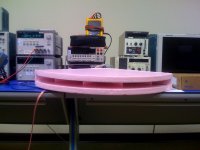

Just screwing around with polystyrene... Seems to work!

But not yet tested with crossovers and rest of the system.

But the wood driver plate drifted off-center as the glue

was drying... I put a peg in the throat to try and fix the

center of dispersion (also seems to work).

I wonder most Smith horns I see built with overhanging lips??

This expansion is conical, not exponential, after the septums.

But why??? A conical expansion theoretically adds no loading,

and can't mitigate any HF sectoral beaming already created

by the exponential throats...

Future experiment will modify the top cover with sectoral

K slots (like JBL Aquarius). That begin an exponential slot

leakage about where the exponential throat area ends...

But not yet tested with crossovers and rest of the system.

But the wood driver plate drifted off-center as the glue

was drying... I put a peg in the throat to try and fix the

center of dispersion (also seems to work).

I wonder most Smith horns I see built with overhanging lips??

This expansion is conical, not exponential, after the septums.

But why??? A conical expansion theoretically adds no loading,

and can't mitigate any HF sectoral beaming already created

by the exponential throats...

Future experiment will modify the top cover with sectoral

K slots (like JBL Aquarius). That begin an exponential slot

leakage about where the exponential throat area ends...

Attachments

Just screwing around? Looks like a reasonably serious attempt to me.

I am not familiar at all with this type of horn, so here's a barrage of questions...

What is the range? Coverage? Is this a design intended for a particular driver, or can they be "rolled" through? Claimed advantages / disadvantages?

I must admit, my curiousity is mainly do to the quite serious and sleek look (i'm a believer that a speaker should look good as well as sound good), and of course, my curiousity of all things audio. I am becoming more attracted to the idea of high sensitivety two-ways to go with my unkown vintage / brand name / power output tube amp.

I am not familiar at all with this type of horn, so here's a barrage of questions...

What is the range? Coverage? Is this a design intended for a particular driver, or can they be "rolled" through? Claimed advantages / disadvantages?

I must admit, my curiousity is mainly do to the quite serious and sleek look (i'm a believer that a speaker should look good as well as sound good), and of course, my curiousity of all things audio. I am becoming more attracted to the idea of high sensitivety two-ways to go with my unkown vintage / brand name / power output tube amp.

I am not familiar at all with this type of horn, so here's a barrage of questions...

You can read Bob Smith's 1951 Audio Engineering article here:

http://audioheritage.csdco.com/vbulletin/showthread.php?t=9148

in mono it has a holographic sound with good subjective vertical dispersion - can't remember if I've run stereo but probably with 416 in K15 - there's my rock n roll bass

An externally hosted image should be here but it was not working when we last tested it.

OK.. Here's a sketchup of the basic idea...

Slots: acting both as plate lens for horizontal dispersion of sector beams.

And as Karlsons for continued exponential expansion of the horn mouths...

Or can just K the top plate only, sorta like JBL Aquarius...

These curves might be rounded the "wrong way" for a dispersion lens.

But artistically correct for a Karlson... Could split the diff and just cut

these notches triangularly? Somebody would surely poke an eye out...

Slots: acting both as plate lens for horizontal dispersion of sector beams.

And as Karlsons for continued exponential expansion of the horn mouths...

Or can just K the top plate only, sorta like JBL Aquarius...

These curves might be rounded the "wrong way" for a dispersion lens.

But artistically correct for a Karlson... Could split the diff and just cut

these notches triangularly? Somebody would surely poke an eye out...

Attachments

Last edited:

Nice!

But your horn seems to be missing two half fins of the sides (and these actually make the expansion non conical)

Not missing. I simply cut an exponential throat in half. Sidewall is the middle.

You migh notice the mouths of those outside sectors are only half as wide.

My latest sketchup does show half fins as you describe. But either way works...

The conical part of concern is the perimeter. After exponential throats have

terminated "too early", and before reaching the edge.

Last edited:

IIRC there were two versions on ebay

An externally hosted image should be here but it was not working when we last tested it.

hey kenpeter - re:styrofoam - over at High Efficiency Speaker Asylum I posted another "The Audio League Report" - this time from Nov. 1954 with text blurbs on the HiFi Fair of that year -(Karlson 12 made its debut at that show) here's the page with the "De Mars Styrocone Speaker" http://img245.imageshack.us/img245/3783/af1954pg2w.gif

I'm now thinking Unity here as well...

An if that news weren't strange enough. I'm also thinking what-if

you fold a Smith horn???? Folded on a parabolic curve... Can it be

tricked to exit from a flat front slot in one phase, as-if a line array?

Does the non-expanding part (after the parabolic) serve as a plane

wave tube?

And if that still ain't strange enough. Also thinkin Smith Unity to

replace the driver in a Karlson type enclosure. That would mean

loading the backs of the cones to the K box. Not sure how thats

gonna mess with EBP??? As most advice I've heard is to seal the

backs of such cones in attempt to raise both Fs and EBP.

I don't think Styrofoam will be the material of choice, but might

still get abused here and there...

An if that news weren't strange enough. I'm also thinking what-if

you fold a Smith horn???? Folded on a parabolic curve... Can it be

tricked to exit from a flat front slot in one phase, as-if a line array?

Does the non-expanding part (after the parabolic) serve as a plane

wave tube?

And if that still ain't strange enough. Also thinkin Smith Unity to

replace the driver in a Karlson type enclosure. That would mean

loading the backs of the cones to the K box. Not sure how thats

gonna mess with EBP??? As most advice I've heard is to seal the

backs of such cones in attempt to raise both Fs and EBP.

I don't think Styrofoam will be the material of choice, but might

still get abused here and there...

Last edited:

Just screwing around with polystyrene... Seems to work!

I'm not a big fan of that kind of horn, but I love the idea of the material and the implimentation. That's really using your head to do things in a very practicle way. More audiophiles should think like this and look at doing things simply, not outrageously complex.

Mr Geddes, how thin would a slot opening need to be to

have reasonably even diffraction over the full audio??

Even if diffraction evenly disperses, I do feel concern

of reflected power from the discontinuity echoing back

down the throat and causing abnormalities.

You saw the scalloped clamshell version I drew?? Does

it seem at all plausible that such Karlson/PlateLens

terminations could mitigate reflected discontinuity's

effects? Blurring discontinuty's distance seen from

the throat...

Is there any "right" way to do diffraction? Or have you

written it off as an evil totally not worth exploring?

have reasonably even diffraction over the full audio??

Even if diffraction evenly disperses, I do feel concern

of reflected power from the discontinuity echoing back

down the throat and causing abnormalities.

You saw the scalloped clamshell version I drew?? Does

it seem at all plausible that such Karlson/PlateLens

terminations could mitigate reflected discontinuity's

effects? Blurring discontinuty's distance seen from

the throat...

Is there any "right" way to do diffraction? Or have you

written it off as an evil totally not worth exploring?

Mr Geddes, how thin would a slot opening need to be to

have reasonably even diffraction over the full audio??

There is no answer to this question.Its not the "slot" that diffracts, its the edges.

Even if diffraction evenly disperses, I do feel concern

of reflected power from the discontinuity echoing back

down the throat and causing abnormalities.

Thats one of the major problems.

You saw the scalloped clamshell version I drew?? Does

it seem at all plausible that such Karlson/PlateLens

terminations could mitigate reflected discontinuity's

effects? Blurring discontinuty's distance seen from

the throat...

Is there any "right" way to do diffraction? Or have you

written it off as an evil totally not worth exploring?

Not much is going to help with a mouth shaped like that.

There is no such thing as "good" diffraction. It's all bad in a playback system and so I never considered exploring what you suggest since its obvious that there isn't a "right" way to do the "wrong" thing.

Edges huh??? So maybe really sharp edges? No flats on the lips?

A baffle step so short that literally every audio frequency folds

back equally (the full amount). I was thinking only the width of

the slot, but the lip faces and outer edges too are crucial to the

overall diffraction.

I'm not entirely convinced yet maybe there isn't a "right" way.

By promoting diffraction to do its thing and not fight against it...

But if its not rewarding hoped for results, I won't kill too much

time on it. Your experience and advice is noted and appreciated,

even as I charge ahead in obviously the "wrong" direction a short

while longer. I may yet come to agree with you, but not before

running an experiment or two...

A baffle step so short that literally every audio frequency folds

back equally (the full amount). I was thinking only the width of

the slot, but the lip faces and outer edges too are crucial to the

overall diffraction.

I'm not entirely convinced yet maybe there isn't a "right" way.

By promoting diffraction to do its thing and not fight against it...

But if its not rewarding hoped for results, I won't kill too much

time on it. Your experience and advice is noted and appreciated,

even as I charge ahead in obviously the "wrong" direction a short

while longer. I may yet come to agree with you, but not before

running an experiment or two...

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Styrofoam Smith Horn