I am looking to bond 8mm HDF (HD3) with 17mm Ply (BB) using green goo. Has anyone else done this? And would this provide me with constrained layer damping for my projects? (OB and sealed bass cabinet)

Once I bond the boards I will be treating it as a 'single' board and use it for cutting, routing & CNCing where necessary.

All thoughts on this are welcome, thanks 🙂

Once I bond the boards I will be treating it as a 'single' board and use it for cutting, routing & CNCing where necessary.

All thoughts on this are welcome, thanks 🙂

I think that the biggest challenge will be to get the bonding coverage you want. How viscous/thick is the "green goo" you mention? I think that you will need to be able to apply high pressure evenly across the entire surface of the boards you want to mate.

Also, why not use a single sheet of 25mm MDF? I understand that you are hoping to achieve some elastic damping from the green-goo interface, but I think that the most important thing to go for in bass enclosures is wall rigidity. While it is highly undesirable to have enclosure walls acting as speakers (which the green goo idea might help with), it is also undesirable to have frictional losses in the walls (due to wall resonance/motion) as this decreases the box's efficiency (in this regard, the green goo idea is a real hindrance). In that respect, you would probably want to stick with the "usual" thick walls & bracing type design.

Now of course, if you want to reduce the enclosure's weight, a very thin, very strong adhesive bond between MDF & cabinet-grade plywood might be a good balance between weight & wall stiffness.

Also, why not use a single sheet of 25mm MDF? I understand that you are hoping to achieve some elastic damping from the green-goo interface, but I think that the most important thing to go for in bass enclosures is wall rigidity. While it is highly undesirable to have enclosure walls acting as speakers (which the green goo idea might help with), it is also undesirable to have frictional losses in the walls (due to wall resonance/motion) as this decreases the box's efficiency (in this regard, the green goo idea is a real hindrance). In that respect, you would probably want to stick with the "usual" thick walls & bracing type design.

Now of course, if you want to reduce the enclosure's weight, a very thin, very strong adhesive bond between MDF & cabinet-grade plywood might be a good balance between weight & wall stiffness.

Last edited:

...it is also undesirable to have frictional losses in the walls (due to wall resonance/motion) as this decreases the box's efficiency (in this regard, the green goo idea is a real hindrance).

Say what? How is 'efficiency' being used in this context?

Hi there,

Do you mean Greenglue, normally sold for damping plasterboard walls?

If so I have done something very similar. used 12mm birch ply and 2 layers 6mm viroc ( a cement/ wood fibre board). I was very pleased with the result you end up with a material of high stiffness but good damping.

But you will have to rethink ypur method of construction, green glue isn't a glue it remains permanently tacky and will creep. Trying to cut or machine the composite board would be a disaster the greenglue would clog blades or bits.

I found an 18Ga brad nailer to be invaluable for temporarily holding the layers together to rout and in the final asembly. make sure you find something to remove any surplus greenglue, it,s horrible stuff to clean up. I used Goo Gone a citrus based adhesive remover. theres probably something like it in OZ.

Good luk I,m sure you will be pleased with the results.

Khush

Do you mean Greenglue, normally sold for damping plasterboard walls?

If so I have done something very similar. used 12mm birch ply and 2 layers 6mm viroc ( a cement/ wood fibre board). I was very pleased with the result you end up with a material of high stiffness but good damping.

But you will have to rethink ypur method of construction, green glue isn't a glue it remains permanently tacky and will creep. Trying to cut or machine the composite board would be a disaster the greenglue would clog blades or bits.

I found an 18Ga brad nailer to be invaluable for temporarily holding the layers together to rout and in the final asembly. make sure you find something to remove any surplus greenglue, it,s horrible stuff to clean up. I used Goo Gone a citrus based adhesive remover. theres probably something like it in OZ.

Good luk I,m sure you will be pleased with the results.

Khush

Hi there,

Do you mean Greenglue, normally sold for damping plasterboard walls?

But you will have to rethink ypur method of construction, green glue isn't a glue it remains permanently tacky and will creep. Trying to cut or machine the composite board would be a disaster the greenglue would clog blades or bits.

Thanks for all the suggestions. Yes, I do mean Green Glue. I didn't realise it would remain tacky. That would be a real problem in construction.

It seems like my best option is to laminate with liquid nails and use some green glue later for damping where needed.

Good thing I asked 😀

It seems like my best option is to laminate with liquid nails and use some green glue later for damping where needed.

Good thing I asked 😀

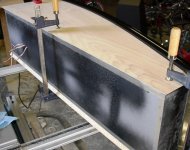

I used clear silicone to bond the layers together:

Then light clamp pressure to hold it till it sets:

That was 1/2" particle board core plywood on 5/8" MDF. The silicone is a fantastic adhesive and sets like rubber.

By far the best scheme is as bmwman91 suggests, just make the panel thicker.

The so called constrained layer damping used by speaker builders is in fact mass damping.

If you look at the hysterisis curves, the materials used in for instance plasterboard constrained layer damping, are not deflected into the hysterisis region by the small displacements found in speaker cabinets.

rcw.

The so called constrained layer damping used by speaker builders is in fact mass damping.

If you look at the hysterisis curves, the materials used in for instance plasterboard constrained layer damping, are not deflected into the hysterisis region by the small displacements found in speaker cabinets.

rcw.

My comment was with respect to the "sealed bass box" portion of the OP.Say what? How is 'efficiency' being used in this context?

Peace, brother!

MJL211093 posted:

MJL211093 posted:

Finally, something I can agree with you on. 😀 I used it between 3/4" mdf & 1/4" durock (ceramic tile underlayment).The silicone is a fantastic adhesive and sets like rubber

By far the best scheme is as bmwman91 suggests, just make the panel thicker.

The so called constrained layer damping used by speaker builders is in fact mass damping.

If you look at the hysterisis curves, the materials used in for instance plasterboard constrained layer damping, are not deflected into the hysterisis region by the small displacements found in speaker cabinets.

rcw.

I don't agree, not at all and the reasons are fairly obvious.

Finally, something I can agree with you on. 😀

I'm sure we would agree on a few things Ed. I like the Durock idea. 🙂

Sounds very much like an open baffle I made.

The construction is: plywood - green goo - MDF - green goo - plywood

Drivers are mounted to the MDF layer, and coupled only through the green goo to anything else.

The MDF layer is cut in half, so the upper and lower drivers are mounted to separate pieces.

The MDF layer comes about 1 cm short of the edges of the baffle, so it does not contact the trim.

The speakers sound very nice, and if you knock on the front baffle with your knuckles, it sounds very dead.

The construction is: plywood - green goo - MDF - green goo - plywood

Drivers are mounted to the MDF layer, and coupled only through the green goo to anything else.

The MDF layer is cut in half, so the upper and lower drivers are mounted to separate pieces.

The MDF layer comes about 1 cm short of the edges of the baffle, so it does not contact the trim.

An externally hosted image should be here but it was not working when we last tested it.

The speakers sound very nice, and if you knock on the front baffle with your knuckles, it sounds very dead.

What is obvious I am not sure.

A natral material like marble for instance shows hysterisis for the very small displacements we are considering, and then becomes close to linear after that.

People who should know tell me that epoxy adhesives have a similar property, and yet nobody in this forum would consider these as candidates for a constrained damping scheme, but at the displacements we are dealing with they are.

rcw.

A natral material like marble for instance shows hysterisis for the very small displacements we are considering, and then becomes close to linear after that.

People who should know tell me that epoxy adhesives have a similar property, and yet nobody in this forum would consider these as candidates for a constrained damping scheme, but at the displacements we are dealing with they are.

rcw.

Hello all,

I have often considered making a sandwich that includes Gypsum wallboard. The architects of the world and their suppliers like UG Gypsum or Domtar have spent lots of time and developement brain power into using wall board as sound dampening material. They even make a specical grade of wallboard that is better at attenuation of the db's than the standard Home Depot grade. Thoughts?

I have often considered making a sandwich that includes Gypsum wallboard. The architects of the world and their suppliers like UG Gypsum or Domtar have spent lots of time and developement brain power into using wall board as sound dampening material. They even make a specical grade of wallboard that is better at attenuation of the db's than the standard Home Depot grade. Thoughts?

why not use a single sheet of 25mm MDF? I understand that you are hoping to achieve some elastic damping from the green-goo interface, but I think that the most important thing to go for in bass enclosures is wall rigidity

Then MDF is not your best choice. Plywood is much stiffer.

MDF is not as well damped either, and certainly not as well damped as a well done constrained layer.

dave

and certainly not as well damped as a well done constrained layer.

The so called constrained layer damping used by speaker builders is in fact mass damping.

Why so?

2 dissimilar materials laminated together with something that remains flexible (constrained layer) is intended to create a dramatic impedance difference across the boundry to reduce transmission.

dave

Errr.... I'm considering exactly that for aluminum sandwich CLD cabinets for a pair of Jordans. I might add a sheet of very fine cloth or paper as a carrier and lossy fill.....People who should know tell me that epoxy adhesives have a similar property, and yet nobody in this forum would consider these as candidates for a constrained damping scheme, ....

Any dramatic change in acoustic impedance causes reflection as well as transmission.

For the constrained layer to be effective the layer must be pushed far into its hysteresis region.

The type of displacements you get in plasterboard, especially when its plate modes are excited causes sufficient flexing of the constraint layer to push it well into its hysteresis region and provide damping, you would have to make your enclosure from something like eighth inch hardboard for it to flex enough for such a layer to be effective.

For a loudspeaker enclosure the best solution for the lowest colouration is the stiffest, you don't need to damp panel flexing if there isn't any.

The point is that a flexible damped panel still transmits more sound than a stiff undamped one, its resonance modes are lower in q that's all.

For instance you might be able to reduce a particular resonance by 10db. This is achieved by broad banding the resonance and increasing the displacement at other frequencies, if you make the panel twice as thick it increases its stiffness by eight times, this reduces the main resonance by ten db. and every other frequency as well, and a general 10db. reduction at all frequencies is better than the same at just at just one.

Rcw.

For the constrained layer to be effective the layer must be pushed far into its hysteresis region.

The type of displacements you get in plasterboard, especially when its plate modes are excited causes sufficient flexing of the constraint layer to push it well into its hysteresis region and provide damping, you would have to make your enclosure from something like eighth inch hardboard for it to flex enough for such a layer to be effective.

For a loudspeaker enclosure the best solution for the lowest colouration is the stiffest, you don't need to damp panel flexing if there isn't any.

The point is that a flexible damped panel still transmits more sound than a stiff undamped one, its resonance modes are lower in q that's all.

For instance you might be able to reduce a particular resonance by 10db. This is achieved by broad banding the resonance and increasing the displacement at other frequencies, if you make the panel twice as thick it increases its stiffness by eight times, this reduces the main resonance by ten db. and every other frequency as well, and a general 10db. reduction at all frequencies is better than the same at just at just one.

Rcw.

Any dramatic change in acoustic impedance causes reflection as well as transmission

I don't see a reflection as a problem. Keeps energy in the box.

the layer must be pushed far into its hysteresis region.

do you have a reference we can read that explains what this means?

For a loudspeaker enclosure the best solution for the lowest colouration is the stiffest, you don't need to damp panel flexing if there isn't any.

That is my approach. Push panel resonances as high as possible (less energy to excite them), and as high a Q as possible (less energy to excite them and less audible if they do get excited). So i won't use MDF because it isn't very stiff.

dave

- Home

- Loudspeakers

- Multi-Way

- constrained layer damping with MDF and Ply