These horns look really nice.

I assume by the looks that they have been constructed using MDF and turned on a lathe?

It is to bad that the LeCleac'h horns are not offered in an elliptical shape. Offering a horizontal dispersion of 90 degrees and vertical dispersion of 40, or no more than 50 degrees.

NW

I assume by the looks that they have been constructed using MDF and turned on a lathe?

It is to bad that the LeCleac'h horns are not offered in an elliptical shape. Offering a horizontal dispersion of 90 degrees and vertical dispersion of 40, or no more than 50 degrees.

NW

Hello Norris,

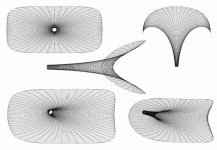

Yes, that's a bit sad that nobody ever built Le Cléac'h horns having a low height/width ratio.

But they'll be quite difficult to build as you can judge by the following 3D views:

Le Cléac'h elliptical with low HF directivity :

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532641&stamp=1212759567

quasi Iwta / JMLC method

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532652&stamp=1212760839

Le Cléac'h constant horizontal directivity

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532660&stamp=1212761603

Best regards from Paris, France

Jean-MIchel Le Cléac'h

Yes, that's a bit sad that nobody ever built Le Cléac'h horns having a low height/width ratio.

But they'll be quite difficult to build as you can judge by the following 3D views:

Le Cléac'h elliptical with low HF directivity :

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532641&stamp=1212759567

quasi Iwta / JMLC method

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532652&stamp=1212760839

Le Cléac'h constant horizontal directivity

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532660&stamp=1212761603

Best regards from Paris, France

Jean-MIchel Le Cléac'h

Norris Wilson said:These horns look really nice.

It is to bad that the LeCleac'h horns are not offered in an elliptical shape. Offering a horizontal dispersion of 90 degrees and vertical dispersion of 40, or no more than 50 degrees.

NW

hi Norris

i know only 3 manufacturers that make elliptical horns. It is quit difficult to make them . One is Haigner from Austria:

http://www.theaudioeagle.com/columns/column03.html

I have no CNC router, i use a big and small lathe, to make my horns, therefore i am not able to make them elliptical.

On this topic at my forum and on my blog i show step by step, how they are build. It is quit a time consuming task.

Jean Michel

is the small angle and aperture of the horn at the throat not a major reason for horn honk ? the faster the horn opens, the bigger the angle, the shorter the horn is, less is honk ?

Angelo

i know only 3 manufacturers that make elliptical horns. It is quit difficult to make them . One is Haigner from Austria:

http://www.theaudioeagle.com/columns/column03.html

I have no CNC router, i use a big and small lathe, to make my horns, therefore i am not able to make them elliptical.

On this topic at my forum and on my blog i show step by step, how they are build. It is quit a time consuming task.

Jean Michel

is the small angle and aperture of the horn at the throat not a major reason for horn honk ? the faster the horn opens, the bigger the angle, the shorter the horn is, less is honk ?

Angelo

Hello Angelo,

Horns presenting an efficient loading of the loudspeaker near their low cut-off lead to a high pressure level at the throat (or in the slots of the phase plug in the case of a compression driver). In pro use when this pressure level is more than 120dB then the air is no more elastically linear and some second order distorsion occurs.

As you know second order may be over 5% to be faintly audible. I doubt if any audible effect due to non linearity of air at the horn throat can be audible in Hifi use... This is not a source of honkiness.

The false idea (IMHO) that long horns lead to honkiness came from a famous paper in JAES Vol. 44 N°1-2, 1996 january-february:

"The sound of midrange horns for studio monitors."by

Keith R. Holland, Frank J. Fahy and Philip R. Newell

a conclusion of which was that to overcome honkiness a horn should be short. Please note that at this time, not too ancient, nearly not attention was taken to properly terminate the mouth of any commercial horns.

But one interest of that paper was to point that the 2 horns for which no "horn sound" could be heard (one large multicellular Altec horn and a medium size axisymetrical horn) were the ones having the least reflected waves from mouth to throat.

IMHO distortion of most horns cannot explain honkiness. Honkiness is more related to the behaviour of a horn to avoid reflections from mouth to throat (and the subsequent appearing of artefacts on the pulse response).

Also, near cut-off frequency most horns present a huge rise in the group delay. This is due to the reactance of the horn near the cut-off. This is also a cause of pulse response distortion and may be audible, specially in the band 300 to 4000Hz. You can surely imagine the fundamental of a musical notes arriving later than its firsts harmonics... While this is a source of bad sound I don't call "honkiness" this effect and it can be easily overcome using an electrical crossover frequency an octave or more above the cut-off frequency.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Horns presenting an efficient loading of the loudspeaker near their low cut-off lead to a high pressure level at the throat (or in the slots of the phase plug in the case of a compression driver). In pro use when this pressure level is more than 120dB then the air is no more elastically linear and some second order distorsion occurs.

As you know second order may be over 5% to be faintly audible. I doubt if any audible effect due to non linearity of air at the horn throat can be audible in Hifi use... This is not a source of honkiness.

The false idea (IMHO) that long horns lead to honkiness came from a famous paper in JAES Vol. 44 N°1-2, 1996 january-february:

"The sound of midrange horns for studio monitors."by

Keith R. Holland, Frank J. Fahy and Philip R. Newell

a conclusion of which was that to overcome honkiness a horn should be short. Please note that at this time, not too ancient, nearly not attention was taken to properly terminate the mouth of any commercial horns.

But one interest of that paper was to point that the 2 horns for which no "horn sound" could be heard (one large multicellular Altec horn and a medium size axisymetrical horn) were the ones having the least reflected waves from mouth to throat.

IMHO distortion of most horns cannot explain honkiness. Honkiness is more related to the behaviour of a horn to avoid reflections from mouth to throat (and the subsequent appearing of artefacts on the pulse response).

Also, near cut-off frequency most horns present a huge rise in the group delay. This is due to the reactance of the horn near the cut-off. This is also a cause of pulse response distortion and may be audible, specially in the band 300 to 4000Hz. You can surely imagine the fundamental of a musical notes arriving later than its firsts harmonics... While this is a source of bad sound I don't call "honkiness" this effect and it can be easily overcome using an electrical crossover frequency an octave or more above the cut-off frequency.

Best regards from Paris, France

Jean-Michel Le Cléac'h

angeloitacare said:hi Norris

i know only 3 manufacturers that make elliptical horns. It is quit difficult to make them . One is Haigner from Austria:

http://www.theaudioeagle.com/columns/column03.html

I have no CNC router, i use a big and small lathe, to make my horns, therefore i am not able to make them elliptical.

On this topic at my forum and on my blog i show step by step, how they are build. It is quit a time consuming task.

Jean Michel

is the small angle and aperture of the horn at the throat not a major reason for horn honk ? the faster the horn opens, the bigger the angle, the shorter the horn is, less is honk ?

Angelo

Hi guys.

I can tell you, that is very time- and money-consuming to build elliptical horns.

Either you make each one on a CNC or you pain yourself with building a mold.

I did it the second way and cast elliptical horns from some kind of special concrete:

(appr. 70cm wide and 50cm tall, 43cm long and 100 pounds each without driver )

)

I´ve had round horns before, but the elliptical has some advantages.

Wider horizontal dispersion, less reflections from ceiling and floor.

Best regards, Michael

I can tell you, that is very time- and money-consuming to build elliptical horns.

Either you make each one on a CNC or you pain yourself with building a mold.

I did it the second way and cast elliptical horns from some kind of special concrete:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

(appr. 70cm wide and 50cm tall, 43cm long and 100 pounds each without driver

I´ve had round horns before, but the elliptical has some advantages.

Wider horizontal dispersion, less reflections from ceiling and floor.

Best regards, Michael

Hello Michael,

Your horns look beautiful.

The only questionable thing I can see is that you just applied some strain ratio to the initial circular section perpendicular to the axis in order to make it elliptical.

But doing this, as the section is still laying inside a plane orthogonal to the axis, the curved length of the vertical and the horizontal axial profiles are not the same. and the perimeter of that section is no more the locus of a single wavefront border. Even we cannot evaluate anymore what is the expansion law of the area of the wavefronts inside the horn.

This is surely not the most perfect method to design a horn having a low height/width ratio starting from an initial round horn...

The shapes I shown in message

http://www.diyaudio.com/forums/showthread.php?postid=1608110#post1608110

like this quasi-Iwata doesn't have this problem.

Best regards from Paris, France

Jean-Michel Le Cléac'h

Your horns look beautiful.

The only questionable thing I can see is that you just applied some strain ratio to the initial circular section perpendicular to the axis in order to make it elliptical.

But doing this, as the section is still laying inside a plane orthogonal to the axis, the curved length of the vertical and the horizontal axial profiles are not the same. and the perimeter of that section is no more the locus of a single wavefront border. Even we cannot evaluate anymore what is the expansion law of the area of the wavefronts inside the horn.

This is surely not the most perfect method to design a horn having a low height/width ratio starting from an initial round horn...

The shapes I shown in message

http://www.diyaudio.com/forums/showthread.php?postid=1608110#post1608110

like this quasi-Iwata doesn't have this problem.

Best regards from Paris, France

Jean-Michel Le Cléac'h

MiWi said:Hi guys.

I did it the second way and cast elliptical horns from some kind of special concrete:

Attachments

Jmmlc said:Hello Norris,

Yes, that's a bit sad that nobody ever built Le Cléac'h horns having a low height/width ratio.

But they'll be quite difficult to build as you can judge by the following 3D views:

Le Cléac'h elliptical with low HF directivity :

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532641&stamp=1212759567

quasi Iwta / JMLC method

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532652&stamp=1212760839

Le Cléac'h constant horizontal directivity

http://www.diyaudio.com/forums/attachment.php?s=&postid=1532660&stamp=1212761603

Best regards from Paris, France

Jean-MIchel Le Cléac'h

Hello Jean Michel

What are the equations of the Le Cléac'h elliptical and constant horizontal directivity ?

Thanx

Discussion on concrete horns has been split off to here http://www.diyaudio.com/forums/showthread.php?s=&threadid=129734

angeloitacare said:hi Norris

i know only 3 manufacturers that make elliptical horns. It is quit difficult to make them . One is Haigner from Austria:

http://www.theaudioeagle.com/columns/column03.html

http://www.theaudioeagle.com/photos/goto/fertig_daylight.jpg

Nice washing machines.

Hi,

I would like to present here my Audio System.

My loudspeakers consists, each one, for:

- 12" JBL-D123 speaker, for the mid-bass/bass, installed in a sealed cabinet.

- JBL-2426J compression driver coupled to a JMMLC horns for the midrange.

- Selenium D220Ti compression driver coupled to a JMMLC horns for the treble.

In the black box located behind driver of treble, are the responsible passive components for the alignment and interlacement between the drivers/speaker meet.

My system is bi-amplified.

The sources (CDTransport Theta Pearl/DAC Theta Chroma and turntable Thorens TD-126 MKII/SME-3009R/Ortofon MC-20 Super MKII/Former Audio Note AN-S4II) are connected to a DIY tubes pre-amplifier, which in turn sends the signal to an DIY active 2 way crossover .

This crossover separates bass and subbass, (and also adjust its cutting and intensity using 2 pots) and send this signal to a Sony TAN-5550 solid state power that feeds a sealed subwoofer Dahlquist DQ-1w, 12". The subwoofer Dahlquist it is over there in the back from room, on photo where appears only the loudspeaker.

The other part of the crossover frequencies to send a DIY pure triode power amplifier made especially by myself in order to drive this kind of speakers. All technical characteristics of this power, mainly damping, were carefully designed and prepared to exploit the maximum yield of these compression drivers/horns-speaker.

The final result is a very clean sound, much balanced tone, very dynamic and with highest resolution and soundstage.

Victório Benatti

I would like to present here my Audio System.

My loudspeakers consists, each one, for:

- 12" JBL-D123 speaker, for the mid-bass/bass, installed in a sealed cabinet.

- JBL-2426J compression driver coupled to a JMMLC horns for the midrange.

- Selenium D220Ti compression driver coupled to a JMMLC horns for the treble.

In the black box located behind driver of treble, are the responsible passive components for the alignment and interlacement between the drivers/speaker meet.

My system is bi-amplified.

The sources (CDTransport Theta Pearl/DAC Theta Chroma and turntable Thorens TD-126 MKII/SME-3009R/Ortofon MC-20 Super MKII/Former Audio Note AN-S4II) are connected to a DIY tubes pre-amplifier, which in turn sends the signal to an DIY active 2 way crossover .

This crossover separates bass and subbass, (and also adjust its cutting and intensity using 2 pots) and send this signal to a Sony TAN-5550 solid state power that feeds a sealed subwoofer Dahlquist DQ-1w, 12". The subwoofer Dahlquist it is over there in the back from room, on photo where appears only the loudspeaker.

The other part of the crossover frequencies to send a DIY pure triode power amplifier made especially by myself in order to drive this kind of speakers. All technical characteristics of this power, mainly damping, were carefully designed and prepared to exploit the maximum yield of these compression drivers/horns-speaker.

The final result is a very clean sound, much balanced tone, very dynamic and with highest resolution and soundstage.

Victório Benatti

hi John

i have choosen a T value ~ 0,8, between hypex and exponential, since i wanted a shorter horn than tractrix ( which follows almost exponential law , T = 1 ). I applied this horn shape on my own new horns, and on Victórios ones. I expected a more natural sound. I am however a little intrigued with the result with the S2. First i used a 6mF cap, but midrange is too strong and forward sounding. With a 3mF cap its a little better, but i observe still too much presence. I guess now its more efficient than the midbass horn. But i will know for shure only, when measuring instruments arrive...might you have a hint what else i could try. To use a even smaller cap value does not seem reasonable to me.

i have choosen a T value ~ 0,8, between hypex and exponential, since i wanted a shorter horn than tractrix ( which follows almost exponential law , T = 1 ). I applied this horn shape on my own new horns, and on Victórios ones. I expected a more natural sound. I am however a little intrigued with the result with the S2. First i used a 6mF cap, but midrange is too strong and forward sounding. With a 3mF cap its a little better, but i observe still too much presence. I guess now its more efficient than the midbass horn. But i will know for shure only, when measuring instruments arrive...might you have a hint what else i could try. To use a even smaller cap value does not seem reasonable to me.

Hello,

As for the axisymetrical horn there is no equation for the profiles of the new horns. Only we know that the area of the wavefronts (at least near cut-off) follow an expansion according to the general hypperbolic horns equation.

To find the coordinates of the profiles, a similar method to the one used for the axisymetrical Le Cléac'h horn is used for each one of the 36 profiles.

Best regards from Paris, France

Jean-Michel Le Cléac'h

As for the axisymetrical horn there is no equation for the profiles of the new horns. Only we know that the area of the wavefronts (at least near cut-off) follow an expansion according to the general hypperbolic horns equation.

To find the coordinates of the profiles, a similar method to the one used for the axisymetrical Le Cléac'h horn is used for each one of the 36 profiles.

Best regards from Paris, France

Jean-Michel Le Cléac'h

TomatoBangBang said:

Hello Jean Michel

What are the equations of the Le Cléac'h elliptical and constant horizontal directivity ?

Thanx

angeloitacare said:

Angelo, these horns are superb!

I've been working on some speaker enclosures using a similar technique (stacked MDF run on a lathe).

I see in your photos that you're painting the finished horns. Could you let me know exactly what products you're using?

The only thing I've found that works (that I can get hold of here in the UK) is a two part urethane automotive paint. It takes many coats (as it soaks in) but will eventually give a good surface that can be sanded smooth. The problem is that it's very expensive, and quite dangerous to use.

I've tried many other coatings, and they work to start with, but after a couple of months, you can see the lines where each sheet of MDF joins the next.

You mention polyurethane + a sandable primer. Is this a polyurethane varnish, or some other coating? Is the primer an automotive paint?

Thanks for any info!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Victórios new LeCleac'h horns