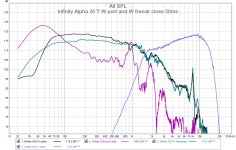

I made some measurements of a commercial low-priced Infinity Alpha 20 speaker. This is an European model made in Denmark in the beginning of third millenium. The box is approximately 12mm MDF and walls are covered with corrugated foam cell, no bracing.

Nearfield measurements at 1cm distance from cone surface and the port. All done with same spl. We can see that port noise and resonances are in major role UMIK-1 mic with calibration, signal via usb-dac to amplifier. RoomEQWizard V5.19 beta6 software. Sorry I don't have a suitable microphone for box vibrations.

Nearfield measurements at 1cm distance from cone surface and the port. All done with same spl. We can see that port noise and resonances are in major role UMIK-1 mic with calibration, signal via usb-dac to amplifier. RoomEQWizard V5.19 beta6 software. Sorry I don't have a suitable microphone for box vibrations.

Attachments

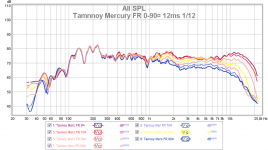

Tall boxes might have internal standing waves (multiple order) in the passband of woofer(s). One example is Cerwin-Wega CLS-215, which was measured by Soundstage. Look at response and impedance around 150Hz!

The revised version XLS-15 has a divider in bass compartment that should help. I couldn't find measurements, sorry.

The revised version XLS-15 has a divider in bass compartment that should help. I couldn't find measurements, sorry.

Attachments

You hear a lot about this "stored energy" thing and I, like you, find it untenable. I don't know of any passive mechanism in vibrations that can do this. I'd be happy to never hear this term again.

The total system stores energy. I would think stuffing or foam would turn the energy to heat faster, but perhaps not equally. Considering the many reflections off different materials that create partial or fully out of phase waves and all the different frequencies involved it seems hard to predict.

What if it's the other way around leaving the fingerprint?

Sounds great, what did you have in mind? There are some specific enclosures that are best not used with stuffing and it helps that these are too small to support higher box modes.

So the stuffing gets hot, remembers how that came about and then recreates sound at those frequencies?

I don't think this takes away the need to stuff, where sound may work back through the cone.

Everything leaves a fingerprint. Even a speaker made of solid granite will have internal resonances. Stuffing though does obviously filter higher frequencies more efficiently, which does muffle a sound. Also some energy will reflect back off the stuffing due to the impedance change, though this can be reduced with very lose irregular placing of the stuffing, but this can't be reduced to zero.

In a normal box speaker you're going to "hear" the sound energy inside the cabinet in one form or another. This might be part of the appeal of horns and t-lines in that the energy is allowed to travel further away from the driver itself allowing for better filtering.

I will say that doing a lower crossover or something like a three way really changes the situation are would make box design easier. Horns and big pro woofers like Earl's designs are a different situation than a full range in a box.

As far as the stuffing storing energy, that was an interesting quote from the article, nothing more.

The total system stores energy.

As far as the stuffing storing energy, that was an interesting quote from the article, nothing more.

How does the "total system" store energy?

Once the energy gets disapated it does not come back. Energy can be stored momentarily as either potential or kinetic energy, but must transfer out within a half period (think a cap and inductor in series transferring energy back and forth. It never stays in either component for more than a 1/2 cycle.) If there is no dissipation then the total energy can get stored indefinitely, but then its not available to do any work. Doing any work at all will dissipate it and then it can never come back ... its gone.

As for the quote: Typical audiophool mumbo-jumbo that has no validity. It just sounds good that's all.

Last edited:

Some things can be eliminated, some can only be reduced. It is only necessary to know what to reduce and by how much to make it insignificant. It works..there is no benefit to obsessing over the impossible.can't be reduced to zero.

Driving Room Modes - Dr. Russell's Acoustics Animations

I wasn't aware of this before but it sounds like if one wants to avoid standing waves the driver should be placed in a low pressure mode (towards the middle of an axis) as opposed to the end. So then a sealed box would benefit more from a middle placement but a t-line trying to generate a standing wave should have the driver at the end of the tunnel (if I'm understanding this right).

Also it sounds like the stuffing could potentially reflect back some out of phase sound waves and affect the cone. However it doesn't impede the flow of sound waves, as they pass right through each other.

Reflection of Wave Pulses from Boundaries

I don't think I'm gonna pull the fiberglass out just yet. I might try to direct the sound into it better.

As far as the energy inside a cabinet, it must be return to the environment as either kinetic (includes sound) or heat energy.

I wasn't aware of this before but it sounds like if one wants to avoid standing waves the driver should be placed in a low pressure mode (towards the middle of an axis) as opposed to the end. So then a sealed box would benefit more from a middle placement but a t-line trying to generate a standing wave should have the driver at the end of the tunnel (if I'm understanding this right).

Also it sounds like the stuffing could potentially reflect back some out of phase sound waves and affect the cone. However it doesn't impede the flow of sound waves, as they pass right through each other.

Reflection of Wave Pulses from Boundaries

I don't think I'm gonna pull the fiberglass out just yet. I might try to direct the sound into it better.

As far as the energy inside a cabinet, it must be return to the environment as either kinetic (includes sound) or heat energy.

Last edited:

but a t-line trying to generate a standing wave should have the driver at the end of the tunnel

While have an end loaded TL generates the strongest quarter-wave, offsetting the driver from the end to kill the 1st unwanted harmonic can allow the recovery of more of the quarter-wave to contribute to bass gain.

dave

If you have a tall speaker with a driver at the top, can a standing wave inside the enclosure cause the cone to twist in the pressure gradient? Could internal reflections cause early cone breakup this way?

I don't think so. I think it would just raise the q slightly of the system by putting more air pressure on the cone, like using a smaller sealed box.

Tall boxes might have internal standing waves (multiple order) in the passband of woofer(s). One example is Cerwin-Wega CLS-215, which was measured by Soundstage. Look at response and impedance around 150Hz!

The revised version XLS-15 has a divider in bass compartment that should help. I couldn't find measurements, sorry.

You can plug the internal box measurements into this calculator to see where the standing waves would be.

mh-audio.nl

If you have a tall speaker with a driver at the top, can a standing wave inside the enclosure cause the cone to twist in the pressure gradient? Could internal reflections cause early cone breakup this way?

I'm reluctant to answer this as I haven't demonstrated it but I think Polk's comment may be reasonable in the first order (overall), and keantoken may have a point at higher orders.I don't think so. I think it would just raise the q slightly of the system by putting more air pressure on the cone, like using a smaller sealed box.

I can't say I've worried too much about it because these modes are being dealt with anyway and I haven't found these affects to be a problem.

Shape and placement of the sound absorbing material will have a big effect on its effectiveness. This is because sound is absorbed only when there is particle velocity. At the walls the particle velocity goes to zero so absorption on the walls does little. I always place the absorption in the middle of the box, not on the walls. The box shape will affect the mode shape and move the locations of maximum particle velocity around. A long tube with absorption on the walls won't see so much sound attenuation because the wave motion is normal to the walls. Place it in the middle of the tube and it becomes very effective. So shape is a factor, but any shape can be optimized if you know what you are looking for - hence no shape is any better than any other. Only the implementations vary.

Interesting. Kef puts a lump of foam in the center of the port of the LS50. IIRC, it's there to absorb high frequency resonances being radiated by the port.

I'm happy to say that the issue I was reporting earlier about how my speakers sounded "stuffy" or lacking in openess was not due to the stuffing or box.

It was just that the drivers weren't yet broken in. The problem went away on its own. Sealed box filled with fiberglass works great. You do want some space around drivers and an adequately sized box.

It was just that the drivers weren't yet broken in. The problem went away on its own. Sealed box filled with fiberglass works great. You do want some space around drivers and an adequately sized box.

I leave enough space to ensure that, when fitting the driver, its magnet assembly does not compress the absorbent filling.Sealed box filled with fiberglass works great. You do want some space around drivers.

Is that in accord with your thinking?

Anyone ever try doing a matrix braced cabinet with a thinner outer skin, say like 1/4 birch ply. This would push the cabinet resonances up higher into the mid range and be more musical, but give solid bass.

I'm going to do a construction methods shootout thread (probably over at avsforum) and want to look at exactly that. It won't be among the first tests, those will be just lay the baseline of how common methods and materials measure. Then I'll move on to CLD construction with what I learned up to that point.

I'm going to do a construction methods shootout thread (probably over at avsforum) and want to look at exactly that. It won't be among the first tests, those will be just lay the baseline of how common methods and materials measure. Then I'll move on to CLD construction with what I learned up to that point.

Boxes are one of the more mysterious aspects of speaker building since a lot of resonances and interactions happen. The concensus is accoustically dead is best. A minority of designs, mostly British, do try to create a more musical sound. Any experiments that shed light on the subject would be good.

I did a sealed constrained layer project a while back. Although I have built (at least) a dozen pairs of speakers since, it is still my reference. The dimensions were based on the golden ratio too. I tried to use everything I knew at the time and thought was important. Diffraction control was high on the priority list. Also braced and damped panels. The skin was marine plywood.I'm going to do a construction methods shootout thread (probably over at avsforum) and want to look at exactly that. It won't be among the first tests, those will be just lay the baseline of how common methods and materials measure. Then I'll move on to CLD construction with what I learned up to that point.

3-way active, time aligned, constrained layer construction

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Sealed enclosure -- golden ratio?