Number 2 is almost done,...

It has been a long time since I was back here. Really great to see your progress. It looks FANTASTIC!

Thanks gentlemen.

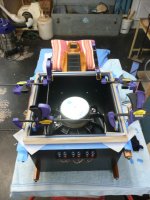

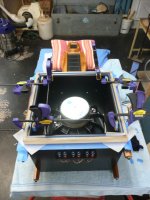

When I put the 2nd speaker together late last night I forgot to put the infill panel in below the mid driver, so when I went down this morning to wire it up the first thing I saw was the infill panel sitting on the bench, doop.

It turned out not to be a difficult as I first thought to put in the panel. I needed to support the body so I could remove two of the bolts holding the body to the box, I thought it was fitting to use a couple of pillows to do it

I am now making the grill covers, I am custom fitting each one to ensure a good fit. I thought I would just build one first as I'm not sure how they will workout,

When I put the 2nd speaker together late last night I forgot to put the infill panel in below the mid driver, so when I went down this morning to wire it up the first thing I saw was the infill panel sitting on the bench, doop.

It turned out not to be a difficult as I first thought to put in the panel. I needed to support the body so I could remove two of the bolts holding the body to the box, I thought it was fitting to use a couple of pillows to do it

I am now making the grill covers, I am custom fitting each one to ensure a good fit. I thought I would just build one first as I'm not sure how they will workout,

Attachments

Thanks djn.

Yesterday started ok, did some work on the test grill surround getting ready to cover it. I had the surround ready for covering when I had to duck off the the doctors to have a cyst removed from my back, which I thought was going to be a doodle, I should have known better. After waiting an interminable amount of time the doctor was finally ready to see me, well as it turned out he didn't know why I was there & suggested that I should make an appointment to get the cyst removed, I advised him that was why I was here, he appeared a bit flustered but managed to rustle up some grumpy nurse to assist. The minor op which I thought would take about 5 minutes went on for what seemed like forever with the doctor tugging & pulling at my numb back while complaining about the blunt scissors & giving me a blow by blow description of what was going on. I polity suggested the he cease & desist with the graphics as I wasn't far from throwing up all over the bed. Eventually the agony (metal not physical) stopped, by which time I was a ball of sweat, I sat up just in time for the doctor to walk past & hold up a plastic container with a huge chunk on my back in it and pronounce, " she was a beauty alright" he then walked straight out of the room & left me on my own. Well within seconds of him leaving, the room was spinning, my mouth was watering & I came VERY close to throwing up & passing out on the floor all at once. Fortunately I had the mental where for all to lay back down on the bed. Eventually the nurse came back in, I regained some of my composure (some was lost forever

) and the nurse bandaged me back up and sent me off. I then shakily drove home to recommence festivities in the garage.

) and the nurse bandaged me back up and sent me off. I then shakily drove home to recommence festivities in the garage.

In retrospect I probably should have taken the rest of the day off, but I didn't. I started covering the test grill cover & it wasn't going all that well, when I got to the corners things where really starting to fall apart and I didn't have my normal composure to step back & think it through, instead I thought I would remove the masking tape from the speaker so I could fit the cover when it was finished, well that's where things really went to HELL. When I was removing the tape it pulled off some of the water based clear coat I had put on the speakers, it did this in a location that wont be seen but you may as well have stabbed me with a knife (I had two onlookers by this time which really didn't help either) to say I was devastated is an understatement, I returned to the grill cover and things just kept getting worse. It wasn't long before I was hacking at the grill cover with a pair of scissors like someone out of a Alfred Hitchcock movie, I suspect the onlookers where thinking of calling the men with the padded suit to give me a fitting.

Anyway I did some repairs that will just have to do, but the virgin has been forever defiled.

Today I had another go at the grill cover & as you will see in the photo it doesn't look too bad, I think I have finally worked out a system to get the covers the way I want them which means I will have to pull this one apart one more time & hopefully make the next three only once, given my track record that's probably wishful thinking.

For reference the other photo shows the blue masking tape that I removed.

I have failed in my mission to get the speakers completely finished before returning to work, there it still tomorrow but I am putting up the white flag for the moment. I have taken the speakers back to my bedroom where they belong so I can recharge my batteries with some beautiful music, the covers will just have to wait.

Hopefully next weekend I will be install speakers I my sons car.

Yesterday started ok, did some work on the test grill surround getting ready to cover it. I had the surround ready for covering when I had to duck off the the doctors to have a cyst removed from my back, which I thought was going to be a doodle, I should have known better. After waiting an interminable amount of time the doctor was finally ready to see me, well as it turned out he didn't know why I was there & suggested that I should make an appointment to get the cyst removed, I advised him that was why I was here, he appeared a bit flustered but managed to rustle up some grumpy nurse to assist. The minor op which I thought would take about 5 minutes went on for what seemed like forever with the doctor tugging & pulling at my numb back while complaining about the blunt scissors & giving me a blow by blow description of what was going on. I polity suggested the he cease & desist with the graphics as I wasn't far from throwing up all over the bed. Eventually the agony (metal not physical) stopped, by which time I was a ball of sweat, I sat up just in time for the doctor to walk past & hold up a plastic container with a huge chunk on my back in it and pronounce, " she was a beauty alright" he then walked straight out of the room & left me on my own. Well within seconds of him leaving, the room was spinning, my mouth was watering & I came VERY close to throwing up & passing out on the floor all at once. Fortunately I had the mental where for all to lay back down on the bed. Eventually the nurse came back in, I regained some of my composure (some was lost forever

In retrospect I probably should have taken the rest of the day off, but I didn't. I started covering the test grill cover & it wasn't going all that well, when I got to the corners things where really starting to fall apart and I didn't have my normal composure to step back & think it through, instead I thought I would remove the masking tape from the speaker so I could fit the cover when it was finished, well that's where things really went to HELL. When I was removing the tape it pulled off some of the water based clear coat I had put on the speakers, it did this in a location that wont be seen but you may as well have stabbed me with a knife (I had two onlookers by this time which really didn't help either) to say I was devastated is an understatement, I returned to the grill cover and things just kept getting worse. It wasn't long before I was hacking at the grill cover with a pair of scissors like someone out of a Alfred Hitchcock movie, I suspect the onlookers where thinking of calling the men with the padded suit to give me a fitting.

Anyway I did some repairs that will just have to do, but the virgin has been forever defiled.

Today I had another go at the grill cover & as you will see in the photo it doesn't look too bad, I think I have finally worked out a system to get the covers the way I want them which means I will have to pull this one apart one more time & hopefully make the next three only once, given my track record that's probably wishful thinking.

For reference the other photo shows the blue masking tape that I removed.

I have failed in my mission to get the speakers completely finished before returning to work, there it still tomorrow but I am putting up the white flag for the moment. I have taken the speakers back to my bedroom where they belong so I can recharge my batteries with some beautiful music, the covers will just have to wait.

Hopefully next weekend I will be install speakers I my sons car.

Attachments

Sorry to hear about all the troubles today. I'm pretty squeemish to, so I might have gone over the edge and puked right there. My brother had a vasectomy last year and the doctor asked if he cared to have a look while it was happening! Has ANYONE ever said, "sure, thanks doc!"?

Speakers are really coming together nicely. The home stretch with all of the fiddly bits is the toughest part to push through. I am too lazy to look back through the thread, so how are crossing over/driving these? Active?

Greg

Speakers are really coming together nicely. The home stretch with all of the fiddly bits is the toughest part to push through. I am too lazy to look back through the thread, so how are crossing over/driving these? Active?

Greg

You've come too far to rush now... deep breathe and wait for next weekend. We can all wait another week.

HI D

As SS suggested step back take 5 and recover

CHeers

HI D

As SS suggested step back take 5 and recover.

CHeers

There is (at least) 6 in a pack of beers up in Queensland

Sorry I fell asleep on the job, they are 98% finished and are playing as they are. I still have to make some wire covers for the speaker terminal connections on the actual mid & tweeter drivers & hopefully take some better photos when my brother brings his camera over.

The front is the side without the screws that where necessary to hold the men together.

I would like to thank everybody that has helped in this long long build, especially Helmuth for all of the advice in the early stages, 56 for all of his encouragement, Andy for getting the screws I wanted & shipping them to Australia, my brother for making the lizards & generally getting in the way only kidding and everybody else who has either encouraged me and or given advice, the list is long.

only kidding and everybody else who has either encouraged me and or given advice, the list is long.

If you look at the first page & then the last you will get a good idea of the journey.

Thanks again

The front is the side without the screws that where necessary to hold the men together.

I would like to thank everybody that has helped in this long long build, especially Helmuth for all of the advice in the early stages, 56 for all of his encouragement, Andy for getting the screws I wanted & shipping them to Australia, my brother for making the lizards & generally getting in the way

If you look at the first page & then the last you will get a good idea of the journey.

Thanks again

Attachments

They look fabulous. Job well done, sir!

I'd like to caution all of my virtual DIY friends using the Neo series, especially the Neo10 to be extra careful with their drivers. I would not recommend soldering on the terminals. I am an expert solderer(taught cable and circuit board soldering for 5 years) and it seems that even so, after several rounds of connecting and disconnecting, that I may have damaged mine. See here for a round of testing done on mine with a Praxis system:

BG Neo10 Testing

We are not sure that soldering/heat is what caused the problems, BUT one of the 4 drivers is new due to an oscillator accident burning one out about 6 months ago and it is the cleanest measuring of the bunch. That one has never been soldered to, only used with crimp-on terminals.

Even so, I still maintain that these are the best mids I've heard to date when used within their limits. I bought and tested nearly a dozen different mids for my project and the Neo10 sounded the best to my ears and worked into the design perfectly.

Greg

I'd like to caution all of my virtual DIY friends using the Neo series, especially the Neo10 to be extra careful with their drivers. I would not recommend soldering on the terminals. I am an expert solderer(taught cable and circuit board soldering for 5 years) and it seems that even so, after several rounds of connecting and disconnecting, that I may have damaged mine. See here for a round of testing done on mine with a Praxis system:

BG Neo10 Testing

We are not sure that soldering/heat is what caused the problems, BUT one of the 4 drivers is new due to an oscillator accident burning one out about 6 months ago and it is the cleanest measuring of the bunch. That one has never been soldered to, only used with crimp-on terminals.

Even so, I still maintain that these are the best mids I've heard to date when used within their limits. I bought and tested nearly a dozen different mids for my project and the Neo10 sounded the best to my ears and worked into the design perfectly.

Greg

Attachments

So the waf factor is high enough now, very nice.

They will look like this.

They will look like this.

An externally hosted image should be here but it was not working when we last tested it.

Impressive!!!

Congratulations! These are the best-looking DIY speakers I've seen so far, and better than the vast majority of commercial speakers out there.

Knowing that a DIYer can make such beautiful speakers gives the rest of us hope in our speaker-building endeavors...

Congratulations! These are the best-looking DIY speakers I've seen so far, and better than the vast majority of commercial speakers out there.

Knowing that a DIYer can make such beautiful speakers gives the rest of us hope in our speaker-building endeavors...

Impressive!!!

Congratulations! These are the best-looking DIY speakers I've seen so far, and better than the vast majority of commercial speakers out there.

Knowing that a DIYer can make such beautiful speakers gives the rest of us hope in our speaker-building endeavors...

Thank you

They look fabulous. Job well done, sir!

I'd like to caution all of my virtual DIY friends using the Neo series, especially the Neo10 to be extra careful with their drivers. I would not recommend soldering on the terminals. I am an expert solderer(taught cable and circuit board soldering for 5 years) and it seems that even so, after several rounds of connecting and disconnecting, that I may have damaged mine. See here for a round of testing done on mine with a Praxis system:

BG Neo10 Testing

We are not sure that soldering/heat is what caused the problems, BUT one of the 4 drivers is new due to an oscillator accident burning one out about 6 months ago and it is the cleanest measuring of the bunch. That one has never been soldered to, only used with crimp-on terminals.

Even so, I still maintain that these are the best mids I've heard to date when used within their limits. I bought and tested nearly a dozen different mids for my project and the Neo10 sounded the best to my ears and worked into the design perfectly.

Greg

One thing I didn't consider in all of this is, if the Neo 10 & or 3 go out of production & I have a failure I'm going to be in all sorts of trouble, with cone speakers you can usually find a replacement of some sort.

I was very careful when I soldered the leads to the drivers, they still sound great.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- OB Project Design Started, Help Requested.