Few, interesting looking material. Good food for thought, certainly interesting reading. With these small ceramic enclosures I don't for see any trouble with ringing in the enclosures. To be honest I made a ceramic speaker enclosure, maybe 2004? At the time though my understanding of speaker design was pretty poor and, I did not own my own kiln. The experiment was short lived. However I did not have any problems with ringing of the cabinet.

Keriwena, thanks for the link I have seen the Norh cabinets before. They certainly are attractive cabinets. It's interesting they did not do more to reduce diffraction on the front baffles. Maybe they just had a price point to meet? I appriciate the link though.

I'll probably go ahead and throw the main section of the cabinets today or tomorrow. Thanks for all the advice.

Sorry to start another MDF vs Plywood debate....

Joe

Keriwena, thanks for the link I have seen the Norh cabinets before. They certainly are attractive cabinets. It's interesting they did not do more to reduce diffraction on the front baffles. Maybe they just had a price point to meet? I appriciate the link though.

I'll probably go ahead and throw the main section of the cabinets today or tomorrow. Thanks for all the advice.

Sorry to start another MDF vs Plywood debate....

Joe

It's definitely not your fault. I'll leave it at that.Sorry to start another MDF vs Plywood debate

I think your ceramic enclosures will be very cool---I looked into making some myself a few years ago but didn't have ready access to a kiln, and definitely don't have your experience with the material. I look forward to seeing your finished products.

On the resonance issue: If you were to knock on one of the ceramic enclosures you don't think it would ring? Most ceramic vessels I've encountered have pretty high Q (weakly damped) resonances but you obviously know more about the ceramics you're making than I do! Just to be clear, I'm referring to vibrations of the ceramic walls not resonances of the air in the enclosure.

Few

On the resonance issue: If you were to knock on one of the ceramic enclosures you don't think it would ring? Most ceramic vessels I've encountered have pretty high Q (weakly damped) resonances but you obviously know more about the ceramics you're making than I do! Just to be clear, I'm referring to vibrations of the ceramic walls not resonances of the air in the enclosure.

Few

Well I certainly wouldn't say that it would not ring at all. However our pots don't ring like the commercial porcelain. Commercial porcelain will give a sustained ring when you knock on it. Our pots do make a high pitched noise when you knock on it with your knuckle, but there is no duration to the ring. I'm thinking gluing the baffle on with something like liquid nails will help to dampen the ringing even further. What comes to mind is how you can hold a bowl by it's foot and knock on it it can ring a bell, however if you hold the bowl by the rim there is no ringing what so ever..... that's my hope at least. We'll see.

Joe

Our pots do make a high pitched noise when you knock on it with your knuckle, but there is no duration to the ring.

Higbh pitch is good... that its duration is short means that the energy is quicky dissipated.

Unlikely to get excited from the inside by the driver.

dave

Well I took a little time after work today to give a try at the enclosures for the Fostex driver. I made them a little shorter than I had drawn before. I didn't get them quite perfect. It's always a little bit difficult to get a new shape quite right. I'll give another try tomorrow evening. I think I like the one on the right best.

I did make them quite thick. They weight around 20lbs each right now, obviously they will loose weight as they dry out, but for their size they are about twice as thick as I would normally make. I think they should be pretty solid, with out any ringing after they are fired.

Joe

oh, in case it's not obvious they are sitting on their "heads" as it were. I'll add feet after they dry our a bit.

I did make them quite thick. They weight around 20lbs each right now, obviously they will loose weight as they dry out, but for their size they are about twice as thick as I would normally make. I think they should be pretty solid, with out any ringing after they are fired.

Joe

oh, in case it's not obvious they are sitting on their "heads" as it were. I'll add feet after they dry our a bit.

Attachments

Looks really great Joe. How long will it take you to take them through the whole glazing(?) firing process?

Few

Our firing is scheduled to start March 17 and finish up sometime on the 19th. We'll probably unload the kiln the 21st. I'll post pictures of the fostex and tangband enclosures before they go in the kiln.

Joe

Well I took a little time after work today to give a try at the enclosures for the Fostex driver. I made them a little shorter than I had drawn before. I didn't get them quite perfect. It's always a little bit difficult to get a new shape quite right. I'll give another try tomorrow evening. I think I like the one on the right best.

I did make them quite thick. They weight around 20lbs each right now, obviously they will loose weight as they dry out, but for their size they are about twice as thick as I would normally make. I think they should be pretty solid, with out any ringing after they are fired.

Joe

oh, in case it's not obvious they are sitting on their "heads" as it were. I'll add feet after they dry our a bit.

lol nice pots!!!hopefully wont ring too much , given as theyre very thick looking! The only thing that would worry me would be when the driver gioes in and you tighten the screws/bolts, and try not to destroy the pot in the process...you COULD glue i spose...If that would be sufficient and you dont mind having to break them to get back in, should you need to....

as a potter, do YOU have any ideas how i could cut a pot such as those, vertically down the centre?

Anglegrinder???

then i could reattach the halves with silicone sealer........

and to all:

sorry about going off topic.

cant stand ppl slating MDF, when its perfectly good for applications as long as you are aware of the disadvatnages and design around them, as with any material.

the ONLY material that COULD be perfect would be a composite. end of story. maybe ceramic interior, with a foam or air gap between that and a wooden/MDF/PLY/nylon exterior...

Last edited:

lol nice pots!!!hopefully wont ring too much , given as theyre very thick looking! The only thing that would worry me would be when the driver gioes in and you tighten the screws/bolts, and try not to destroy the pot in the process...you COULD glue i spose...If that would be sufficient and you dont mind having to break them to get back in, should you need to....

as a potter, do YOU have any ideas how i could cut a pot such as those, vertically down the centre?

Anglegrinder???

then i could reattach the halves with silicone sealer........

mondogenerator

I'm planning on glueing on a wooden front baffle then screwing the drivers to that. I'm not brave enough to glue my drivers in place

As far as cutting a ceramic vase or jar in half..... might be difficult. The best way to do it is if you know somebody with a brick saw. These use a diamond blade and spray water on the blade to keep it from heating up. Assuming you don't know anybody with a brick saw, you'll need a diamond blade of some type. Probably an angle grinder. I would cut a little and then let the pot cool back down. The biggest danger is the pot cracking from thermal shock. To be honest you'll probably break a few before you get it right. Might be easier to find a potter to cut one in half before it's fired. I would make on for you and send it your way, but you would probably be best finding somebody on your side of the Atlantic. Shipping would probably be a bear.

Joe

But MDF has higher energy storage... creating a continual ooze of low level time smeared grunge that kills the downward dynamic range.

Can you please give a more "scientific" explanation to this? Just asking because from what I know about materials, it doesn't make any sense.

We're talking about a small ring of MDF here, not a complete cabinet. If anyone thinks that using MDF to make a baffle ring for the cabinets illustrated is a bad idea from an acoustic point of view, I have some herpetologically based oil to sell you that will remove those effects and give it a nice shine as well.

But MDF has higher energy storage... creating a continual ooze of low level time smeared grunge that kills the downward dynamic range.

Can you please give a more "scientific" explanation to this? Just asking because from what I know about materials, it doesn't make any sense.

I'm completely with you on this. In fact I tried to clear up some of this confusion once before (see post #10 of this thread), which was in response to an older thread---see, for example, post 177. Maybe you can make more headway than I did (or straighten out any mistakes in my attempts at an explanation).

Few

I don't know about you, but even if i was doing an MDF cabinet i wouldn't use it for a baffle.

dave

I had a little difficulty parsing that. I'll assume you meant that you wouldn't use MDF for the baffle even if the rest of the cabinet was made of MDF. I have no issues with using MDF for a baffle, especially if the driver holes have to be rebated. I find it easier to laminate two sheets with the right size holes in each. (I don't have a circle cutter for my router, I really must get one.)

Using MDF all round avoids the reflections that occur when, for example, a plywood baffle is mated to an MDF cabinet.

Just a quick update, I have finished up making the enclosures and am starting to load the kiln. I've attached pictures of what I've got so far. The tangband enclosures are the ones with the stands. I drilled holes in the stands so I can put a binding post in the stand. I'll probably then fill the stand up with either sand or expandable foam... not sure yet. I didn't get a good picture of the two fostex enclosures in the studio so I'm including a picture of one of them loaded in the kiln. Just small feet on these ones, holes drilled in the bottom for binding posts. Not much else to say. I'll update this thread as things progress.

Joe

Joe

Attachments

Using MDF all round avoids the reflections that occur when, for example, a plywood baffle is mated to an MDF cabinet.

Using different materials together is superior, not inferior. Audibly so, if you build the cabinet out of layers of different materials with significantly different "Q"s.

With the right combination of materials, we're not even talking subtle here, but a large improvement.

I have made myself, test enclosures that ring like a bell, when using a single material, but when building the same cabinet with damped multi-layer construction with different materials, the cabinet became about as acoustically dead as a lump of dirt.

A small ring of MDF will be OK - but - using something like a sorbothane gasket to decouple the driver from the ceramic enclosure would be superior.

A small ring of MDF will be OK - but - using something like a sorbothane gasket to decouple the driver from the ceramic enclosure would be superior.

I'm not familiar with sorbthane. I just googled it and it looks interesting. Two questions: I was planning on using liquid nails between the baffle and enclosure this would certainly have some dampening qualities, do you think sorbothane would be significantly superior? Also what would be the best way to adhere this material to the ceramic enclosure and the baffle to the sorbothane?

Thanks

Joe

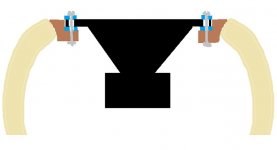

Well, basically you want the speaker frame that normally touches the baffle to touch only the soft rubber gasket, there are various ways to accomplish that, here is a rough picture for one example:

[edit] you would want a ring forming a gasket behind the driver frame, but, for screws on the front you could have little washers [of Sorbothane].

[edit] you would want a ring forming a gasket behind the driver frame, but, for screws on the front you could have little washers [of Sorbothane].

Yes, people have used Corian and Corian like materials to build speakers.has anyone used corian?

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Ceramic speaker enclosures