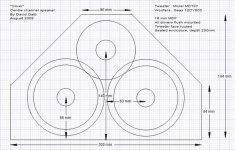

Here's my latest design which I'm planning to build in the next few weeks, if I can tear myself away from the Olympics.

Its designed to sit on top of my 50"plasma TV. The Tweeter is the Morel MDT37 , woofers are the Seas 12CY003

Basically I've arrived at this shape as a compromise between a horizontal WTW and a vertical WT.

The Morel tweeter has a plastic face, which I will route to allow the closest possible placement of the woofers.

The twin woofer design allows closer proximity of the tweeter, while giving a cone area equal to a single 6" driver.

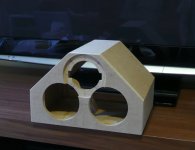

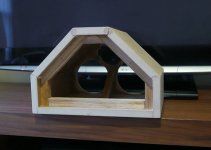

The pyramid shape also looks less bulky when sitting on top of a flat screen TV.

So far, my simulations indicated arounf +/- 2dB deviation within 20 deg off-axis (vertical or horizontal).

Its designed to sit on top of my 50"plasma TV. The Tweeter is the Morel MDT37 , woofers are the Seas 12CY003

Basically I've arrived at this shape as a compromise between a horizontal WTW and a vertical WT.

The Morel tweeter has a plastic face, which I will route to allow the closest possible placement of the woofers.

The twin woofer design allows closer proximity of the tweeter, while giving a cone area equal to a single 6" driver.

The pyramid shape also looks less bulky when sitting on top of a flat screen TV.

So far, my simulations indicated arounf +/- 2dB deviation within 20 deg off-axis (vertical or horizontal).

Attachments

Thanks. Yep, it's 2 way.

I'm now thinking of using the Seas T25C003 (shallow waveguide) instead, as I don't think I need quite the depth in the MDT37's waveguide (to match the woofer's acoustic centres). Should have better off axis behaviour too.

I'm now thinking of using the Seas T25C003 (shallow waveguide) instead, as I don't think I need quite the depth in the MDT37's waveguide (to match the woofer's acoustic centres). Should have better off axis behaviour too.

I was thinking the same thing, especially if the speaker is some amount higher than ear level. That Seas still has good coil depth, kinda like a "semi-horn". I really like the newer semihorn styles... I have 2 tweets with the "wide angle" faces, and love the way they align/blend/image with matching midwoofers.

Nice choice/s!

TTYL, kyrie

Nice choice/s!

TTYL, kyrie

I think a band saw would be the best thing for getting most of the material out. Probably the safest to. You can lay the tweeter flat on the table on the backside, assuming it has a flat back, and the blade only moves in one direction towards the table which makes for smooth predictable cuts. Then you can clean it up with a dremel or file.

If you can remove the faceplate of the tweeter then about any method will work since there is not much chance of damaging the tweeter.

If you can remove the faceplate of the tweeter then about any method will work since there is not much chance of damaging the tweeter.

The tweeter face is removable so it's quite easy to work on.

I dont have a band saw, so maybe the best/safest option will be just using a metal file with lots of elbow grease, and cleaning up with the dremel.

The edge wont be visible (it will be hidden by the overlapping woofer), so it won't matter if it's a bit rough.

I dont have a band saw, so maybe the best/safest option will be just using a metal file with lots of elbow grease, and cleaning up with the dremel.

The edge wont be visible (it will be hidden by the overlapping woofer), so it won't matter if it's a bit rough.

if you can clamp the faceplate down with wood, it will route fine and safely. I'm sandwiched face plates between too sheets of thin mdf scrap before, and also just had it secured to a piece of scrap. While not maybe necessary for everyone, my poor skills makes having a piece of scrap quite important. That way I can route into the wood as well and it just seems to make cleaner edges, and allows better router control.

David,

Alu routes really nicely, forget about it if its steel. You'll kill the bit or router not to mention cutting 6mm steel would be a risky at the best of times but alu and plastic is no problem. I'm 99% sure seas use alu or plastic faceplates.

Here's a pic of an Audiotechnology driver frame that I altered with the router, this is an alu frame BTW. The cuts were very clean.

What you should have done is left the routing of the baffle, do the tweeter recess, mount the tweeter and fix down, then route your mid/bass recesses whilst at the same time cutting away the faceplate of the tweeter. That would give the neatest finish.

You could still do this if you make up a mock baffle identical to the real one and follow the above.

Alu routes really nicely, forget about it if its steel. You'll kill the bit or router not to mention cutting 6mm steel would be a risky at the best of times but alu and plastic is no problem. I'm 99% sure seas use alu or plastic faceplates.

Here's a pic of an Audiotechnology driver frame that I altered with the router, this is an alu frame BTW. The cuts were very clean.

An externally hosted image should be here but it was not working when we last tested it.

What you should have done is left the routing of the baffle, do the tweeter recess, mount the tweeter and fix down, then route your mid/bass recesses whilst at the same time cutting away the faceplate of the tweeter. That would give the neatest finish.

You could still do this if you make up a mock baffle identical to the real one and follow the above.

G'day ShinOBIWAN

Good advice thanks.

Yes, fixing the face-plate to a bit of scrap should allow me to route it without too many hassles.

However, I am tending to think it is steel, not aluminium, just by the weight of the thing (it is very heavy), so I guess I might have to just file it back by hand ....

I'll ponder it a bit longer while I work on the cabinets.

Cheers

Good advice thanks.

Yes, fixing the face-plate to a bit of scrap should allow me to route it without too many hassles.

However, I am tending to think it is steel, not aluminium, just by the weight of the thing (it is very heavy), so I guess I might have to just file it back by hand ....

I'll ponder it a bit longer while I work on the cabinets.

Cheers

David:

Maybe I'm dense, but what about that comment makes you think it's steel? Also, aluminum is non-ferrous so couldn't you simply use a magnet to determine if the faceplate is non-ferrous? This would be especially simple if it's removable so you would have no interference from tweeter motor.

Maybe I'm dense, but what about that comment makes you think it's steel? Also, aluminum is non-ferrous so couldn't you simply use a magnet to determine if the faceplate is non-ferrous? This would be especially simple if it's removable so you would have no interference from tweeter motor.

Making some progress - sprayed on 6 coats of enamel followed by 10 clear coats. Lots of "orange-peel" but after a week or so I'll cut and polish them.

An externally hosted image should be here but it was not working when we last tested it.

Turns out the T25C003 faceplate IS aluminium, so routing was easy

I did it freehand, precision not required as it will be overlapped by the midbass drivers.

I did it freehand, precision not required as it will be overlapped by the midbass drivers.

An externally hosted image should be here but it was not working when we last tested it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- "Oliver" centre channel project