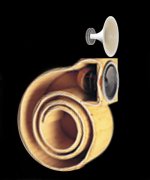

I present for your review my final design horn project.

I am posting it here to seek any advice on improving the specific elements but overall I am very pleased with concept. Despite my huge EGO, no rally it’s hugh, I look forward to your input about any flaws or limitations that my be present.

My design thesis:

To build a high efficiency (reasonably) full range compact modular horn based speaker with a clear path for future upgrades.

As shown:

Compression driver: P Audio SD 450 (filtered at 600 hz).

Horn: 18” round Tractrix (built in-house of a carbon composite).

Woofer: PHL Audio 4130.

Horn surround: 6” Aluminum or Carbon Fiber tube (6-way adjustable).

Horn frame: 1” stainless round stock or filled tube (extended to the floor).

Bass enclosure: 2 Cuft (built in-house of a carbon/Kevlar phenolic).

Regarding the Compression driver: I originally envisioned using a TAD 2001/ 2002 (and my indeed use in the future) but the P Audio compression driver comes to me highly recommend. I will use it as a starting point and go from there.

Regarding the Horn: To tell you the truth, I chose the 18” round design primarily for its aesthetics. I am stuck on it’s shape, that is to say, the horn must be round but I am flexible as to the final diameter. I will however design it’s mounting flange to accommodate both the P Audio or the TAD drivers.

Regarding Woofer: Again my choice of a single 12” woofer is based highly on the aesthetic needs of my design but is dose limit me to about the 50-60 hz region. The two other options would be two PHL 4530’s (more bass) or a horn loaded 10” PHL 3820 (more horn). Feel free to chime in here as this seems to be the biggest ? I am dealing with.

Regarding Horn frame: I like the idea of extending the frame all the way to the floor and de-coupled from the woofer enclosure via hollow tubes. This allows for greater flexibility as the speaker evolves. What problems do you see with the approach?

Regarding Bass enclosure: During the day I make carbon composite parts so I will more than likely make the bass enclosure out of a Carbon/Kevlar phenolic. How it is loaded is still open to consideration.

Thanks in advance for your input.

Regards, Neil

arcdesigns@earthlink.net

P.S. I would like to thank Andre (e-speakers.com) for his help so far.

I am posting it here to seek any advice on improving the specific elements but overall I am very pleased with concept. Despite my huge EGO, no rally it’s hugh, I look forward to your input about any flaws or limitations that my be present.

My design thesis:

To build a high efficiency (reasonably) full range compact modular horn based speaker with a clear path for future upgrades.

As shown:

Compression driver: P Audio SD 450 (filtered at 600 hz).

Horn: 18” round Tractrix (built in-house of a carbon composite).

Woofer: PHL Audio 4130.

Horn surround: 6” Aluminum or Carbon Fiber tube (6-way adjustable).

Horn frame: 1” stainless round stock or filled tube (extended to the floor).

Bass enclosure: 2 Cuft (built in-house of a carbon/Kevlar phenolic).

Regarding the Compression driver: I originally envisioned using a TAD 2001/ 2002 (and my indeed use in the future) but the P Audio compression driver comes to me highly recommend. I will use it as a starting point and go from there.

Regarding the Horn: To tell you the truth, I chose the 18” round design primarily for its aesthetics. I am stuck on it’s shape, that is to say, the horn must be round but I am flexible as to the final diameter. I will however design it’s mounting flange to accommodate both the P Audio or the TAD drivers.

Regarding Woofer: Again my choice of a single 12” woofer is based highly on the aesthetic needs of my design but is dose limit me to about the 50-60 hz region. The two other options would be two PHL 4530’s (more bass) or a horn loaded 10” PHL 3820 (more horn). Feel free to chime in here as this seems to be the biggest ? I am dealing with.

Regarding Horn frame: I like the idea of extending the frame all the way to the floor and de-coupled from the woofer enclosure via hollow tubes. This allows for greater flexibility as the speaker evolves. What problems do you see with the approach?

Regarding Bass enclosure: During the day I make carbon composite parts so I will more than likely make the bass enclosure out of a Carbon/Kevlar phenolic. How it is loaded is still open to consideration.

Thanks in advance for your input.

Regards, Neil

arcdesigns@earthlink.net

P.S. I would like to thank Andre (e-speakers.com) for his help so far.

Attachments

Perhaps the Lambda TD12 or TD15 series would

fit your needs?

Wide band drivers capable of great sonics up to

1khz-2khz, so regardless of what "low pass" frequency

you choose, they work great, makes tweaking easy...

If you port the Lambda box, you can get some great bottom

end.

Sensitivity is pretty good too, but you'll have to

biamp the setup for ultimate SQ.

http://www.lambdacoustics.com/drivers/TDdrivers.html

fit your needs?

Wide band drivers capable of great sonics up to

1khz-2khz, so regardless of what "low pass" frequency

you choose, they work great, makes tweaking easy...

If you port the Lambda box, you can get some great bottom

end.

Sensitivity is pretty good too, but you'll have to

biamp the setup for ultimate SQ.

http://www.lambdacoustics.com/drivers/TDdrivers.html

Arcdesigns said:Horn: 18" round Tractrix (built in-house of a carbon composite).

Isn't 18" quite a bit more than you need for 600 Hz?

Regarding Woofer: Again my choice of a single 12" woofer

You might consider a pr in push-push and not have to deal with baffle-step (plus all the other benefits of push-push)

The Lambdas are VERY good.

dave

Here are 2 more pics.

Dual PHL 4530's in two different setups.

Thanks for the reply "thylantyr"

Regarding the Lambda's: I think the will drop below my design goal as far as efficiency. I am designing these speakers to be used with a pair of 8W mono blocks.

Keep them coming.

Dual PHL 4530's in two different setups.

Thanks for the reply "thylantyr"

Regarding the Lambda's: I think the will drop below my design goal as far as efficiency. I am designing these speakers to be used with a pair of 8W mono blocks.

Keep them coming.

Attachments

I've been horny for a long time

Why not do it right (or close to it) first time?

Really, it's less hassle and expense. Measure twice, cut once.

The flare rate works out to be 227Hz for a full size trax with a 1"throat. Waaay too big for what you're trying to do. Abouve about 25x the flare rate it will beam like a lighthouse, and have a very narrow sweetspot.

I've heard quite a few of the PAudio drivers (though not the SD450), and well, they're not that good IMO. If you can find the $, go for a Radian 450PB or a Beyma 380M for not much more money. Titanium diaphram compression drivers all have a particular sound to me, and it's not one I like at all. The Radian is Al, and the Beyma mylar.

The TAD is an exceptional driver, but if you have a direct radiating bass/midbass up to 600Hz, all you're going to hear is the lack of integration between them. The PHLs may be good, but they're not a TAD. (more below)

Trax flares don't run effectively down to their flare frequency, and need a flare <i>length</i> of 1/2 wavelength at the minimum frequency you want to use, so adjust the rate accordingly. My new mid/high horns will have a Fc of 270Hz to get me response to 400Hz. To get the most out of a flare, you need to tune it to the specific driver you're going to use, so something setup for the TAD will likely sound pretty average with the

If you use the Radian, one designer has successfully used a 340Hz trax and gets a measured 450Hz response.

If you're going to do a good horn mid and up, why hobble it with a little direct radiator below? They will sound very different and will be a huge PITA to try to integrate sonically. Sure you'll be able to get it sounding OK, but nowhere near as good as you could, if you hornload all the way down to 80-100Hz or so. If you don't have space for a pair of LABhorns or Edgar Monoliths to do <80Hz, some big conventional subs will be less of a clash acoustically operating down there. There are tons of good Pro drivers that'll do well in a midbass horn up to several hundred Hz. One of the PHLs might be good too, I just have no experience with them to comment, and haven't run the numbers. Bruce Edgar's 80Hz hypex midbass flare shells would be my personal choice (at about $400)

All the rest of it is window dressing unless you get the fundamentals right.

But of course this is only my opinion of how to do it.

Cheers

Pic is of Edgar Titan System, Monolith Hornsub, and the designer, Dr Bruce Edgar

Arcdesigns said:My design thesis:

To build a high efficiency (reasonably) full range compact modular horn based speaker with a clear path for future upgrades.

Why not do it right (or close to it) first time?

Really, it's less hassle and expense. Measure twice, cut once.

Compression driver: P Audio SD 450 (filtered at 600 hz).

Horn: 18” round Tractrix (built in-house of a carbon composite).

The flare rate works out to be 227Hz for a full size trax with a 1"throat. Waaay too big for what you're trying to do. Abouve about 25x the flare rate it will beam like a lighthouse, and have a very narrow sweetspot.

I've heard quite a few of the PAudio drivers (though not the SD450), and well, they're not that good IMO. If you can find the $, go for a Radian 450PB or a Beyma 380M for not much more money. Titanium diaphram compression drivers all have a particular sound to me, and it's not one I like at all. The Radian is Al, and the Beyma mylar.

The TAD is an exceptional driver, but if you have a direct radiating bass/midbass up to 600Hz, all you're going to hear is the lack of integration between them. The PHLs may be good, but they're not a TAD. (more below)

Trax flares don't run effectively down to their flare frequency, and need a flare <i>length</i> of 1/2 wavelength at the minimum frequency you want to use, so adjust the rate accordingly. My new mid/high horns will have a Fc of 270Hz to get me response to 400Hz. To get the most out of a flare, you need to tune it to the specific driver you're going to use, so something setup for the TAD will likely sound pretty average with the

If you use the Radian, one designer has successfully used a 340Hz trax and gets a measured 450Hz response.

Woofer: PHL Audio 4130.

Bass enclosure: 2 Cuft (built in-house of a carbon/Kevlar phenolic).

Regarding Woofer: Again my choice of a single 12” woofer is based highly on the aesthetic needs of my design but is dose limit me to about the 50-60 hz region. The two other options would be two PHL 4530’s (more bass) or a horn loaded 10” PHL 3820 (more horn). Feel free to chime in here as this seems to be the biggest ? I am dealing with.

If you're going to do a good horn mid and up, why hobble it with a little direct radiator below? They will sound very different and will be a huge PITA to try to integrate sonically. Sure you'll be able to get it sounding OK, but nowhere near as good as you could, if you hornload all the way down to 80-100Hz or so. If you don't have space for a pair of LABhorns or Edgar Monoliths to do <80Hz, some big conventional subs will be less of a clash acoustically operating down there. There are tons of good Pro drivers that'll do well in a midbass horn up to several hundred Hz. One of the PHLs might be good too, I just have no experience with them to comment, and haven't run the numbers. Bruce Edgar's 80Hz hypex midbass flare shells would be my personal choice (at about $400)

All the rest of it is window dressing unless you get the fundamentals right.

But of course this is only my opinion of how to do it.

Cheers

Pic is of Edgar Titan System, Monolith Hornsub, and the designer, Dr Bruce Edgar

Attachments

Arcdesigns said:]Here are 2 more pics.

Dual PHL 4530's in two different setups.

Neither of those is the most effective use of 2 drivers. Push-push -- two drivers magnet-to-magnet, in phase, firing out of opposite faces of the cabinet.

If Brett is right on the cutoff, then the top end of the horn (remember 3, maybe 4 octaves for the horn) will be lacking.

dave

Thanks for the rethink

Thanks Planet 10 and Brett for the input.

Planet 10 can you post a Pic or link to a push-pull design that would work?

I have added a pic of a Edgar style bass horn with a smaller tractrix horn (not to scale). Is this more in your line of thinking Brett?

Although I am more than willing to completely scrap my first concept and start from scratch, as a designer I am going to place a great deal of weight on the aesthetics. I will also want to utilize my ability to create complex shapes out of composite materials. What about the inverted bass horn used in the Nautilus prototype (wood) and final production (FRP), could I make any gains from this approach?

As I already own the P Audio SD 450?s, and they did come recommended, I would like to follow thru and make a pair of horns for them.

Here is a Horn 101 question:

If it seems the mid-horn wants to be quite small why are there so many large mid horns in the current crop of commercial designs?

Truth be told, but maybe only in a perfect world, I would love a big horn.

Thanks Planet 10 and Brett for the input.

Planet 10 can you post a Pic or link to a push-pull design that would work?

I have added a pic of a Edgar style bass horn with a smaller tractrix horn (not to scale). Is this more in your line of thinking Brett?

Although I am more than willing to completely scrap my first concept and start from scratch, as a designer I am going to place a great deal of weight on the aesthetics. I will also want to utilize my ability to create complex shapes out of composite materials. What about the inverted bass horn used in the Nautilus prototype (wood) and final production (FRP), could I make any gains from this approach?

As I already own the P Audio SD 450?s, and they did come recommended, I would like to follow thru and make a pair of horns for them.

Here is a Horn 101 question:

If it seems the mid-horn wants to be quite small why are there so many large mid horns in the current crop of commercial designs?

Truth be told, but maybe only in a perfect world, I would love a big horn.

Attachments

If you want to run dual mono blocks of 8 watts, then dedicate those blocks

for the horn....... then get some

balsy 2 channel solid state amplifier of

>100w x 2 to run the Lambda TD's -

hehe!!

If you get the 4 ohm TD12X,

sensitivity is rated at 97db,

most solid state amplifiers

are 4 ohm stable nowadays.

Compromise must be made, do you

want;

order of preference

1. high sensitivity

2. great sound quality

*or*

1. great sound quality

2. high sensitivity

Lambda would give you unbeatable

SQ.............. if you are willing to

sacrifice a little sensitivity and

run the dedicated amp for them.

for the horn....... then get some

balsy 2 channel solid state amplifier of

>100w x 2 to run the Lambda TD's -

hehe!!

If you get the 4 ohm TD12X,

sensitivity is rated at 97db,

most solid state amplifiers

are 4 ohm stable nowadays.

Compromise must be made, do you

want;

order of preference

1. high sensitivity

2. great sound quality

*or*

1. great sound quality

2. high sensitivity

Lambda would give you unbeatable

SQ.............. if you are willing to

sacrifice a little sensitivity and

run the dedicated amp for them.

Re: Thanks for the rethink

The TLb is one, Steve Zettel's Sub is push-pull push-push (with good linear woofs the push-pull is extraneous -- i like to get good magnet to magnet coupling), here are concepts of some http://www.t-linespeakers.org/FALL/bipolar/index.html]RS 40-1354 push-push bipoles[/URL], a push-push dipole concept, and the pic below is an ideal situation where the woofer is designed to have a securing bolt go thru the pole piece (not many of these).

dave

Arcdesigns said:Planet 10 can you post a Pic or link to a push-pull design that would work?

The TLb is one, Steve Zettel's Sub is push-pull push-push (with good linear woofs the push-pull is extraneous -- i like to get good magnet to magnet coupling), here are concepts of some http://www.t-linespeakers.org/FALL/bipolar/index.html]RS 40-1354 push-push bipoles[/URL], a push-push dipole concept, and the pic below is an ideal situation where the woofer is designed to have a securing bolt go thru the pole piece (not many of these).

An externally hosted image should be here but it was not working when we last tested it.

dave

Re: Re: Thanks for the rethink

Looks like a weapon of mass

destruction

planet10 said:

The TLb is one, Steve Zettel's Sub is push-pull push-push (with good linear woofs the push-pull is extraneous -- i like to get good magnet to magnet coupling), here are concepts of some http://www.t-linespeakers.org/FALL/bipolar/index.html]RS 40-1354 push-push bipoles[/URL], a push-push dipole concept, and the pic below is an ideal situation where the woofer is designed to have a securing bolt go thru the pole piece (not many of these).

An externally hosted image should be here but it was not working when we last tested it.

dave

Looks like a weapon of mass

destruction

New Pic

Thanks thylantyr and Planet10 for the new replies.

Thylantyr, If I were to use the Lambda's what type of enclosure?

I seems to me, if I do bi-amp the woofers with a SS amp I will not need to worry about efficiency and would of course favor sound quality. I am not there yet, but I am keeping an open mind.

Here is pic of Planet10's Push/Pull with a 12" horn roughly 36" high. That little horn looks kind of cute.

I guess I would need 2 tubes per side. The first, as the TL. The second, as a frame for the horn arm.

Brett, I tried to look at your web page to see pics of your speakers but all I saw was...well you know what I saw. No wonder your Horny.

Can you post a pic or 2.

Thanks again, Neil

Thanks thylantyr and Planet10 for the new replies.

Thylantyr, If I were to use the Lambda's what type of enclosure?

I seems to me, if I do bi-amp the woofers with a SS amp I will not need to worry about efficiency and would of course favor sound quality. I am not there yet, but I am keeping an open mind.

Here is pic of Planet10's Push/Pull with a 12" horn roughly 36" high. That little horn looks kind of cute.

I guess I would need 2 tubes per side. The first, as the TL. The second, as a frame for the horn arm.

Brett, I tried to look at your web page to see pics of your speakers but all I saw was...well you know what I saw. No wonder your Horny.

Can you post a pic or 2.

Thanks again, Neil

Attachments

Re: New Pi'

Actually, if it was me, I would use

a single Lambda TD15H or TD15X

per channel, ported box works nice.

The regular TD series should be able

to handle a 500 watt amplifier. I have

the Apollo upgrade (cost more), and

this version has no problems with a

600w amp, itching for 1000w amp

(heh), but sounds great even with a

100w amp. Just don't exceed

mechanical limits of 10mm linear

x-max.

If space is an issue, then the TD12

series would be nice too, but technically, Nick told the Lambda

users that the 15" sounds just

a little we-bit better than the 12"

woofer when it comes to midrange

performance.

I've tried the TD15 in a sealed

3 ft^3 and ported 4 ft^3 tuned

to approx 35hz. I prefer the ported

box, best band for the buck. Better

effeciency, lower excursion at low

frequencies and if you use dual

4" flared ports in the rear of the

box, the sound quality is excellent

as you don't hear any port noise

even with 600w of power.

The TD series is amazing, with

heavy parametric EQ'ing, I can

make my 15" woofer sound like

a tweeter (lol)....

Don't fear the 2" voice coil, the

woofer is able to dissipate lots

of heat if need be........

Plus, Lambda's are hand made,

and the new phase plus is longer,

chrome plating if you want, makes

the woofer look "manly"... LOL

Girls will love the speaker system ... LOL

Arcdesigns said:Thylantyr, If I were to use the Lambda's what type of enclosure?

I seems to me, if I do bi-amp the woofers with a SS amp I will not need to worry about efficiency and would of course favor sound quality.

Actually, if it was me, I would use

a single Lambda TD15H or TD15X

per channel, ported box works nice.

The regular TD series should be able

to handle a 500 watt amplifier. I have

the Apollo upgrade (cost more), and

this version has no problems with a

600w amp, itching for 1000w amp

(heh), but sounds great even with a

100w amp. Just don't exceed

mechanical limits of 10mm linear

x-max.

If space is an issue, then the TD12

series would be nice too, but technically, Nick told the Lambda

users that the 15" sounds just

a little we-bit better than the 12"

woofer when it comes to midrange

performance.

I've tried the TD15 in a sealed

3 ft^3 and ported 4 ft^3 tuned

to approx 35hz. I prefer the ported

box, best band for the buck. Better

effeciency, lower excursion at low

frequencies and if you use dual

4" flared ports in the rear of the

box, the sound quality is excellent

as you don't hear any port noise

even with 600w of power.

The TD series is amazing, with

heavy parametric EQ'ing, I can

make my 15" woofer sound like

a tweeter (lol)....

Don't fear the 2" voice coil, the

woofer is able to dissipate lots

of heat if need be........

Plus, Lambda's are hand made,

and the new phase plus is longer,

chrome plating if you want, makes

the woofer look "manly"... LOL

Girls will love the speaker system ... LOL

do you know Timos site?

http://www-user.uni-bremen.de/~carnivor/radial/radial.html

/till still waiting for his TD2001s

http://www-user.uni-bremen.de/~carnivor/radial/radial.html

/till still waiting for his TD2001s

Re: Re: New Pic: Nautilus bass horn

This is imperative to know, especially for horn systems. IME, they are <b>much</b> harder to get right, they do not design as easily as 'box' speakers do, the different types of flares all have a different sonic signature, dispersion pattern and few people know where the inevitable design compromises can be made to acheive the desired result.

Your designs look beautiful (I wish mine looked as good), but that is no guarantee they will sound any good. I'm not trying to be negative towards your project, but rather help to make it work well.

thylantyr said:What is your system design goals for

the sound system you want ?

Seems like your cutting/pasting

systems together

This is imperative to know, especially for horn systems. IME, they are <b>much</b> harder to get right, they do not design as easily as 'box' speakers do, the different types of flares all have a different sonic signature, dispersion pattern and few people know where the inevitable design compromises can be made to acheive the desired result.

Your designs look beautiful (I wish mine looked as good), but that is no guarantee they will sound any good. I'm not trying to be negative towards your project, but rather help to make it work well.

Design Goals

Thanks for the input Thylantry

As stated in post #1:

"To build a high efficiency (reasonably) full range compact modular horn based speaker with a clear path for future upgrades."

Further refined as:

"...to be used with a pair of 8W mono blocks."

"I am going to place a great deal of weight on the aesthetics."

"Truth be told, but maybe only in a perfect world, I would love a big horn."

Indeed I am cutting and pasting systems together. It would seem based on the replies to the fist image that I had it all wrong...

Not a problem, I am always eager to learn and am a quick study.

The subsequent pics have reflected the input I have been given with the hopes of a reply that goes something like this:

?Ok, now your on the right track. Lower this...invert that...and get back to me.?

Thanks again, Neil

What is your system design goals for

the sound system you want ?

Seems like your cutting/pasting

systems together

Thanks for the input Thylantry

As stated in post #1:

"To build a high efficiency (reasonably) full range compact modular horn based speaker with a clear path for future upgrades."

Further refined as:

"...to be used with a pair of 8W mono blocks."

"I am going to place a great deal of weight on the aesthetics."

"Truth be told, but maybe only in a perfect world, I would love a big horn."

Indeed I am cutting and pasting systems together. It would seem based on the replies to the fist image that I had it all wrong...

Not a problem, I am always eager to learn and am a quick study.

The subsequent pics have reflected the input I have been given with the hopes of a reply that goes something like this:

?Ok, now your on the right track. Lower this...invert that...and get back to me.?

Thanks again, Neil

Making it work

Hi Brett, thanks for the reply.

If I was looking for praise I would have not posted here in the first place. You guys are tough, but it seems tough is what I need.

The right design can only emerge if I am willing to combine my skills with the input of others.

What I bring to the table is the ability to visualize the design, alter as needed and finally build it. What I need from you and others is to help me focus in on the correct path.

I have a full composite production facility in which to make any of the needed parts and a growing desire to make something exceptional.

Over the last few days, following my first post, what I have come to realize is:

First, I am not going to be able to do this alone.

Second, this could be a really great project.

Thanks again and keep me focused.

Cheers, Neil

P. S. As a heads up. The time and cost in making a composite part is always in the tool (mold), if we get that right for the horn then I will be happy to make the subsequent parts available. So let's think in terms of what is the best compression driver for the task.

I'm not trying to be negative towards your project, but rather help to make it work well.

Hi Brett, thanks for the reply.

If I was looking for praise I would have not posted here in the first place. You guys are tough, but it seems tough is what I need.

The right design can only emerge if I am willing to combine my skills with the input of others.

What I bring to the table is the ability to visualize the design, alter as needed and finally build it. What I need from you and others is to help me focus in on the correct path.

I have a full composite production facility in which to make any of the needed parts and a growing desire to make something exceptional.

Over the last few days, following my first post, what I have come to realize is:

First, I am not going to be able to do this alone.

Second, this could be a really great project.

Thanks again and keep me focused.

Cheers, Neil

P. S. As a heads up. The time and cost in making a composite part is always in the tool (mold), if we get that right for the horn then I will be happy to make the subsequent parts available. So let's think in terms of what is the best compression driver for the task.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- I'm getting Horny!