Well I've been out of the speaker building loop for a little while now as my Wife and I moved up into the great midwest and built ourselves a pottery. Things are starting to feel as though they are slowing down a bit(as much as possible while running your own business), so I'm begining to think a little about speaker building again.

I would like to build myself some high efficiency three way speakers. I hear good things about open baffle. My listening space is quite small though and I don't think I could get enough distance between the rear of the speaker and the back wall to make the open baffles really sing.

So I'm thinking about trying some ceramic enclosures to reduce the box modes and hopefully reduce diffraction as well. My thinking is to make the shape similar to the B&W shaped tear drops, but cutting off the last several inches to make them something along the lines of an aperiodic transmission line.

For the three way I would love to build a ceramic enclosure for the 6-8 inch mid (audax PR170m0?), and possibly for whatever goes above that as well. However I'm still a little ways away from being able to afford everything for the three ways, and I would like to work out the ideas for the ceramic enclosure.

I'll start with making some ceramic enclosures for some 4"tangbands that I have lying around. My idea is to glue a MDF disc onto the front of the enclosures to mount the drivers to. Using MDF since it is easy to sand and shape, and then paint. This could also give some room for filling in with wood filler (or something else ... bondo?) trying to get the smoothest transition possible from MDF to ceramic enclosure.

Our next firing is mid march, so I'll probably throw them in the next week or so. Questions: Are the proportions of the "aperiodic transmission line" critical? I wouldn't think so as they not for bass, but merely to flatten impedence (this is an idea I'm "borrowing" from planet10 to give credit where credit's due) and reduce reflections. Also would there be much benefit to making them unsymmetrical internally? Options would be flattening one side, or adding in a small divider internally, possibly filling this cavity with "Great Stuff" after firing (somewhat time consuming to build up an internal wall though).

Anyways I'll be making these fairly soon, and post pictures as it progresses. Right now though I'm all ears as to suggestions, concerns, and ideas.

thanks

Joe

I would like to build myself some high efficiency three way speakers. I hear good things about open baffle. My listening space is quite small though and I don't think I could get enough distance between the rear of the speaker and the back wall to make the open baffles really sing.

So I'm thinking about trying some ceramic enclosures to reduce the box modes and hopefully reduce diffraction as well. My thinking is to make the shape similar to the B&W shaped tear drops, but cutting off the last several inches to make them something along the lines of an aperiodic transmission line.

For the three way I would love to build a ceramic enclosure for the 6-8 inch mid (audax PR170m0?), and possibly for whatever goes above that as well. However I'm still a little ways away from being able to afford everything for the three ways, and I would like to work out the ideas for the ceramic enclosure.

I'll start with making some ceramic enclosures for some 4"tangbands that I have lying around. My idea is to glue a MDF disc onto the front of the enclosures to mount the drivers to. Using MDF since it is easy to sand and shape, and then paint. This could also give some room for filling in with wood filler (or something else ... bondo?) trying to get the smoothest transition possible from MDF to ceramic enclosure.

Our next firing is mid march, so I'll probably throw them in the next week or so. Questions: Are the proportions of the "aperiodic transmission line" critical? I wouldn't think so as they not for bass, but merely to flatten impedence (this is an idea I'm "borrowing" from planet10 to give credit where credit's due) and reduce reflections. Also would there be much benefit to making them unsymmetrical internally? Options would be flattening one side, or adding in a small divider internally, possibly filling this cavity with "Great Stuff" after firing (somewhat time consuming to build up an internal wall though).

Anyways I'll be making these fairly soon, and post pictures as it progresses. Right now though I'm all ears as to suggestions, concerns, and ideas.

thanks

Joe

Last edited:

And ... making a flat surface could be the easier job when buildingJoe,

MDF is easy to shape, but isn't great for baffles.

a curved enclosure using ceramic .

I know that on larger enclosures Baltic Birch is the material of choice by many around here. My main speakers are made out of a combination of baltic birch plywood and Walnut.

However on a small baffle, maybe 8" in diameter max for the tangbands, I wouldn't think the choice of wood would have such a large impact. I defer to your expertise in this area though Dave. Do people here think something like baltic birch would make a noticeable improvement on the front baffles?

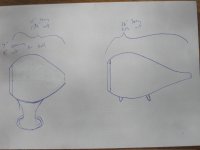

Two other questions: Dave, you mention diminishing cross section is key, do you think something like the picture I attached is going to be a problem. I had invisionned it with a increase in cross section to start out so as to provide a more gentle continuous curve starting from the driver itself to help reduce diffraction. Will this initial increase in cross section cause troubles?

Next question as my budget is short and I don't know when I'll be able to afford a high quality 6" driver for a nice high effeciency three way, I'm considering testing this out with my main speakers now as well. As they are right now they are a 4" fostex (108) in a sealed enclosure inside a MLTL with an eminence delta 12lf. The crossover is at 300 Hz. If I build a enclosure like the one attached for the fostex driver. How tall of a stand can I build without running into issues of the system sounding like two seperate sources instead of sounding like a single point source? In other words how far apart can two drivers be with a 300Hz crossover and still function well together (3rd order acoustic x-over) ? I'm guessing some where around a 1/4 wave length? or ~11". Does this sound reasonable?

thanks

Joe

However on a small baffle, maybe 8" in diameter max for the tangbands, I wouldn't think the choice of wood would have such a large impact. I defer to your expertise in this area though Dave. Do people here think something like baltic birch would make a noticeable improvement on the front baffles?

Two other questions: Dave, you mention diminishing cross section is key, do you think something like the picture I attached is going to be a problem. I had invisionned it with a increase in cross section to start out so as to provide a more gentle continuous curve starting from the driver itself to help reduce diffraction. Will this initial increase in cross section cause troubles?

Next question as my budget is short and I don't know when I'll be able to afford a high quality 6" driver for a nice high effeciency three way, I'm considering testing this out with my main speakers now as well. As they are right now they are a 4" fostex (108) in a sealed enclosure inside a MLTL with an eminence delta 12lf. The crossover is at 300 Hz. If I build a enclosure like the one attached for the fostex driver. How tall of a stand can I build without running into issues of the system sounding like two seperate sources instead of sounding like a single point source? In other words how far apart can two drivers be with a 300Hz crossover and still function well together (3rd order acoustic x-over) ? I'm guessing some where around a 1/4 wave length? or ~11". Does this sound reasonable?

thanks

Joe

Attachments

A baffle is the weakest panel in the box because of the big hole... and MDF won't reliably hold a screw.

dave

An externally hosted image should be here but it was not working when we last tested it.

dave

Not as exotic, but I use "ceramic plates" in a sandwich for my subs. I glue 12" or 16" ceramic floor tiles between two 1/2 inch sheets of plywood. It makes a cabinent that is far more rigid than my prototype of four layers of 5/8 MDF. Lighter too.

I am not sure I would go ceramic for mid-range and up because it is so rigid, its resonance frequencies will be in the audible range. That is why MDF is so popular; it is not very rigid so the resonance can be below the useful range. In my sub I push the resonance frequencies above my useful range.

Very interesting options in shapes, but how many you would have to built before you get the dimensions just right after the shrinkage in the kiln? Boxes still have their place.

I am not sure I would go ceramic for mid-range and up because it is so rigid, its resonance frequencies will be in the audible range. That is why MDF is so popular; it is not very rigid so the resonance can be below the useful range. In my sub I push the resonance frequencies above my useful range.

Very interesting options in shapes, but how many you would have to built before you get the dimensions just right after the shrinkage in the kiln? Boxes still have their place.

A baffle is the weakest panel in the box because of the big hole... and MDF won't reliably hold a screw.

dave

Fair enough MDF is out....

I am not sure I would go ceramic for mid-range and up because it is so rigid, its resonance frequencies will be in the audible range. That is why MDF is so popular; it is not very rigid so the resonance can be below the useful range. In my sub I push the resonance frequencies above my useful range.

Very interesting options in shapes, but how many you would have to built before you get the dimensions just right after the shrinkage in the kiln? Boxes still have their place.

Tvrgeek, I'm not too worried about resonance from the enclosure for two reasons. One, I believe having wood glued on the front baffle will help damp any ringing before it begins. Two the clay body we use is much different than commercial porcelain you are maybe thinking of, it is a much more "open" body, meaning that it has a sand like material added to it. It does not ring in the same way a commercial porcelain plate will.

And as far as shrinkage and sizing goes, I believe as I have some wiggle room as far as size goes, since I am using these for midrange and not tuning the boxes for a certain frequency. Also although we are just starting our pottery now I had been working as a full time production potter for the seven years before this, throwing exact shapes for other people, often making matching sets. I know our clay body shrinks 12% from wet to fired, so I feel pretty confident that I can make what I want. I'm just trying to get suggestions so I can figure out exactly what it is that I want

thanks for the advice so far

Joe

diminishing cross section is key, do you think something like the picture I attached is going to be a problem.

A strong taper reduces the length of the line required to hit the target. The taper also shifts the higher order resonances up making it easier to kill them.

Ideally the length corresponds with a 1/4 wave resonance = the driver Fs, but because of the aperiodic damping and a higish XO it is not a real problem if it isn't.

An intial expansion should actually work as a HP filter as well, you can see a similar concept used in Scottmoose's Olson-stype stepped horns. Each bend has an expanded area and acts to keep HF out of the horn mouths.

B&W did a lot of research to end up with the shape you are using... theirs has to be longer because they are half-wave.

The crossover is at 300 Hz...How tall of a stand can I build without running into issues of the system sounding like two seperate sources instead of sounding like a single point source?

When we were prototyping Tysen we started with the woofer at the floor. Measured ripple was high (XO ~333Hz), and flipping the (separate) woofer enclosure the other way to get the woofer as close as possible to the mid-tweeter cleaned things up a lot. Sounded more coherent as well. My advice would be to get them as close together as practical.

dave

into the great midwest

PS: what consititutes the MidWest? Looking at the map i always put it in a vertical strip that includes Colorado... but i get the feeling it means more eastward?

dave

What about horns? Can you make a big horn? Throw one on a wheel I mean. Or even smaller horns. I guess firing them would be the problem when they got big. Plus the bigger they are, the more problems with flaws. Still, I'd be interested to know. I saw some large items fired outdoors in a primitive kiln. I think it was wood fired, but it might have been charcoal.

w

w

thanks Dave! that makes sense about the increased cross section in the begining acting as a high pass filter, same as increasing the chamber in a BLH. From your advice I think I will alter what I drew in the previous post in two ways. Slightly lengthening the "tail" although I don't think I can go a full 1/4 length as I think the fs is some where in the 70's, a little too long there. But I'll certainly lengthen in from what I drew. I'll also shorten the stand some. I was thinking putting it up higher on the stand like that would help reduce diffraction even more by putting it farther away from any other objects. Maybe I'll still keep the Tang band's stand a little taller. Certainly not the fostex's stand though, it just doesn't seem to have the excursion to go any lower than 300Hz with out some kind of horn loading.

As far as the Midwest goes, I always consider it more of a band east to west.... Maybe the Dakotas to Illinois? Probably some grey area there....

wakibaki

I mentioned wanting to eventually build a high effeciency three way... my only reservation on the Audax PR0170m0 is that I've heard it's not well suited for horn use. It would be fun to compare a driver on both a front loaded horn and a ceramic enclosure.... hmmm maybe I could try that with the fostex? Anyways if and when I do build a front horn I'll probably use a method similar to this. I don't think ceramic horns would be a great idea for two reasons, one I could be wrong, but I feel like the horn shape would be more prone to ringing at the mouth of the horn. Also with my midrange enclosures if I end up being a half and inch off here or there... ehh, no biggie as long as I get the curves consistent, keep the baffle area flat, and have two that match. However even a quarter of an inch off inside the throat of a horn would be pretty bad.

A little off topic do you recall whose large wood fired kiln you saw? We fire all our pots in a large outdoor wood kiln, not all that common anymore.

Joe

As far as the Midwest goes, I always consider it more of a band east to west.... Maybe the Dakotas to Illinois? Probably some grey area there....

wakibaki

I mentioned wanting to eventually build a high effeciency three way... my only reservation on the Audax PR0170m0 is that I've heard it's not well suited for horn use. It would be fun to compare a driver on both a front loaded horn and a ceramic enclosure.... hmmm maybe I could try that with the fostex? Anyways if and when I do build a front horn I'll probably use a method similar to this. I don't think ceramic horns would be a great idea for two reasons, one I could be wrong, but I feel like the horn shape would be more prone to ringing at the mouth of the horn. Also with my midrange enclosures if I end up being a half and inch off here or there... ehh, no biggie as long as I get the curves consistent, keep the baffle area flat, and have two that match. However even a quarter of an inch off inside the throat of a horn would be pretty bad.

A little off topic do you recall whose large wood fired kiln you saw? We fire all our pots in a large outdoor wood kiln, not all that common anymore.

Joe

A baffle is the weakest panel in the box because of the big hole...

dave

Very true

and MDF won't reliably hold a screw.

dave

Very mistaken. It will provided you drill the right sized pilot hole and use vaseline on screw threads to lubricate as you tighten it, and of course use the large threaded 'chipboard' type screws.

Well after thinking about it, I think the tangband and fostex will go in different enclosures. The tangbands are being used as computer speakers so space is somewhat limited. The fostex on the other hand are in the living room, and have a little more space. I've attached a picture of what I think I will make. The short one on the stand will be the tangband. The only question I have here is with it being so short, can I still stick with the aperiodic loading or would I be better off making it sealed. I'm not too concerned with bass performance, as this is just for the computer, and is running off of an unmodified sonic impact (so there's no bass either way). The fostex I'm going to stick with the original plan except for removing the stand to get the fostex closer to the 12" driver, for better integration. I don't think I can do a full 1/4 wavelength aperiodic transmission line, hopefully somewhere between 18-24" will suffice.

Anything thoughts or suggestions?

Joe

Anything thoughts or suggestions?

Joe

Attachments

Hi Joe.

Have a look at this thread and scroll down to posts 17 & 19

http://www.diyaudio.com/forums/multi-way/134896-porcelain-enclosure-speakers-2.html

You should hear Toccata and Fugue on these!

Have a look at this thread and scroll down to posts 17 & 19

http://www.diyaudio.com/forums/multi-way/134896-porcelain-enclosure-speakers-2.html

You should hear Toccata and Fugue on these!

The only question I have here is with it being so short, can I still stick with the aperiodic loading or would I be better off making it sealed. I'm not too concerned with bass performance, as this is just for the computer, and is running off of an unmodified sonic impact (so there's no bass either way). The fostex I'm going to stick with the original plan except for removing the stand to get the fostex closer to the 12" driver, for better integration. I don't think I can do a full 1/4 wavelength aperiodic transmission line, hopefully somewhere between 18-24" will suffice.

Anything thoughts or suggestions?

The box doesn't need to be 1/4 wl long to make it aperiodic, and in a TL, the steeper the taper the shorter the line should be.

dave

A quick survey of speakers built commercially and by knowledgeable DIYers over the last decade or two will show that there is nothing resembling a consensus supporting the rejection of MDF as a cabinet material. I'm not suggesting you reject that advice out of hand, but I wouldn't recommend blindly accepting it either. Instead, it might be best to sample the advice from multiple sources before drawing your conclusions.

Have you considered damping the ceramic enclosure's walls' vibrations if they turn out to be a problem?

Finally, this might be of no use at all, but I'd be tempted to experiment with something like this material. You could pour it so that it molds perfectly to the driver and the ceramic enclosure. Its stiffness might mate well with your ceramic enclosure walls.

Few

Have you considered damping the ceramic enclosure's walls' vibrations if they turn out to be a problem?

Finally, this might be of no use at all, but I'd be tempted to experiment with something like this material. You could pour it so that it molds perfectly to the driver and the ceramic enclosure. Its stiffness might mate well with your ceramic enclosure walls.

Few

A quick survey of speakers built commercially and by knowledgeable DIYers over the last decade or two will show that there is nothing resembling a consensus supporting the rejection of MDF as a cabinet material.

And roaches outnumber humans... IMO MDF as a "quality" loudspeaker building material is the most successful snake oil perpetrated on hifi lovers ever

dave

And roaches outnumber humans... IMO MDF as a "quality" loudspeaker building material is the most successful snake oil perpetrated on hifi lovers ever

dave

LOL no that would be acrylic paint blobs on my driver.....

seriously though. Ply IS better, but MDF isnt really any worse than chipboard, which was used for years, or for that matter 'solid' wood. many people still advocate real wood use where it makes no sense, ie pine TL's, which would probably be the least solid boxes i can think of.

Its a matter of degrees. 19mm ply, 25mm MDF, or 6mm steel, are similar equivalents. Since birch ply is denser, but stiffer than MDF its advantages are slightly counteracted. similarly, MDF although slightly less dense needs a larger thickness to match ply, and i do believe that a thickness 133% that of ply yields equal to slightly higher stiffness. steel of 6 mm thickness is probably stronger than either material.

The main problem is internal damping.

steel is the worse,

then PLly next,

followed by MDF

since most MDF is about 0.75-0.8 times as dense as good BB ply, applying 130% thickness to an equivalent MDF panel, would yield simliar weights, stiffnesses, and as such resonant frequencies. ONLY the damping internal to the material would determine Q of peaks and distribution of resonances harmonically above the fundamental.

IN short, ceramic would ring like hell, unless a suitable damping method was found, much like a steel cabinet would.

As if you didnt know that already lol

LOL no that would be acrylic paint blobs on my driver.....

Don't judge till you have been experienced... besides most people still believe those measels are snale oil, and as the largest vendor of same i can assure you not successfully perpatrated (certianly be careful if you get to Owston, some people there seriously pleased with their spotted drivers)

MDF isnt really any worse than chipboard

MDF is easier to finish and work, but not as good.

for that matter 'solid' wood

In the hands of someone who knows how to keep it from "exploding" when the weather changes it can be very special.

19mm ply, 25mm MDF, or 6mm steel, are similar equivalents

But MDF has higher energy storage... creating a continual ooze of low level time smeared grunge that kills the downward dynamic range.

steel is the worse,

then PLly next,

followed by MDF

Because of all the layers and the impedance changes across the boundaries, plywood is better damped than MDF. Because MDF is homogonous its resonances have lower Q which makes them more audible.

IN short, ceramic would ring like hell, unless a suitable damping method was found, much like a steel cabinet would.

But if you can get the resonance up high enuff, and the Q of the resonance high enuff, it will never get excited and it will be as if it has no ring at all.

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Ceramic speaker enclosures