Hi,

Driver with Underhung voice coil can to be good for bass as Overhung voice coil?

Voice Coil Heigh - 16mm

HE Magnetic Gap Heigh - 6mm

give x-max of +/-5mm.

Or

Voice Coil Heigh - 5.5mm

HE Magnetic Gap Heigh - 16mm

give x-max of +/-5.25mm.

The drivers is 150W RMS power.

Anybody can help please?

Thanks.

Driver with Underhung voice coil can to be good for bass as Overhung voice coil?

Voice Coil Heigh - 16mm

HE Magnetic Gap Heigh - 6mm

give x-max of +/-5mm.

Or

Voice Coil Heigh - 5.5mm

HE Magnetic Gap Heigh - 16mm

give x-max of +/-5.25mm.

The drivers is 150W RMS power.

Anybody can help please?

Thanks.

I think coil copper volume and surface area will be a significant determination of power capacity which will drive up the volume of the magnet structure for a given speaker with underhung motor. In woofers the increase in cost may not be offset by any meaningful increase in performance. It does have some neato factor.

there is often a loss of sensitivity/efficiency with underhung

but not always

very long Xmax overhung aint too good either, in that respect

but I guess its possible make underhung with high sensitivity, keeping Xmax very low

many modern tweeters are underhung

all about compromises

no two people want the exact same driver, and part of the problem

so, many drivers are made more 'flexible' that they may actually need to be

many other good drivers are the opposite, with much too little safety margin

unfortunately probably some good ones, or would have been

but not always

very long Xmax overhung aint too good either, in that respect

but I guess its possible make underhung with high sensitivity, keeping Xmax very low

many modern tweeters are underhung

all about compromises

no two people want the exact same driver, and part of the problem

so, many drivers are made more 'flexible' that they may actually need to be

many other good drivers are the opposite, with much too little safety margin

unfortunately probably some good ones, or would have been

Thanks,

The two driver is Morel Carbon:

https://www.madisound.com/store/product_info.php?manufacturers_id=141&products_id=8485

https://www.madisound.com/store/product_info.php?manufacturers_id=141&products_id=8474

The SCM634 is a "midrange" but with WinISD the bass is better from SCW636.

Idea?

The two driver is Morel Carbon:

https://www.madisound.com/store/product_info.php?manufacturers_id=141&products_id=8485

https://www.madisound.com/store/product_info.php?manufacturers_id=141&products_id=8474

The SCM634 is a "midrange" but with WinISD the bass is better from SCW636.

Idea?

Are you talking midbass or subwoofer?

The fact is, if two hypothetical drivers had identical T/S parameters and soft parts, except that one was overhung and one was underhung, they would perform largely the same.

The only difference might be that the underhung motor might have less distortion based on a more constant Le over excursion (Le/x), and often flatter BL over excursion (BL/x), too. Underhung drivers can also be made to have the least possible moving mass because the entire voice coil contributes motive force all the time, not just a fraction of winding as in an overhung driver.

These benefits accrue mostly in the midrange, which is why underhung subwoofers are so rare.

The main downside of underhung is the materials cost of the huge magnets and flux return circuits that can be required to hit BL and Xmax targets.

In the end, though, when making performance comparisons, it's not very useful to generalize. There are very well-made drivers in both topologies. You have to evaluate the performance if each on a case-by-case basis.

Edit--oops, others beat me to the post, and I see you're talking about specific drivers... Interesting how close their specs are! It almost looks like Morel used the same parts for both, except for the top plate and the voice coil.

The fact is, if two hypothetical drivers had identical T/S parameters and soft parts, except that one was overhung and one was underhung, they would perform largely the same.

The only difference might be that the underhung motor might have less distortion based on a more constant Le over excursion (Le/x), and often flatter BL over excursion (BL/x), too. Underhung drivers can also be made to have the least possible moving mass because the entire voice coil contributes motive force all the time, not just a fraction of winding as in an overhung driver.

These benefits accrue mostly in the midrange, which is why underhung subwoofers are so rare.

The main downside of underhung is the materials cost of the huge magnets and flux return circuits that can be required to hit BL and Xmax targets.

In the end, though, when making performance comparisons, it's not very useful to generalize. There are very well-made drivers in both topologies. You have to evaluate the performance if each on a case-by-case basis.

Edit--oops, others beat me to the post, and I see you're talking about specific drivers... Interesting how close their specs are! It almost looks like Morel used the same parts for both, except for the top plate and the voice coil.

Last edited:

If I had my own speaker manufacturing company.

1) all woofers would use a NdFeB differential drive motors

- very linear

- very low distortion for bass

- low inductance without copper sleeve flux reduction

- acceptable Mms for bass

- cones would be carbon_fiber/kevlar loaded paper

- I believe the basic 1984 patent has expired, but new "extended" patents exist

http://www.jblpro.com/catalog/support/getfile.aspx?docid=1253&doctype=3

2) all midrange would use a radial NdFeB underhung motor with full copper sleeve on the pole piece

- very linear and very low distortion

- very low Mms

- low inductance

- cones would be carbon_fiber/kevlar loaded paper

3) all tweeters would be NdFeB HEIL or advanced Ribbon designs

- Beyma TPL 150, RAAL 150-10, DIY ribbon.

- capable of both monopole and dipole radiation pattern

- waveguide can be added to HEIL, but not ribbon

- avoids the multiple distortion effects of compression driver on horns.

- superior SPL vs. freq, distortion, and polar response: wrt dome or horn

(you can DIY a $400 RAAL ribbon for about $70)

google "Measurements performed on 16 horns"

- reflected waves

- defracted waves

- high order modes

1) all woofers would use a NdFeB differential drive motors

- very linear

- very low distortion for bass

- low inductance without copper sleeve flux reduction

- acceptable Mms for bass

- cones would be carbon_fiber/kevlar loaded paper

- I believe the basic 1984 patent has expired, but new "extended" patents exist

http://www.jblpro.com/catalog/support/getfile.aspx?docid=1253&doctype=3

2) all midrange would use a radial NdFeB underhung motor with full copper sleeve on the pole piece

- very linear and very low distortion

- very low Mms

- low inductance

- cones would be carbon_fiber/kevlar loaded paper

3) all tweeters would be NdFeB HEIL or advanced Ribbon designs

- Beyma TPL 150, RAAL 150-10, DIY ribbon.

- capable of both monopole and dipole radiation pattern

- waveguide can be added to HEIL, but not ribbon

- avoids the multiple distortion effects of compression driver on horns.

- superior SPL vs. freq, distortion, and polar response: wrt dome or horn

(you can DIY a $400 RAAL ribbon for about $70)

google "Measurements performed on 16 horns"

- reflected waves

- defracted waves

- high order modes

(you can DIY a $400 RAAL ribbon for about $70)

Sorry to go OT but how do I do this?

If I had my own speaker manufacturing company.

1) all woofers would use a NdFeB differential drive motors

- very linear

- very low distortion for bass

- low inductance without copper sleeve flux reduction

- acceptable Mms for bass

- cones would be carbon_fiber/kevlar loaded paper

- I believe the basic 1984 patent has expired, but new "extended" patents exist

http://www.jblpro.com/catalog/support/getfile.aspx?docid=1253&doctype=3

I'm a fan of DD, too. (Currently have JBL LSR32's in my listening room.) DD can be thought of as two overhung motors working together. WRT the topic of this thread, it's fun to imagine how an UNDERHUNG DD motor might compare.

Last edited:

DIY RAAL Ribbon.... Sorry to go OT but how do I do this?

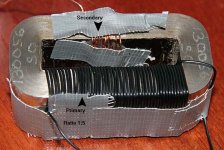

RAAL 140-10 copy... DIY materials:

Cold Finish Mild Steel Rectangle 1018

0.25" X 3" MILD STEEL 1018 COLD FINISH RECTANGLE

24" Length - $16.74 for three 6" high sides

Neodymium Magnets N42 3"x1/2"x1/2" NdFeB Rare Earth Magnets

Our price: $3.95 * 4 = $16

Cut open a film-foil capacitor for 5um to 9um aluminum foil for the ribbon

A premium amorphous C-Core is $22. A grade 77 ferite toroid core is $9.

Amidon FT240-77 or FT240-J or FT240-K are ~ $9

Magnet wire can be used for a trifilar transformer winding. If you use C-core sections it is straight foward to pre-wind copper foil coils on formers that slip onto the two C-Cores.

The ribbon cavity is stuffed with poly-fill or wool to absorb rear waves.

Attachments

Thank you all

is maybe look a like, but the sounds?

probably sounds like a ribbon

If thats what you want, I would say 'go for it'

but be prepared that nothing will ever be the same again

Right. No DD motors I'm aware of are underhung by any stretch. And you make a good point about how a pair of antiphase woofers, one mounted backward, can be considered a "differential pair," with advantages in canceling 2nd-order nonlinearity of both motor and suspension.

But DD motors offer some interesting improvements in motor linearity by working the geometries and induction of two voice coils against each other, sidestepping several distortion mechanisms. Not the least of which is Le(i) distortion, or cycling the magnetic operating point of the motor up and down its nonlinear BH curve.

But DD motors offer some interesting improvements in motor linearity by working the geometries and induction of two voice coils against each other, sidestepping several distortion mechanisms. Not the least of which is Le(i) distortion, or cycling the magnetic operating point of the motor up and down its nonlinear BH curve.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Overhung or underhung voice coils?