danieljw said:nice work helmuth !

Thanks Daniel your a Measuring pro I see nice.

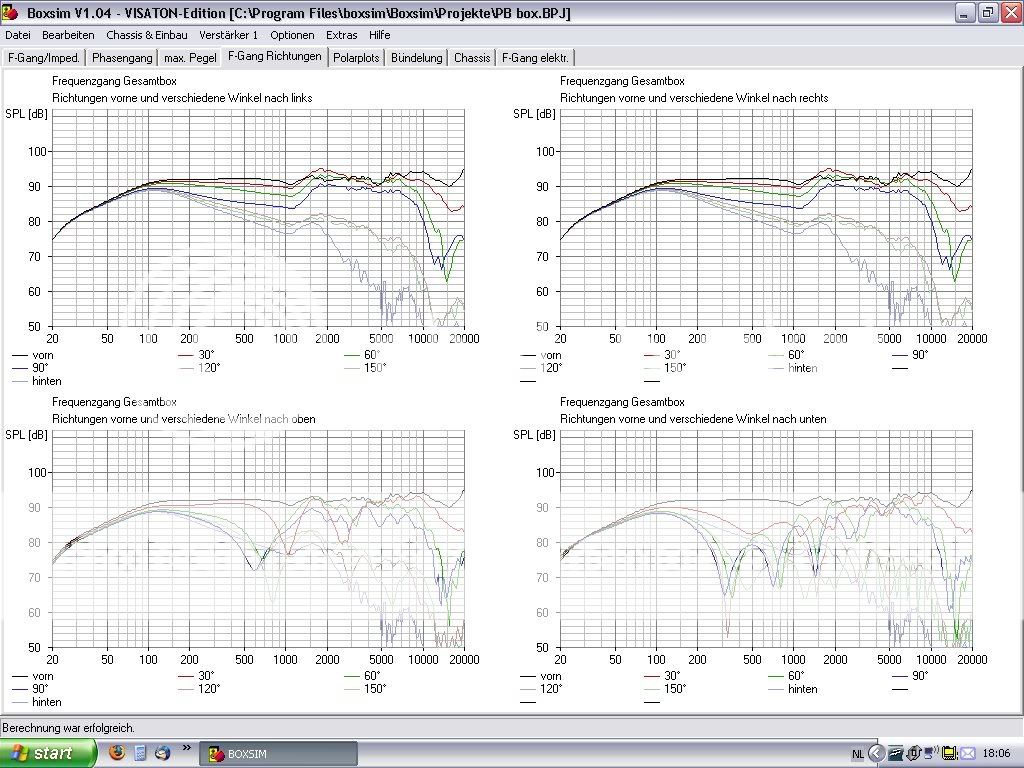

Here a Have picture of the predicted radiation pattern to left and right above and below.

Greetz

danieljw said:looks like the efficiency is quite respectable too, which is good.

-Dan

Yes due the amazing capabilities off the Monacor sub with a SPL of 91dB/1Wmtr

. In this set up -3db 26Hz. -10dB19Hz

. In this set up -3db 26Hz. -10dB19HzLook here for data.

Monacor SPH250ctc

The baffle gain did the rest for the Mivoc it fits together real nice without level adjusting. Minimal components cost effective and good.

There are many people how are searching rare brands and expensive parts to make something special. In the budget circuit there is many stuff what is very useful to build a perfect working speaker when you know what your doing.

I really like this project while the cost decreased in this case during the time(thanks to mivoc's good price performance). Normally it is the other way around

I have a good feeling about the outcome of the project sound quality, financially and the looks.

So keep tuned, Helmuth

Helmuth said:

Yes due the amazing capabilities off the Monacor sub with a SPL of 91dB/1Wmtr. In this set up -3db 26Hz. -10dB19Hz

Sorry Helmuth, I dont want to spoil your fun

But driver Fs of 20hz could be a bit optimistic...at Monacors own graphs it looks like quite a bit higher, could be wrong though...its always like that with Monacor

Anyway, not sure about pushing that woofer very low...depends on SPL

I didn't look at it. I see you are tight it will have its reason. I cant believe they will give faulty TS-parameters.tinitus said:

Sorry Helmuth, I dont want to spoil your fun

But driver Fs of 20hz could be a bit optimistic...at Monacors own graphs it looks like quite a bit higher, could be wrong though...its always like that with Monacor

What I can hear the output down to 30Hz is good audible. So I am not concerned.

Anyway, not sure about pushing that woofer very low...depends on SPL

The box will be 200W rms that is not a design goal at all.

High-end quality low distortion for normal price is the goal. With this driver sub low in a small enclosure is easy. The carbon cone and the aluminium frame does the rest.

The restriction of the sub is the x-max of the sph250ctc that is 4,5mm. In simulation that means at 20W it reaches x-max. 20Watt is more then enough to listen loud (with a spl of 90dB 1Wmtr)for music in a medium size living room.

I would advice a 70Watt amp for this speaker. The high Rms power of al the drivers in the speaker is very good to prevent power compression distortion.

Here a picture of the filterparts.

Erse coils nice havey stuff.

Janzen denmark flatwire and correcting coils

Claritycap MKP

Hi every body,

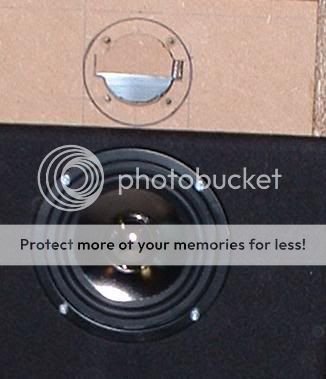

To get a nice finish al speakers have to fall in the baffle. I have a grinder, to make nice things out of wood you need one, really great to work with.

Here you are seeing the face plate that will cover the front of the box.

The WTP138 and bassreflex pipe will fit equal with the plate.

If you look good on the photo you can see the bold where the grinder turns around.

To get a nice finish al speakers have to fall in the baffle. I have a grinder, to make nice things out of wood you need one, really great to work with.

Here you are seeing the face plate that will cover the front of the box.

The WTP138 and bassreflex pipe will fit equal with the plate.

If you look good on the photo you can see the bold where the grinder turns around.

danieljw said:yes who eve invented the "router" or grinder as you call it seriously needs a medal ! they are so useful.

-Dan

Hi Dan,

So router is the word often I do not know the right translation

I can not wait to build it to gather. I only miss cloth to cover the faceplate. I thought cloth is better than paint it doesn't scratch or become spots of fingers on it.

I will use black speaker cover cloth.

Good, night

I am going to bed now it is 30 min past twelve here.

Helmuth said:bin in the garage and did some more work with the router. I have rounded the edges of the

panels en around the woofer.

Don't forget to relieve the back of the driver cut-outs for better air flow.

dave

danieljw said:looks good helmuth,

I just finished my box work for the elsinore speakers... i have to putty all the screw holes now

at will you use to fill the holes / smooth the surface ?

-Dan

I do not have to smooth the surface because I will use black speakercover cloth to cover the MDF front panels. It doesn't scratch and you won't see any fingers on it.

When you see the fatboy project there I have used velours to cover the mdf worked very good.

planet10 said:

Don't forget to relieve the back of the driver cut-outs for better air flow.

dave

Good idea but I am afraid the hammer nuts I use won't fit then.

Helmuth said:

Good idea but I am afraid the hammer nuts I use won't fit then.

Just mark the screwholes carefully, and leave the exstra needed wood around them

Anyway, routing the back does more good than the hammer nuts...even a relatively small rounding will help

Attachments

planet10 said:

Don't forget to relieve the back of the driver cut-outs for better air flow.

dave

tinitus said:

Just mark the screwholes carefully, and leave the exstra needed wood around them

Anyway, routing the back does more good than the hammer nuts...even a relatively small rounding will help

Now I hope your pleased with the made cut out.

I also removed the little plate by bending them back.

Thanks for the tip Planet10.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- High-end 3 way dáppolito with aluminiumcone