I have acquired a small stash of various EOM Vifa and Scan Speak drivers. I want to test them for frequency response. I wasn't able to find this topic specifically covered. So, I have a few of questions.

1. Is there an optimum baffle size to use for testing driver frequency response?

2. Should drivers be tested without a baffle?

3. Does the optimum baffle vary with the size or type of the driver?

I've tried to test them without a baffle and all the woofers and mid-range drivers seem to have a similar 3 to 5 dB peak in the 1K to 2K range. I suspect that my measuring is not setup quite right or perhaps it is related to the lack of a baffle.

I'm using a Behringer 8000 mic and UB802 Preamp; M-Audio Audiophile USB sound card and SpectraPlus FFT software.

I'd appricate any suggestions and pointers to help get me going in the right direction.

Rick

1. Is there an optimum baffle size to use for testing driver frequency response?

2. Should drivers be tested without a baffle?

3. Does the optimum baffle vary with the size or type of the driver?

I've tried to test them without a baffle and all the woofers and mid-range drivers seem to have a similar 3 to 5 dB peak in the 1K to 2K range. I suspect that my measuring is not setup quite right or perhaps it is related to the lack of a baffle.

I'm using a Behringer 8000 mic and UB802 Preamp; M-Audio Audiophile USB sound card and SpectraPlus FFT software.

I'd appricate any suggestions and pointers to help get me going in the right direction.

Rick

Everyone seems to have their own answer to this. I normally use a sealed test box and use a model to guess the LF response. Background noise from Rt. 50 is so high, I can't measure LF accurately anyway. It is a small-ish box, but I made a 4 foot sq extended baffle panel to lower the step out of my measurement range. It folds in half.

Every 8000 seems seems to be different, but that peak does sound odd. Have you done a loop-back calibration of just the electronics to be sure that is not a problem? Just sitting, what does the background noise like like? Have you done a measurement on any handy complete speaker?

Every 8000 seems seems to be different, but that peak does sound odd. Have you done a loop-back calibration of just the electronics to be sure that is not a problem? Just sitting, what does the background noise like like? Have you done a measurement on any handy complete speaker?

I did a loopback test on the electronics setup and I get a nice flat line accross the the spectrum, which is why I suspect my process might be at fault. Measuring crossovers seems to work fine with no hump. It might be the mic...

Thank you for the suggestion on using the large baffle. I have trouble measuring low frequencies too. In the winter, the furnace comes on fairly often and that generates plenty of low frequency noise.

Thank you for the suggestion on using the large baffle. I have trouble measuring low frequencies too. In the winter, the furnace comes on fairly often and that generates plenty of low frequency noise.

I did more testing and isolated it to the laptop computer cooling fan. When the internal temperature gets to a certain point, it goes to a higher speed and creates a spike between 1K and 2K. I moved my testing area and added to some material to block the fan sound. Now, my frequency curves are smoother and closer to the manufacturer's published data.

If it helps, Zaph describes his entire test setup here: Zaph|Audio. He uses a braced, constrained layer 4'x8' MDF board and noted "It's easy to think... [that it]... is just a big board with a cutout for mounting drivers, but that's not the case. It required a lot of experimentation to get it right". Worth reading!

Zaph is always a good resource. I just switched from an Audigy II USB and Audio Buddy preamp to an e-mu 1616e all in one. Vastly lower 60 Hz and harmonics, much better overload limits and lower noise floor across the board. Big bucks but worth it.

Unfortunately my background noise is very low frequency from being only half a mile from US Rt 50. You don't notice in the day, but if you go out at 2AM to do measurements, it becomes quite clear where all the noise you measure comes from. I believe John ( Zaph) lives in a very rural location. Joe DeApollito does his work in a large basement. Gad that would be nice, big basement, line it with quietrock.

A baffel is just a big sheet, but it should be big enough that the baffel step is lower than what you are measuring, and the driver is flush. I use duct tape to cover the seams and gaps, no screws sticking up, all the same care on the back side as if you were building the final box, and for open back drivers. No problem for sealed back tweeters, but don't make a great baffle and stand it up a foot from a wall.

Unfortunately my background noise is very low frequency from being only half a mile from US Rt 50. You don't notice in the day, but if you go out at 2AM to do measurements, it becomes quite clear where all the noise you measure comes from. I believe John ( Zaph) lives in a very rural location. Joe DeApollito does his work in a large basement. Gad that would be nice, big basement, line it with quietrock.

A baffel is just a big sheet, but it should be big enough that the baffel step is lower than what you are measuring, and the driver is flush. I use duct tape to cover the seams and gaps, no screws sticking up, all the same care on the back side as if you were building the final box, and for open back drivers. No problem for sealed back tweeters, but don't make a great baffle and stand it up a foot from a wall.

If you're making measurements in an anechoic environment, then the standard test baffle is needed to distribute the effects of diffraction from the baffle edge.I have acquired a small stash of various EOM Vifa and Scan Speak drivers. I want to test them for frequency response. I wasn't able to find this topic specifically covered. So, I have a few of questions.

1. Is there an optimum baffle size to use for testing driver frequency response?

2. Should drivers be tested without a baffle?

3. Does the optimum baffle vary with the size or type of the driver?

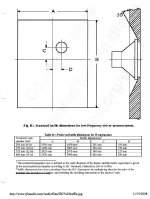

If, however, you're making in-room measurements with an MLS-based system, then you'll be using a window on the impulse response to limit reflections. In that case, the optimum baffle is not the standard baffle with offset, it is the largest baffle that your room can support (i.e. floor to ceiling if possible) with the driver centered. The width should be the same as the height. Wider is of no benefit. The centered driver provides the maximum time in the impulse response prior to any edge diffraction or floor/ceiling reflections. The window on the impulse then eliminates these.

Dave

Thank you for the tips and plans. The Zaph board looks impressive, but I doubt I can easily handle that 150 pound monster. I'm working out of my garage since my house doesn't have a basement. I will need to build a baffle that fits in my space and that I can reasonably move around. Everything is about trade-offs.

Thanks again!

Rick

Thanks again!

Rick

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Baffle Size for Driver Testing