Here are some budget project speakers I built this week. The pyramid speakers are made from 500 pound test triple wall corrugate (aka cardboard). I fitted them with Vifa A10CC-07 (made for M&K and $5 from deepsurplus.com) two way drivers and Eminence Alpha 8 ($45 from Parts Express) woofers. Simple 3-way crossovers from Parts Express and it is amazing how good they sound.

A very innovative build. Some questions. How did you join the edges of the cardboard? Is the woofer box closed or ported? What are the crossover frequencies and slopes? Thanks.

A very innovative build. Some questions. How did you join the edges of the cardboard? Is the woofer box closed or ported? What are the crossover frequencies and slopes? Thanks.

They are hot glued but on a industrial level

An externally hosted image should be here but it was not working when we last tested it.

There are no ports and they are not totally sealed at this point. The bottoms are open. Whatever they are sitting on acts like the bottom of the speaker. On carpet a bit of air flow, more like polyfill, but I don't see much difference in sound. They still have nice bass for such a small woofer.

Crossover frequencies of 800 Hz and 5,000 Hz with 12 dB per octave roll-off.

I think, based on a bit of experience, that cardboard is a wonderful material to use with speakers. Just to state my position, I'm in the "Pulp is Pulp" camp, although I certainly believe that different glues, adhesive materials or finish can affect the sound.

Best Regards,

TerryO

Best Regards,

TerryO

I've built more than a few cardboard boxes.

After building my last pair of cardboard speakers (Mets with a set of TB unobtainium 3"), i realized that Chris could have thrown a pair of plywood boxes in half the time it took me.

dave

After building my last pair of cardboard speakers (Mets with a set of TB unobtainium 3"), i realized that Chris could have thrown a pair of plywood boxes in half the time it took me.

dave

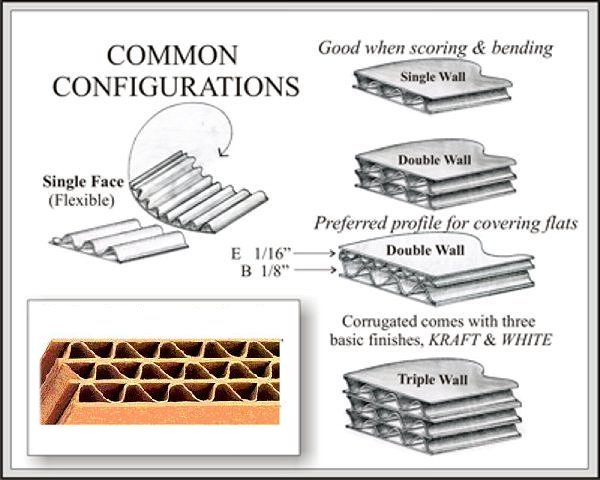

I have the advantage of working at a corrugators. I built the boxes in about 20 minutes in our design room. Any job is easier when you have all the correct tools at hand. Add another 30 for cutting the holes, adding drivers and crossovers. So in round numbers, it took about an hour.

There are quite a few advanatages to your design, I wonder if you were aware of all of them?

- Low mass = low stored energy (resonance)

- Pyramid shape will destroy internal standing waves

- Low mounted woofer - both enhanced bass and reduced floor bounce cancellation

- non-rectangular baffle, improved (spread out) diffraction effect on HF

- Aside from how inexpensive they are (both time and materials) those are all I can think of at the moment, I'm beat, just finished my CSE 560 final project *whew*

Hello Wardsweb, I like the design. I have a couple pairs of the A10CC-07's and was thinking of what to do with the second pair, now I have another possibility!😎

I will let people know though, I went to deepsurplus.com site yesterday and wasn't able to find the A10CC's. It appears that either they sold out of them, or for some reason took them off the site. It seems wierd as they had over 800 of them available when I looked back in January, and that wasn't too much different from the quantity they had listed back during the summer. I knew I should have bought a few more last year!

Peace,

Dave

P.S. Apex Jr.Home Page still has the A10CC's for $14.95/ea. And there are others listing them on ebay, for varying prices per pair.

I will let people know though, I went to deepsurplus.com site yesterday and wasn't able to find the A10CC's. It appears that either they sold out of them, or for some reason took them off the site. It seems wierd as they had over 800 of them available when I looked back in January, and that wasn't too much different from the quantity they had listed back during the summer. I knew I should have bought a few more last year!

Peace,

Dave

P.S. Apex Jr.Home Page still has the A10CC's for $14.95/ea. And there are others listing them on ebay, for varying prices per pair.

I cannot think of any negative reason why you should not sell a flat-pack corrugated speaker box kit. There are some seriously strong double sided adhesive tape available and I am sure that you can print some sort of grain or pattern on the outside. It just may start a new business.

It seems a brilliant and cost effective idea at a production packing and shipping don't supply drivers, just carboard.

It seems a brilliant and cost effective idea at a production packing and shipping don't supply drivers, just carboard.

Thank you Nico for reawakening this old thread 🙂 I had not seen this one before, and WardWeb did have some interesting builds. There are several of us here at DIYAudio and elsewhere that build with not-wood materials. xrk971 is the most prolific and best-known (to me anyway) using foamcore board. I nominate myself as king of coroplast (preferably free advertising signs collected from along highways.). The main advantages of all these materials is, of course that they are cheap (free sometimes) and certainly easier to work than wood. A knife and a straight-edge is all that is needed for most cuts, compared to a work shop when trying to cut MDF or ply 🙂 It is excellent to prototype ideas or even for completed builds. If the BBC/Harbeth enclosure idea is correct, then these materials have the added advantage (I think) of having different resonance than comparable wood boxes. BBC used thin ply with damping (bitumen = a rubber or tar product I think).

I don't have the testing equipment, but for (say) > 200 Hz, probably any of these "not wood" products make a good -- if not perfect --- speaker box. I am quite sure, even based on some failed experiments, that a subwoofer does best in a heavy, thick-walled enclosure and not coroplast 🙄

I don't have the testing equipment, but for (say) > 200 Hz, probably any of these "not wood" products make a good -- if not perfect --- speaker box. I am quite sure, even based on some failed experiments, that a subwoofer does best in a heavy, thick-walled enclosure and not coroplast 🙄

Nice! I managed to salvage a whole heap (30 or so) large triple ply corrugated cardboard from a neighbor who just moved in and was throwing them out. Great stuff to use. I sometimes laminate this with a foam core center for a 3 layer composite that is very strong and resonance free. I bond the layers together with 3M 777 spray contact cement. For areas where resonance is an issue such as front baffle - I use latex caulking in between layers for mass and CLD (damping). The cardboard takes on Spax construction screws very well and if clamped with screws or tacked with hot glue - joints made with Titebond work well too.

Nice speakers! Finally a build with those Vifa coaxials. 🙂

Btw, I am am envious of your hot melt glue gun. Never knew an industrial sized one existed before. 😀

Nice speakers! Finally a build with those Vifa coaxials. 🙂

Btw, I am am envious of your hot melt glue gun. Never knew an industrial sized one existed before. 😀

Last edited:

Cardbox is less strong than wood but has very high inner damping. It is good for horns and waveguides, because air pressure can get out by the way of least resistance, unlike in a pressure chamber such as a sealed box. Cardbox is too weak for resonance enclosures such as quarter-waves and bassreflex. When building sealed boxes from cardboard one should go big, choosing drivers with low moving mass and high compliance, say drivers which need a big and obtain a generous air volume, build the boxes with less than right angles, say not rectangular but of diamond shape (18 facets are fine), and use inner braces.

Xrk971 build a Weedhorn and you can make a different kind of joint :-D

Sent from my SPH-L300 using Tapatalk

Sent from my SPH-L300 using Tapatalk

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Corrugate speakers...aka cardboard