I hope this is the right forum for this thread.

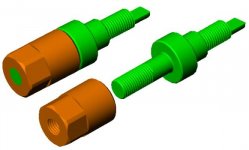

Here are my plans for a DIY speaker binding post. II can see questions being asked as to why DIY such a thing. Especially when a pair of Cardas is available for $25 or so. Yes, but not so in India. You have to import the stuff and pay custom duty etc that will push the cost to stratospheric limits. So here we are, a quality binding post for less than Rs. 100 each (around US$ 2).

Here are my plans for a DIY speaker binding post. II can see questions being asked as to why DIY such a thing. Especially when a pair of Cardas is available for $25 or so. Yes, but not so in India. You have to import the stuff and pay custom duty etc that will push the cost to stratospheric limits. So here we are, a quality binding post for less than Rs. 100 each (around US$ 2).

Attachments

The material will be pure copper bar. I am thinking of either gold or silver plated, but I suspect bare copper will sound better. A pair of them will be mounted in a 2” x 3” insulated acrylic board. All machining will be done in a CNC. I am also attaching the CAD drawing if anybody is inclined to play around.

Comment please

Comment please

Attachments

You must have a killer PC.

We never bother to model threads as the rendering goes all choppy when you rotate, pan, or zoom.

Those look good, but take a look at www.cardas.com you may be able to buy them for less than you can build them. They have the same binding posts.

Jeff

We never bother to model threads as the rendering goes all choppy when you rotate, pan, or zoom.

Those look good, but take a look at www.cardas.com you may be able to buy them for less than you can build them. They have the same binding posts.

Jeff

Thanks for the comments

As you rightly said, that isn't too much of a worry. I plan to use copper spades.

The Nut will have nurling edge. In the rendering I've missed out the retainer nut for the inside. But I need to know if the basic design is ok. Have never seen a Cardas.

Also, can some one confirm that uncoated copper should be better than Gold or silver coating. I don't see oxidation in copper as a major issue.

Thanks again.

Not quite..a vanilla PIII. AutoCad 2000, and SolidWorks for simulation.Milzie said:You must have a killer PC.

Peter Daniel said:... don't accept banana connectors...

As you rightly said, that isn't too much of a worry. I plan to use copper spades.

The Nut will have nurling edge. In the rendering I've missed out the retainer nut for the inside. But I need to know if the basic design is ok. Have never seen a Cardas.

Also, can some one confirm that uncoated copper should be better than Gold or silver coating. I don't see oxidation in copper as a major issue.

Thanks again.

Those look great...you've inspired me. I'll have to get some copper stock and go crazy on my grandfathers lathe!

Quick suggestion maybe. On the shaft... i noticed it's completely round. What you might want to do...is make that biggest diameter HEX instead of round so that you can attach a wrench to it when you are securing the shaft from the inside. Otherwise...when wrenching a bolt on from the inside...you won't be able to grab it easily.

Good luck!

-Matthew K. Olson

Quick suggestion maybe. On the shaft... i noticed it's completely round. What you might want to do...is make that biggest diameter HEX instead of round so that you can attach a wrench to it when you are securing the shaft from the inside. Otherwise...when wrenching a bolt on from the inside...you won't be able to grab it easily.

Good luck!

-Matthew K. Olson

Mattyo5 said:.... make that biggest diameter HEX...

Yes that did cross my mind, but I wanted to keep minimum number of operations. Perhaps I can grab the shaft with plier while tightening it.

Thanks

Mattyo5 said:EEEE..

..just a thought

..just a thought actually hex sounds better...will implement it...

Thanks

If it helps, here's a closup of Cardas most popular posts. I don't know if plated or bare copper sounds better, but for myself I usually stay with bare copper. As long as you have spade cconnector lamped in a clean post, oxidation sholdn't be a problem in contact area.

Attachments

Peter Daniel said:a closup of Cardas

Ahhhhhhhhaaaaaaaa.........thanks soooo much..you are my main man Peter. That pic definetly changes many ideas I had. Time for modifications.

The length of a shaft is 1.630". In a shaft, on a nut side, the hole is 0.154" and 0.330 deep. When the nut is on, the hole is 0.540 deep, the hole in a nut is 0.160 and the top of the nut is 0.1 thick.

On a mounting side of the shaft (side which is inside a chassiss) there is another hole, 0.193" diameter and 0.65 deep. This helps with soldering a lot. I know because I trimmed some longer posts and it was really hard to solder without that hole.

Dia. of the threaded part of the shaft is 0.373, the neck is 0.240 and the stopper is 0.50 (which is also the dia. of the nut). The mounting nut looks like 5/16 and the thread is finer than 28 (I don't know what's the next standard value)

On a mounting side of the shaft (side which is inside a chassiss) there is another hole, 0.193" diameter and 0.65 deep. This helps with soldering a lot. I know because I trimmed some longer posts and it was really hard to solder without that hole.

Dia. of the threaded part of the shaft is 0.373, the neck is 0.240 and the stopper is 0.50 (which is also the dia. of the nut). The mounting nut looks like 5/16 and the thread is finer than 28 (I don't know what's the next standard value)

Attachments

thanks

Thanks Peter Daniel so much for the detailed measurements. I really appreciate the gesture.

I should have the first proto of the Cardas clone sometime next week. Lets see how it turns out. Maybe I can send you a pair as mark of my gratitude. Thanks again.

Meanwhile have one on me

Thanks Peter Daniel so much for the detailed measurements. I really appreciate the gesture.

I should have the first proto of the Cardas clone sometime next week. Lets see how it turns out. Maybe I can send you a pair as mark of my gratitude. Thanks again.

Meanwhile have one on me

speaking of hex stock, You could make the nuts out of hex stock,

Turn down the area that contacts the spades to a round shape.

No need to machine the wrench flats

These would be even cheaper, and then you would have to make us all some The reallly cool material seems to be Berillium Copper, what ever that is.

The reallly cool material seems to be Berillium Copper, what ever that is.

Turn down the area that contacts the spades to a round shape.

No need to machine the wrench flats

These would be even cheaper, and then you would have to make us all some

You could get tellurium copper from http://www.mcmaster.com/. Check the item 9100K13. This is the same material that Cardas is using.

>>Alloy 145 Tellurium Copper

Conforms to ASTM B301. Temper is half hard (H02). To Order: Please specify 1-, 3-, or 6-ft. length where prices are shown.

Alloy 145 Sample— Size is 1/2" Dia. x 6" Lg. 9100K337 Each $4.11

Rods— Length tolerance is ± 1/2". Diameter tolerance for 1/8" to 1" is ±.002", for 1 1/8" to 2" is ±.003".

Each

Dia. 1 ft. 3 ft. 6 ft.

1/8" 9100K11 ——

—— $3.93

1/4" 9100K12 ——

—— 10.98

3/8" 9100K13 ——

$12.06 21.46

1/2" 9100K14 $7.55

20.63 36.80

5/8" 9100K15 11.82

32.24 57.48

Each

<<<

And I wouldn't mind to get a pair.

>>Alloy 145 Tellurium Copper

Conforms to ASTM B301. Temper is half hard (H02). To Order: Please specify 1-, 3-, or 6-ft. length where prices are shown.

Alloy 145 Sample— Size is 1/2" Dia. x 6" Lg. 9100K337 Each $4.11

Rods— Length tolerance is ± 1/2". Diameter tolerance for 1/8" to 1" is ±.002", for 1 1/8" to 2" is ±.003".

Each

Dia. 1 ft. 3 ft. 6 ft.

1/8" 9100K11 ——

—— $3.93

1/4" 9100K12 ——

—— 10.98

3/8" 9100K13 ——

$12.06 21.46

1/2" 9100K14 $7.55

20.63 36.80

5/8" 9100K15 11.82

32.24 57.48

Each

<<<

And I wouldn't mind to get a pair.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- DIY Speaker Binding Post