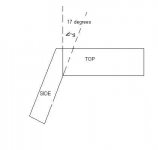

I'm trying to work out how to create a 17 degree angle bevel on butt jointed MDF for a speaker build. The attached image (this posting) (not to scale) shows what I mean.

The angle is required because one side of the cabinet will be sloped (17 degrees).

I have a plunge router, jigsaw, circular saw.

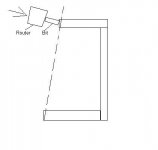

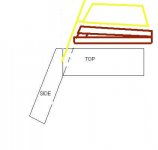

I had an idea to construct the top, right side and bottom (which are all at 90 degrees) with the top and bottom cut to length such that 17 degrees would result if you drew line between corners (see 2nd posting). I could then temporarily clamp a front baffle (and back) then router along the edge of the MDF, directly down on the edge as shown. I would then repeat the process when the side piece is attached from the top to trim down the side piece edge protruding out the top.

My only concern with the above approach is tearing out the MDF. The other possibility is to make a sort of bevel jig for the router but I can't find any plans (let alone how to accurately calibrate it for a 17 degree angle cut with a flush trim bit).

Any help appreciated. (or link to a woodworking site for newbies).

Thanks,

David.

The angle is required because one side of the cabinet will be sloped (17 degrees).

I have a plunge router, jigsaw, circular saw.

I had an idea to construct the top, right side and bottom (which are all at 90 degrees) with the top and bottom cut to length such that 17 degrees would result if you drew line between corners (see 2nd posting). I could then temporarily clamp a front baffle (and back) then router along the edge of the MDF, directly down on the edge as shown. I would then repeat the process when the side piece is attached from the top to trim down the side piece edge protruding out the top.

My only concern with the above approach is tearing out the MDF. The other possibility is to make a sort of bevel jig for the router but I can't find any plans (let alone how to accurately calibrate it for a 17 degree angle cut with a flush trim bit).

Any help appreciated. (or link to a woodworking site for newbies).

Thanks,

David.

Attachments

Thanks guys for the effort you've gone to - esp. Rob.

I thought about a fence/guide and running the circular saw along it. My circular saw is basic but allows the baseplate to be pivoted for an angle cut. I would do both top andbottom pieces at the same time sandwhiched together to ensure the angle is the same. The problem I have is in setting an accurate 17 degree angle on the baseplate.

The table saw is a good idea. The local timber yard will pre-cut the pieces and if they can get the angle +/- 1 degree and sandwhich both top and bottom pieces and cut at same time (guaranteeing the angle will be the same) - then a 1 degre variance would equate to only +/- 16mm difference in length of the bottom piece (considering I am building a 960mm high cabinet).

I can get them to oversize the bottom piece so that I can flush trim 16mm+ down with the router.

Thanks,

David.

I thought about a fence/guide and running the circular saw along it. My circular saw is basic but allows the baseplate to be pivoted for an angle cut. I would do both top andbottom pieces at the same time sandwhiched together to ensure the angle is the same. The problem I have is in setting an accurate 17 degree angle on the baseplate.

The table saw is a good idea. The local timber yard will pre-cut the pieces and if they can get the angle +/- 1 degree and sandwhich both top and bottom pieces and cut at same time (guaranteeing the angle will be the same) - then a 1 degre variance would equate to only +/- 16mm difference in length of the bottom piece (considering I am building a 960mm high cabinet).

I can get them to oversize the bottom piece so that I can flush trim 16mm+ down with the router.

Thanks,

David.

The easiest way is to set a 17 degree angle on your table saw and cut all the angled pieces at the same time.

If you have trouble setting your saw you could eyeball it and cut a piece of scrap which you can then lay a protractor on, then adjust your saw accordingly. Cut scrap, adjust. Cut scrap, adjust. Etc, until you get it perfect.

If you have trouble setting your saw you could eyeball it and cut a piece of scrap which you can then lay a protractor on, then adjust your saw accordingly. Cut scrap, adjust. Cut scrap, adjust. Etc, until you get it perfect.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Creating odd angle bevels