Hi All,

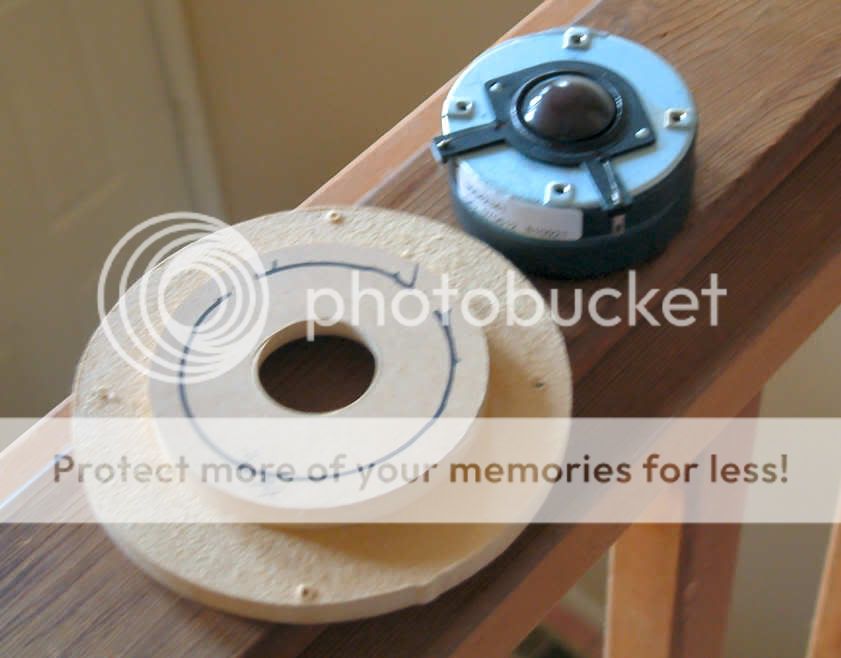

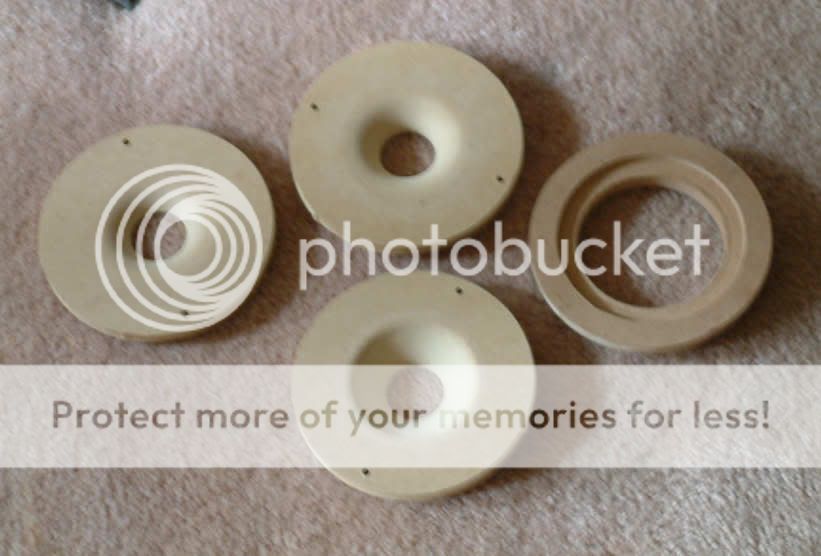

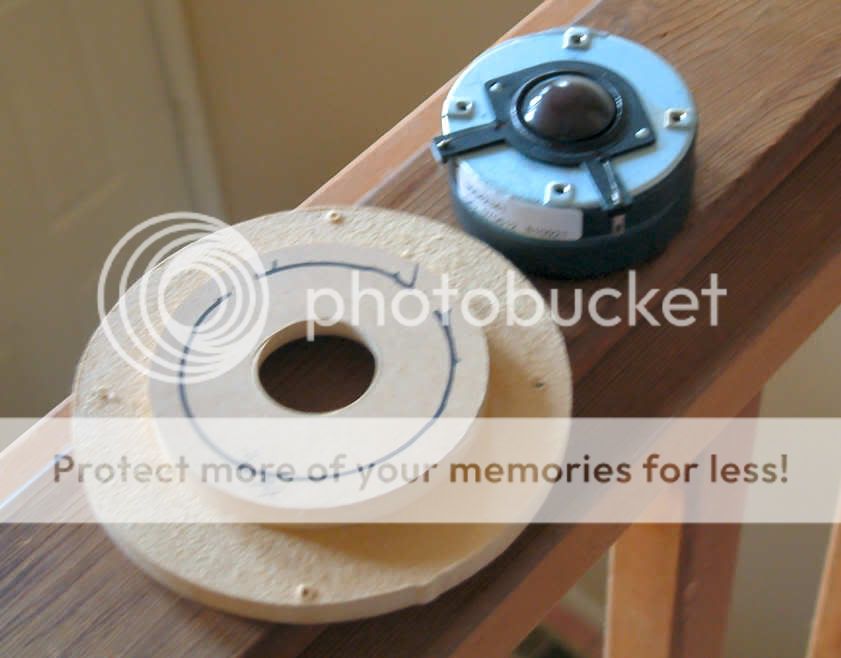

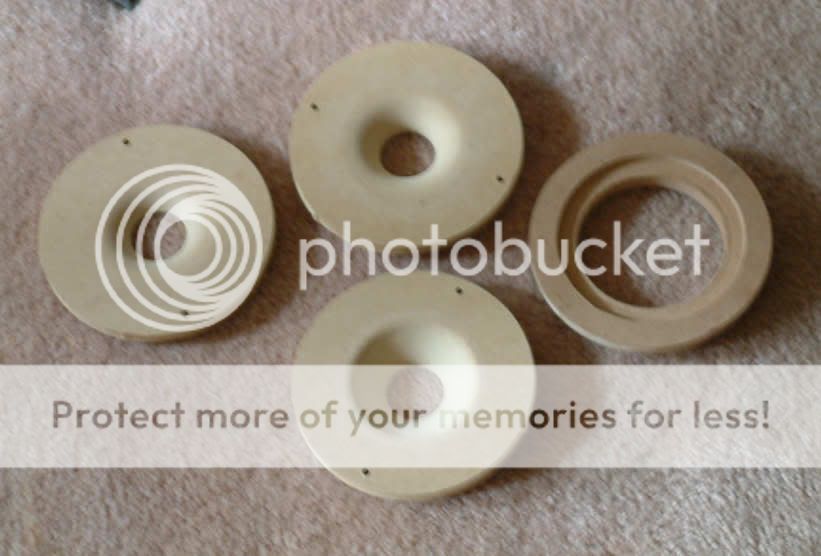

I have been doing some testing with shallow waveguides for my BaSSlines project that I thought you all might be interested in. I posted this in my BaSSlines thread, but realized many of you who might be interested could miss it there. I created an insert into the baffle that would allow me to make multiple WG's and insert them into the same baffle (see photo below), with same tweeter, same mic setup, position, etc. The tweeter is the Peerless HDS with the face plate removed. The tweeter is mounted by pressing it to the back of he WG cutout, held by a woof fixture. The measurements were all taken at 1 meter, with the mic 80" high, in the center of a room with vaulted ceilings probably 15' high at that point and with a 4ms gated window.

All the WG's were created from mdf by boring a hole with a forstner bit, then rounding over the appropraite amount and then routing from the back for the palnned depth of either 1/2" deep or 3/4" deep in these cases. These are something just about any DIYer can build petty easily, which was the idea. There are a few tricks to doing this, most notably, when using a 3/4" rounvoer bit, you have to have a backer piece to you mdf baffle that you also bore a hole through. This backer piece is needed for the bearing of the deeper 3/4" roundover bit to ride on. All the bore through holes on these were adjusted so the final throat sizes are about 1-1/4" +- 1/32" at the final size.

Most of the plots show the waveguide perfomance at 0-15-30-45 and 60º of axis horizontally, so you can see the effect on axis and the directivity off axis. The first plot is the HDS with a standard flush mount. My goal with the waveguide is to get some boost at the low end so that when qualized out in the crossover you get the possible benefits of lowered distortion, slighly higher sensitivity, better off axis directivity and a counter to the typical rising responce of the HDS tweeter on axis, which might be fatiguing to some over time. Also included are some comparisons of the favorite WG results on axis with each other.

I'll include some photos of the waveguide testing insert setup in this post and in the next one I'll post the results.

I have been doing some testing with shallow waveguides for my BaSSlines project that I thought you all might be interested in. I posted this in my BaSSlines thread, but realized many of you who might be interested could miss it there. I created an insert into the baffle that would allow me to make multiple WG's and insert them into the same baffle (see photo below), with same tweeter, same mic setup, position, etc. The tweeter is the Peerless HDS with the face plate removed. The tweeter is mounted by pressing it to the back of he WG cutout, held by a woof fixture. The measurements were all taken at 1 meter, with the mic 80" high, in the center of a room with vaulted ceilings probably 15' high at that point and with a 4ms gated window.

All the WG's were created from mdf by boring a hole with a forstner bit, then rounding over the appropraite amount and then routing from the back for the palnned depth of either 1/2" deep or 3/4" deep in these cases. These are something just about any DIYer can build petty easily, which was the idea. There are a few tricks to doing this, most notably, when using a 3/4" rounvoer bit, you have to have a backer piece to you mdf baffle that you also bore a hole through. This backer piece is needed for the bearing of the deeper 3/4" roundover bit to ride on. All the bore through holes on these were adjusted so the final throat sizes are about 1-1/4" +- 1/32" at the final size.

Most of the plots show the waveguide perfomance at 0-15-30-45 and 60º of axis horizontally, so you can see the effect on axis and the directivity off axis. The first plot is the HDS with a standard flush mount. My goal with the waveguide is to get some boost at the low end so that when qualized out in the crossover you get the possible benefits of lowered distortion, slighly higher sensitivity, better off axis directivity and a counter to the typical rising responce of the HDS tweeter on axis, which might be fatiguing to some over time. Also included are some comparisons of the favorite WG results on axis with each other.

I'll include some photos of the waveguide testing insert setup in this post and in the next one I'll post the results.

Here are some results:

HDS mounted Flush: 0-15-30-45-60º

1/2" deep WG, 1/2" roundover: 0-15-30-45-60º

1/2" deep WG, 3/4" roundover: 0-15-30-45-60º

3/4" deep WG, 3/4" roundover: 0-15-30-45-60º

3/4" deep WG, 3/4" roundover, with 1/2" deep 45º chamfer after, sharp edges sanded round by hand: 0-15-30-45-60º

3/4" deep WG, 3/4" deep 45º chamfer, sharp edges sanded round by hand: 0-15-30-45-60º

Here are the flush mount (red), 1/2" deep/1/2" roundover(pink), 1/2" deep/3/4" roundover (blue) and 3/4" deep/3/4" roundover (black), all on axis.

My conclusion is: it depends on what you are looking for. The deeper wavegides have more boost, but all peak at about 4kHz on axis. The 1/2" deep waveguide, with 1/2" roundover has the flattest FR on axis from 4kHz and up on axis. The 1/2" deep/3/4" roundover WG and the 3/4" deep/3/4" roundover WG have the best off axis responce when you get out to 30º and beyond and the most directivity. I'm now leaning toward either the 1/2" deep/3/4" roundover of the 1/2" deep/1/2" roundover WG's from a raw response point of view. I will see how they look in the crossover design.

I hope these results will encourage some of you to experiment with this concept. I think it has a lot of merit and is not at all hard to do with just a router and standard bits. It helps if you have a drill press and a router table as well.

HDS mounted Flush: 0-15-30-45-60º

1/2" deep WG, 1/2" roundover: 0-15-30-45-60º

1/2" deep WG, 3/4" roundover: 0-15-30-45-60º

3/4" deep WG, 3/4" roundover: 0-15-30-45-60º

3/4" deep WG, 3/4" roundover, with 1/2" deep 45º chamfer after, sharp edges sanded round by hand: 0-15-30-45-60º

3/4" deep WG, 3/4" deep 45º chamfer, sharp edges sanded round by hand: 0-15-30-45-60º

Here are the flush mount (red), 1/2" deep/1/2" roundover(pink), 1/2" deep/3/4" roundover (blue) and 3/4" deep/3/4" roundover (black), all on axis.

My conclusion is: it depends on what you are looking for. The deeper wavegides have more boost, but all peak at about 4kHz on axis. The 1/2" deep waveguide, with 1/2" roundover has the flattest FR on axis from 4kHz and up on axis. The 1/2" deep/3/4" roundover WG and the 3/4" deep/3/4" roundover WG have the best off axis responce when you get out to 30º and beyond and the most directivity. I'm now leaning toward either the 1/2" deep/3/4" roundover of the 1/2" deep/1/2" roundover WG's from a raw response point of view. I will see how they look in the crossover design.

I hope these results will encourage some of you to experiment with this concept. I think it has a lot of merit and is not at all hard to do with just a router and standard bits. It helps if you have a drill press and a router table as well.

Thanks for posting that info and pics, I guess maybe I'll go ahead and do some speakers like that myself - I had been dreaming of a custom CNC'd baffle... No reason to wait until I have CNC access, I guess.

With the improved time alignment, I imagine you need to do your crossover a little differently than the typical ones w/inverted phase on the tweeter?

I've tried to read articles about "linear phase" crossovers, but, don't yet understand how to do one myself - I would like to have perfect time alignment eventually...

FWIW I've found that this: http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=277-046

Seems to fit fine on various other tweeter magnet assemblies.

I'm WAS thinking of filing the tabs off a Dayton DC28F, but, then again, I thought, maybe I should just buy the morel tweeter instead of trying to be so cheap

I have done that same thing you've done making a waveguide in MDF, but I used a 3/4" dome tweeter. I didn't go so far as to build a speaker with it yet, however

With the improved time alignment, I imagine you need to do your crossover a little differently than the typical ones w/inverted phase on the tweeter?

I've tried to read articles about "linear phase" crossovers, but, don't yet understand how to do one myself - I would like to have perfect time alignment eventually...

FWIW I've found that this: http://www.partsexpress.com/pe/showdetl.cfm?&Partnumber=277-046

Seems to fit fine on various other tweeter magnet assemblies.

I'm WAS thinking of filing the tabs off a Dayton DC28F, but, then again, I thought, maybe I should just buy the morel tweeter instead of trying to be so cheap

I have done that same thing you've done making a waveguide in MDF, but I used a 3/4" dome tweeter. I didn't go so far as to build a speaker with it yet, however

These simple waveguide mounts certainly offers some options for a closer phyical time alignment, which could make it easier on the crossover design to achieve a good phase match (assuming a passive xover, that is). It also offers some low end boost, which when equalized out in the crossover should make for a bit stronger low end performance and distortion reduction, not to mention improved off axis directivity. In my case, it also adds a physical way to counter the rising response of the HDS tweeter, which means I don't have to do so electrically in the crossover.

I also like the way it looks.

I've already successfully used this concept, which was Zaph's idea in the first place, in my Duo project.

I also like the way it looks.

I've already successfully used this concept, which was Zaph's idea in the first place, in my Duo project.

Hi, I know this is an old thread by now, but do you have any more info on the 3/4 & 3/4, the one showing best directivity off axis? How did you do the wg?

How where these wg's when it comes to crossover, where they easy to implement?

I have these tweeters in a wg in my Elsies, but would be fun to try another wg profile in another speaker design.

How where these wg's when it comes to crossover, where they easy to implement?

I have these tweeters in a wg in my Elsies, but would be fun to try another wg profile in another speaker design.