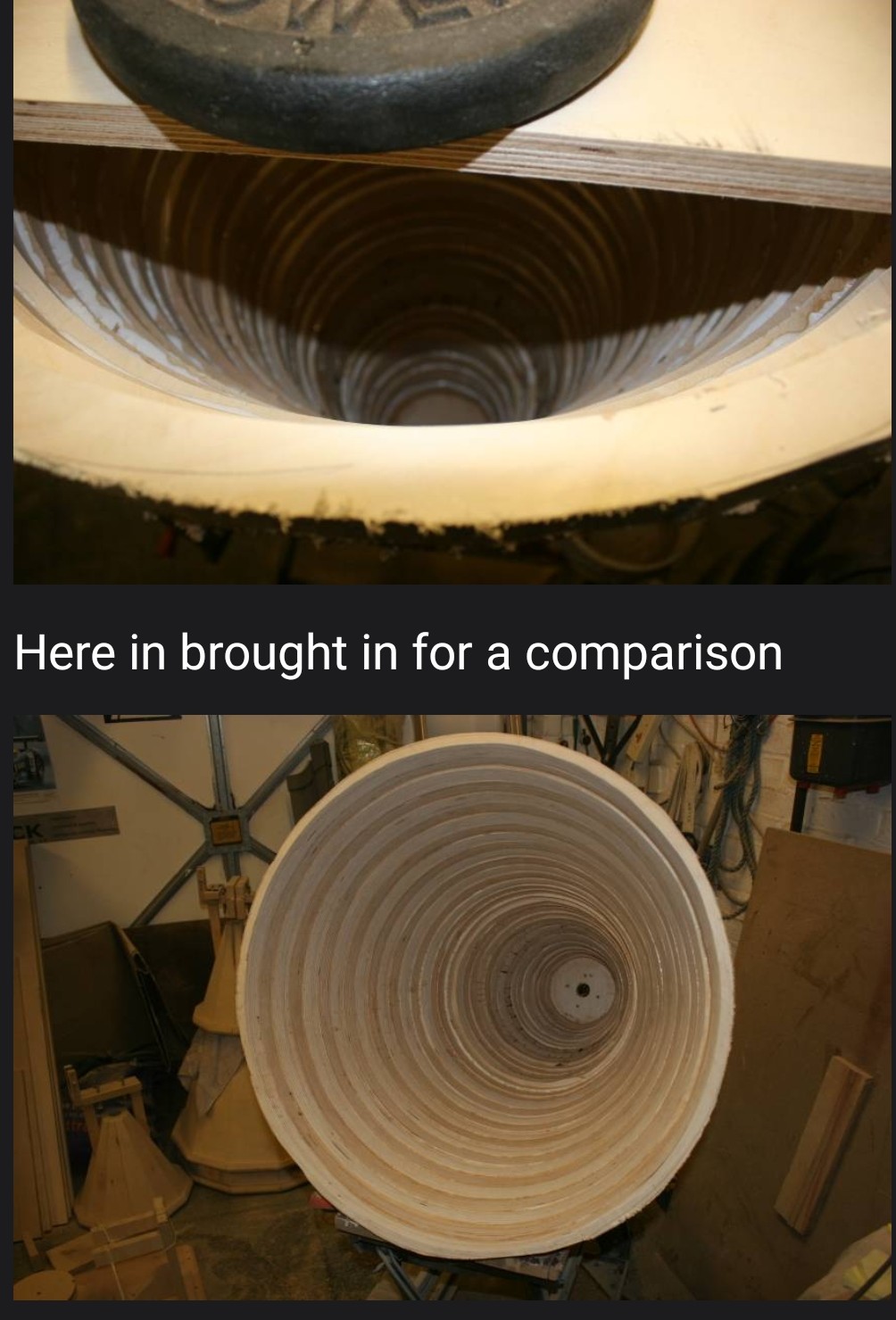

Brought it in to see how it looks - Tiny at 72cm diameter against the Conical 90cm.

Smaller throat / hyperbol flare, more compression, they model quite a bit better than the conical at any rate.

Fine and true even as rough work from the listening chair.

I'm am going to spray paint them the same as the other pairs for a matched look.

I will be able to lower the rig a fair bit and have them further away from the rear wall if I want to.

Knackered now but proved to myself I can DIY it. Time for a pint.

After some plotting and working out, I needed 32 rings of 24mm birch ply. This gave 76.8cm - near enough to the 75 horn resp is telling me.

Jig sawing them out uses much less wood and less mess than a router. The mess comes later

With 3 pieces of ply I could cut all the rings I needed, ever reducing following the Hyperbolic curve.

I revolved the piece letting the jig saw follow the plot line.

All rings cut and peering into the ring mass while gluing. Some clamps and weights and plenty of PVA squeezed out.

The horn lathe was a bit of a disaster. Not really stable enough and hard to get at the right speed.

It would have been fine if I was doing a plug (cutting the outer surface for GRF and had another bearing at the front. Needing to get inside preludes that.

So a really coarse grit on the a big drum sander and lots of power sanding.

So far I've done about half way down the horn on a first pass. Easy enough to get accurate even in coarse mode. I have the throat area to do. Further in but less area to cover. It's best done with the horn standing up. Perhaps another evenings work.

I might use the horn lathe again for light final skim and probably have human helper powering it

Brought it in to see how it looks - Tiny at 72cm diameter against the Conical 90cm.

Smaller throat / hyperbol flare, more compression, they model quite a bit better than the conical at any rate.

Fine and true even as rough work from the listening chair.

I'm am going to spray paint them the same as the other pairs for a matched look.

I will be able to lower the rig a fair bit and have them further away from the rear wall if I want to.

Knackered now but proved to myself I can DIY it. Time for a pint.

Last edited:

Great work as always Speed. I saw on a TV show about woodworking the guy did the same as you with cutting rings with a jig saw, but he cut on a 45 degree angle as was able to use one sheet of plywood for the blank. The 45 allowed him to stack one cut right onto the next.

P.S., he was making bowls but it was the same principle.

P.S., he was making bowls but it was the same principle.

Yep good point. I thought about it but my recirculating jig will only do vertical or 45 degrees. Pretty useless really. Should get a new one...

45 would give me very steep cone - still lots of material to remove and more hassle for the saw too.

At it nears the throat the angle reduces quite a bit.

Getting the angles right'ish would save a lot of sanding work and use even less ply I guess.

The smaller diameter curve and no flat surfaces means even less resonance (more dead when you knock on it), than the 12 sided conical. Got to be a good thing. However, I've ever heard the concial solution suffering from resonance when playing though.

A fellow DIY'er did square exponential (I think it was) and ended up with several braces inside. That was on a 12" driver which meant they had to be much longer too.

45 would give me very steep cone - still lots of material to remove and more hassle for the saw too.

At it nears the throat the angle reduces quite a bit.

Getting the angles right'ish would save a lot of sanding work and use even less ply I guess.

The smaller diameter curve and no flat surfaces means even less resonance (more dead when you knock on it), than the 12 sided conical. Got to be a good thing. However, I've ever heard the concial solution suffering from resonance when playing though.

A fellow DIY'er did square exponential (I think it was) and ended up with several braces inside. That was on a 12" driver which meant they had to be much longer too.

Great work as always Speed. I saw on a TV show about woodworking the guy did the same as you with cutting rings with a jig saw, but he cut on a 45 degree angle as was able to use one sheet of plywood for the blank. The 45 allowed him to stack one cut right onto the next.

P.S., he was making bowls but it was the same principle.

Well, Interesting this large horn building lark.

Many have have said that you can calc and calc but you only really know what you have got until you build and listen.

That is exactly what I have found with this part of the project. Sims and calcs are one thing, nice flat freqs one thing, how they will sound is another altogether.

I build the back box on Saturday and brought the horn in for a listen. I'd started out with a lowish area mouth. 15cm diameter = ~177cmsq. I'd put in a few extra discs of 24mm birch ply to accomplish this so the horn length was greater.

Hmm, dire was the first word that came to mind for the sound. Listening to just the bass horns for prolonged periods is always a challenge but in comparisons with the larger conical, things did not sound good.

The rather lovely rich bass was not there, the top end seemed to sound strained and tinny.

Measuring showed none of the tinniness traits - looked fine in fact, more extended top end if anything but not much really. Lower end was interesting - dip in the slope / a step much earlier than Hornresp predicted it seems.

After a rest I then enlarged the throat to 17cm diameter 227cmsq. This gave a some improvement. Still rather strangled upper freqs compared to the conical with a 20cm / 314cmsq throat, but definitively an improvement. The larger throat gave less of the step in lower bass when measured.

As a last ditch attempt to make something of this horn (other than firewood or a wigwam cat house, with suitable door cut in the side), I then enlarged the throat to the same as the conicals. This shortened the horn length to a little over the original design.

Listening extensively this evening to just the bass and then LH / RH side comparisons things are now pretty good. The bass coming from this horn has regained its pleasant upper freq character and tone - gone are the strangled sounds and it competes on a level field with the conical now in this.

On the sound overall I hear less colouration on the more rigid circular construction smaller horn now than the conical. It's a bit tighter (general over used adjective when considering the sort of boom boxes it is usually associated with in describing), a little punchier and faster than the conical too.

The upper registers seem to integrate better with the tractrix mid horn.

I can't explain why the larger throat works better - driver / horn properties that sims can't figure out?

I have ended up listening to the system with one conical and one Exponential horn for the evening. Quite a pleasing sound overall.

So definitely worth the effort to build a 2nd prototype for a proper listen.

Here's how she looks in situ - just plonked down

This was a pic with the smallest throat size... As you can see plenty of potential for lowering the other drivers and making the sound more compact - That will have to wait until the 2nd horn is build and the sound liked.

A comparison

I'll be cutting more rings soon - this time with more suitable angled edges if I can and to the same dims as the first one

Many have have said that you can calc and calc but you only really know what you have got until you build and listen.

That is exactly what I have found with this part of the project. Sims and calcs are one thing, nice flat freqs one thing, how they will sound is another altogether.

I build the back box on Saturday and brought the horn in for a listen. I'd started out with a lowish area mouth. 15cm diameter = ~177cmsq. I'd put in a few extra discs of 24mm birch ply to accomplish this so the horn length was greater.

Hmm, dire was the first word that came to mind for the sound. Listening to just the bass horns for prolonged periods is always a challenge but in comparisons with the larger conical, things did not sound good.

The rather lovely rich bass was not there, the top end seemed to sound strained and tinny.

Measuring showed none of the tinniness traits - looked fine in fact, more extended top end if anything but not much really. Lower end was interesting - dip in the slope / a step much earlier than Hornresp predicted it seems.

After a rest I then enlarged the throat to 17cm diameter 227cmsq. This gave a some improvement. Still rather strangled upper freqs compared to the conical with a 20cm / 314cmsq throat, but definitively an improvement. The larger throat gave less of the step in lower bass when measured.

As a last ditch attempt to make something of this horn (other than firewood or a wigwam cat house, with suitable door cut in the side), I then enlarged the throat to the same as the conicals. This shortened the horn length to a little over the original design.

Listening extensively this evening to just the bass and then LH / RH side comparisons things are now pretty good. The bass coming from this horn has regained its pleasant upper freq character and tone - gone are the strangled sounds and it competes on a level field with the conical now in this.

On the sound overall I hear less colouration on the more rigid circular construction smaller horn now than the conical. It's a bit tighter (general over used adjective when considering the sort of boom boxes it is usually associated with in describing), a little punchier and faster than the conical too.

The upper registers seem to integrate better with the tractrix mid horn.

I can't explain why the larger throat works better - driver / horn properties that sims can't figure out?

I have ended up listening to the system with one conical and one Exponential horn for the evening. Quite a pleasing sound overall.

So definitely worth the effort to build a 2nd prototype for a proper listen.

Here's how she looks in situ - just plonked down

This was a pic with the smallest throat size... As you can see plenty of potential for lowering the other drivers and making the sound more compact - That will have to wait until the 2nd horn is build and the sound liked.

A comparison

I'll be cutting more rings soon - this time with more suitable angled edges if I can and to the same dims as the first one

Last edited:

After some plotting and working out, I needed 32 rings of 24mm birch ply. This gave 76.8cm - near enough to the 75 horn resp is telling me.

Hi Speedysteve7,

It would seem from the above photo that you may have manually scaled your horn dimensions directly from a hardcopy printout of the Hornresp schematic diagram. Are you aware that Hornresp can automatically calculate this information for you? Simply select the File> Export > Horn Data menu command from the Schematic Diagram window.

To illustrate, I have attached an exported text file for your 75 cm horn design showing the required radius at 24 mm increments. (Unnecessary information has been deleted from the file).

Kind regards,

David

Attachments

Thanks David,

Nope I was not really aware of that. I may have played with the exports / outputs at some time and though - nice, and forgotten all about it. That is very interesting,

I will certainly look into it and use on the 2nd horn proto but cannot cut to angle precision. If I like the sound, probably take the route of getting perhaps time to get a decent band saw or my plywood firm to CNC the rings for me to close to perfection for a bit of hand finishing only...

That would be a big help.

Nope I was not really aware of that. I may have played with the exports / outputs at some time and though - nice, and forgotten all about it. That is very interesting,

I will certainly look into it and use on the 2nd horn proto but cannot cut to angle precision. If I like the sound, probably take the route of getting perhaps time to get a decent band saw or my plywood firm to CNC the rings for me to close to perfection for a bit of hand finishing only...

That would be a big help.

Hi Speedysteve7,

It would seem from the above photo that you may have manually scaled your horn dimensions directly from a hardcopy printout of the Hornresp schematic diagram. Are you aware that Hornresp can automatically calculate this information for you? Simply select the File> Export > Horn Data menu command from the Schematic Diagram window.

To illustrate, I have attached an exported text file for your 75 cm horn design showing the required radius at 24 mm increments. (Unnecessary information has been deleted from the file).

Kind regards,

David

Last edited:

Missed this one...

Yes. I too have found that important but not as big a change to sound properties as throat size on this occasion.

I forgot in my write up that I did that test this on Sunday...

I loaded it with 1lt volume increments until it sounded about best. That involved trying 1 - 5 lts reduced vol and listening to each change. 5 lts is the max reduction I can easily get in there.

TBH this does not to my ears affect the sound as much as the throat size on this horn/driver combo.

I must do it again with the new larger throat and see the effects are though. At present I am running with the same vol as I do for the Conicals - may or may not be perfectly optimal. It's roughly what seemed best from Hornresp for the conical actually. For this hyper horn Hornresp is stating 3 lts less as optimum vol but that change is hard to hear TBH.

Yes. I too have found that important but not as big a change to sound properties as throat size on this occasion.

I forgot in my write up that I did that test this on Sunday...

I loaded it with 1lt volume increments until it sounded about best. That involved trying 1 - 5 lts reduced vol and listening to each change. 5 lts is the max reduction I can easily get in there.

TBH this does not to my ears affect the sound as much as the throat size on this horn/driver combo.

I must do it again with the new larger throat and see the effects are though. At present I am running with the same vol as I do for the Conicals - may or may not be perfectly optimal. It's roughly what seemed best from Hornresp for the conical actually. For this hyper horn Hornresp is stating 3 lts less as optimum vol but that change is hard to hear TBH.

Interesting reports. Did you retune the back chamber each time to meet the resonance of the horn? I've found this to be vital to enjoy delicious bass...

Steve,

I have found that this is a bit more complicated! The fight between the driver/back chamber VS the horn-resonance/horn-flare is a very strange (and near chaotic?) thing. Clever people can explain this I'm sure.

I have had practical experience trying different drivers on my 115hz exponentials.

The impedance spikes can be quite sharp and its only when you get them together, and they start cancelling themselves does the horn start to make music. Suddenly you get a power and a effortlessness that seems to defy nature. Also, when annulled properly you can use the horn much lower and cross-over not far above the horn flair frequency. Which is good, considering the size/space cost of mid-bass horns.

I think this tuning is next to impossible to do by ear (and I do almost EVerything by ear!) - when you get near the correct volume small changes make a big difference, and without looking at the impedance peaks you just don't know whether to add or reduce volume. Its quite tedious. In my experience the simulations can't get you anywhere near I'm afraid...

Interestingly, the drivers that I like the sound of were the most tricky to annul. I expect there is a reason for that correlation somewhere.

I have found that this is a bit more complicated! The fight between the driver/back chamber VS the horn-resonance/horn-flare is a very strange (and near chaotic?) thing. Clever people can explain this I'm sure.

I have had practical experience trying different drivers on my 115hz exponentials.

The impedance spikes can be quite sharp and its only when you get them together, and they start cancelling themselves does the horn start to make music. Suddenly you get a power and a effortlessness that seems to defy nature. Also, when annulled properly you can use the horn much lower and cross-over not far above the horn flair frequency. Which is good, considering the size/space cost of mid-bass horns.

I think this tuning is next to impossible to do by ear (and I do almost EVerything by ear!) - when you get near the correct volume small changes make a big difference, and without looking at the impedance peaks you just don't know whether to add or reduce volume. Its quite tedious. In my experience the simulations can't get you anywhere near I'm afraid...

Interestingly, the drivers that I like the sound of were the most tricky to annul. I expect there is a reason for that correlation somewhere.

Payday - I bought a bandsawand a proper jigsaw to be able to get fine control over the angles. Will be able to do nice tilted cuts according to the data export from Hornresp for my larger throated design.

Cool!!! It is so much easier to prototype when you have good tools. Come to think of it, I think I need a new Lathe

With the new horn, it looks like you could bring down your other drivers a couple feet overall. You might get a more coherent sound stage.

Yes and yes. The height reduction thing was the main objective of the Exp horn.

The secondary objective was perhaps improved sound.

No point in trying it until I have two mid bass horns the same size hence the pics as is.

Photos and perspectives can be deceptive. The Hyper horns are 18cm smaller in diameter. So can only bring down by that much. Still a fair bit really.

A new lathe - Nice. Mine is a USA Southbend imported into England as part of the help the USA helping the early war effort in the early 1940's.

Still does a good enough job today. Something of an antique - there are of course even older Southbend's though... I guess it will see my out and beyond!

**********************************************

I realise I did not say anything about Hornresp when David posted with his helpful advice. I'd like to say what a marvelous tool and aid to this lark Hornresp really is.

Thank you so much David for it and the advice.

**********************************************

I've been out playing with the new toys - Cut the 18 largest rings all angled as per the output sheet from Hornresp

This one is going to be much quicker to lick into the Hyper shape.

Hope to have it shaped and perhaps even the back box built - or save that for one evening next week.

I am listening to Ray Lamontagne - Trouble album as I type. The stereo separation of the some of the track on the rich upper bass makes it easy to hear the new sound this hyper horn is making. I LIKE IT. Not just a bit different but a whole other experience of detail and kick.

I'll take some photos after the next workshop session - cutting out the next 17 rings (they get smaller and smaller and quicker and quicker), and have them gluing over night...

The secondary objective was perhaps improved sound.

No point in trying it until I have two mid bass horns the same size hence the pics as is.

Photos and perspectives can be deceptive. The Hyper horns are 18cm smaller in diameter. So can only bring down by that much. Still a fair bit really.

A new lathe - Nice. Mine is a USA Southbend imported into England as part of the help the USA helping the early war effort in the early 1940's.

Still does a good enough job today. Something of an antique - there are of course even older Southbend's though... I guess it will see my out and beyond!

**********************************************

I realise I did not say anything about Hornresp when David posted with his helpful advice. I'd like to say what a marvelous tool and aid to this lark Hornresp really is.

Thank you so much David for it and the advice.

**********************************************

I've been out playing with the new toys - Cut the 18 largest rings all angled as per the output sheet from Hornresp

This one is going to be much quicker to lick into the Hyper shape.

Hope to have it shaped and perhaps even the back box built - or save that for one evening next week.

I am listening to Ray Lamontagne - Trouble album as I type. The stereo separation of the some of the track on the rich upper bass makes it easy to hear the new sound this hyper horn is making. I LIKE IT. Not just a bit different but a whole other experience of detail and kick.

I'll take some photos after the next workshop session - cutting out the next 17 rings (they get smaller and smaller and quicker and quicker), and have them gluing over night...

Cool!!! It is so much easier to prototype when you have good tools. Come to think of it, I think I need a new Lathe

With the new horn, it looks like you could bring down your other drivers a couple feet overall. You might get a more coherent sound stage.

Last edited:

I realise I did not say anything about Hornresp when David posted with his helpful advice. I'd like to say swat a marvelous tool and aid to this lark Hornresp really is. Thank you so much David for it and the advice.

Hi Speedysteve7,

You're most welcome. Thanks for the kind words, and for your private email message.

Kind regards,

David

NP David.

Well, 2nd one knocked up:

Much less edge smoothing needed with the angle cuts.

Not finished fully but quite smooth in there for the 100 - 350Hz waveys.

Quite an effort to get done in a weekend.

Listening now - Drottningholm Baroque ensemble among others. Great church organ use on bass and DEEP bass (Tapped H handles that pf course).

Bass vocals are nice too.

Quite different to the big conicals. More detail is audible. I can turn these up more and get a nice character to tenor and bass vocals.

I'd say they integrate better with the mid horns - others have said the same thing about round Hyper or Exponential profile bass horns. How much diff round vs square actually makes I do not know - prob not much, but I like the round look.

I have back box tuning to do by measuring (more guidance needed by maravedis on that one) - should take care of an evening or two

Then I can drop the other drivers and re-time align and see how that sounds - never ends, just as it should be

Well, 2nd one knocked up:

Much less edge smoothing needed with the angle cuts.

Not finished fully but quite smooth in there for the 100 - 350Hz waveys.

Quite an effort to get done in a weekend.

Listening now - Drottningholm Baroque ensemble among others. Great church organ use on bass and DEEP bass (Tapped H handles that pf course).

Bass vocals are nice too.

Quite different to the big conicals. More detail is audible. I can turn these up more and get a nice character to tenor and bass vocals.

I'd say they integrate better with the mid horns - others have said the same thing about round Hyper or Exponential profile bass horns. How much diff round vs square actually makes I do not know - prob not much, but I like the round look.

I have back box tuning to do by measuring (more guidance needed by maravedis on that one) - should take care of an evening or two

Then I can drop the other drivers and re-time align and see how that sounds - never ends, just as it should be

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 5 way horn speaker system project - tapped, bass, mids and tweeter passive active