Here how the inside is made. I used combination of 5/8 MDF on the outside and 3/4 maple plank (3" wide) used for flooring on the inside. I wanted to combine both materials as MDF is pretty stable and good for laminating, while maple I hoped would add some properties to the better sound. Front baffle is also hardwood and I used here a cut-off from Ikea tabletop. I didn't want to use MDF as I used screws to hold the side panels and MDF is not really strong enough for that. To set the shape of the inside channels, I used 1/4 MDF side panels and that helped me in assembling everything that is seen in this pic.

Attachments

For the sides I chose 1" x 6" maple boards and they are glued to the 1/4 sub panels. I also had to use screws to both simplify construction and prevent maple boards fram warping. I used filler to cover the holes and biscuit foints to strengthen everything. The corners are rounded on a router with 3/4" radius bit and everything is sanded with 220 grid paper and later sealed with Thompson Water Seal used for decks. It gives very smooth and natural looking finish, which I personally think is nicer than using laquer. The listening tests are still to follow. I still have some doubts as to how much damping should I use and if to cover all sides with foam on the inside or not. Just to add extra rigidity I attached 6" x 6" copper plates to the side panels, where the woofer is mounted.

I used some blown rubber around tweeter. First it improves the sound of high frequencies, second it gives better look, as I had impression that visually the tweeter was too low. It's better balanced now

I used some blown rubber around tweeter. First it improves the sound of high frequencies, second it gives better look, as I had impression that visually the tweeter was too low. It's better balanced now

Attachments

Looking at that response graph, it seems like you have a good little driver, little evidence of cone breakup modes at any rate.

Looking at the roll off though, it looks like it might be a bit steep to integrate well with a first order on the tweeter, you might need to go second, or even third to sum flat.

Looking at the roll off though, it looks like it might be a bit steep to integrate well with a first order on the tweeter, you might need to go second, or even third to sum flat.

Second order is what I actually had in mind as the similar aproach was used in a Titus (or Titan maybe), a small Triangle monitor. No crossover on midbass and secon order filter on the same tweeter I'm using here. Sam Telling, of Stereophile, was raving about imaging properties of that small Triangle monitor and I also built it few years ago.

Banned

Joined 2002

JasonL said:I would say some thing but i email you for questions now and never get a responce. So yeah. !

Obviously, I must have been busy building those speakers. I have to find info on those Freds.

Banned

Joined 2002

aka?

What is this blown rubber stuff? I must know it by a different name.Peter Daniel said:I used some blown rubber around tweeter. First it improves the sound of high frequencies

this might sound odd to some but I have a audio control 4 way adjustable active crossover and I use that on speakers I build and listen and test....then I design the passive components......I use my ears more than my test equipment because after all...I`m the one that has to listen to it

DIRT®

DIRT®

Banned

Joined 2002

I spent whole day today choosing proper caps for the crossover (actually a single series cap in tweeters network). I had some Hovlands, Siemens MKV, MIT RTX, Jensens, and some silver foil bypass caps. On certain material it seemed like a chosen combination was fine, but when I switched to different type of musinc it was too bright or too annoying. Finally at the end of a day I settled on 3u MIT RTX cap, bypassed by 0.022u silver foil cap. That cap seemed to be most neutral, and although not as warm sounding as Siemens on classical or jazz, yet on industrial or rock, it provided the most neutral tonal balance. Alone it would be too dark sounding and silver foil bypass provided more life and sparkle.

I also played a bit with a gasket material. I tried placing woofer directly to the box, yet this was the worst sounding choice. Not only I didn't get much bass, but also mids were very poor sounding. Cork that I used originally, was better, but best solution so far I got with using rubber. I had a small sheet of rubber membrane used on roofs (under decking) and this worked fine.

I also played a bit with a gasket material. I tried placing woofer directly to the box, yet this was the worst sounding choice. Not only I didn't get much bass, but also mids were very poor sounding. Cork that I used originally, was better, but best solution so far I got with using rubber. I had a small sheet of rubber membrane used on roofs (under decking) and this worked fine.

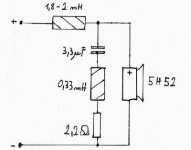

Peter Daniel said:Here's the recommended crossover for AudioTechnology woofer. I wonder what a notch filter is used here for?

The big coil is baffle step compensation and 1st order electrical XO in one package and I guess that a notch is for taking care of one of the resonances in the upper band of the woofer (one appears at aprox. 8kHz and second at 15 kHz). For which one it is meant is hard to say without looking at a impedance graph.

argo

Speaker Finishes

Peter,

The Speaker look nice, however you might try Waterlox for your next finish. It a quality Tung Oil Varnish best for hand application.

However, if you have a spray gun it hard to beat BEHLEN QUALALACQ LACQUER.

When using Lacquer you will need a sanding sealer or shellac first. Waterlox looks best when you apply it over shellac. Of course Shellac by it self look super but its' not very durable.

http://www.homesteadfinishing.com/htdocs/Lacquer.htm

http://www.waterlox.com/

Peter,

The Speaker look nice, however you might try Waterlox for your next finish. It a quality Tung Oil Varnish best for hand application.

However, if you have a spray gun it hard to beat BEHLEN QUALALACQ LACQUER.

When using Lacquer you will need a sanding sealer or shellac first. Waterlox looks best when you apply it over shellac. Of course Shellac by it self look super but its' not very durable.

http://www.homesteadfinishing.com/htdocs/Lacquer.htm

http://www.waterlox.com/

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- It's been a long time since I built my last set of speakers