Joining panels at the corners would be interesting for the lightweight concrete panels. The edges of the panel sides would have to still be thick enough to incorporate some reinforcement ninety degree sharp bends in quarter inch rebar or a grid of smaller reinforcing steel. The inner convex panel would have to be narrower at the each end to accomodate a full ninety degree turn of steel [or aluminum] reinforcing grid, or even mesh, and the concrete vibrated around it while filling. The bottom floor panel could be of similar convex shape and reinforced and filled accordingly.

The floor, the rear panel, both side walls, and at the end a matching top with convex inner panel could all be poured and vibrated together in one go of it.

The floor, the rear panel, both side walls, and at the end a matching top with convex inner panel could all be poured and vibrated together in one go of it.

...and a beeeeeeeeeeeeeeaaaauuuuuutiful polished granite multi-piece baffle with hardwood thin strips as driver breaks between the granite pieces. Even cheap floor stone tiles could be used this way with stunning effect. All glued to 3/4" plywood or mdf, of course, and routed first.

I think I have my next speakers figured out...

I think I have my next speakers figured out...

I think I have my next speakers figured out...

Apparently

Good luck and post pics.

Apparently

Good luck and post pics.

Your project and photos are highly inspirational.

It's all your fault!

I'm extremely pleased with my first DIY speakers, a simple two way with Vifa drivers and Solen passive crossover, air coils, MKP and MOX resistors, cheap enough direct from Solen in Montreal.

These will go active crossovers in the preamp box out to biamps soon enough for the next leg of DIY before more speakers. That's coming faster than I thought. Actually that sounds better for the 3-way like yours. Maybe I'll leave the 2-ways as is.

Spring is almost here for my speaker projects, the grass is greening up.

there may be a problem.a piece of 4" PVC pipe for the ports.

View attachment 157355

The port/s ends should have around 1.5diameters of clear space around them.

You pic show less than 0.5diameters.

I don't even know why I kept them but they will be good to use here.

Sounds vaguely familiar.

there may be a problem.

The port/s ends should have around 1.5diameters of clear space around them.

You pic show less than 0.5diameters.

So for two 4" ports you would need clear space of 16" x 32"? Perhaps in an idea world - unfortunately I don't live in such a world and have learned to accept compromises to actually get things done.

I have seen many speakers that utilize one or more of the enclosures panels as one side of a rectangular port, and I have built such speakers myself. In other words, I don't see this as a problem at all. I'm more concerned about how the lowest woofer is firing directly back to these ports and I'm looking at the possibility of putting some kind of baffle between it and the ports.

Yes, the recommendation is to aim for a clear space sphere of ~=20inch diameter. 10inch diameter sphere may work adequately.for .... 4" ports you would need clear space

For a 3" port that clear space recommendation drops to 12inch sphere and may work well at 6inch diameter

But, as you say, what you have planned may work very well.

It's all your fault!

Spring is almost here for my speaker projects, the grass is greening up.

I accept the blame without shame.

All my grass is still deep-frozen with this everyday minus 15C or more temperatures. Sping is still in the early concept planning stage here.

Sounds vaguely familiar.

Deja vu?

What can I say Jacco - maybe it's prescience on my part, maybe it's my ability to adapt my plan on the fly to use of the crap I have on hand in a constructive, useful way. When I start a project the materials and procedures I will use are not written in stone.

Fact is, in my line of work I come across materials that have potential everyday and I can recognize the ones that will be used...for the most part. I do have to bring the excess to the dump occasionally but even then there is the risk of finding a treasure or two. On my last trip to the dump, I found a pair of these:

DC-DC converters, just laying there in the metal pile. Naturally I snatched them up. At the very least I can use the beautiful meters for a shop power supply and they have a pair of hefty heatsinks. Cost: nothing. I can live with that.

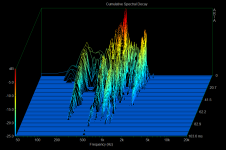

I decided to install the woofers temporarily to do some preliminary measurements this afternoon, to see if I'm on the right track. I used my homemade accelerometer to do the measurements, first on what is the "most resonant" part of the big side panel and then on the best braced speaker I have - my compact TL.

Things to keep in mind: there is no stuffing or any other panel damping in place in this new box - it is as it was pictured a few posts ago, except now I have the woofers in. The compact TL does have stuffing and some damping material.

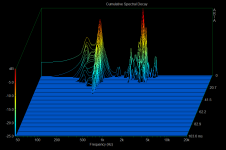

First is the compact TL. This is the "quietest" panel on the box, I measured in several places where there was a panel that spanned a reasonable distance. In this case about 3" and the box material is 1/2" BB plywood with maple veneer.

Looks pretty good, no?

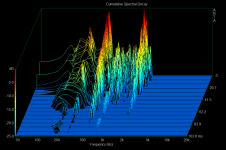

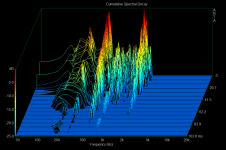

Next is the side panel of the new box, pretty much dead centre - the "noisiest" location on the panel. This panel has no damping, not stuffing, no veneer. It spans 25 inches front to back and ~45 inches top to bottom.

This result is impressive and encouraging and I expect a huge improvement when the box is finished (front baffle on, back panel doubled, stuffing put in).

Peak measurement output from the big side panel was ~5db less than the panel on the compact TL. Both were feed the same signal (2.83Vrms). This is interesting when you consider that the two 12" woofers are that much more efficient than the 5.5" driver in the compact TL. Certainly, the way I heard it the test signal was louder from the 12s.

Things to keep in mind: there is no stuffing or any other panel damping in place in this new box - it is as it was pictured a few posts ago, except now I have the woofers in. The compact TL does have stuffing and some damping material.

First is the compact TL. This is the "quietest" panel on the box, I measured in several places where there was a panel that spanned a reasonable distance. In this case about 3" and the box material is 1/2" BB plywood with maple veneer.

Looks pretty good, no?

Next is the side panel of the new box, pretty much dead centre - the "noisiest" location on the panel. This panel has no damping, not stuffing, no veneer. It spans 25 inches front to back and ~45 inches top to bottom.

This result is impressive and encouraging and I expect a huge improvement when the box is finished (front baffle on, back panel doubled, stuffing put in).

Peak measurement output from the big side panel was ~5db less than the panel on the compact TL. Both were feed the same signal (2.83Vrms). This is interesting when you consider that the two 12" woofers are that much more efficient than the 5.5" driver in the compact TL. Certainly, the way I heard it the test signal was louder from the 12s.

Glue some relatively hard isolating boards on the outside

Clothe it in something nice, and done

I would try using some of the foam on the outside of the box. Perhaps difficult to contain though.

Otherwise the progress looks great John.

Otherwise the progress looks great John.

Thanks Cal,

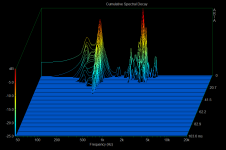

I just did a measurement on the back panel. This is 3/4" particleboard and the span is ~8 inches from centre brace to side panel and ~45 inches from top to bottom:

Not too shabby for that size of a flat panel.

One of the problems I had was mounting the accelerometer and I have settled on an excellent way but it involves some waiting. I originally used duct seal to stick it on but now I use a very small dab of silicone to glue it to the panel. Dabs of duct seal hold it in place while it dries - about 10 minutes.

This result is impressive and encouraging and I expect a huge improvement when the box is finished (front baffle on, back panel doubled, stuffing put in).

Peak measurement output from the big side panel was ~5db less than the panel on the compact TL. Both were feed the same signal (2.83Vrms). This is interesting when you consider that the two 12" woofers are that much more efficient than the 5.5" driver in the compact TL. Certainly, the way I heard it the test signal was louder from the 12s.

If we just look at the graphs and ignore the issue of unequal stimulus (levels should be set for the same SPL), the new box is WAY worse. If we consider that the SPL level of 2 12" should be way higher than the single 5.5" (4 ohm vrs 8 ohm?), then the graphs are meaningless.

The 3-way should also dramatically improve once the front and back edges are clamped with the installation of the back panel.

Blink comparison

Ignoring the level problem...

The Q of the ~1 k resonance is about the same, the BB is much better damped.

The 2nd major peak is higher in frequency on the 3-way (a good thing) and both are about the same Q, the BB being much better damped again.

The lowest resonance on both has much lower levels, is lower Q (more audiable) & higher in level on the 3-way, and not as well damped.

There is a lot of hash on the 3-way between the 2 big peaks.

Bear in mind that given the stimulus levels the above analysis is meaningless

Now John, can you redo with the same level of stimulus (at what freq to set them equal may become a question later). And it would be nice if you could get at least 40 dB on the vertical

Report back and i'll pop those pictures in the blink compare page. Then we can say something meaningful.

dave

One of the problems I had was mounting the accelerometer

A new thread just on how to do these kinds of things would be good... my accelerometer just arriver from mouser.

dave

If we just look at the graphs and ignore the issue of unequal stimulus (levels should be set for the same SPL), the new box is WAY worse. If we consider that the SPL level of 2 12" should be way higher than the single 5.5" (4 ohm vrs 8 ohm?), then the graphs are meaningless.

Hi Dave,

Like I said, preliminary. Just trying to gage the performance before I go any further.

But, regardless of output spl, to say the new box is WAY worse would be an exaggeration. You can clearly see the panels resonant frequency at 2k which demonstrates that the panel stiffness is there, equal in fact to the much smaller, better braced two-way.

To put both speakers at equal spl output will take more time than I currently have. I'd need to carefully measure the response (with a mic) from each at exactly the same distance and this will be an approximation at best.

The woofers are wired parallel so yes, 4 ohm. Output from the woofers is much greater than the 2-way but the magnitude of the panel response was lower - 5db lower and this is perhaps the most encouraging news. Higher spl output from the drivers yet lower panel emissions.

You can clearly see the panels resonant frequency at 2k which demonstrates that the panel stiffness is there, equal in fact to the much smaller, better braced two-way.

In that sense you are right. Just hope that the LF stuff is from an unclamped backside.

dave

A new thread just on how to do these kinds of things would be good... my accelerometer just arriver from mouser.

dave

Did you get the ACH-01?

Shoulda made your own:

Piezo buzzer from a busted clock radio epoxied onto a piece of copper clad board.

I used the plastic cap from a canister of cutting discs for the Dremel to cover it and a hunk of duct seal for good measure. Dabs of duct seal to hold it in place until the silicone dries:

A modified mic preamp amplifies the signal from it (still needs a case):

At first I was concerned about the accuracy and response of using a piezo buzzer for this but it seems to work fine. I did a frequency response test on it using a small 2" speaker (yes, the one from that busted clock radio), covered the cone with a piece of cardboard glued to the frame and stuck on the accelerometer. Drove the speaker with my function generator and it looks good right up to the roll off of the speaker.

It didn't cost a cent (even brand new they are less than $2). Recommended activity for all of you restless men of action.

It didn't cost a cent (even brand new they are less than $2). Recommended activity for all of you restless men of action.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Large 3-ways design / build